Method for treating tunnel collapse using pavilion-type bracket

A pavilion and tunnel technology, which is applied in the field of tunnel collapse using pavilion supports, can solve problems such as high strength and rigidity requirements, large collapse cavity height, and difficulty in connecting hydraulic props to the top, so as to improve construction efficiency and reduce labor intensity , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

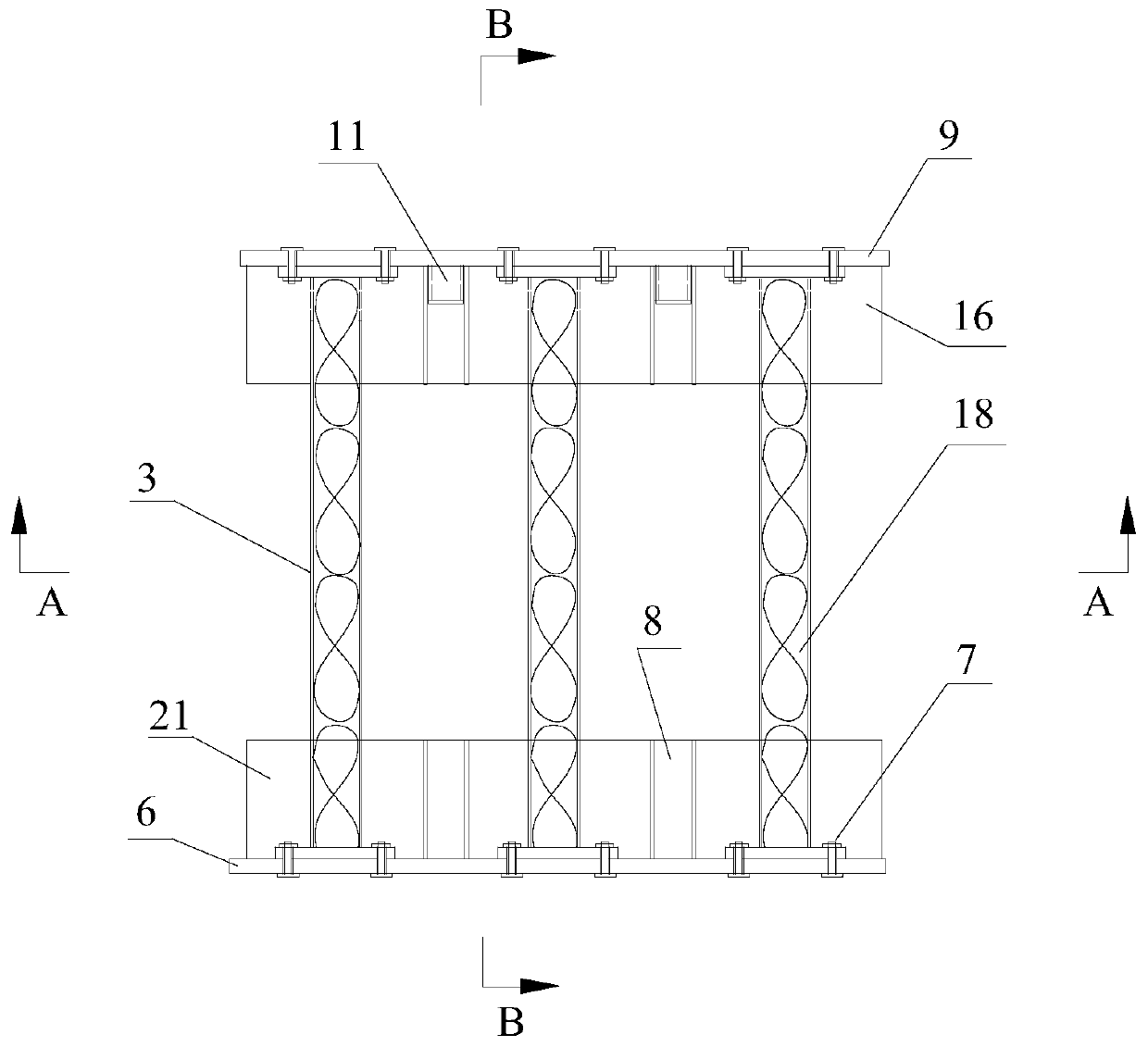

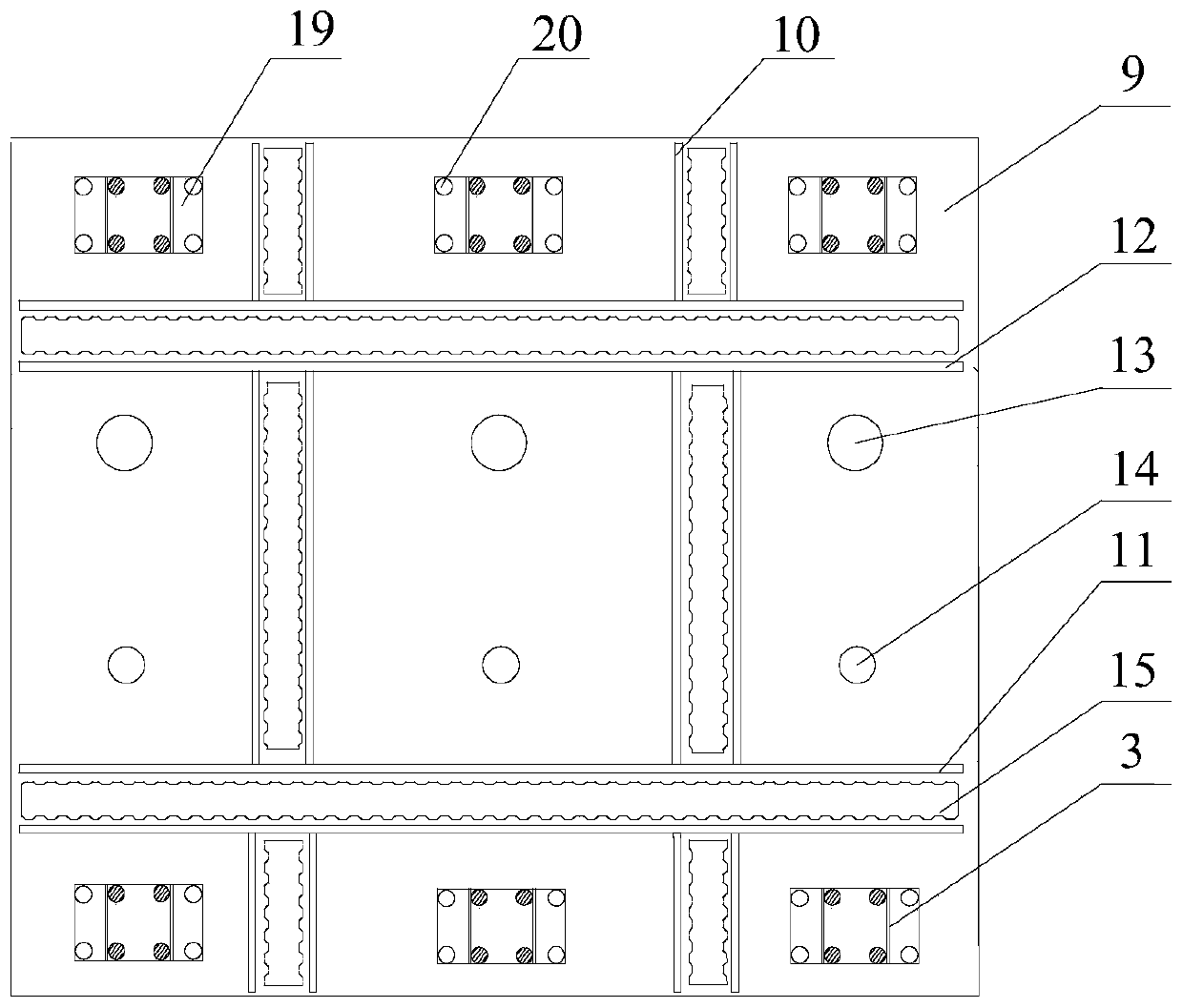

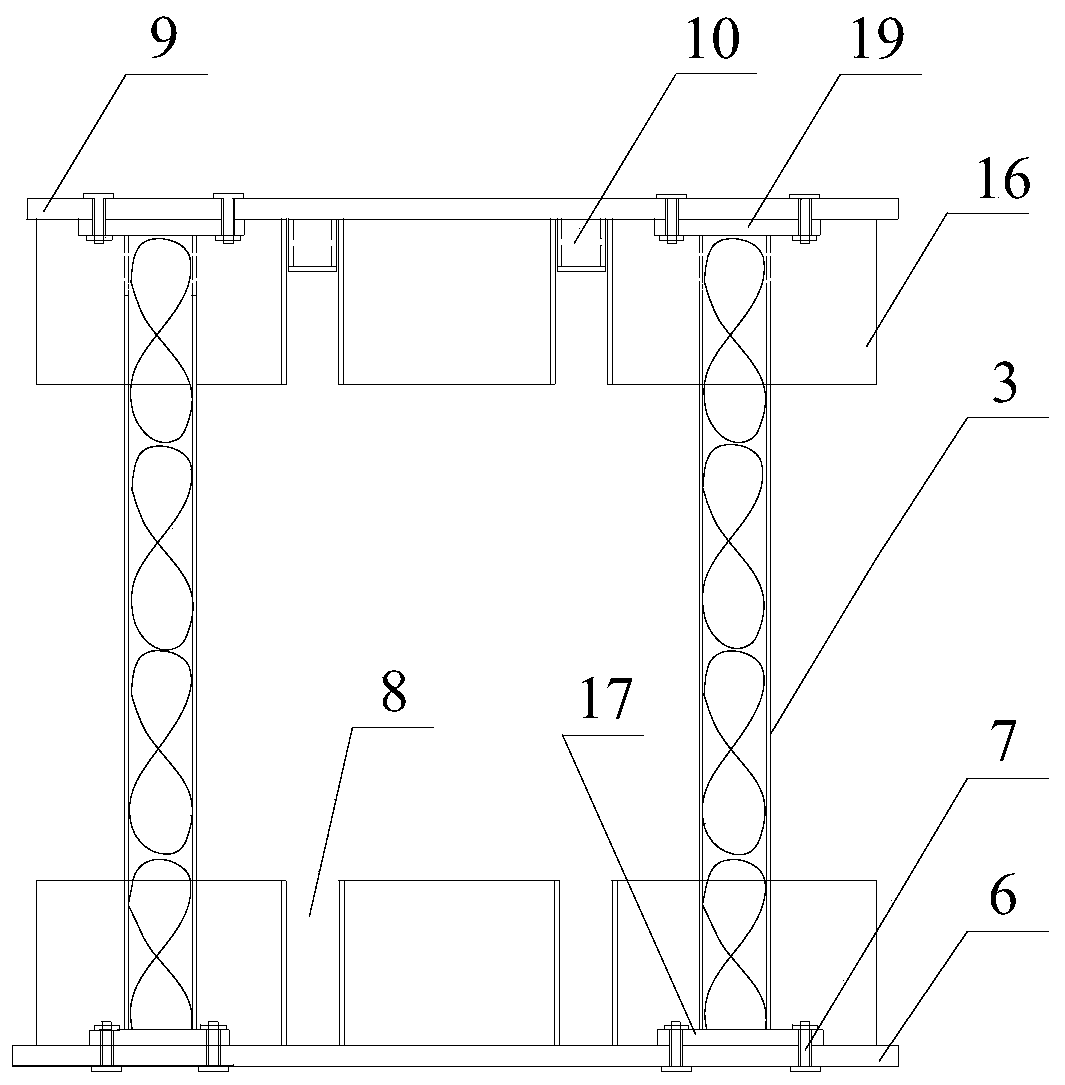

[0042] Such as Figure 1 to Figure 14 As shown, a method for dealing with tunnel collapse using a pavilion-type support provided by the present invention is specifically implemented as follows.

[0043]A method for dealing with tunnel collapse using a pavilion-type support, the steps comprising:

[0044] Step 1. Install the pavilion-type support structure, including the assembly base 1, the shield plate 2, the column 3, the longitudinal roof beam 10 and the horizontal roof beam 11, the longitudinal roof beam 10 and the horizontal roof beam 11 are fixed on the shield plate 2, and the column 3 is fixed Between base 1 and shield 2.

[0045] Specifically, the size of the shield plate 2 is selected according to the scope of the collapse. The shield plate 2 is made of a steel plate, and its structure includes a top steel plate and an upper rib 16. The lower surface of the top steel plate 9 is arranged with an upper rib 16, which forms a The top pillar groove 12, the longitudinal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com