Non-disturbance type supporting structure used for tunnel vault collapsed cavity processing

A non-disturbance type, supporting structure technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as increased crack probability, safety risks, and heavy internal burdens, so as to achieve controllable engineering volume, improve safety, and Quality Guaranteed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

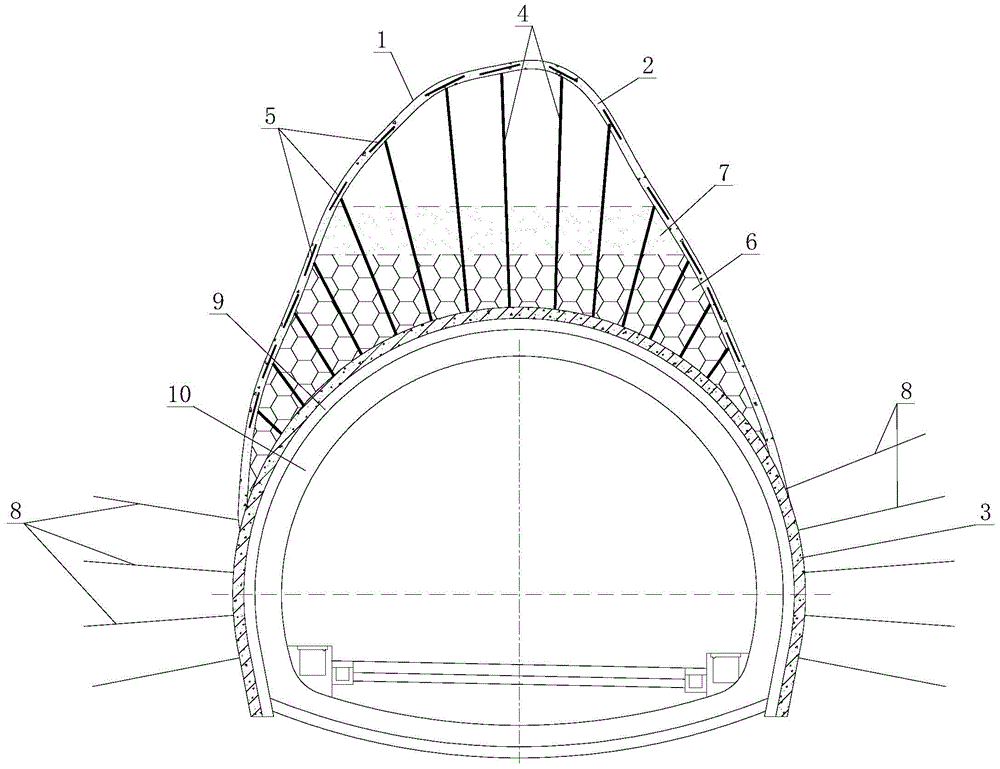

[0045] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the non-disturbance support structure used for tunnel vault collapse cavity treatment in this embodiment includes a concrete reinforcement mesh layer 2 laid on the cavity wall surface 1 and a concrete reinforcement mesh layer 2 along the cavity cavity The protection arch 3 erected on the section, the protection arch 3 is located under the concrete reinforcement mesh layer 2, and a number of supports 4 are arranged between the protection arch 3 and the concrete reinforcement mesh layer 2, and the protection arch 3 is driven by the support 4 Participate in bearing the load, and realize that the concrete reinforcement mesh layer 2 and the arch protection arch share the load, so as to reduce the construction risk and potential operation risk in the process of cavity collapse; the arch back of the protection arch 3 and the inner wall of the concrete reinforcement mesh layer 2 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com