Optical fiber jumper with spring protection layer

A technology of optical fiber jumper and protective layer, which is applied in the field of photoelectric communication equipment, can solve the problems of affecting optical signal transmission, damage to the fiber core, and insufficient strength of optical fiber jumper, so as to improve the overall strength, improve the compressive capacity, and prevent excessive The effect of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the accompanying drawings.

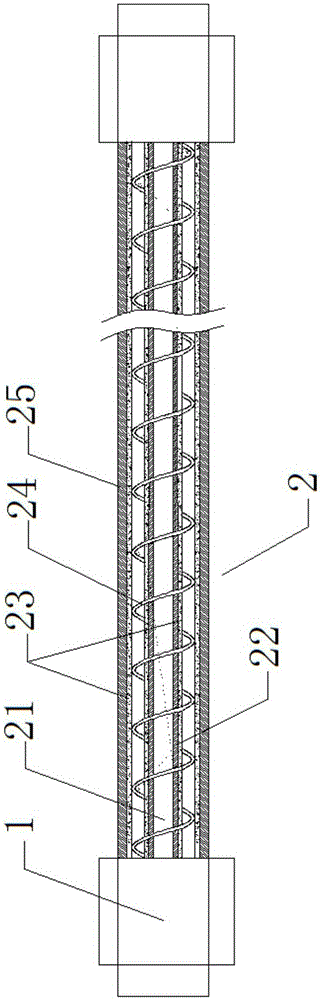

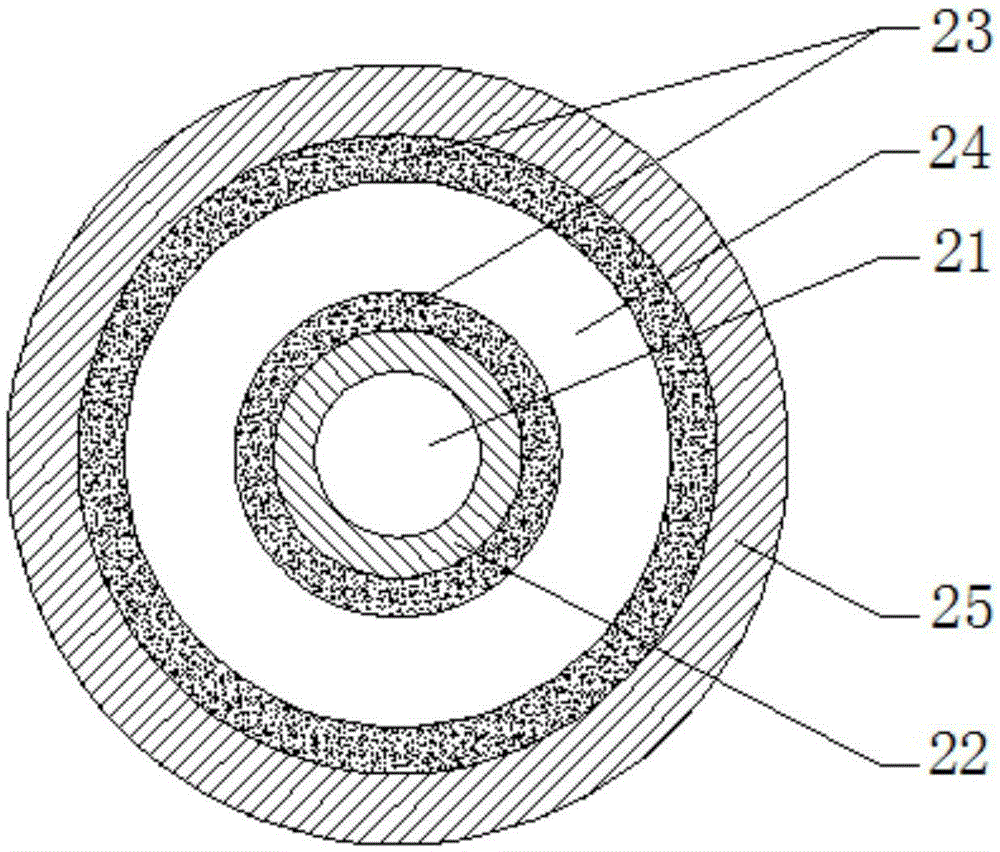

[0013] Such as figure 1 and figure 2 As shown, an optical fiber jumper with a spring protective layer includes an optical cable 2 and connectors 1 arranged at both ends of the optical cable 2. The optical cable 2 includes an outer protective layer and a glass core 21 for light transmission inside. The outer protective layer is from the inside to the The outside includes a glass envelope 22 and an insulating rubber layer 25. A spring protection layer 24 is also provided between the glass envelope 22 and the insulating rubber layer 25. The gap between the spring protection layer 24 and the glass envelope 21 and the insulating rubber layer 25 is filled with Sponge 23, the two ends of the spring in the spring protective layer 24 are respectively fixed on the two connectors 1, so as to improve the radial compression resistance of the jumper.

[0014] The material of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com