A full-surface super-hydrophobic antifreeze high-strength wood and its manufacturing method

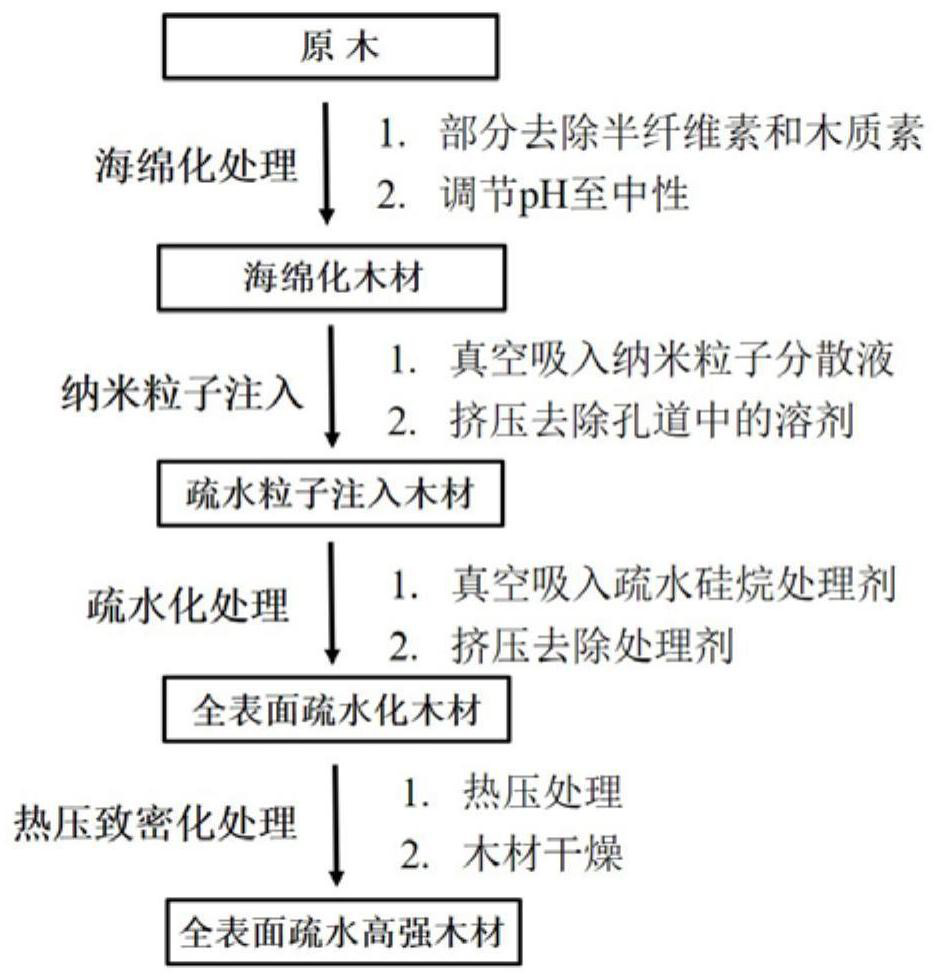

A manufacturing method and full-surface technology, applied in the field of wood manufacturing, can solve problems such as insufficient penetration depth, low penetration, and unsatisfactory hydrophobic effect on the inner surface of wood, so as to solve pore blockage, enhance connectivity, excellent frost resistance and high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

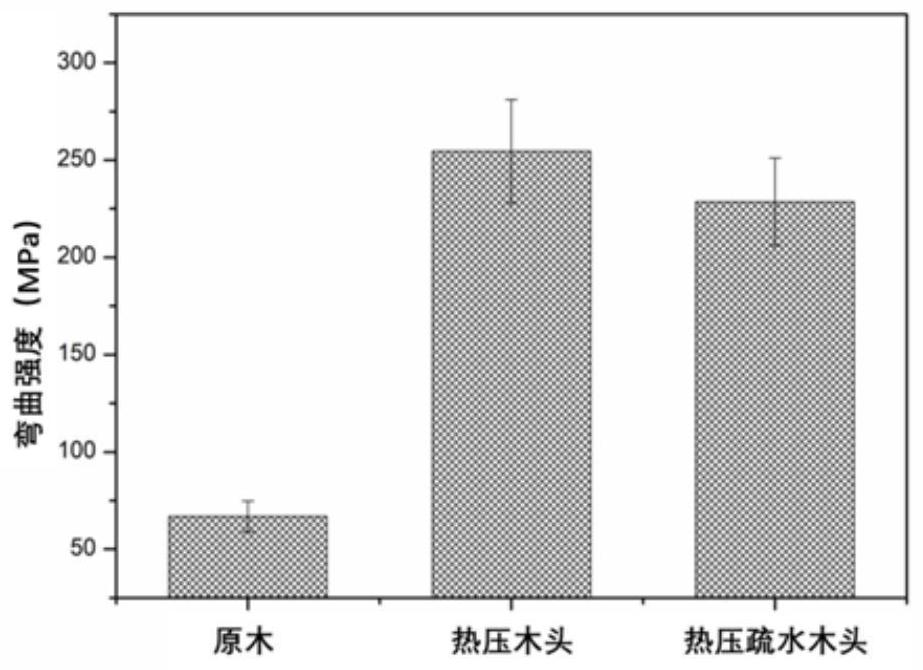

[0082] Example 1: Red Walnut

[0083] According to the method of the present invention, 1.5wt% hydrophobic nanoparticle solution and red walnut are placed in a vacuum drying box to evacuate, the vacuum degree is 1.5bar, and the pressure is kept for 30 minutes; after the adsorption is completed, use an extruder to apply 800KPa on the wood surface pressure and repeat the squeeze-release process 15 times. After completion, under the condition of 100°C, apply a pressure of 5 MPa on the surface of the wood to reduce the thickness of the wood to the minimum, and then keep the hot pressing state for 30 minutes. The test results after treatment are shown in Table 1.

Embodiment 2

[0084] Example 2: Beech

[0085] According to the method of the present invention, 2wt% hydrophobic nanoparticle solution and beech wood are placed in a vacuum drying oven to evacuate, and the vacuum degree is 2bar, and the pressure is kept for 30 minutes; Repeat the squeeze-release process 15 times. Put the 2wt% perfluorosilane solution and the wood in a vacuum drying oven, evacuate at a vacuum degree of 2 bar, and hold the pressure for 30 minutes. After completion, under the condition of 100°C, apply a pressure of 5 MPa on the surface of the wood to reduce the thickness of the wood to the minimum, and then keep the hot pressing state for 30 minutes. The test results after treatment are shown in Table 1.

Embodiment 3

[0086] Embodiment 3: heart peach

[0087] According to the method of the present invention, 2wt% hydrophobic nanoparticle solution and beech wood are placed in the vacuum drying box to evacuate, and the vacuum degree is 2bar, hold pressure for 30 minutes; Repeat the squeeze-release process 15 times. Put the 2wt% perfluorosilane solution and the wood in a vacuum drying oven, evacuate at a vacuum degree of 2 bar, and hold the pressure for 30 minutes. Repeat the step after the first adsorption is completed 3 times. After completion, under the condition of 100°C, apply a pressure of 5 MPa on the surface of the wood to reduce the thickness of the wood to the minimum, and then keep the hot pressing state for 30 minutes. The test results after treatment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com