Spraying equipment for improving spraying efficiency of inner wall of furniture

A technology for spraying equipment and furniture, applied in spraying devices, spraying devices, etc., can solve the problems of poor spraying quality, easy spraying on clothes, low efficiency, etc., so as to reduce the labor intensity of workers, improve the quality of spraying, and improve the spraying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

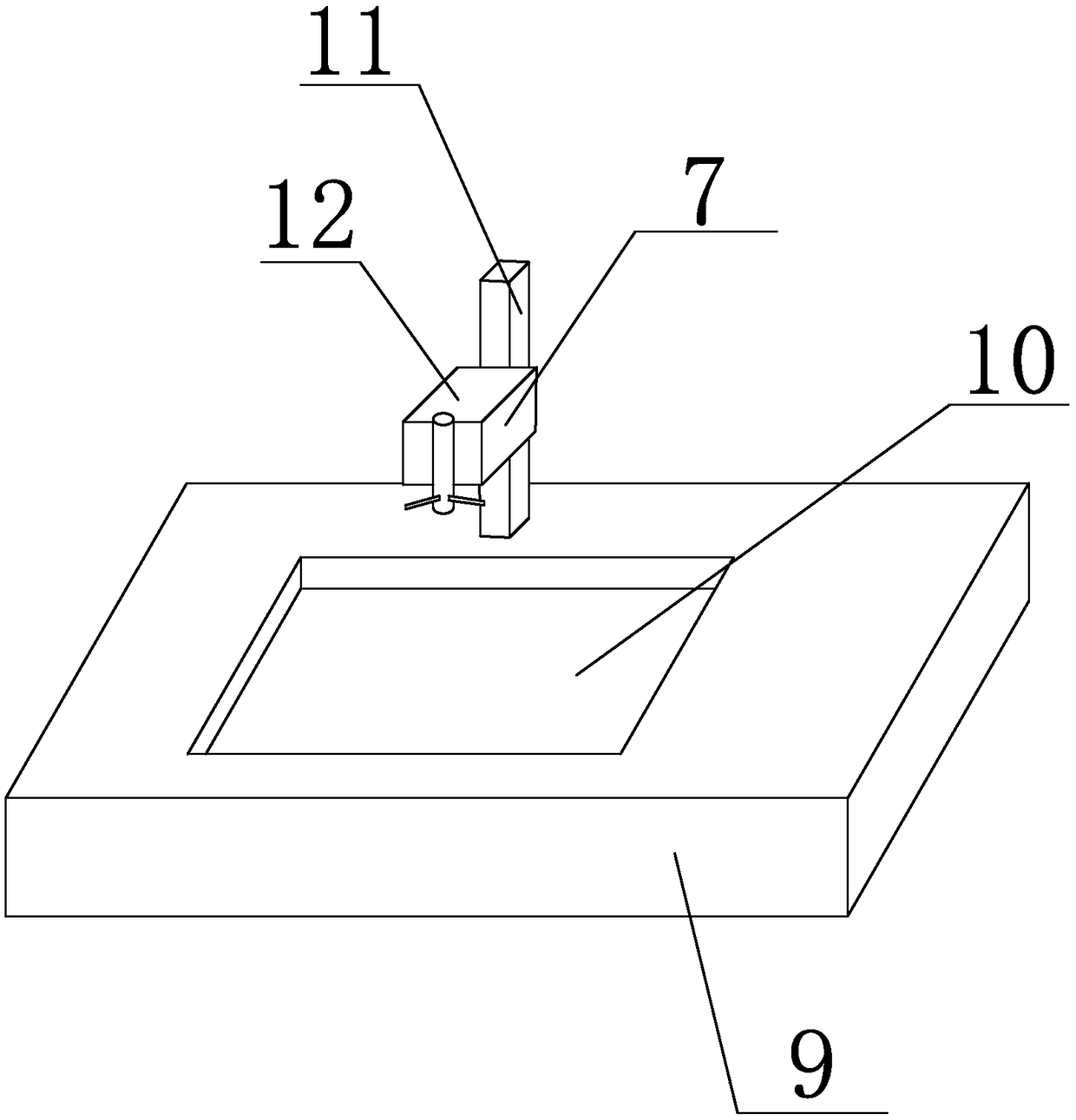

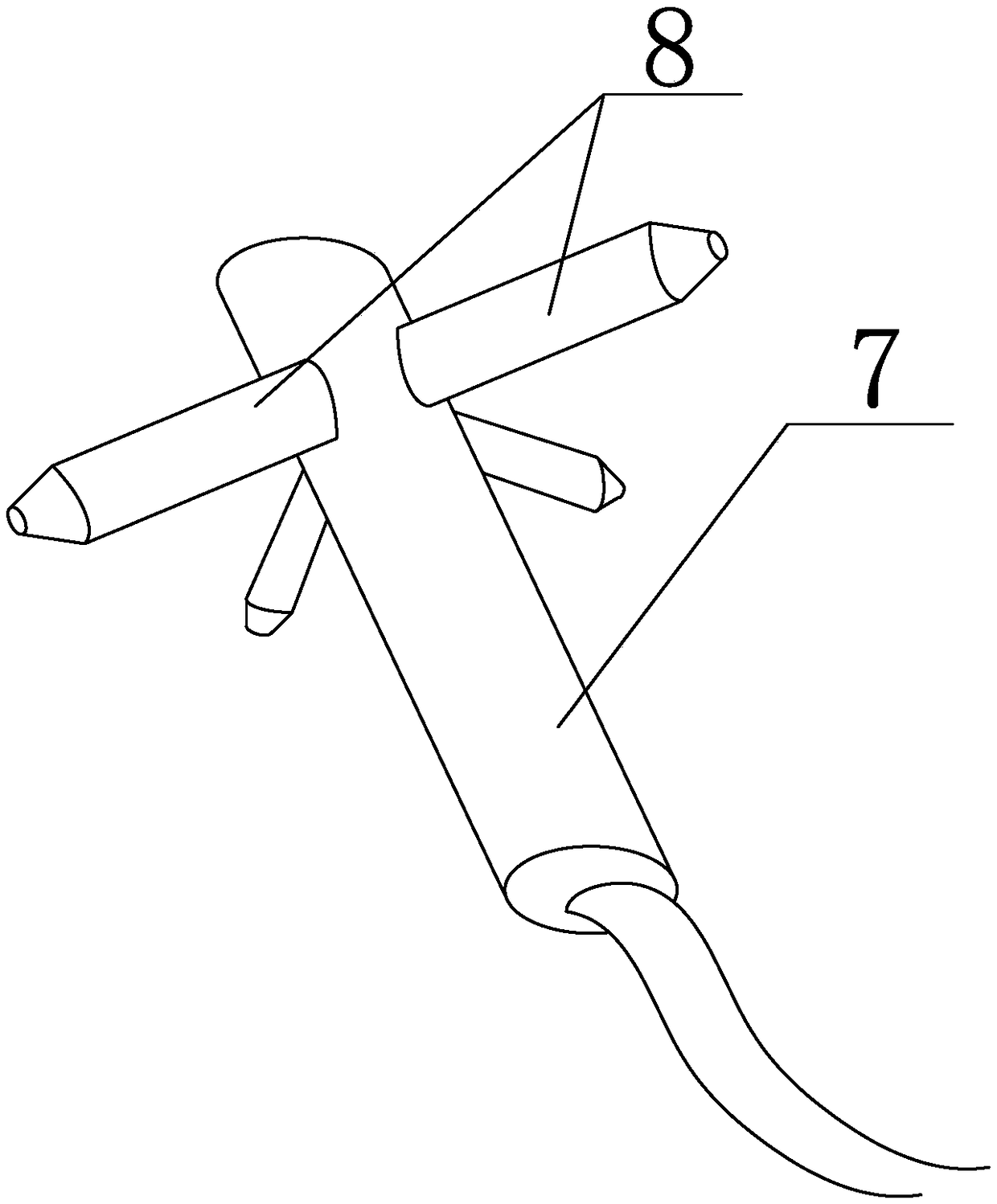

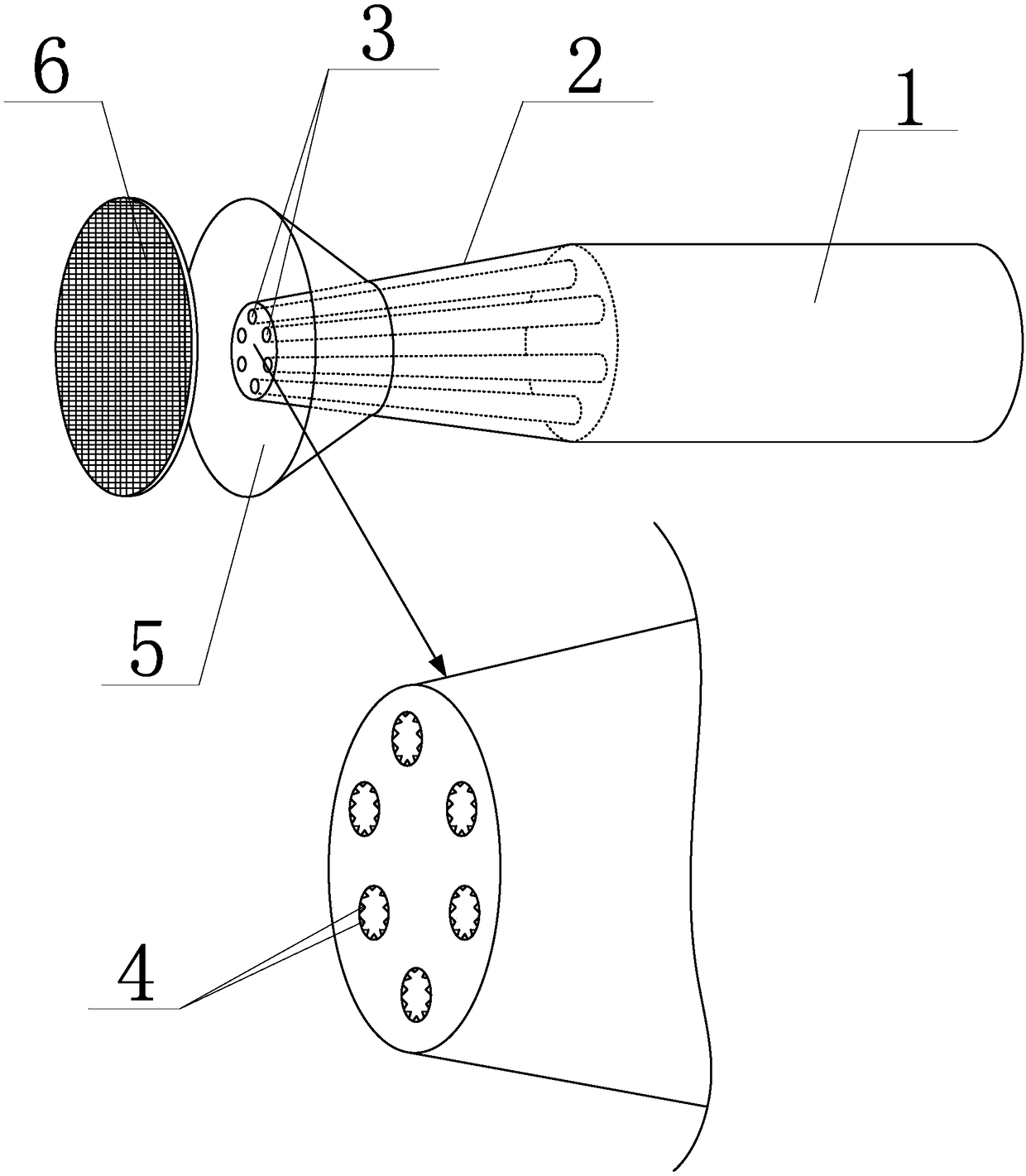

[0023] Such as figure 1 , figure 2 and image 3 As shown, the present invention is a spraying equipment for improving the spraying efficiency of the inner wall of furniture, including a workbench 9, the upper surface of the workbench 9 is provided with a furniture placement groove 10, and one side of the placement groove 10 is provided with a column 11, and the column 11 The installation block 12 is slidingly connected, and the installation block 12 can slide up and down along the column 11. The front end of the installation block 12 is equipped with a vertical feed pipe 7, and the bottom side wall of the feed pipe 7 is vertically arranged along the circumferential direction. There are four nozzles 8, which communicate with the feed pipe 7. The nozzles 8 include a paint nozzle 1, and the outlet end of the paint nozzle 1 is connected with a nozzle 2. The nozzle 2 is in the shape of a truncated cone. The diameter of one end of the paint spray pipe 1 is smaller than the diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com