Tunnel collapse disposing method and tunnel collapse support structure

A technology of supporting structure and processing method, which is applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc., can solve the problems of increased investment and delay of construction period, and achieve the effect of shortening the construction period and saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

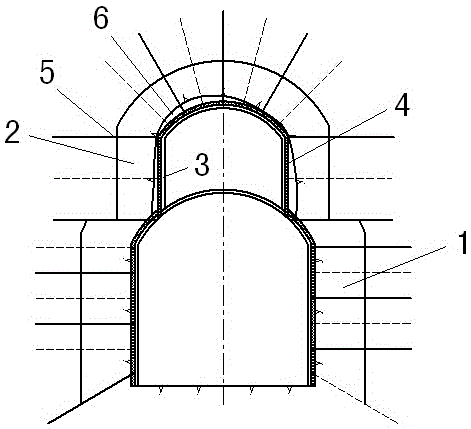

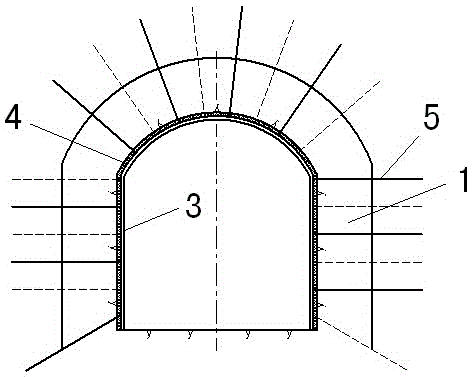

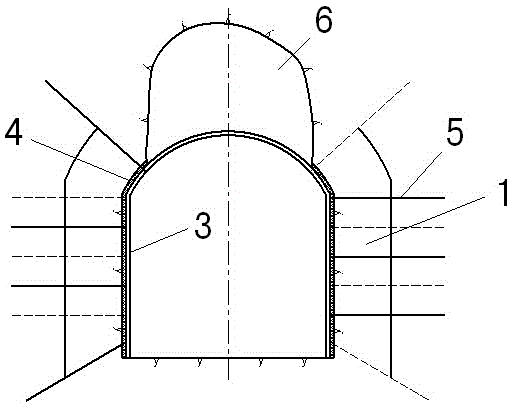

[0018] In this example, the existing primary support such as figure 2 Shown, the structural representation when the present invention implements is as figure 1 As shown, due to the stress release and adjustment of the surrounding rock, the effect of groundwater, and the existence of weak zones in the surrounding rock, the local parts of the first-stage support occurred as follows: figure 2 For the collapse shown, if the support is not carried out in time, the collapse may continue to expand, so it is necessary to carry out secondary support for the collapsed part of the tunnel. The secondary support adopts arch-on-arch support.

[0019] The structure of the present invention is as figure 1 Shown: The structure includes the previous primary support 1, and the secondary support is carried out in the collapse cavity 6 on the top of the primary support. The structure of the secondary support is the same as that of the primary support structure, including steel arches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com