High-thermal-shock-resistant fire-resistant and thermal-insulating interlocking dry-code special material and preparation method thereof

A special material and thermal shock resistance technology, which is applied in the field of high thermal shock resistance, refractory, heat-insulating, interlocking dry code special materials and their preparation, to achieve the effects of preventing heat loss, reducing the weight of kiln cars, and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

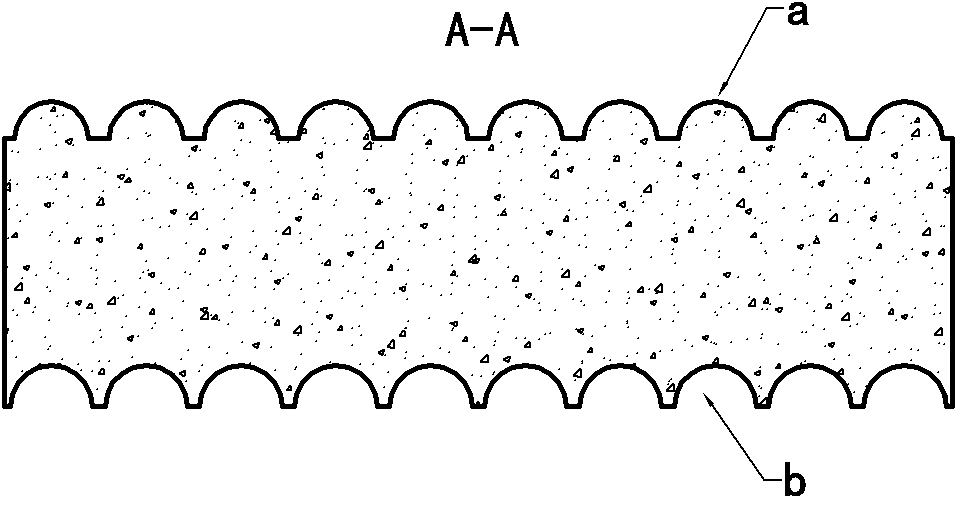

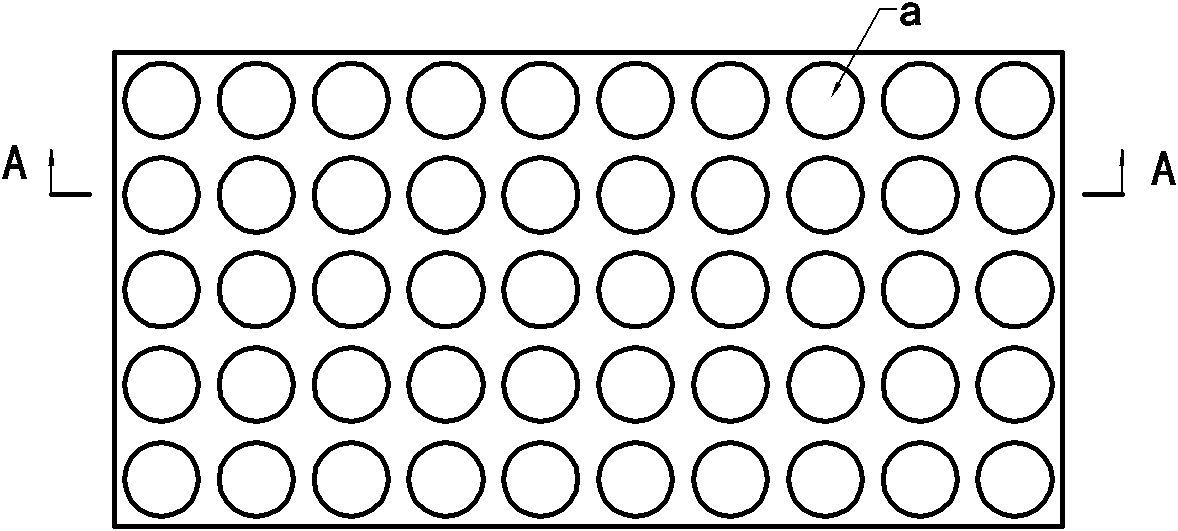

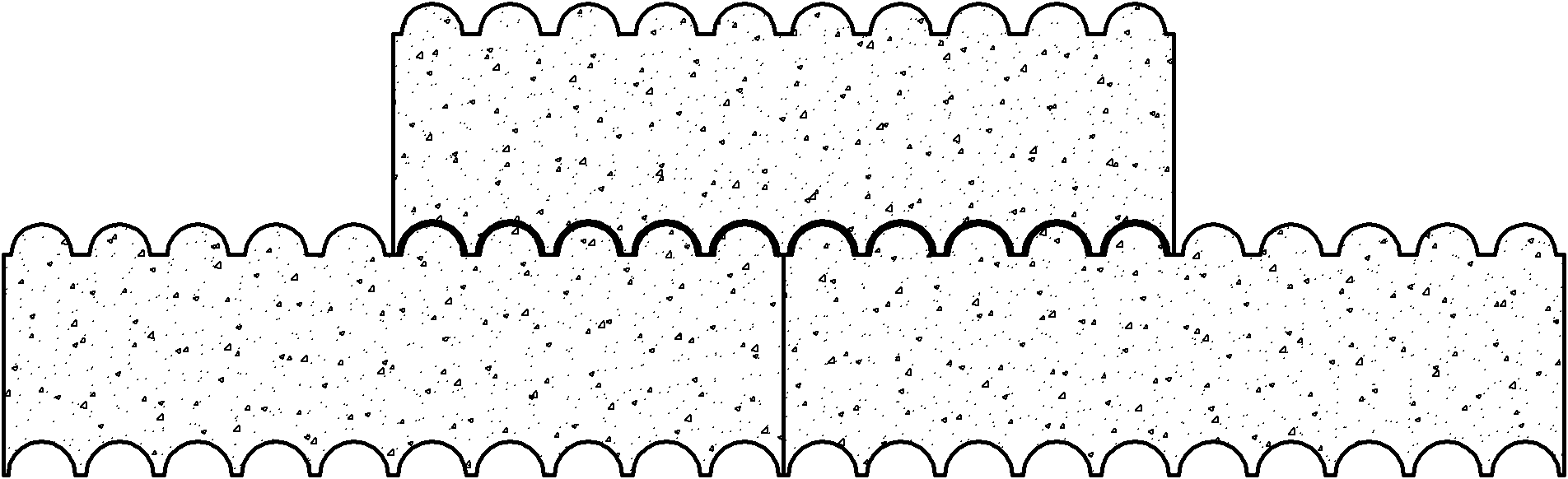

[0032] Example 1 1. A special material with high thermal shock resistance, refractory and heat insulation interlocking dry code (round convex dry code brick).

[0033] refer to Figure 1-Figure 3 , this round convex dry code brick is a rectangular brick body. On the top of the brick body, there is a spherical crown card convex matrix a, and under the brick body, there is a concave cavity b matrix. The concave cavity matrix is connected with the other brick body Ball crown card convex a matrix concave-convex card sleeve fit.

Embodiment 2

[0034] Example 2 1. A special material with high thermal shock resistance, refractory and heat insulation interlocking dry code (square convex dry code brick).

[0035] refer to Figure 4-Figure 6 , this square convex dry code brick is a rectangular brick body. On the upper side of the brick body, there is a square-shaped convex matrix a, and on the lower side of the brick body, there is a concave cavity b matrix. The concave cavity matrix is connected with another brick. The square platform of the body is fitted with a matrix concave-convex ferrule.

Embodiment 3

[0036] Example 3 1. A special material with high thermal shock resistance, refractory heat insulation interlocking dry code, its structure is the same as that of embodiment 1 or embodiment 2, and the raw and auxiliary materials prepared by it include the following materials by weight: aggregate 40wt%, composite matrix 60wt% of raw materials, based on 100% of aggregate and composite matrix materials, plus: 12wt% of waste burnt additives; 10wt% of crystal nucleating agents, 3.1wt% of binders, 4.5wt% of plasticizers, Water is the 16-18wt% of material sum, wherein:

[0037] (A) Aggregate, selected from cordierite-mullite, cordierite, high alumina and clay waste refractory brick clinker, the waste refractory brick clinker is classified, selected, impurity removed, crushed, screened and classified, It is prepared by removing iron, and the particle size passes through a 80-mesh sieve. High-alumina waste refractory brick clinker accounts for 40wt% of the aggregate; clay waste refrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com