Borehole in-situ test sounding loading device and using method

A loading device and in-situ testing technology, which is applied in measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of poor test accuracy, complex structure, cumbersome test process, etc., to increase stress and avoid stress concentration , Test the effect of lightness and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

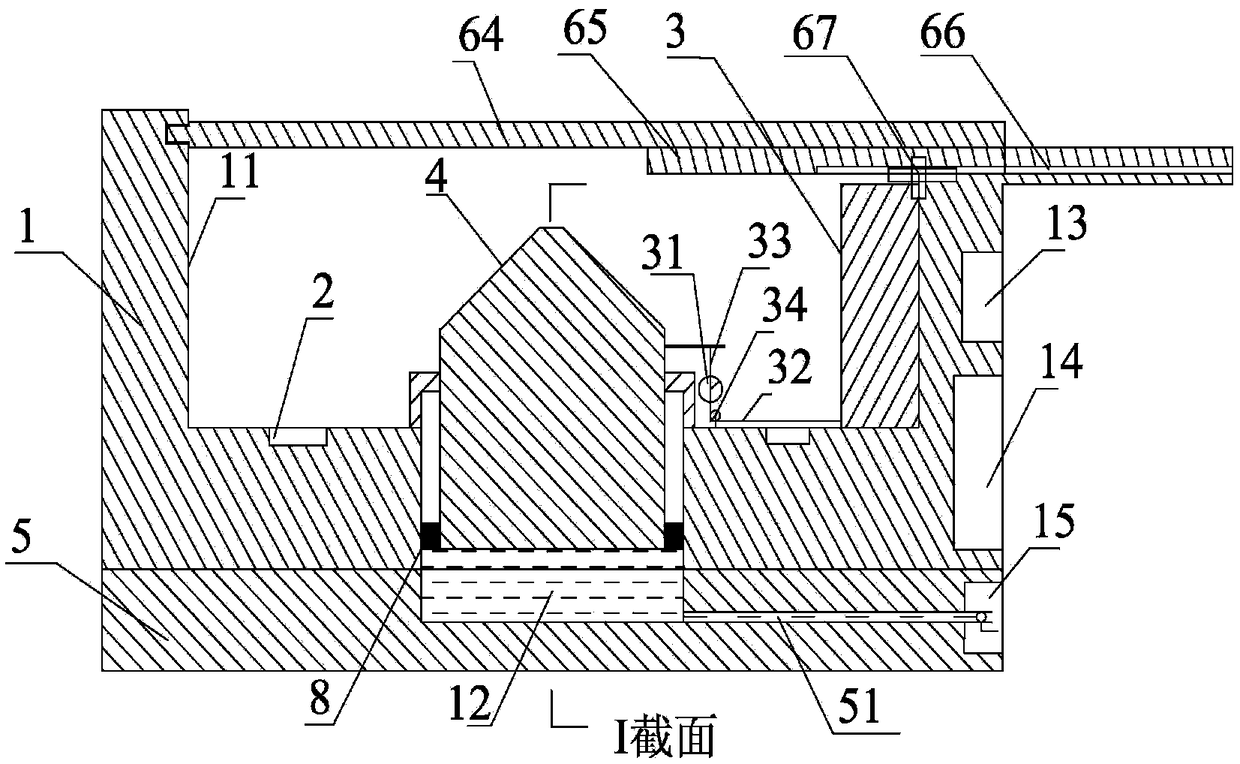

[0041] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

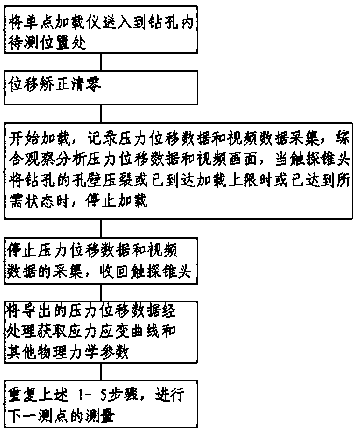

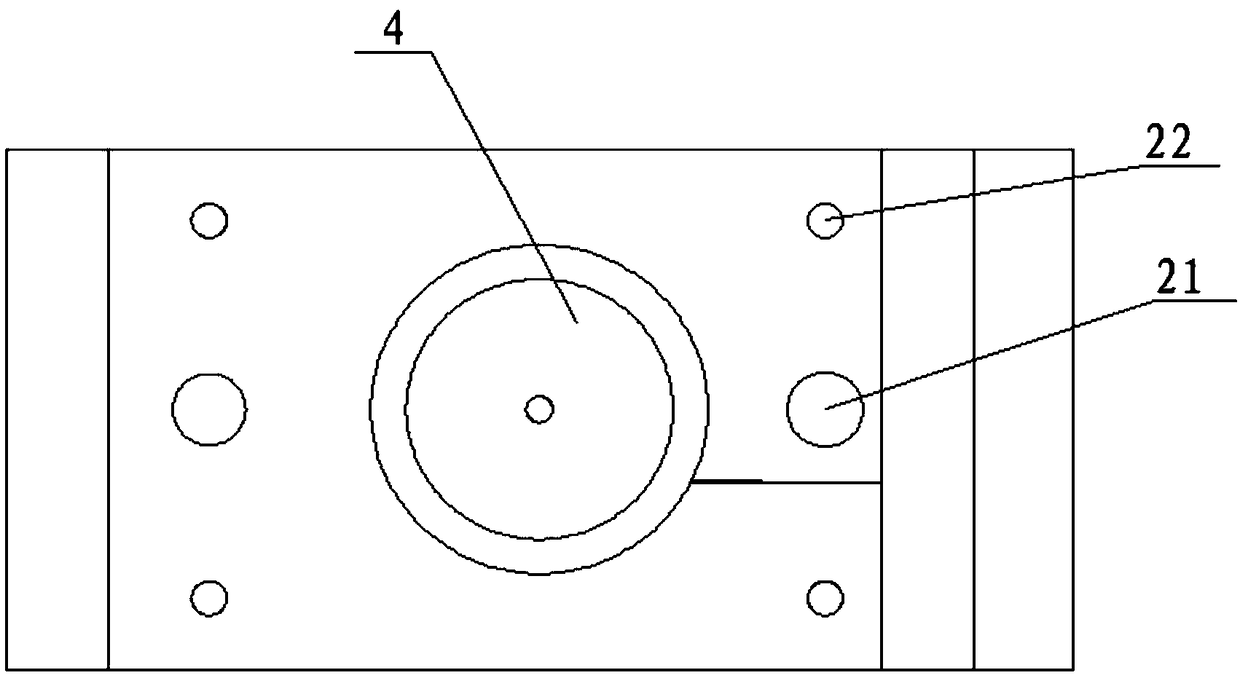

[0042] Such as Figure 1-3 As shown, the drilling in-situ test penetrating loading device of the present invention includes a single point loading instrument 1, a video acquisition unit 2, a displacement measuring unit 3, a penetrating cone 4 and a pressure base 5,

[0043] The single-point loading instrument 1 is provided with a concave cavity 11 at the top, and a pressure chamber 12 at the bottom. The side is also provided with a wire interface 13, a push rod interface 14 and an oil circuit interface 15 in sequence, the wire interface 13 is connected with the external controller 6, and the push rod interface 14 is connected with the external power propulsion system (not shown in the figure) , the oil circuit interface 15 is connected with the external hydraulic loading system 7; the front end of the penetrating cone head 4 of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com