Down-the-hole drill follow-pipe hole-forming backfill concrete stable free face collapse processing construction method

A construction method and down-the-hole drilling technology, which are applied in earth-moving drilling, vertical well equipment, wellbore lining, etc., can solve the problem that the extension surface of the collapse cannot be supported, and achieve the effects of wide application range, simple construction technology and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

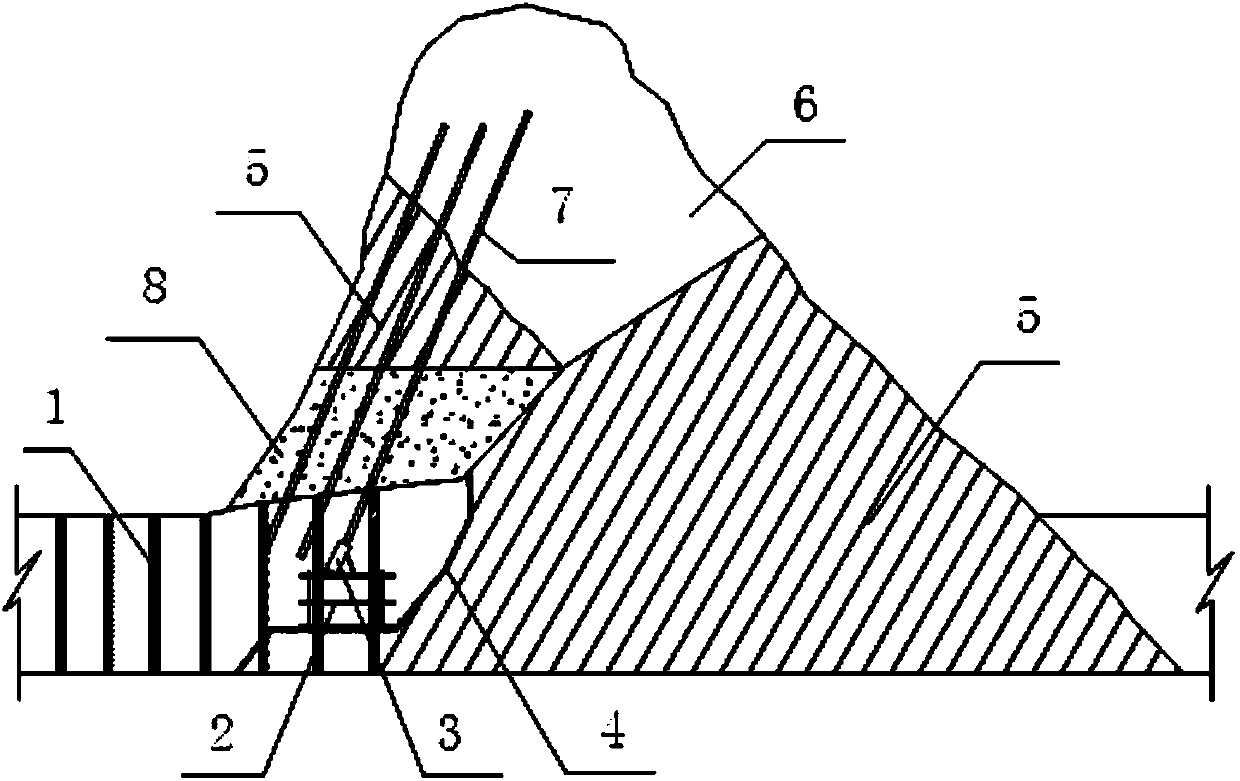

[0021] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] as attached figure 1 As shown, the down-the-hole drill and the pipe forming hole of the present invention backfill the concrete to stabilize the empty surface and deal with the landslide construction method, and the specific steps are as follows:

[0023] The first step: seal the collapse cavity 6 with sprayed concrete to prevent the slag from injuring people after the collapse, and pull out a small platform at the position of the collapse cavity 6, and pile up sand bags (not shown in the figure) to seal it. Concrete with a thickness of 20cm is sprayed on the outside of the bag to strengthen the strength of the sand bag; the thickness of the sand bag is between 2.5m and 3m; the sand bag is bonded with sprayed concrete layers when stacked.

[0024] Step 2: pull out a platform inside the supported steel arch 1 at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com