Double-cushion airbag shock absorber

A shock absorber, double buffer technology, applied in the direction of shock absorber, gas-liquid shock absorber, spring/shock absorber, etc. It can overcome the problems such as severe vibration of the vehicle and the body, and achieve the effect of overcoming the flow to fill the lag defect, eliminating the hidden danger of empty travel, and prolonging the overall life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

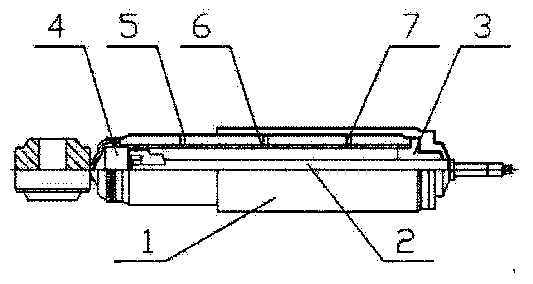

[0012] Such as figure 1 As shown, a double-buffer airbag shock absorber includes a shock absorber main body, a piston rod, an oil guide, a piston assembly and an oil storage cylinder, an oil storage cylinder is arranged in the working cylinder of the shock absorber main body, and the piston The rod is inserted into the oil storage cylinder, the piston assembly is arranged at the tail end of the piston rod, the oil guide is arranged at the upper end of the oil storage cylinder, and the working cylinder is composed of the first cylinder and the second cylinder with different diameters. body, a transition section is provided between the first cylinder and the second cylinder, the surface of the body of the piston rod is provided with a helically arranged oil groove, and the bottom of the oil storage cylinder is provided with a cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com