Reflux condenser pipe special for microwave chemistry

A technology of reflux condenser and microwave chemistry, which is applied in chemical instruments and methods, steam/steam condensers, chemical/physical/physicochemical processes using energy, etc., and can solve organic solvent dissipation, liquid explosion, and damage experiments Personnel health and other issues, to achieve the effect of increasing separation loss, increasing energy loss, and exacerbating energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

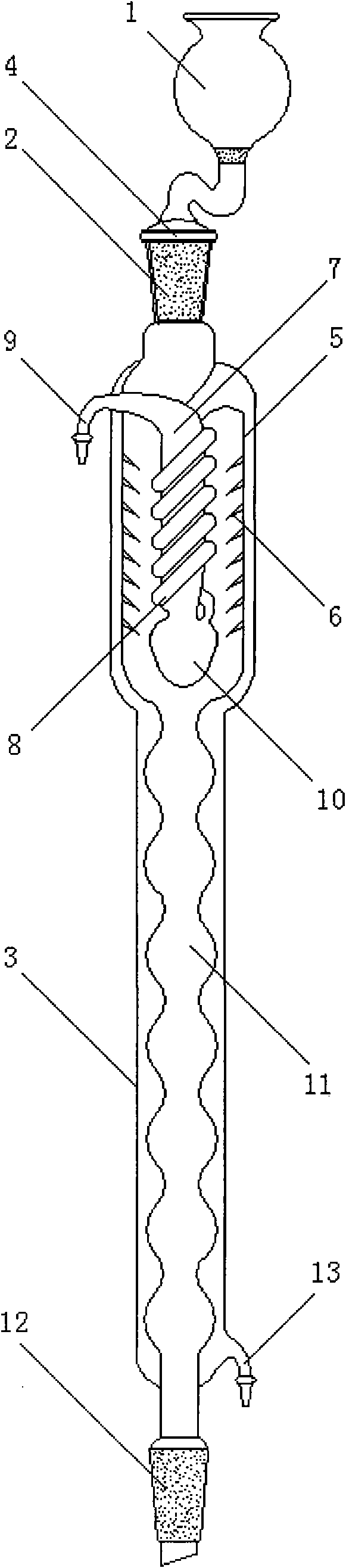

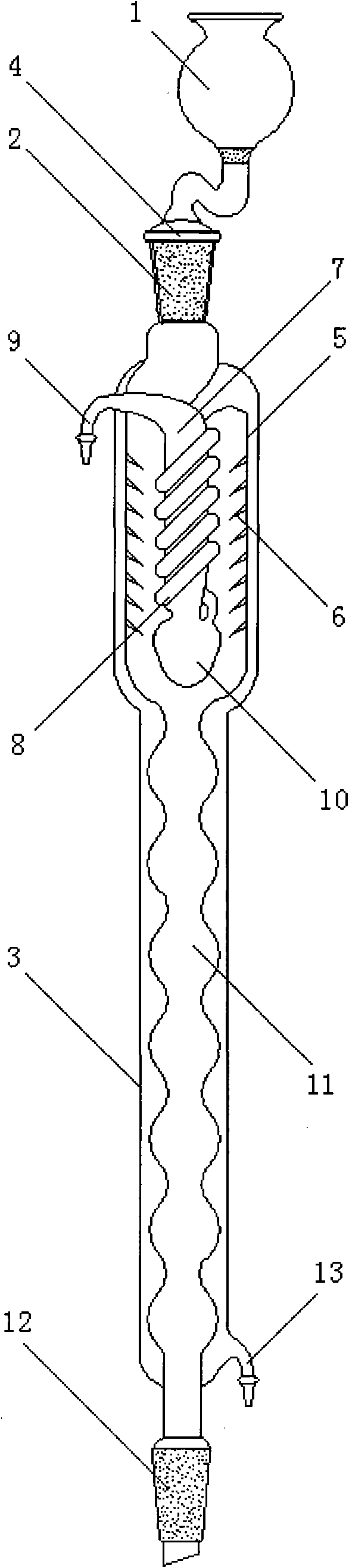

[0014] figure 1 Among them, the spherical funnel 1 is closely matched with the standard grinding mouth 4 on the upper end of the outer water casing 3 through the standard grinding plug 2, and a piece of glass sand core partition is welded to the bottom of the spherical container of the spherical funnel 1, and the neck of the spherical funnel 1 is a U-shaped tube, the lower end of the U-shaped tube is welded with the standard grinding plug 2; the standard grinding port 4 is welded with the outer water casing 3, and the outer water casing 3 is an upper part with a diameter of 5-6 cm and a length of 10-15 cm. cm, the lower part has a diameter of 3 to 5 cm and a thick glass tube with a length of 20 to 25 cm; a barrel-shaped tube 5 with a diameter of 4 to 5 cm and a length of 8 to 13 cm is welded in the thick glass tube; The force thorn 6 and the stilling thorn 6 are that the barrel-shaped tube 5 is in a hot-melt state, and a pointed cone is used to poke a sharp thorn with a thick ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com