Patents

Literature

34results about How to "Reduced separation loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel multi-blade centrifugal fan

ActiveCN105508265AImprove work efficiencyReduce speed differencePump componentsRadial flow pumpsAir volumeEngineering

The invention discloses a novel multi-blade centrifugal fan. The novel multi-blade centrifugal fan comprises a volute, a volute tongue and a plurality of fan blades fixed in the volute, wherein one lateral side of the volute tongue is fixed on the inner lateral side of the air outlet of the volute, the other lateral side of the volute tongue is a concave face, a plurality of air guide grooves are formed in the concave face, the two end faces of each fan blade are arc-shaped faces, a zigzag structure is arranged on one arc-shaped face of each fan blade, a bionic non-smooth structure is arranged on the other arc-shaped face of each fan blade, and airflow sequentially passes the bionic non-smooth structures and the zigzag structures and then is discharged from the air outlet of the volute. The novel multi-blade centrifugal fan has the advantages that the air quantity and air pressure of the fan are increased effectively, the noise of the fan is lowered effectively, and the efficiency of the fan is increased effectively.

Owner:XI AN JIAOTONG UNIV

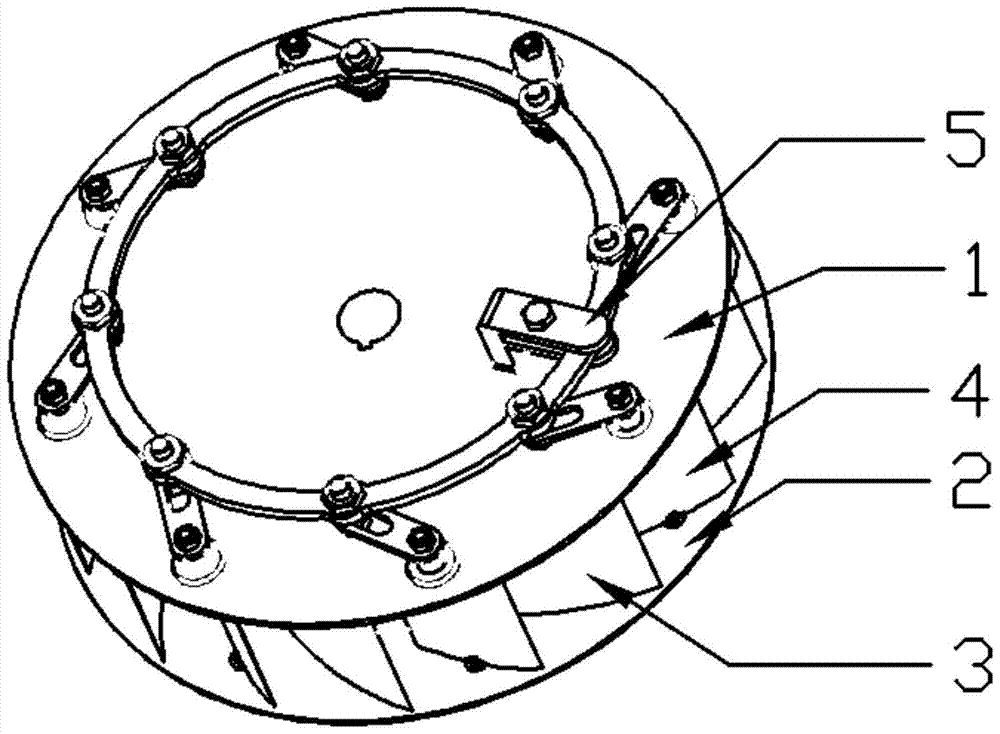

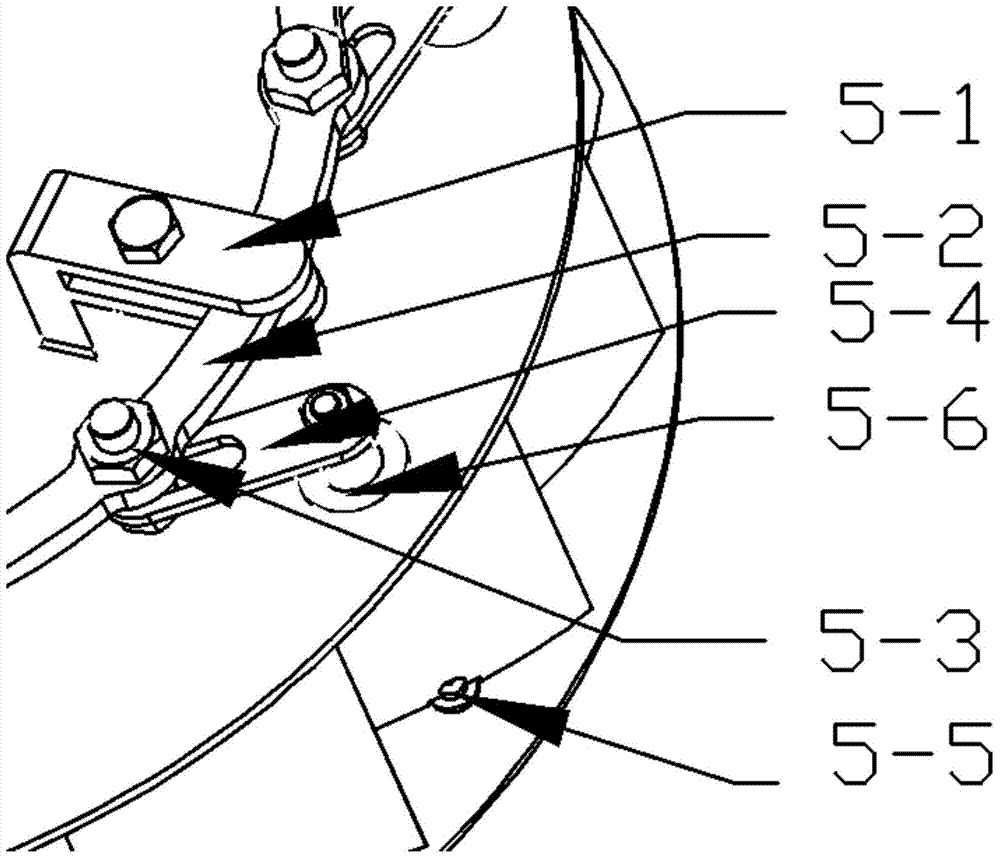

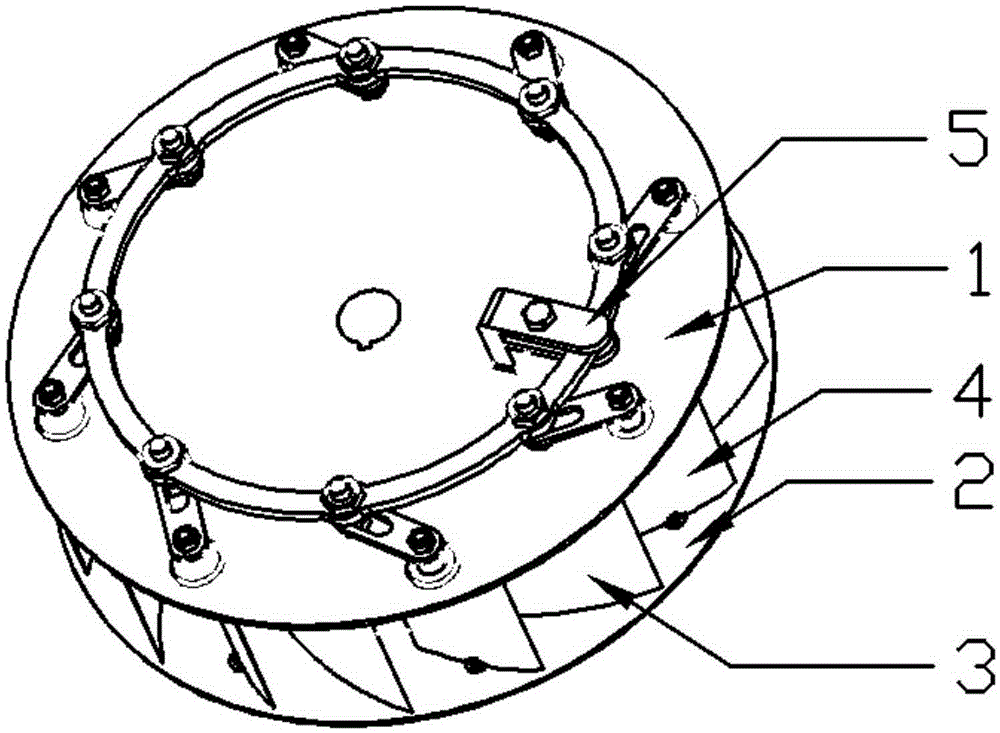

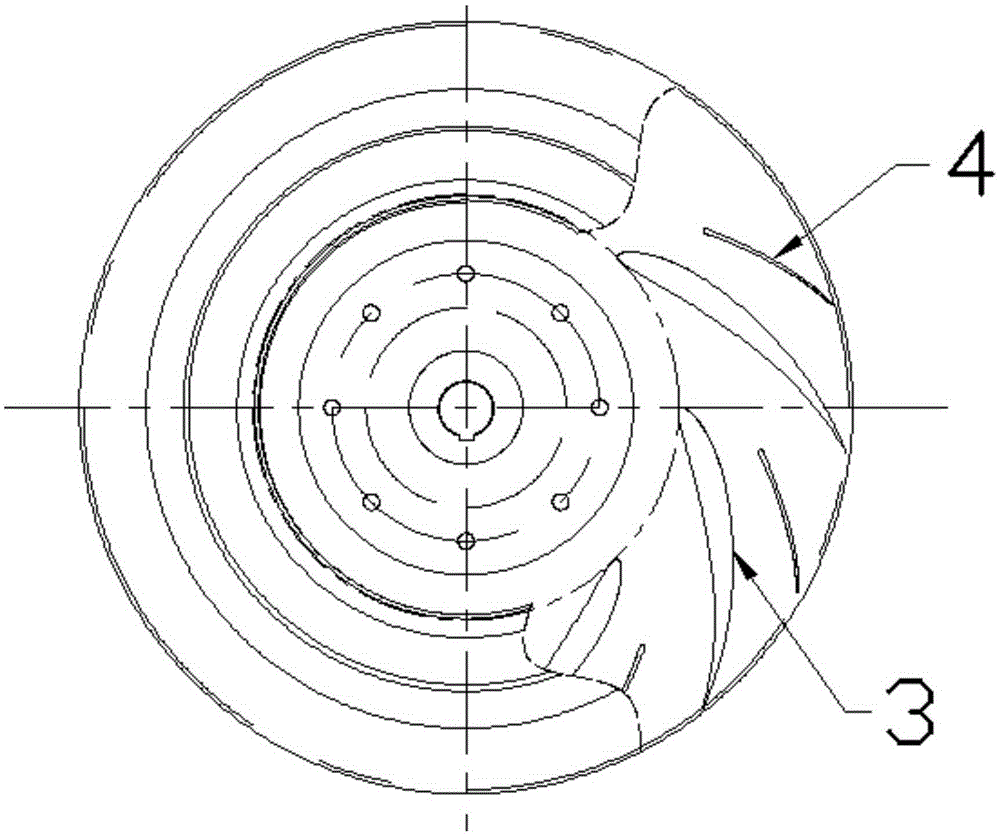

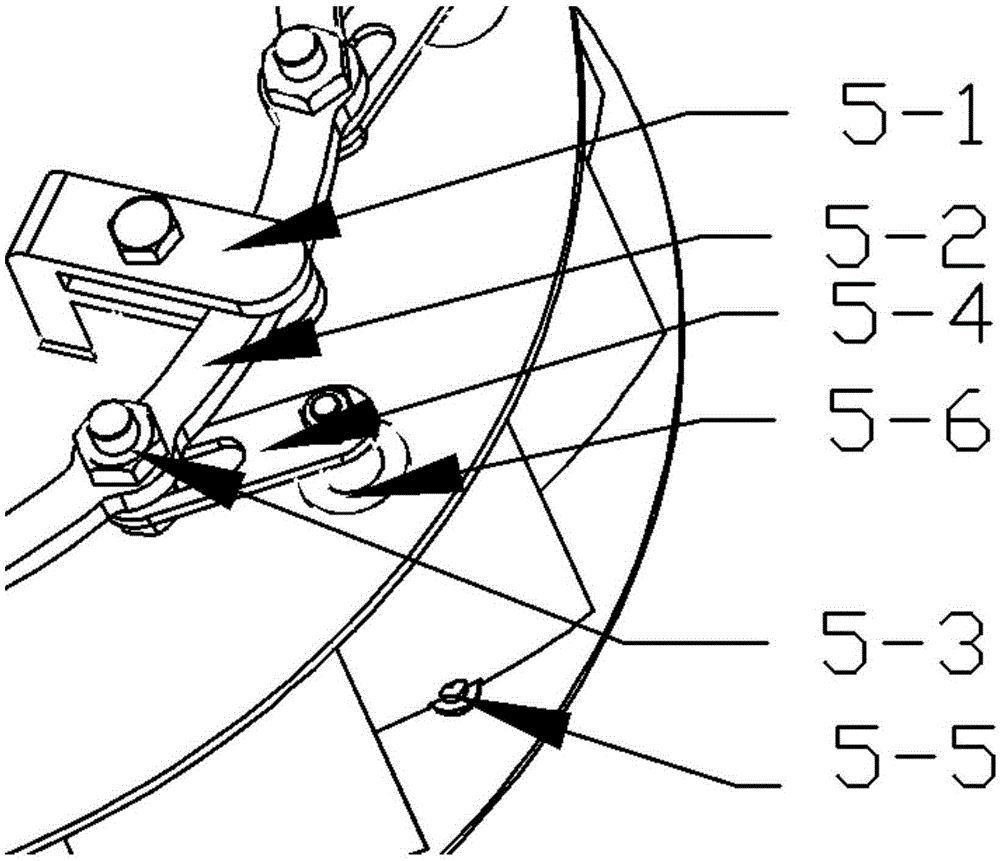

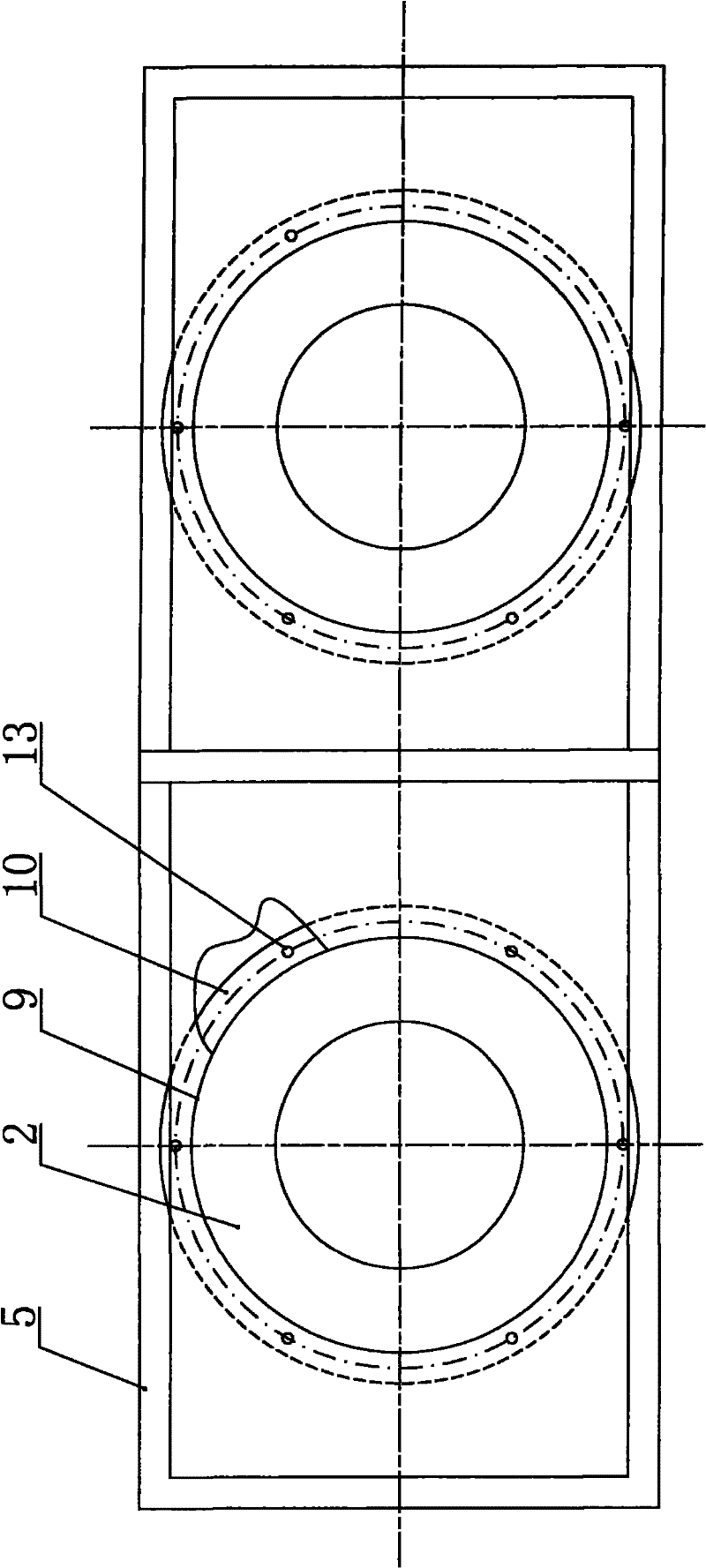

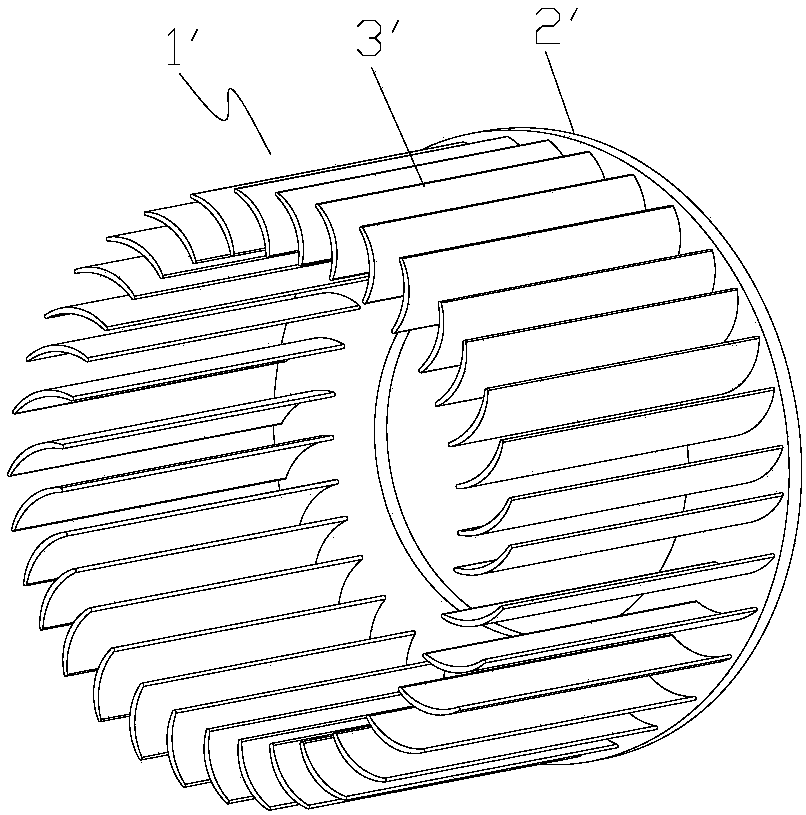

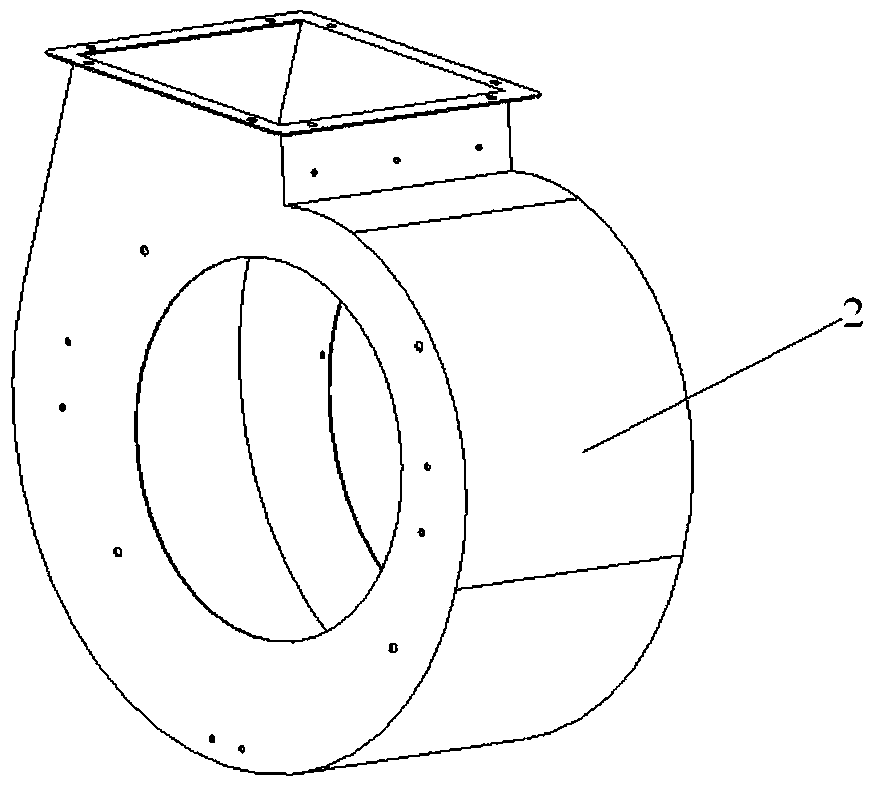

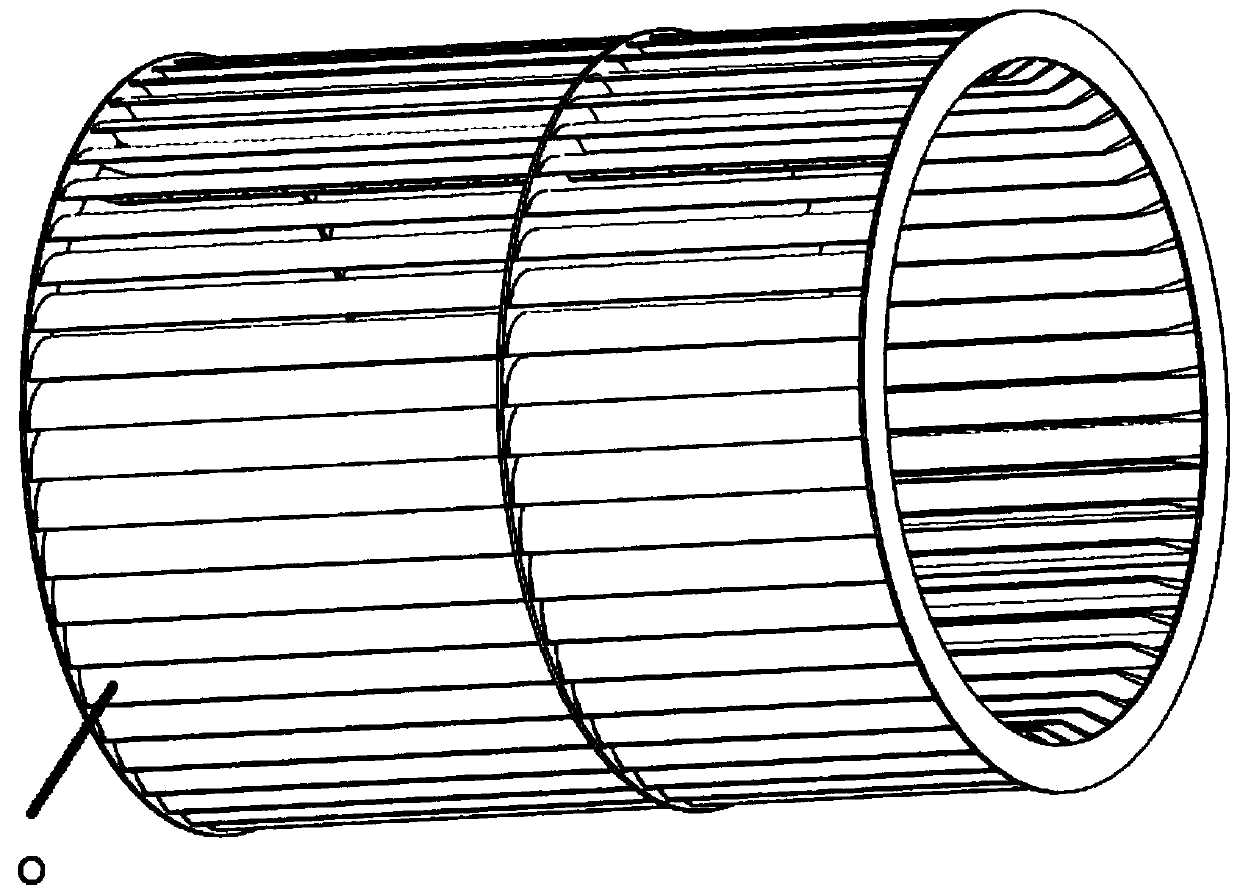

Centrifugal fan impeller capable of adjusting splitting vanes

InactiveCN105332945AImprove performanceImprove operational efficiencyPump componentsPumpsImpellerService efficiency

The invention discloses a centrifugal fan impeller capable of adjusting splitting vanes, and aims at solving the problems that the common working conditions of a current fan product in use do not match with the rated working conditions, thus the service efficiency of a fan is low, and the efficient operation range of the fan is reduced. The centrifugal fan impeller capable of adjusting the splitting vanes is characterized in that a circular guide ring and a wheel disc form a revolving pair; a main fixing frame which is provided with a circular guide ring fixing device is fixed to the wheel disc; the circular guide ring is connected to n upper fixing devices for the circular ring and the splitting vanes; the splitting vanes are connected to a wheel cover through upper fixing devices for the wheel cover and the splitting vanes, and the splitting vanes are connected with the wheel disc through upper fixing devices for the wheel disc and the splitting vanes; each upper fixing device for the circular ring and the splitting vanes is connected to the corresponding upper fixing device for the wheel disc and the splitting vanes through a splitting vane adjusting part. According to the centrifugal fan impeller, the circular guide ring can be rotated to drive the splitting vane adjusting parts to swing so as to adjust the angles of the splitting vanes, thus the maximum operation efficiency can be obtained according to different working conditions, and the maximum operation efficiency which can be achieved only under the rated working conditions can be obtained by a centrifugal fan under the off-rating conditions.

Owner:ZHEJIANG SCI-TECH UNIV

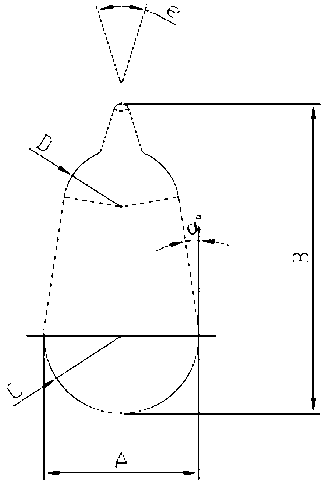

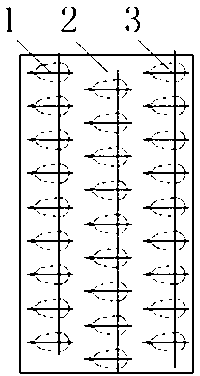

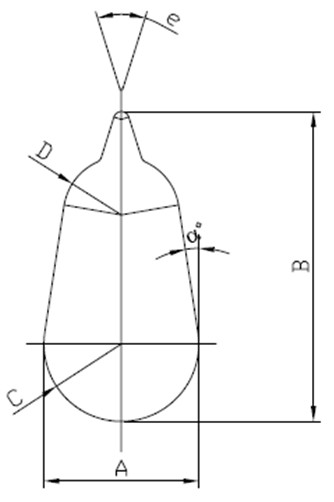

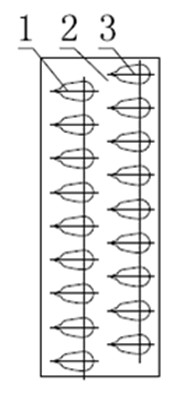

Drip-imitating tube-type demister and demister device

ActiveCN102068858ASolve the problem of intercepting too much slurryAddress riskDispersed particle separationFlue gasEngineering

The invention provides a drip-imitating tube-type demister, which is characterized by comprising at least two layers of parallel rows of tubes, wherein the rows of tubes are formed by tubes which are uniformly arrayed, the two ends of the rows of tubes are respectively supported on a plate, and the direction of flue gas flow is vertical to the direction of the short axis of the inner tubes of therow of tubes. The invention also provides a demister device, which is characterized by comprising the drip-imitating tube-type demister, wherein the drip-imitating tube-type demister is arranged at aflue gas desulfurization tower or the upstream of a horizontal flue, the demister is arranged at the downstream of the flue gas desulfurization tower, or a vane demister is arranged at the downstreamof the horizontal flue. The invention has the advantages that the demister reduces partial flow resistance, the area for blocking mist drop can be enlarged, demisting effect is improved, and scale isnot easy to form.

Owner:RPT SHANGHAI ENVIRONMENTAL EQUIP

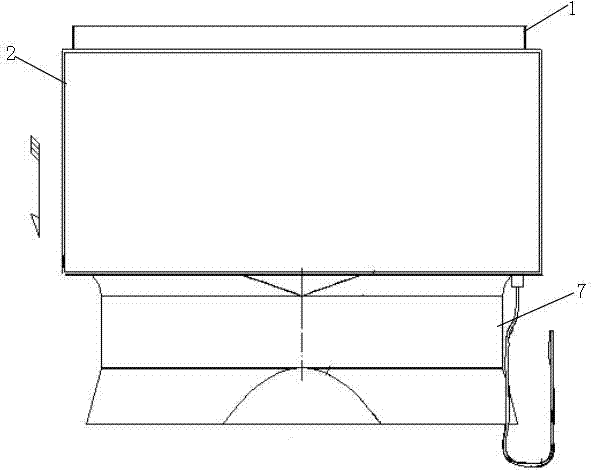

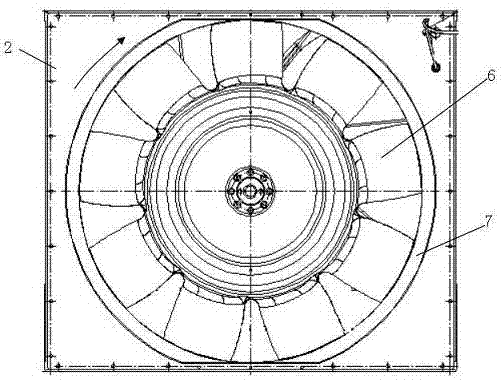

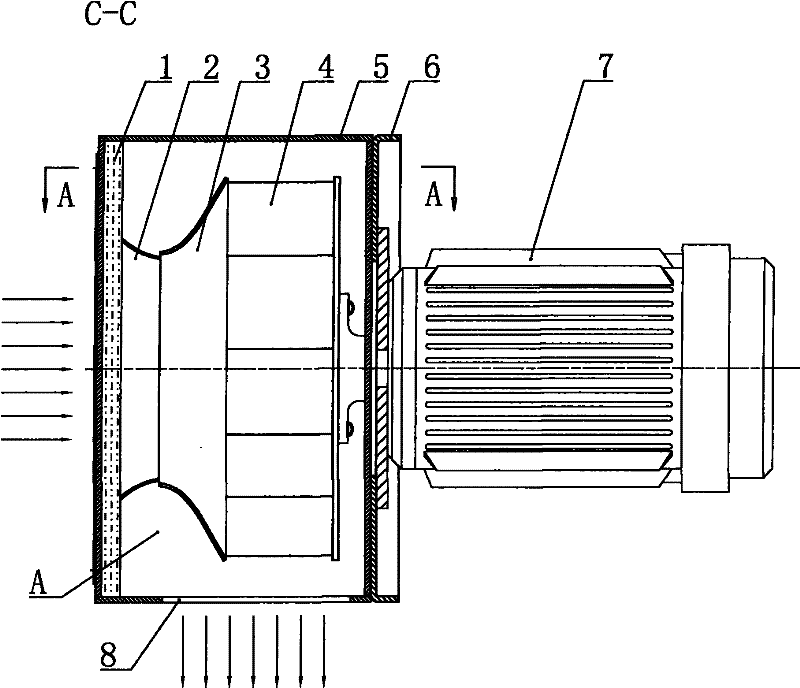

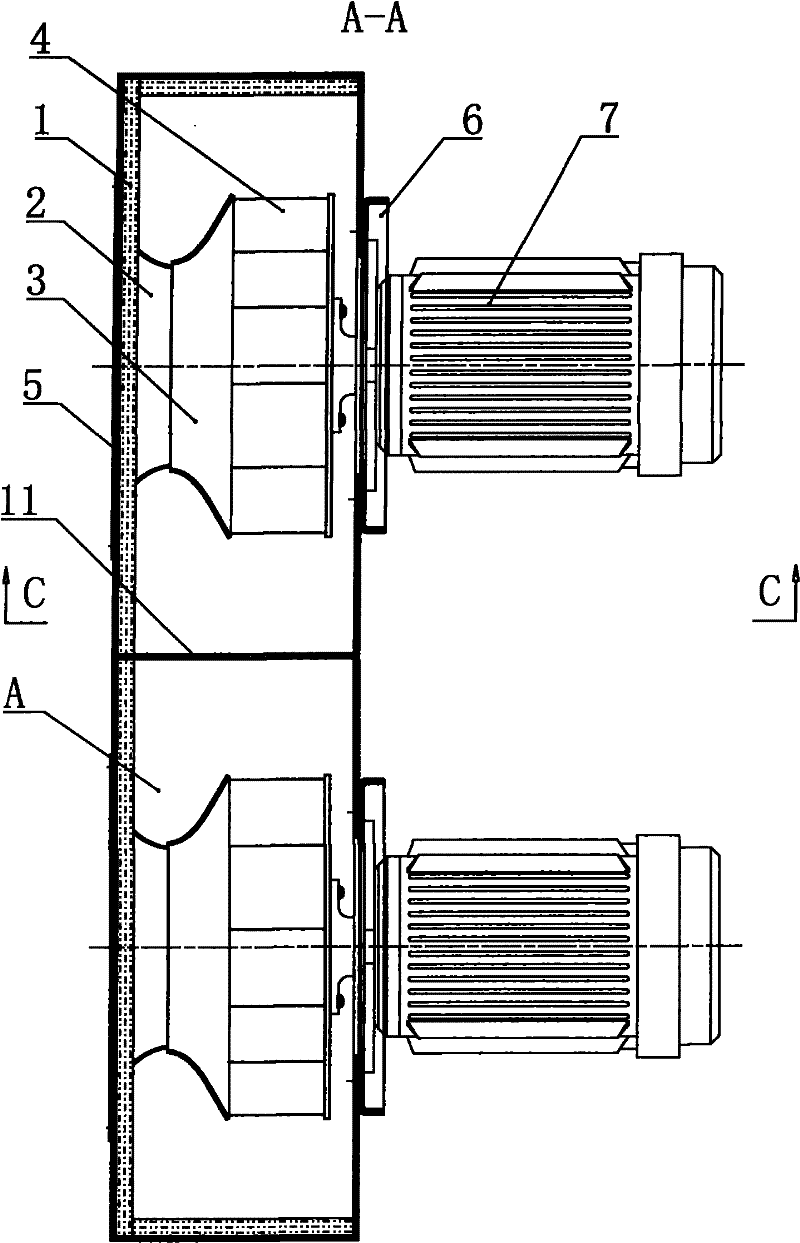

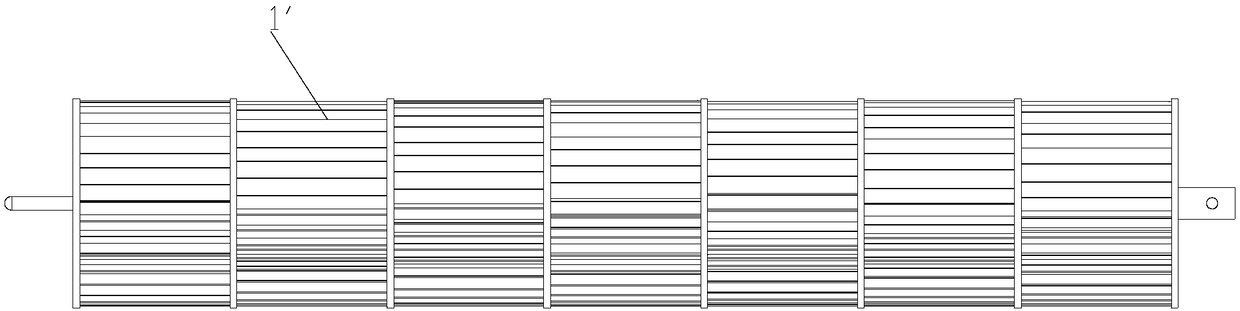

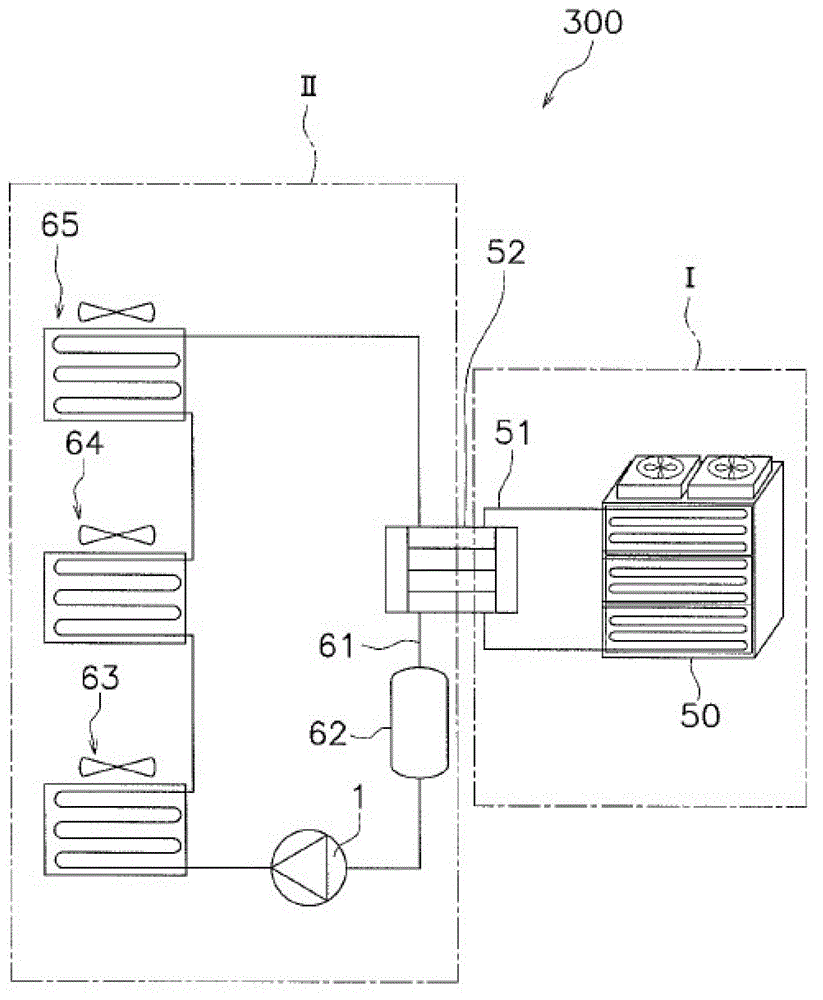

Cooling fan for traction converter of high-speed electric locomotive

InactiveCN102536857AGuaranteed cooling effectControl power consumptionPump componentsPump installationsImpellerElectric power

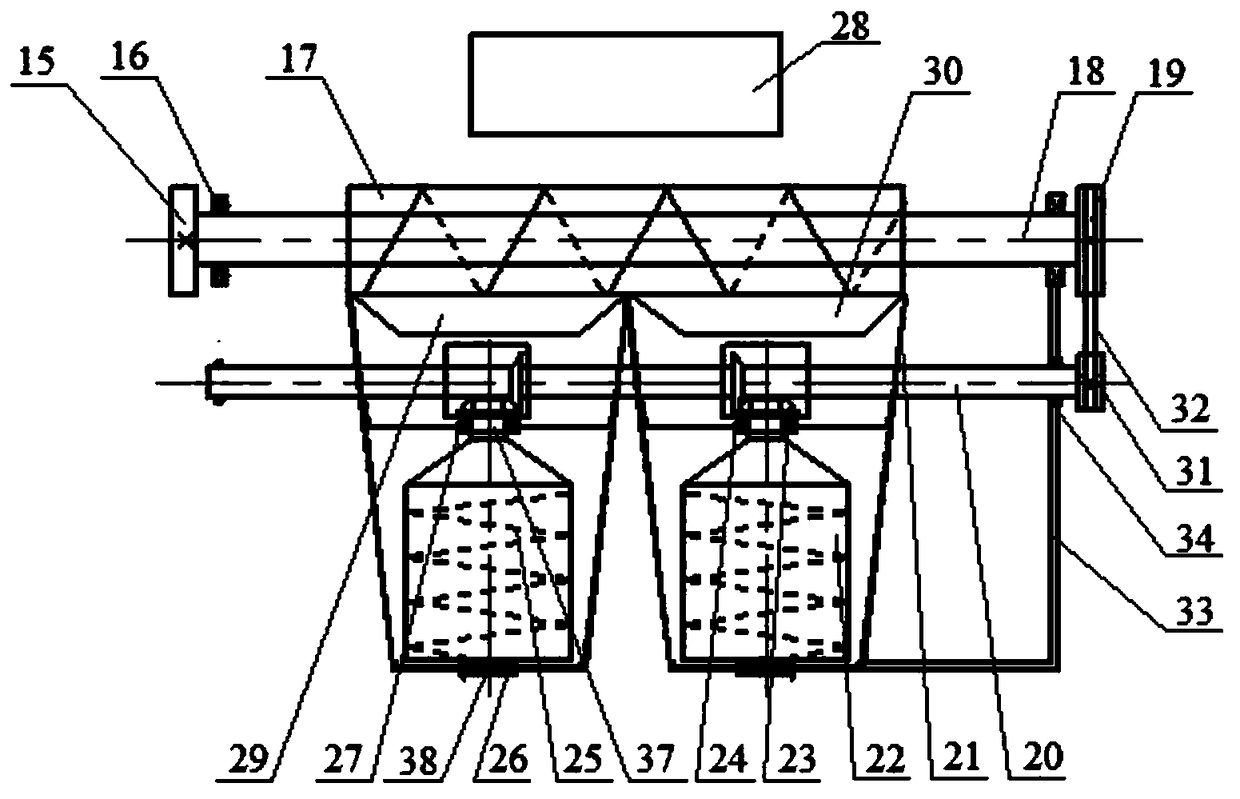

The invention relates to a cooling fan for a traction converter of a high-speed electric locomotive. The cooling fan comprises a rectangular box body (5), wherein a clapboard (11) is arranged at the middle of the box body (5) to divide the box body (5) into two independent cavities, a motor (7) is installed at rear side of each cavity, and an air inlet (9) and an air outlet (8) are respectively arranged at the front side and the lower side of each cavity. The cooling fan is characterized in that the rear side of each cavity is connected with the front end of the motor (7), an impeller (4) is arranged in each cavity and is coaxially installed on the output shaft of the motor (7), and two impellers (4) rotate counterclockwise during working so as not to mutually intervene. The cooling fan provided by the invention is mainly used for cooling the traction converters of motor trains with speed per hour of more than 380 km / h, and can satisfy the requirements of resisting low-temperature impact and high-speed vibration.

Owner:洛阳北玻三元流风机技术有限公司 +1

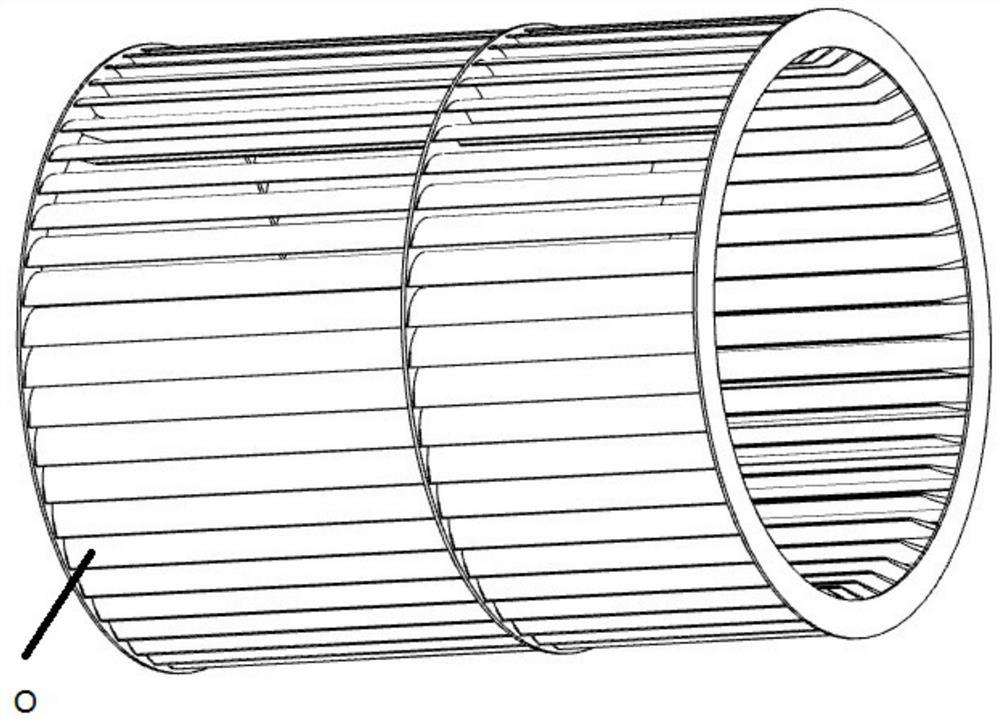

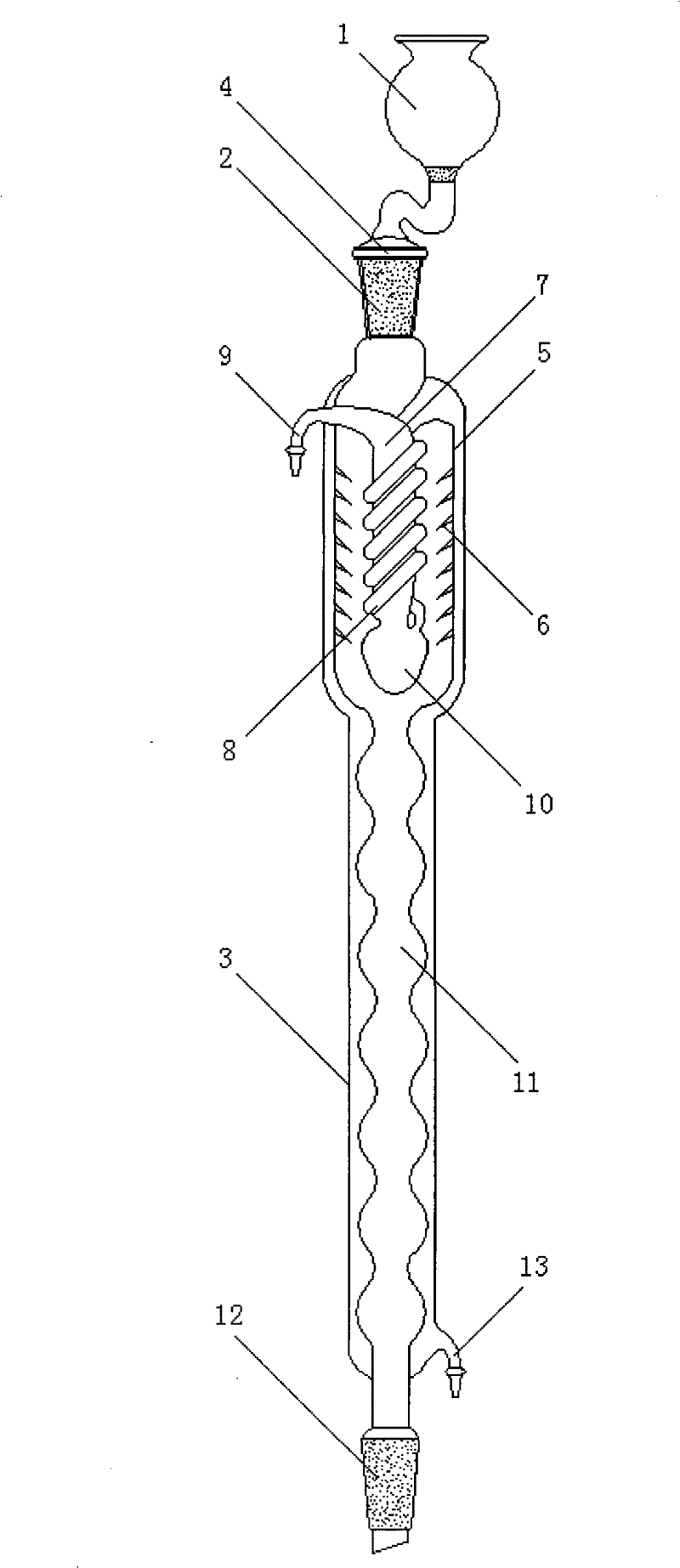

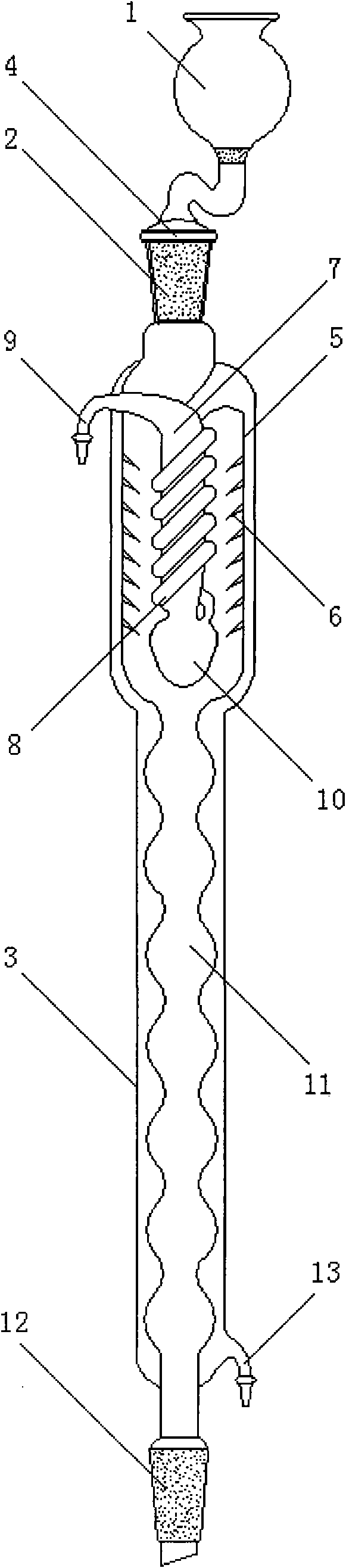

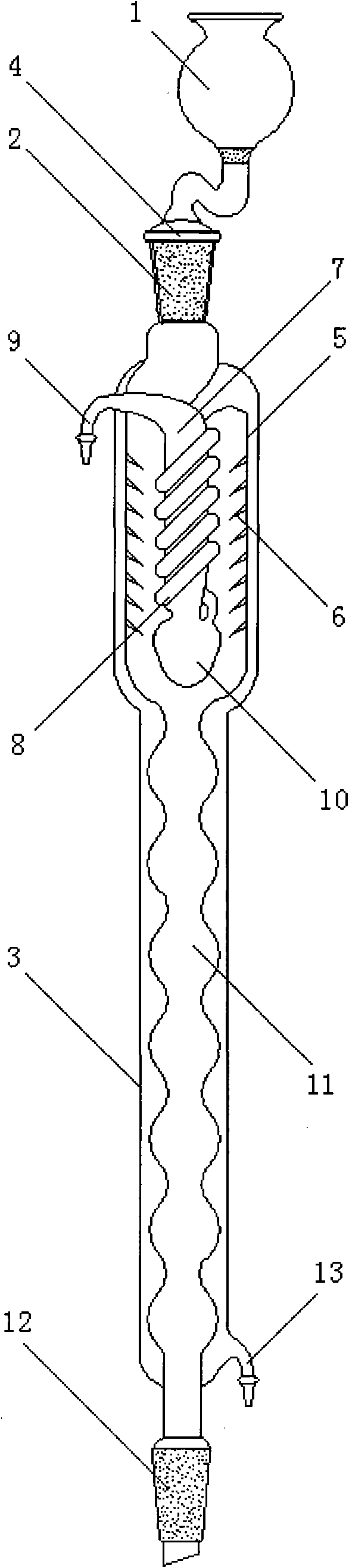

Reflux condenser pipe special for microwave chemistry

InactiveCN101780423AIncreased separation lossReduced separation lossSteam/vapor condensersLaboratory glasswaresRefluxOrganic solvent

The invention discloses a reflux condenser pipe special for microwave chemistry, which mainly comprises an external layer water sleeve (3), a standard ground (4), a barrel-shaped pipe (5), baffle stabs (6), an inner core pipe (7), a coil pipe (8), a water distribution head (10) and a serial ball pipe (11). The reflux condenser pipe special for the microwave chemistry is characterized in that: the standard ground (4) at the upper end of the external layer water sleeve (3) is welded with the barrel-shaped pipe (5) together; the baffle stabs (6) are uniformly distributed at the periphery of the inner wall of the barrel-shaped pipe (5); the lower end of the barrel-shaped pipe (5) is welded with the upper end of the serial ball pipe (11); the lower end of the inner core pipe (7) is connected with the water distribution head (10); and the coil pipe (8) is coiled outside the inner core pipe (7), and the lower end of the coil pipe (8) is connected with the water distribution head (10). Therefore, blasting explosion and high consumption of an organic solvent can be effectively prevented.

Owner:王锦化

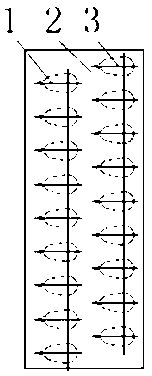

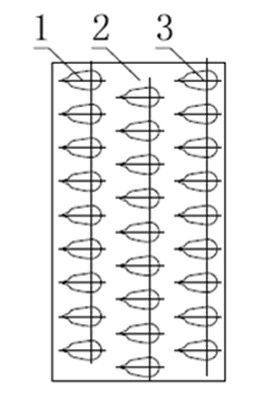

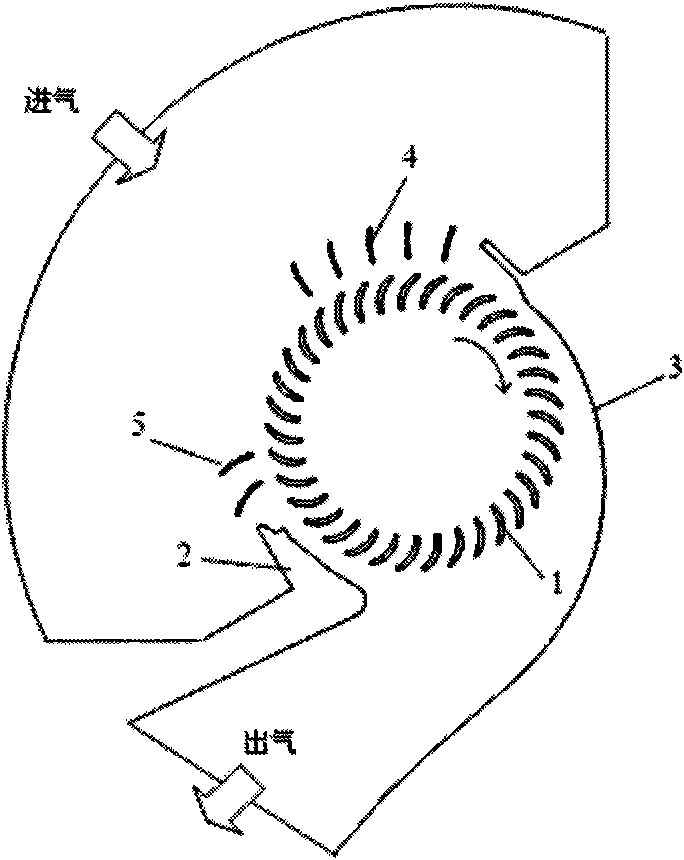

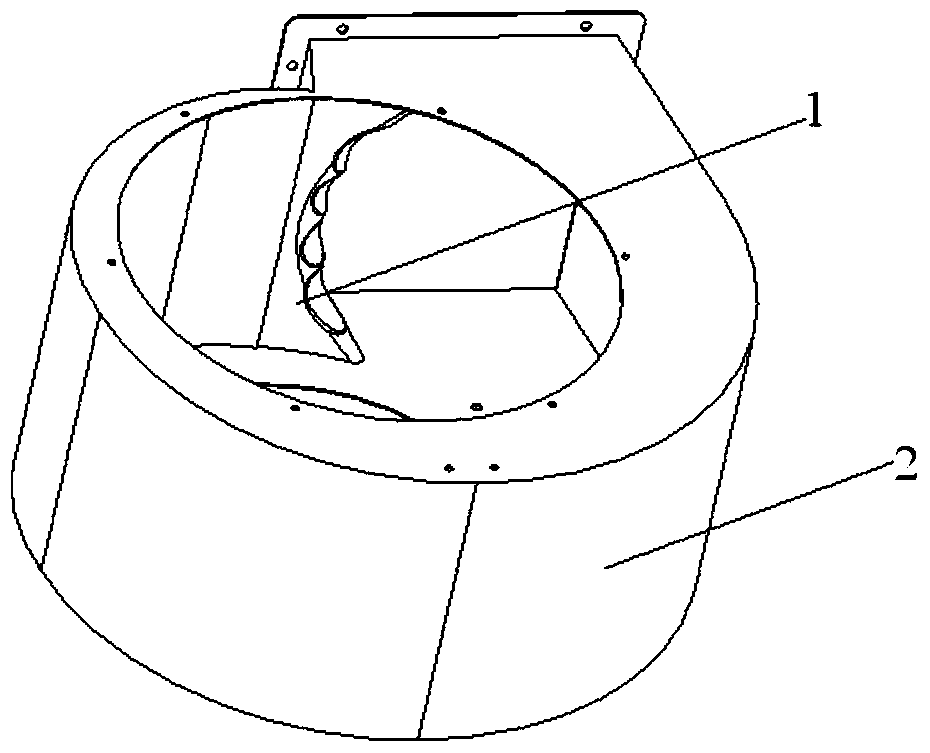

Double prerotation air intake guide blade of cross flow fan

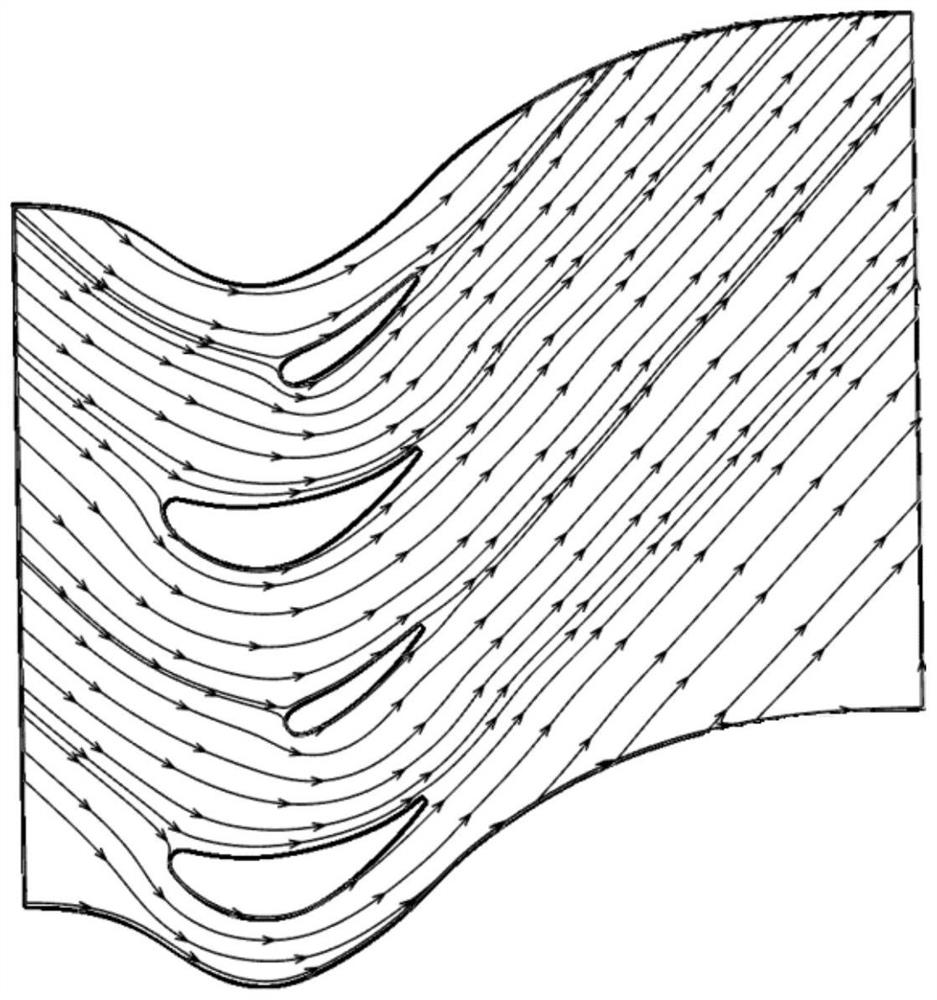

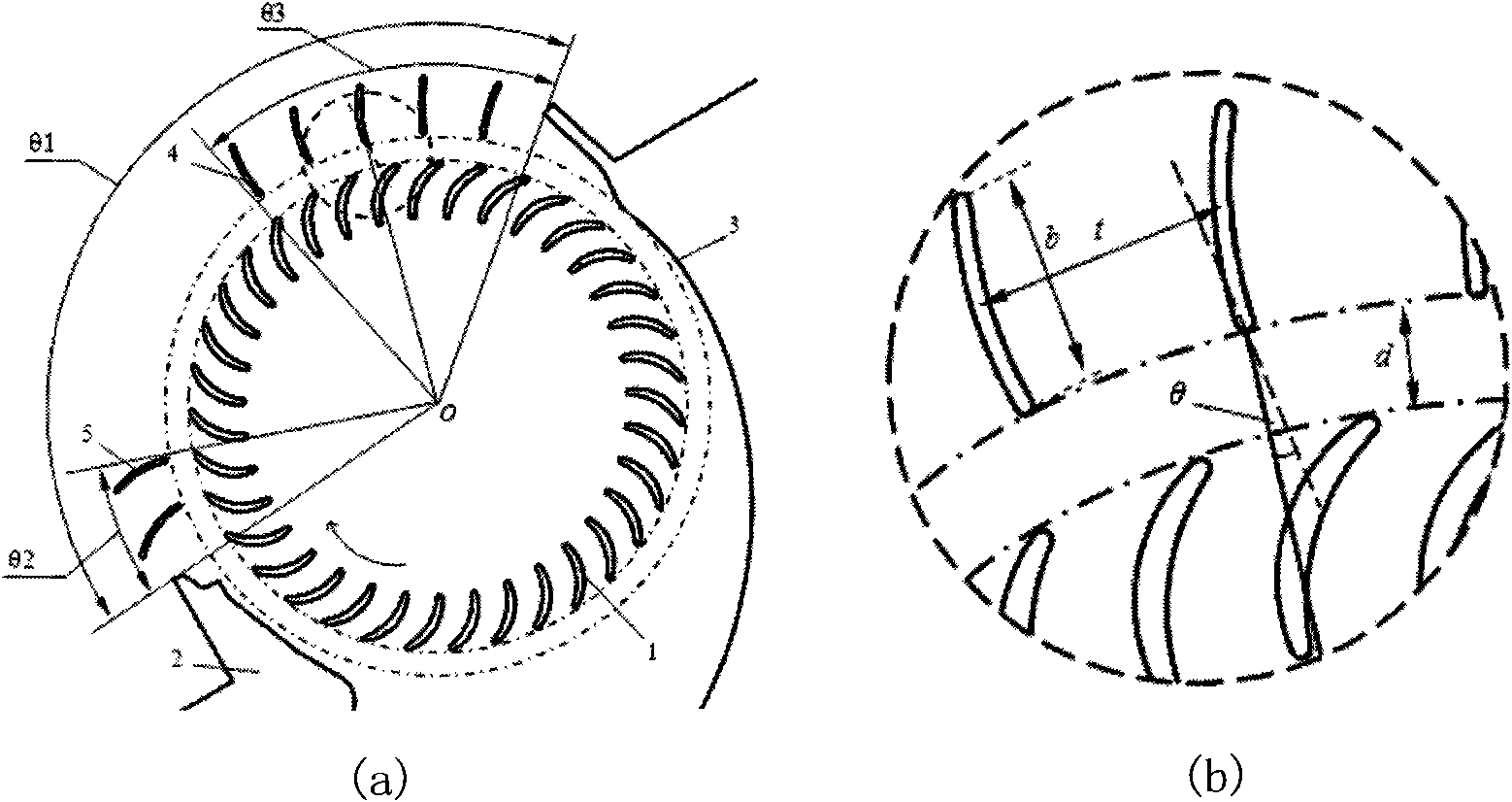

ActiveCN101655102AReduced flow separationReduced separation lossPump componentsPumpsImpellerCross-flow filtration

The invention relates to a double prerotation air intake guide blade of a cross flow fan, which belongs to the technical field of impeller machinery and comprises a positive prerotation guide blade group and a negative prerotation guide blade group, wherein the positive prerotation guide blade group comprises a plurality of air intake guide blades and the negative prerotation guide blade group comprises a plurality of air intake guide blades, the air intake guide blades of the positive prerotation guide blade group are sequentially arranged from to the end part of a volute of an air inlet of the cross flow fan to the center of the air inlet of the cross flow fan, and the air intake guide blades of the negative prerotation guide blade group are sequentially arranged from the end part of a volute tongue of the air inlet of the cross flow fan to the center of the air inlet of the cross flow fan. The invention can improve the local air intake condition of the cross flow fan and increase the operation efficiency of the cross flow fan as well as expand the stable operation working condition range of the cross flow fan, has simple structure, and can be conveniently arranged on various ventilated cross flow fans.

Owner:SHANGHAI JIAO TONG UNIV

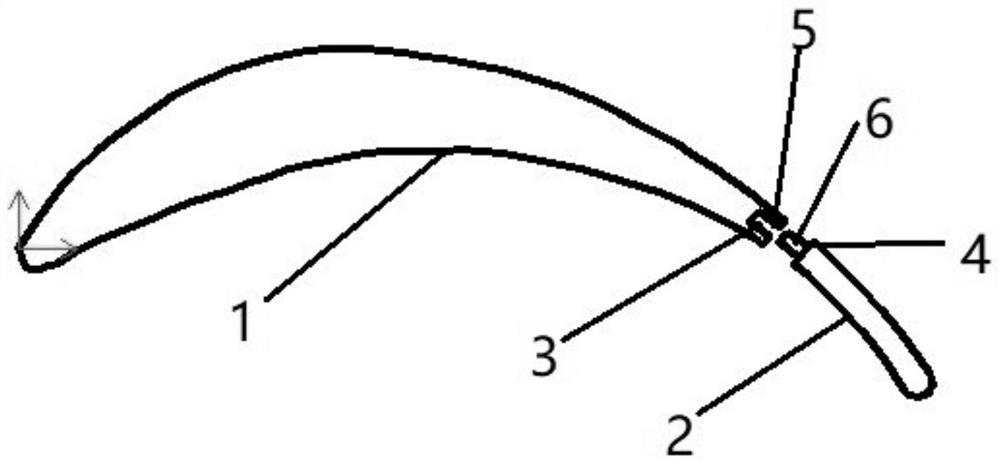

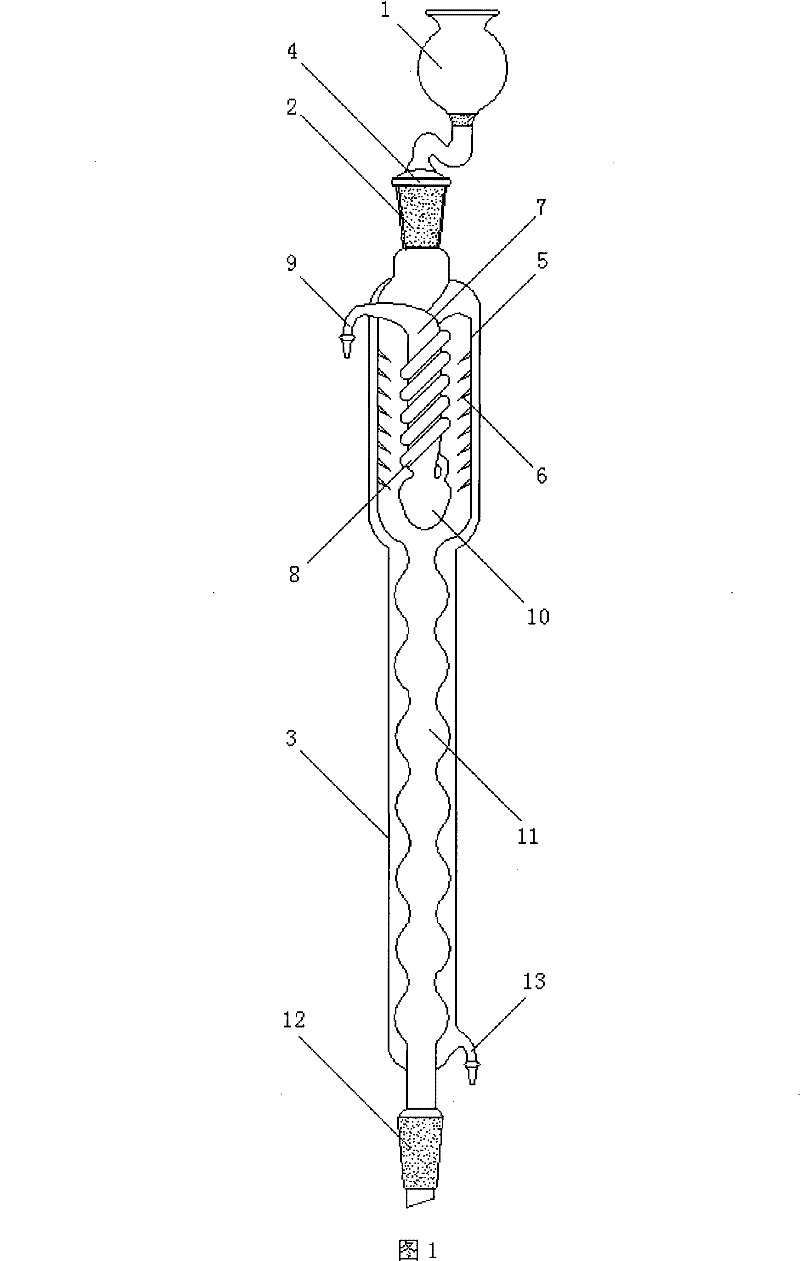

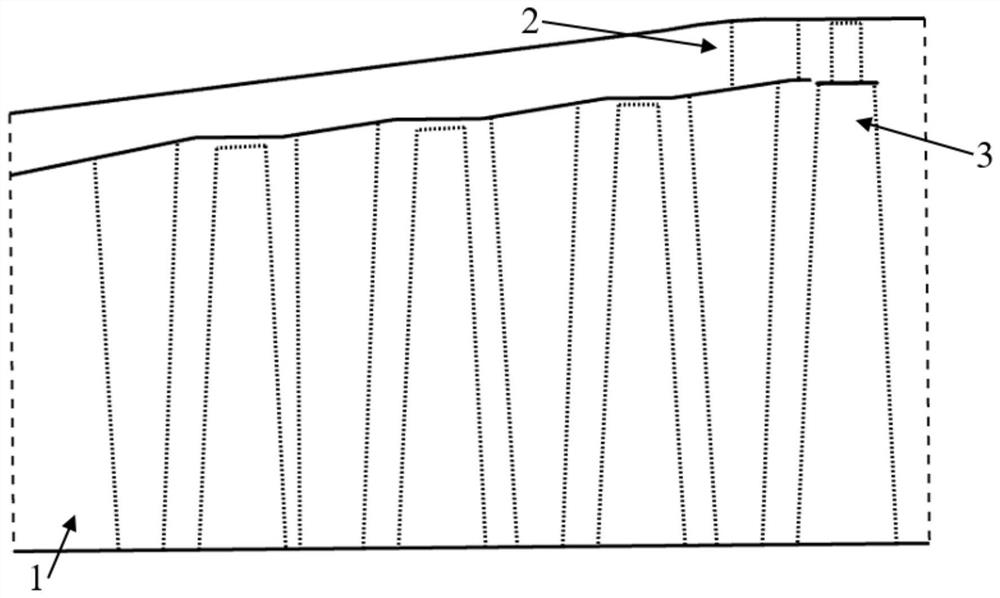

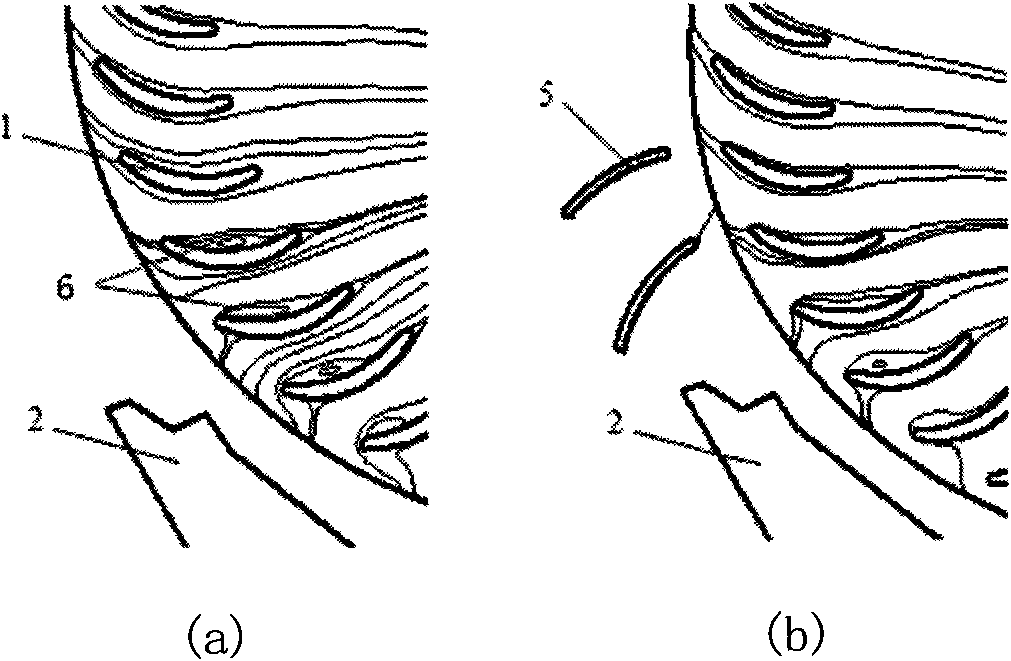

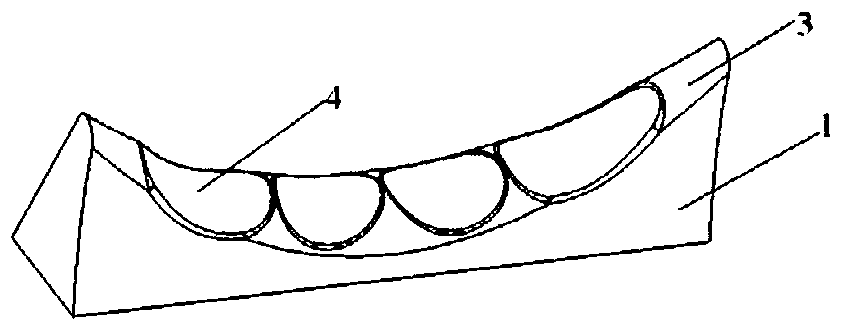

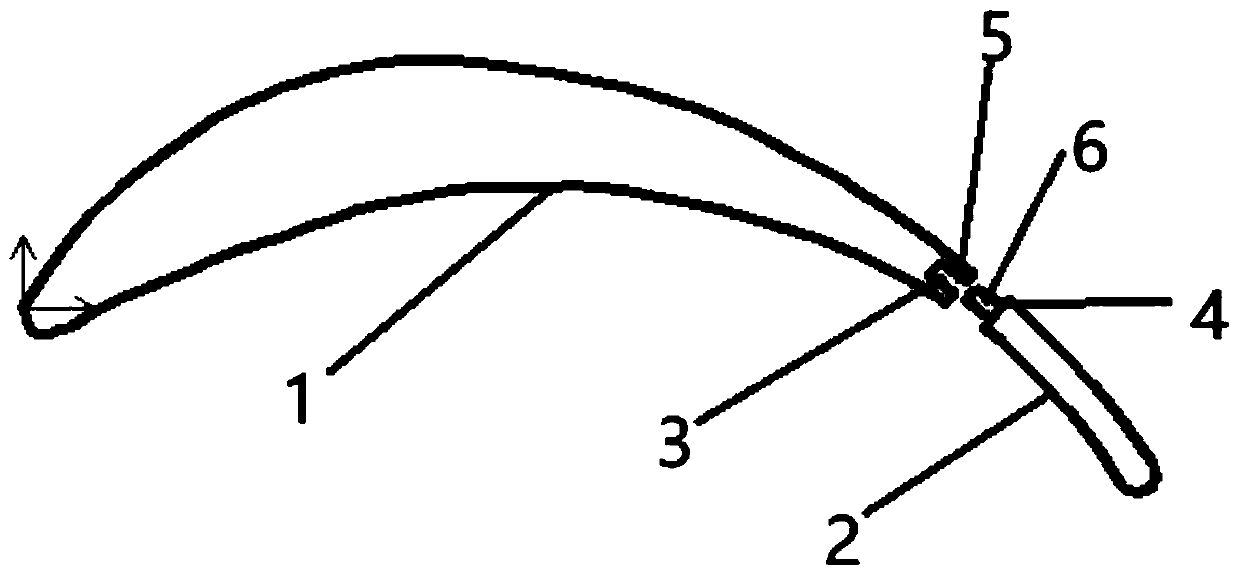

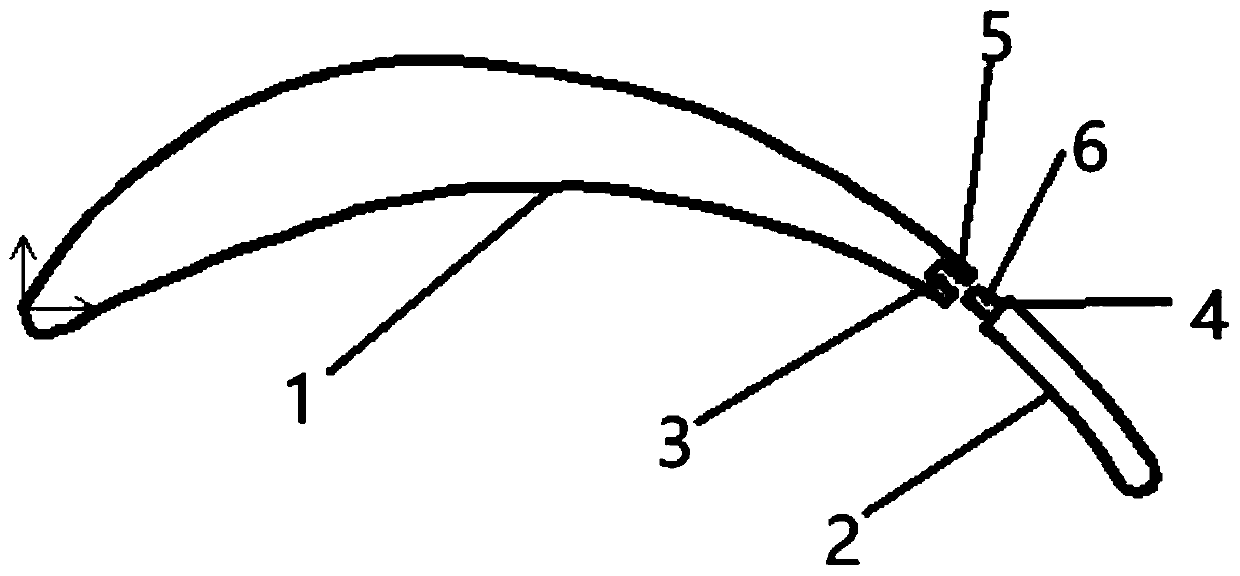

Cross-flow fan blade, cross-flow fan, indoor unit and air conditioner

PendingCN108105152APlay a role in rectificationPlay a stabilizing rolePump componentsLighting and heating apparatusPulp and paper industryFan blade

The invention provides a cross-flow fan blade, a cross-flow fan, an indoor unit and an air conditioner. The cross-flow fan blade comprises a blade body (1); the blade body (1) comprises a blade back (2); and the blade back (2) is provided with a rectification projection (3) projected on the blade back (2). The cross-flow fan blade can reduce the airflow separation phenomenon at the back part of the blade when the fan is rotated, and reduces the airflow separation loss.

Owner:GREE ELECTRIC APPLIANCES INC

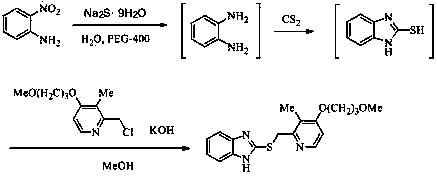

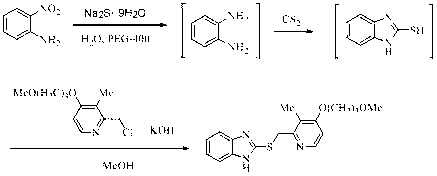

Method for preparing sulfur ether intermediates of proton pump inhibitor

ActiveCN102702173AReasonable designPrevent oxidative deteriorationOrganic chemistryNitrobenzenePyrrole

The invention relates to a method for preparing sulfur ether intermediates of a proton pump inhibitor. According to the method, an ortho-nitroaniline compound is subjected to a continuous three-step and one-pot reaction process of reduction, cyclization and condensation by taking water and low alcohols as solvents under the alkaline condition to prepare a series of sulfur ether intermediates of the proton pump inhibitor () in high efficiency, wherein X and Y are nitrogen atoms or carbon atoms, and R1 is selected from one of hydrogen, methoxyl, pyrrole-1-yl and difluoro methoxyl; and R2, R3 and R4 are selected from one of hydrogen, methyl, methoxyl, 3-methoxyl n-propoxy, 2,2,2-trifluoro-ethyoxyl and methyl sec-butylamino respectively. The method has the advantages that a one-pot synthetic process is reasonable in design, easy and convenient to operate and environment-friendly, separation loss in the synthetic process is avoided, and target products are high in yield. A structural general formula is shown in the specification.

Owner:WUTONG AROMA CHEM CO LTD

A New Type of Multiblade Centrifugal Fan

ActiveCN105508265BImprove work efficiencyReduce speed differencePump componentsRadial flow pumpsEngineeringFan blade

The invention discloses a novel multi-blade centrifugal fan. The novel multi-blade centrifugal fan comprises a volute, a volute tongue and a plurality of fan blades fixed in the volute, wherein one lateral side of the volute tongue is fixed on the inner lateral side of the air outlet of the volute, the other lateral side of the volute tongue is a concave face, a plurality of air guide grooves are formed in the concave face, the two end faces of each fan blade are arc-shaped faces, a zigzag structure is arranged on one arc-shaped face of each fan blade, a bionic non-smooth structure is arranged on the other arc-shaped face of each fan blade, and airflow sequentially passes the bionic non-smooth structures and the zigzag structures and then is discharged from the air outlet of the volute. The novel multi-blade centrifugal fan has the advantages that the air quantity and air pressure of the fan are increased effectively, the noise of the fan is lowered effectively, and the efficiency of the fan is increased effectively.

Owner:XI AN JIAOTONG UNIV

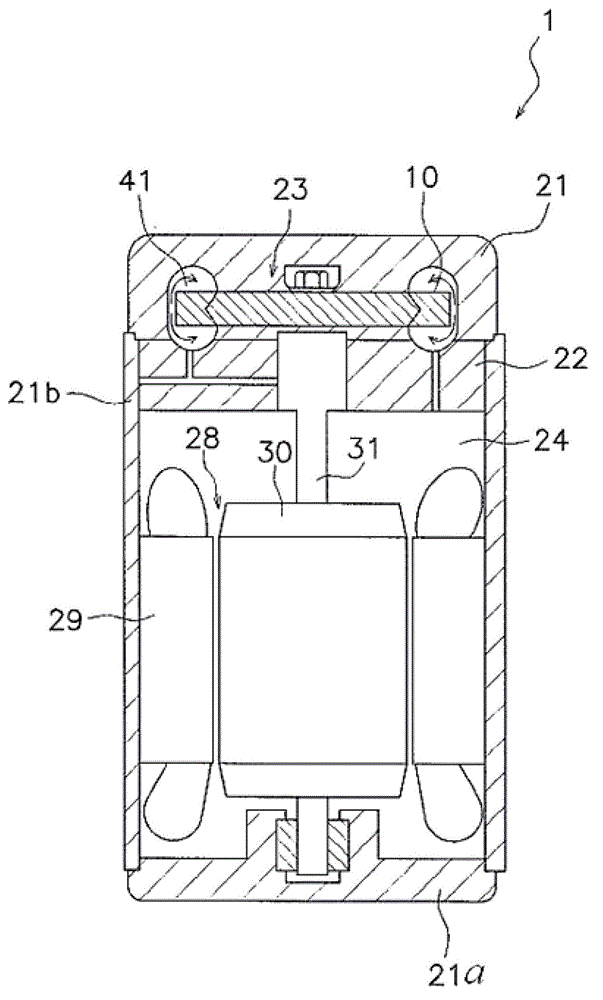

Refrigerant pump

InactiveCN103032338BNo conflictGuaranteed energyPump componentsPump installationsImpellerEngineering

The invention discloses a refrigerant pump, which comprises a shell, wherein the interior of the shell is partitioned into a rotor chamber and a motor chamber by a dividing plate, an impeller is arranged in the rotor chamber, and a refrigerant main runner is formed between the rotor chamber and the impeller; and the rotor chamber is also provided with a suction inlet and an exhaust outlet which cover the side part and the radial outer side of the impeller. The shape of the shell which is in contact with fluid is approximately identical with the eddy direction, so that the eddy loss is reduced; and in addition, the separating loss of the fluid flowing at an inlet of the impeller is reduced, and the flowing property of the fluid is improved. On the basis that the shapes of blades incline towards the rotating direction, the runner between the side surfaces of the blades and the shell component is semicircular, so that the impeller efficiency can be further improved, and the whole efficiency of the pump can be further improved.

Owner:XI AN JIAOTONG UNIV +1

Method for preparing hinokitiol metal compound and complex

InactiveCN111620766AReduced separation lossEasy accessOrganic compound preparationCarbonyl compound separation/purificationAmmonium compoundsOrganic solvent

The invention provides a method for preparing a hinokitiol metal compound or a hinokitiol ammonium compound. The method comprises the following steps: dissolving hinokitiol in a water-soluble organicsolvent to obtain a hinokitiol solution with a hinokitiol concentration of 6-25 mol / L; fully mixing and reacting the obtained hinokitiol solution with an aqueous solution of water-soluble metal salt or ammonium salt at room temperature, wherein the water-soluble metal salt is selected from metal salt with solubility not lower than 35 g / 100ml at room temperature, or the concentration of the aqueoussolution of the water-soluble metal salt or ammonium salt is not lower than 25% at room temperature, and the aqueous solution of the water-soluble metal salt or ammonium salt is further preferably asaturated solution of the water-soluble metal salt at 30-50 DEG C; and controlling the molar ratio of the water-soluble metal salt or ammonium salt to the hinokitiol to be 1: (0.9-5) to prepare a hinokitiol metal compound or hinokitiol ammonium compound solution. The method provided by the invention can fundamentally improve the instability characteristic that the hinokitiol is easy to decompose when meeting light, and avoids environmental pollution load and treatment cost of wastewater caused by the use of an acid solution.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI +1

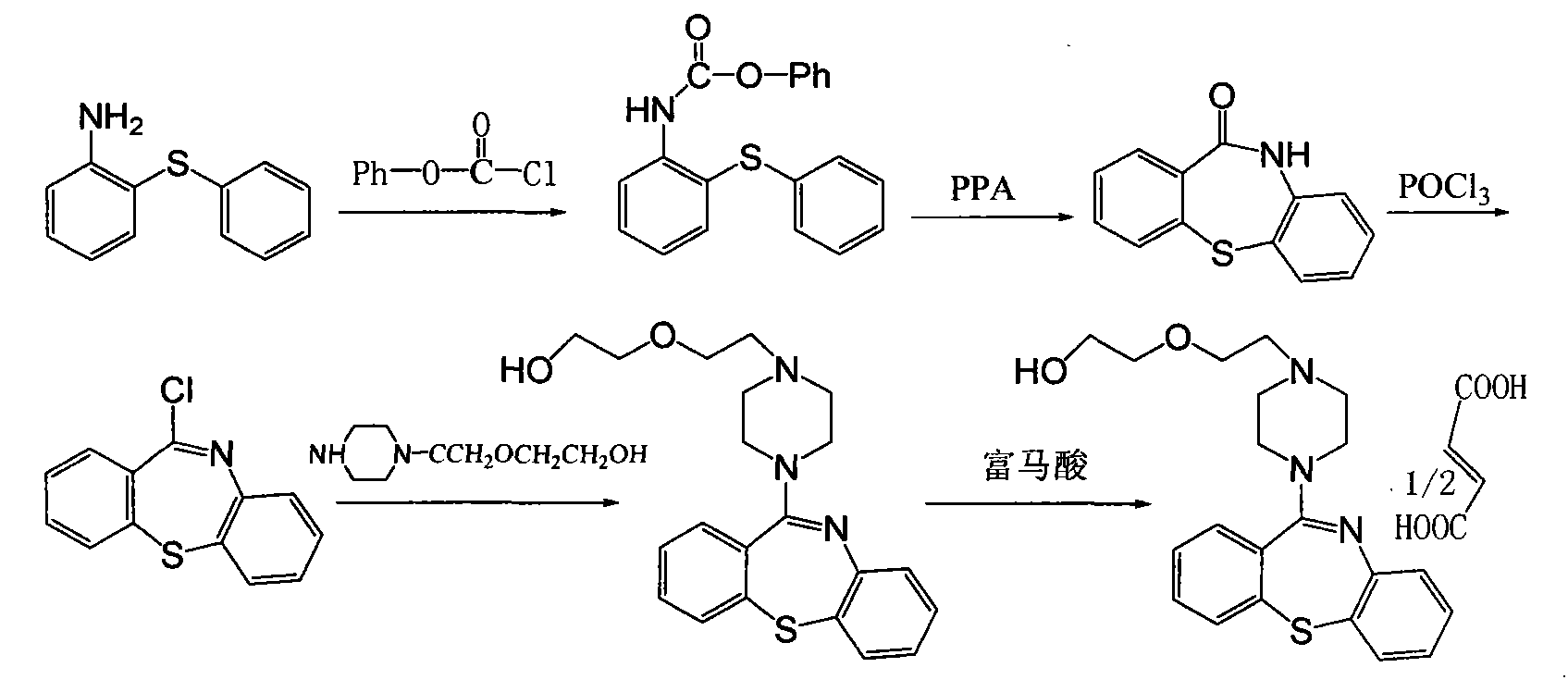

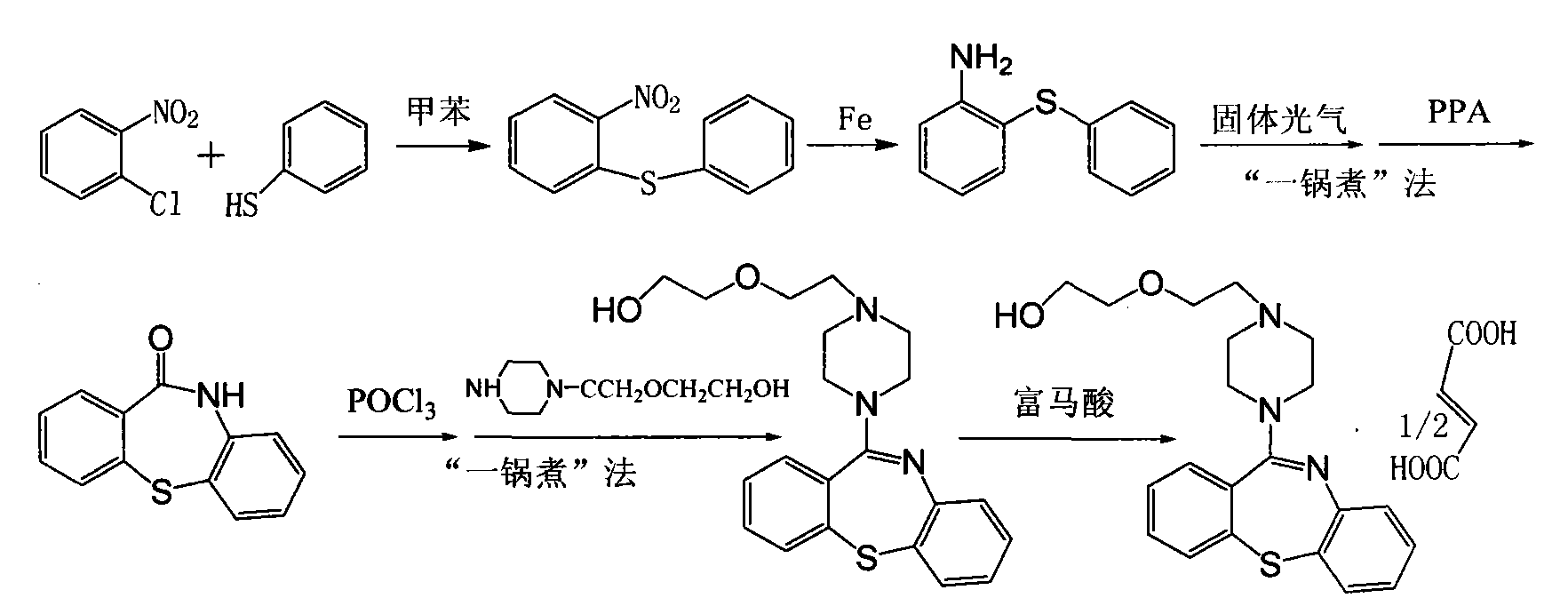

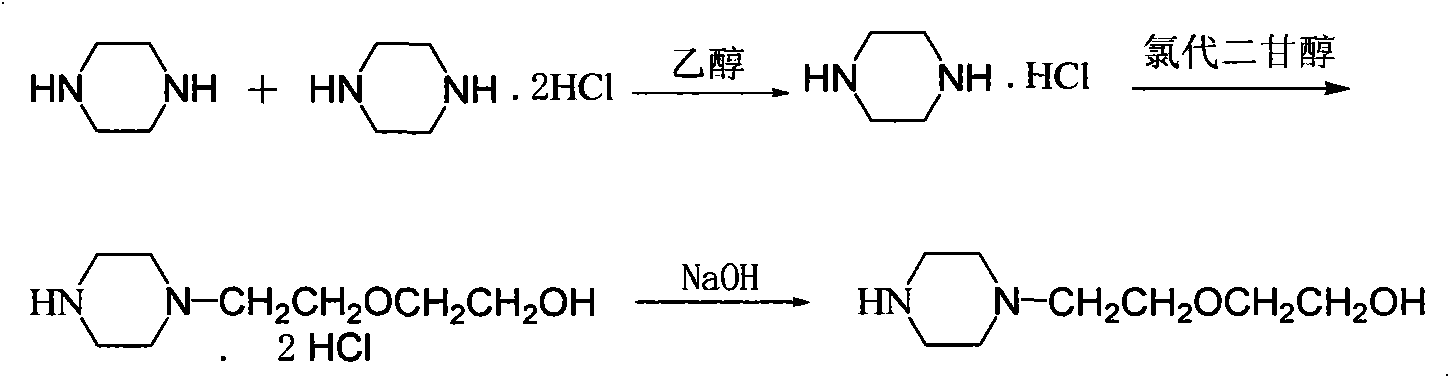

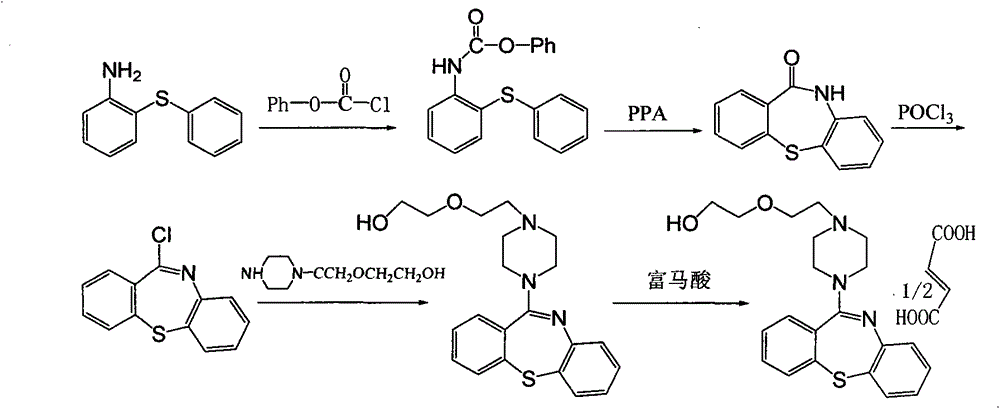

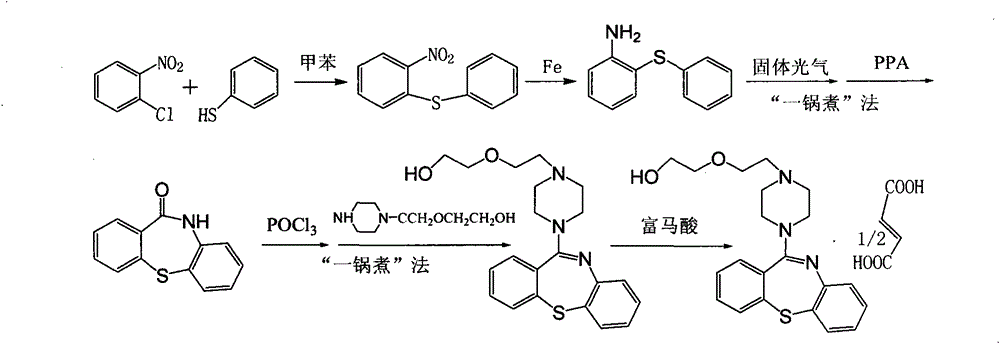

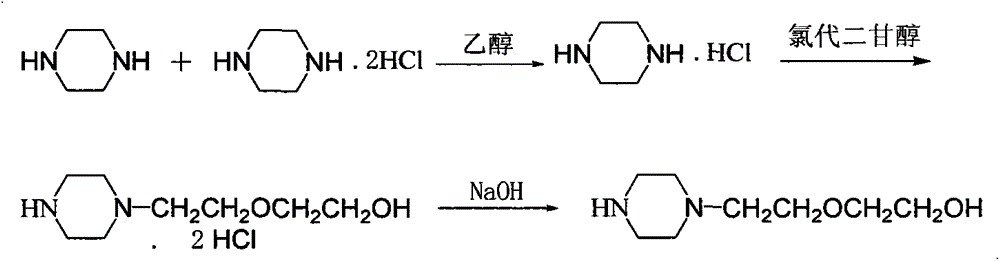

Preparation method of quetiapine hemifumarate

InactiveCN104016945AReduced separation lossEasy to operateOrganic chemistryO-nitrochlorobenzeneQuetiapine hemifumarate

The invention discloses a preparation method of quetiapine hemifumarate. The preparation method of quetiapine hemifumarate comprises the following steps: etherifying, hydrogenating, condensing and carrying out chlorination by taking o-chloronitrobenzene and thiophenol as raw materials, and finally salifying with fumaric acid, thereby obtaining quetiapine hemifumarate. The production technology is simple to operate and convenient for large-scale production, the cost is saved and the high-purity high-yield quetiapine hemifumarate can be obtained.

Owner:渭南畅通药化科技有限公司

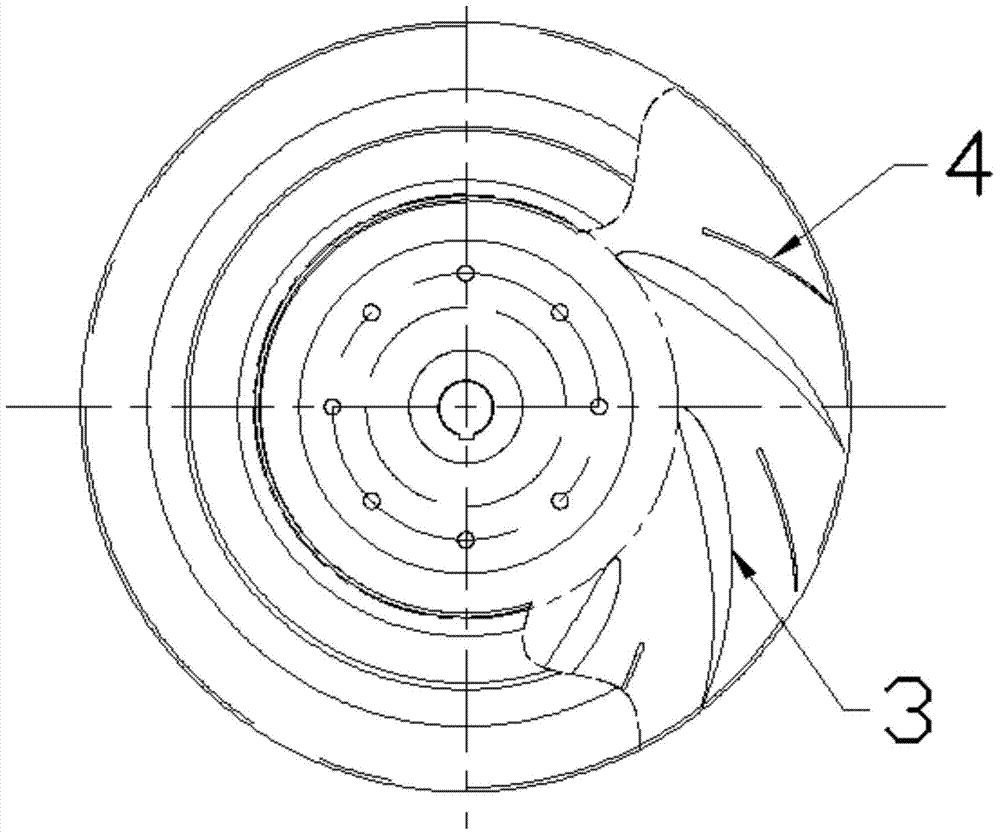

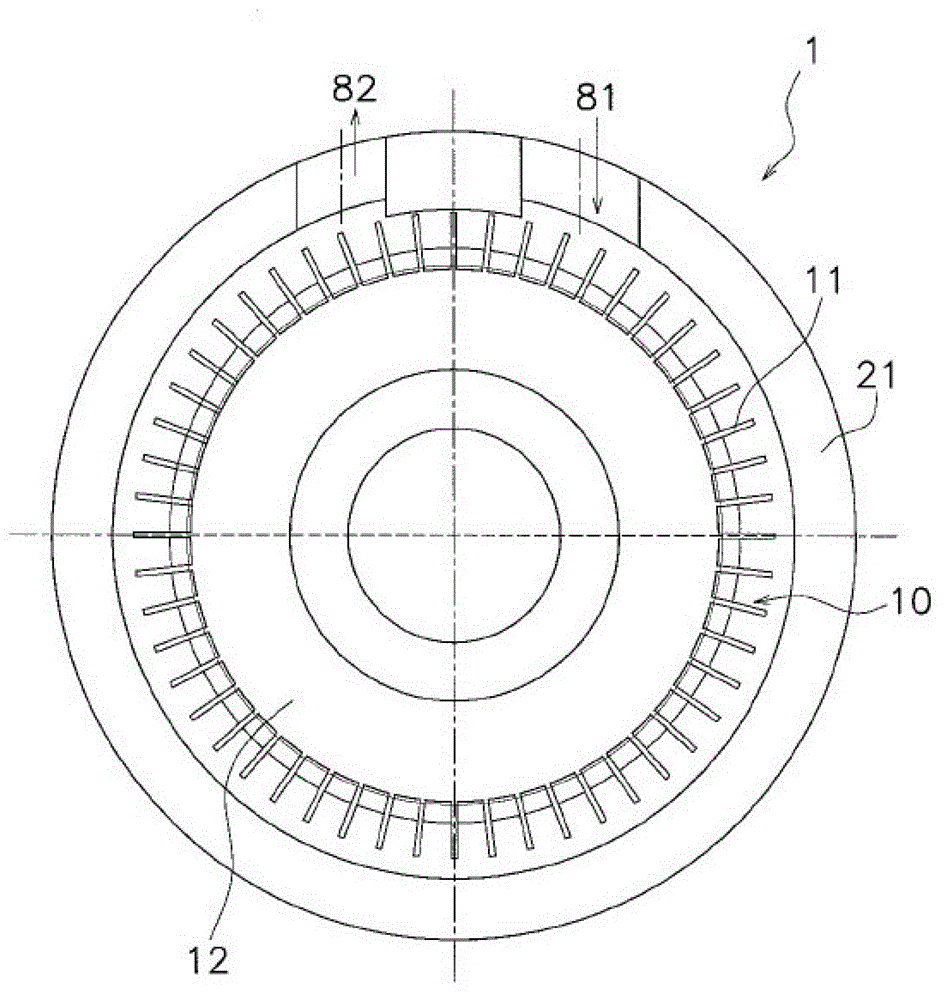

Multi-wing centrifugal fan blade, vane wheel and multi-wing centrifugal fan

ActiveCN109973427AReduce inlet impact loss and blade trailing edge separation lossGood aerodynamic performancePump componentsPumpsCentrifugal fanPulp and paper industry

The application discloses a multi-wing centrifugal fan blade, a vane wheel and a multi-wing centrifugal fan. The multi-wing centrifugal fan blade comprises a wing-shaped blade part and an arc-shaped blade part, wherein the tail end of the wing-shaped blade part is connected with the head end of the arc-shaped blade part. According to the multi-wing centrifugal fan blade disclosed by the application, the multi-wing centrifugal fan blade comprises the wing-shaped blade part and the arc-shaped blade part, the angle of an exit and entrance of the blade can be freely regulated through regulating the arc-shaped blade part, and the wing-shaped blade part adopts an optimal bending angle design, so that the bending angle of the blade cannot be too large; and through the wing-shaped blade part, theinlet impact loss of the arc-shaped blade part and the separation loss of a tail edge of the blade can be reduced, so that the inlet impact loss of the whole blade and the separation loss of the tailedge of the blade are reduced, the blade meets the optimal pneumatic performance, and the problem that in the prior art, the blade which is small in bending angle, low in inlet impact loss and low inseparation loss of the tail edge of the blade is not generated is solved.

Owner:FANS TECH ELECTRIC CO LTD

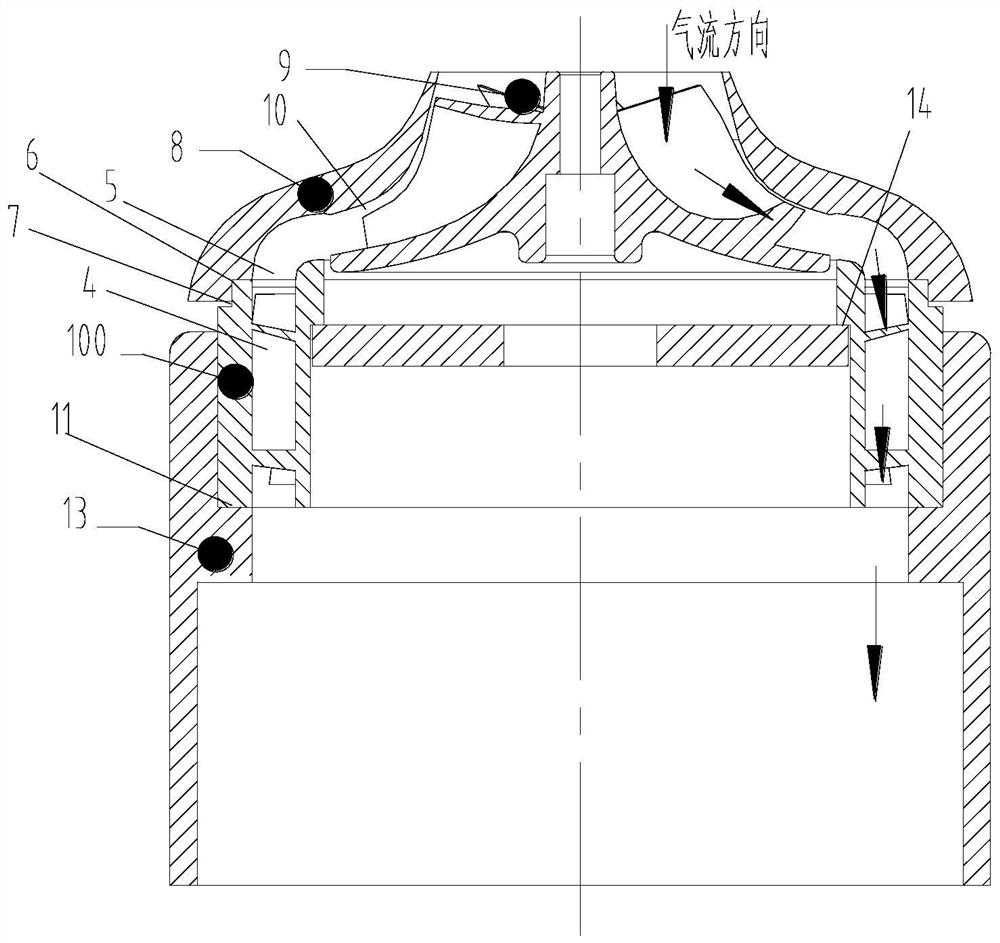

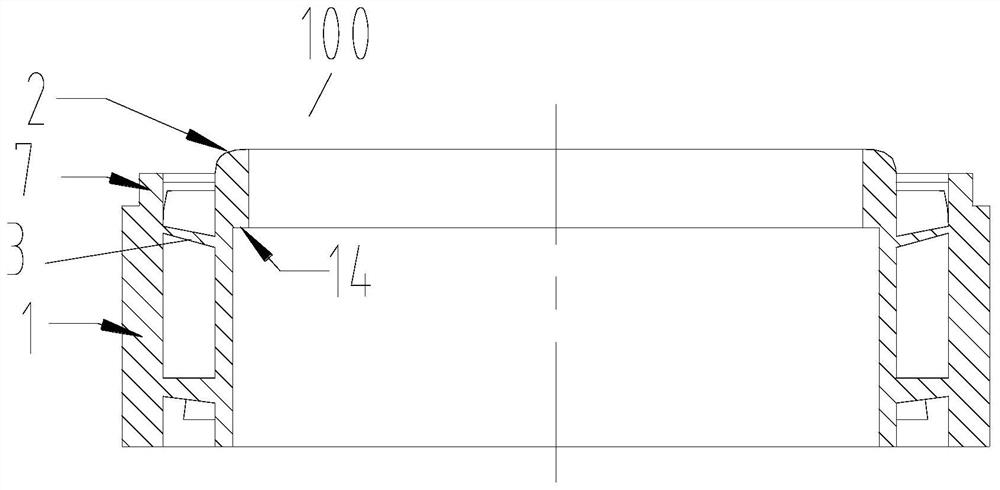

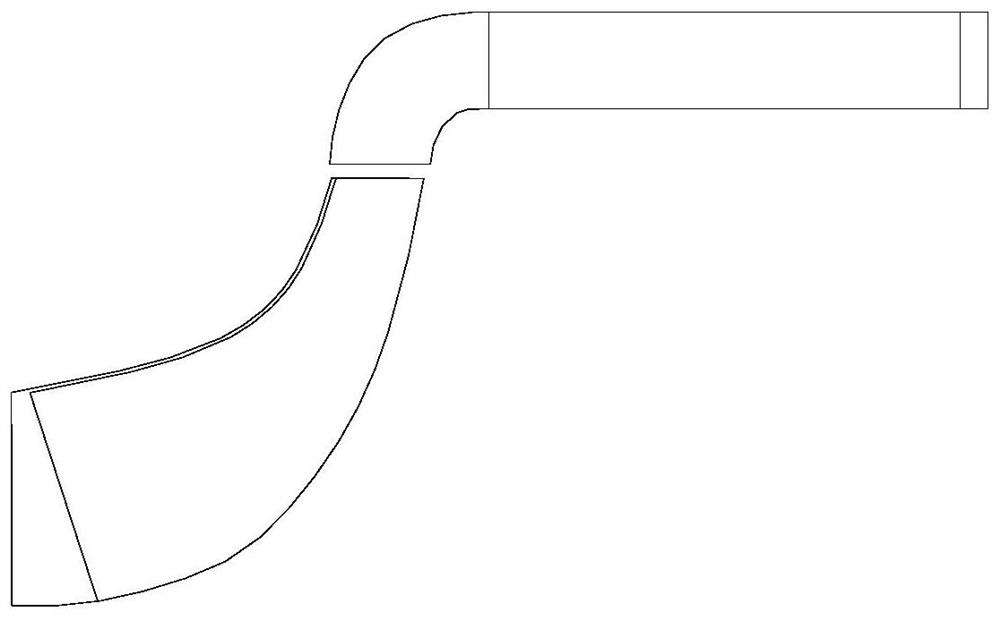

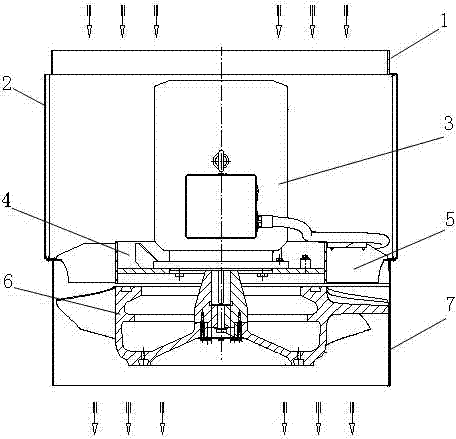

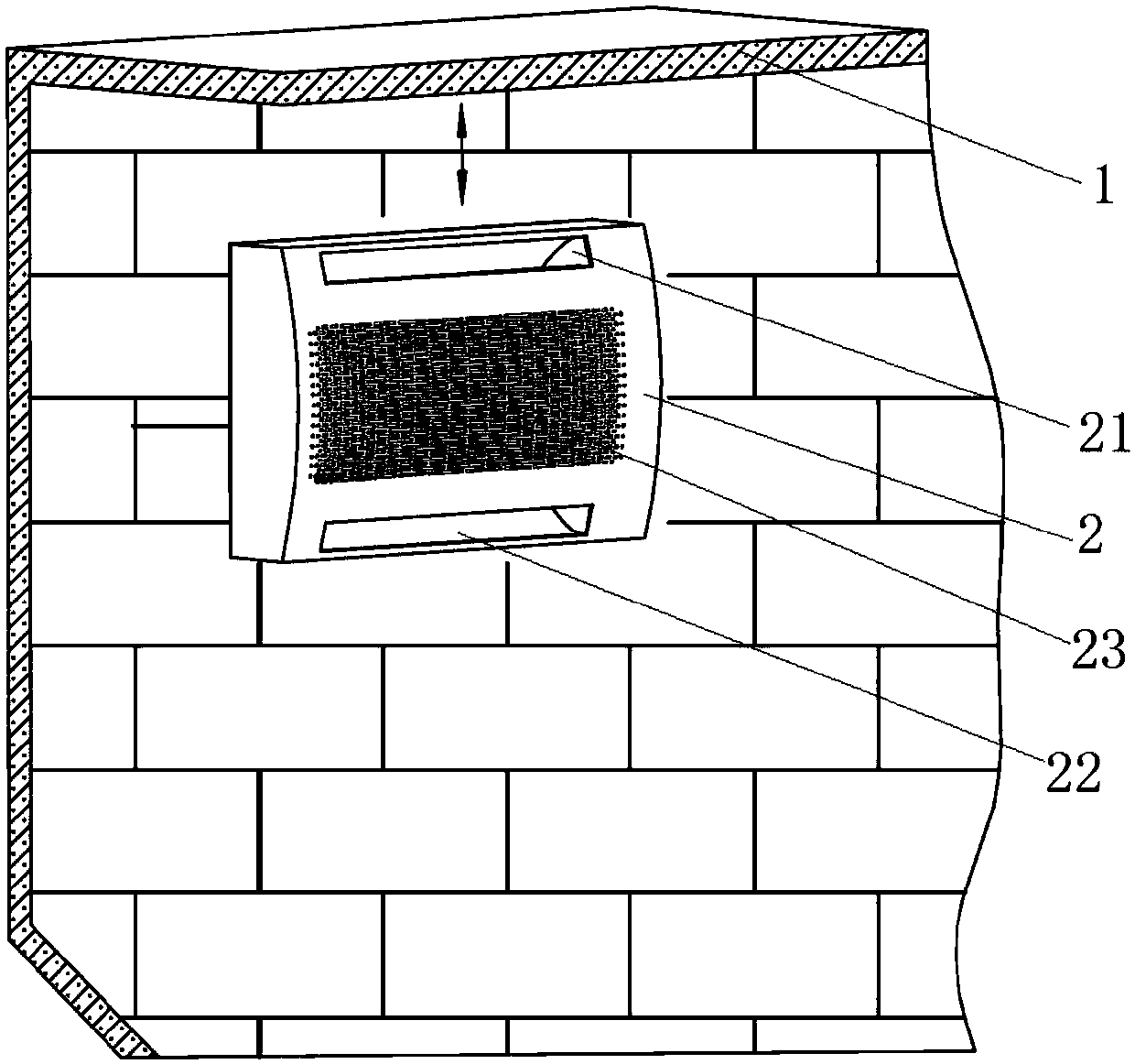

Air supply device, air conditioner and air supply method for air conditioner

ActiveCN105605678BAvoid unusual noise situationsReduced barrier to separationDucting arrangementsHeating and refrigeration combinationsStopped workEngineering

The invention relates to an air supply apparatus, air conditioning equipment and an air supply method of the air conditioning equipment, and relates to the technical field of an air conditioner. The invention mainly adopts the technical scheme that the air supply apparatus comprises at least two air duct assemblies, wherein each air duct assembly comprises an air duct, a fan and a guidance and control apparatus. One end of each air duct is arranged as an air inlet, and the other end of the air duct is arranged as an air outlet; the fans are arranged at the positions, which are close to the air inlets, in the air ducts; the guidance and control apparatuses are arranged at the positions of the air inlets of the air ducts. When the air duct assemblies work, the guidance and control apparatuses enable air flow subjected to heat exchange by a heat exchanger to be led into the air ducts from the air inlets. When the air duct assemblies stop working, the guidance and control apparatuses seal the air inlets of the air ducts. The air conditioning equipment comprises the air supply apparatus. The air supply method of the air conditioning equipment is characterized by adopting the air conditioning equipment to deliver the air flow subjected to heat exchange by the heat exchanger into a room. The air supply apparatus, the air conditioning equipment and the air supply method of the air conditioning equipment, which are disclosed by the invention, are mainly used for avoiding the condition that the air flow in an inner cavity of the air conditioning equipment disturbs fan blades of fans in a work stop state to cause generation of abnormal noise.

Owner:GREE ELECTRIC APPLIANCES INC

A kind of preparation method of quetiapine hemifumarate

InactiveCN104016945BReduced separation lossEasy to operateOrganic chemistryO-nitrochlorobenzeneQuetiapine hemifumarate

The invention discloses a preparation method of quetiapine hemifumarate. The preparation method of quetiapine hemifumarate comprises the following steps: etherifying, hydrogenating, condensing and carrying out chlorination by taking o-chloronitrobenzene and thiophenol as raw materials, and finally salifying with fumaric acid, thereby obtaining quetiapine hemifumarate. The production technology is simple to operate and convenient for large-scale production, the cost is saved and the high-purity high-yield quetiapine hemifumarate can be obtained.

Owner:渭南畅通药化科技有限公司

Method for efficiently separating cucurbit [n] uril

The invention is applicable to the field of host-guest chemistry in supramolecular chemistry, and provides a method for efficiently separating cucurbit [n] uril. The method comprises the following steps: dissolving a cucurbit [n] uril mixture in water, and carrying out separation and purification to obtain a cucurbit [5, 7] uril mixture with good water solubility and a cucurbit [6, 8] uril mixturewith poor water solubility; and efficiently separating and purifying the cucurbituril homolog by utilizing different solubility of different cucurbiturils in a mixed solvent of formic acid and acetone. The method has the characteristics of simple separation process, short separation time, high separation efficiency, less separation loss and pure separation product.

Owner:WUHAN UNIV OF SCI & TECH

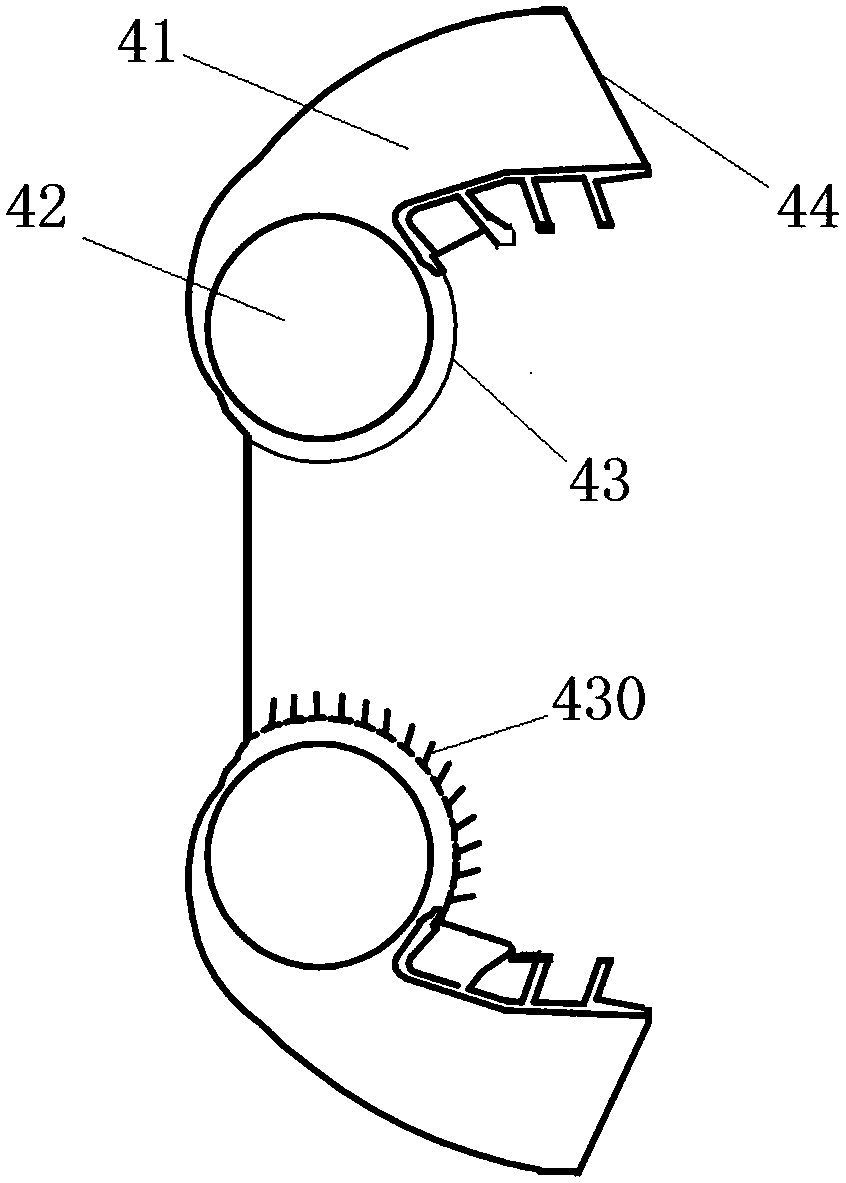

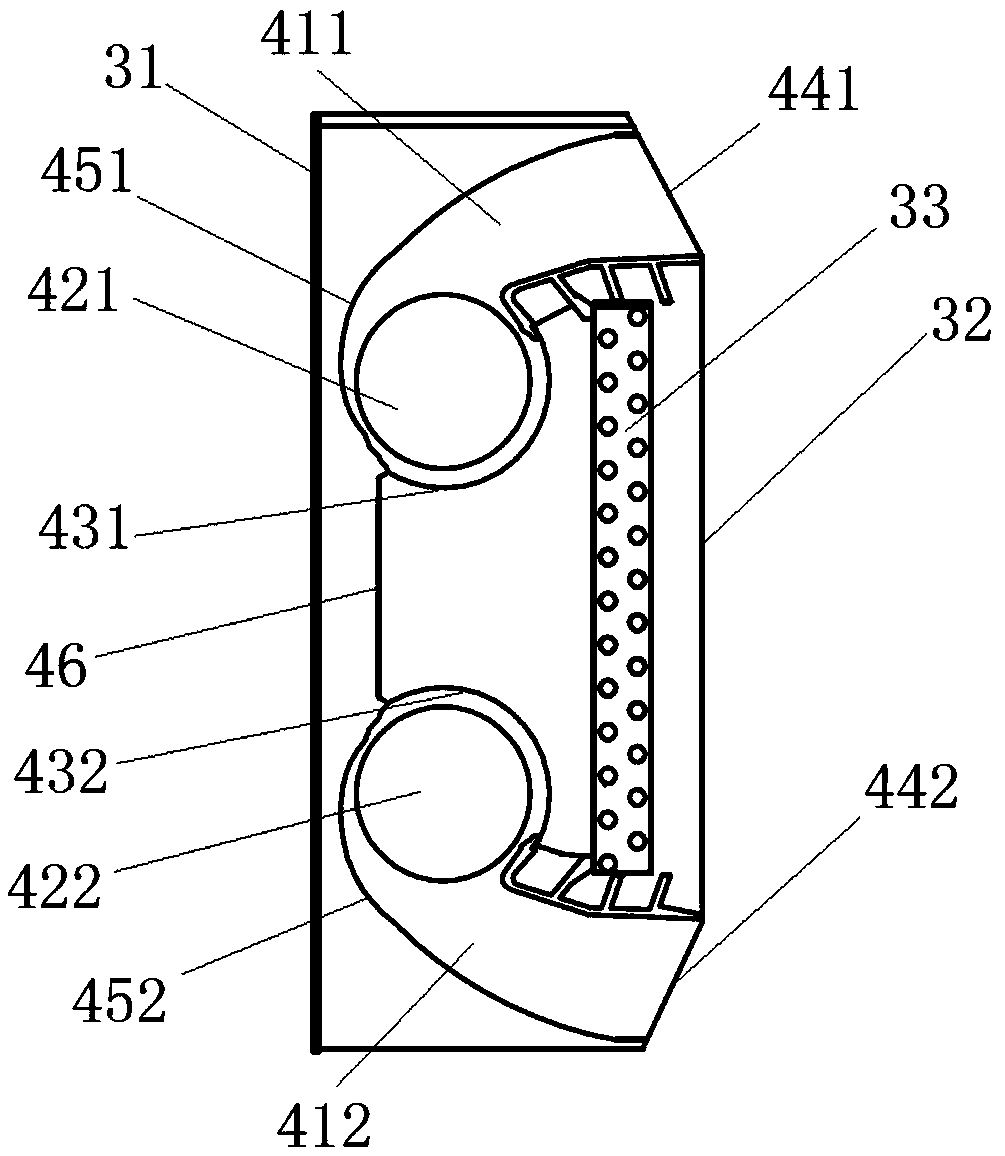

Pneumatic component comprising axial diffuser, dust collector and compressor

PendingCN114776631AReduced radial structure sizeReduce noisePump componentsPumpsElectric machineryImpeller

The invention provides a pneumatic component comprising an axial diffuser, a dust collector and a compressor, the pneumatic component comprises a wheel cover, an impeller and the axial diffuser, the impeller is located in the wheel cover, an airflow channel is formed between the impeller and the wheel cover, the axial diffuser is connected to one axial end of the impeller, and the axial diffuser is connected to the other axial end of the impeller. And the impeller is arranged in the axial diffuser and can enable airflow coming out of the airflow channel to enter the axial diffuser to be pressurized, the width of the airflow outlet end of the impeller is smaller than that of the airflow inlet end of the axial diffuser, a certain gap is formed between the airflow outlet end of the impeller and the airflow inlet section of the axial diffuser, and a vaneless diffusion section is formed. The structure of the diffuser can axially extend under the condition that the effective diffusion capacity is not reduced, the radial structure size of the motor is effectively reduced, and noise is reduced.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Novel axial-flow fan with small-aspect-ratio blades having obliquely-cut and twisted blade roots

ActiveCN103016369BGet cooling effectEasy to fixPump componentsPump installationsImpellerInlet channel

The invention belongs to the technical field of ventilators, and particularly relates to an axial-flow fan. A novel axial-flow fan with small-aspect-ratio blades having obliquely-cut and twisted blade roots comprises an air inlet chamber, a motor, a support ring, support plates, an impeller, an exhaust segment and the like, wherein the motor is arranged on the support ring in the center of the back part of the air inlet chamber, and is directly connected with the impeller through a shaft; the hub and blades of the impeller are designed integrally; the trailing edges of the blade roots of the blades are cut obliquely; an air inlet is formed in the air inlet end of the air inlet chamber and is connected with an air inlet channel at the front end; the exhaust segment is tightly connected with the air inlet chamber to construct a main through flow part; and the outlet segment of the exhaust segment is enlarged gradually. Due to the adoption of the novel axial-flow fan, the stability of axial air inflow of inlet air current and an inlet flow field is ensured; the fan is simple and compact in structure, and is convenient to manufacture; and under the conditions of limited size, low rotating, low flow and the like, the impeller has high boosting capability and high running efficiency.

Owner:DALIAN UNIV OF TECH

Drip-imitating tube-type demister and demister device

The invention provides a drip-imitating tube-type demister, which is characterized by comprising at least two layers of parallel rows of tubes, wherein the rows of tubes are formed by tubes which are uniformly arrayed, the two ends of the rows of tubes are respectively supported on a plate, and the direction of flue gas flow is vertical to the direction of the short axis of the inner tubes of therow of tubes. The invention also provides a demister device, which is characterized by comprising the drip-imitating tube-type demister, wherein the drip-imitating tube-type demister is arranged at aflue gas desulfurization tower or the upstream of a horizontal flue, the demister is arranged at the downstream of the flue gas desulfurization tower, or a vane demister is arranged at the downstreamof the horizontal flue. The invention has the advantages that the demister reduces partial flow resistance, the area for blocking mist drop can be enlarged, demisting effect is improved, and scale isnot easy to form.

Owner:RPT SHANGHAI ENVIRONMENTAL EQUIP

A centrifugal fan impeller with adjustable splitter blades

InactiveCN105332945BImprove performanceImprove operational efficiencyPump componentsPumpsImpellerEngineering

Owner:ZHEJIANG SCI-TECH UNIV

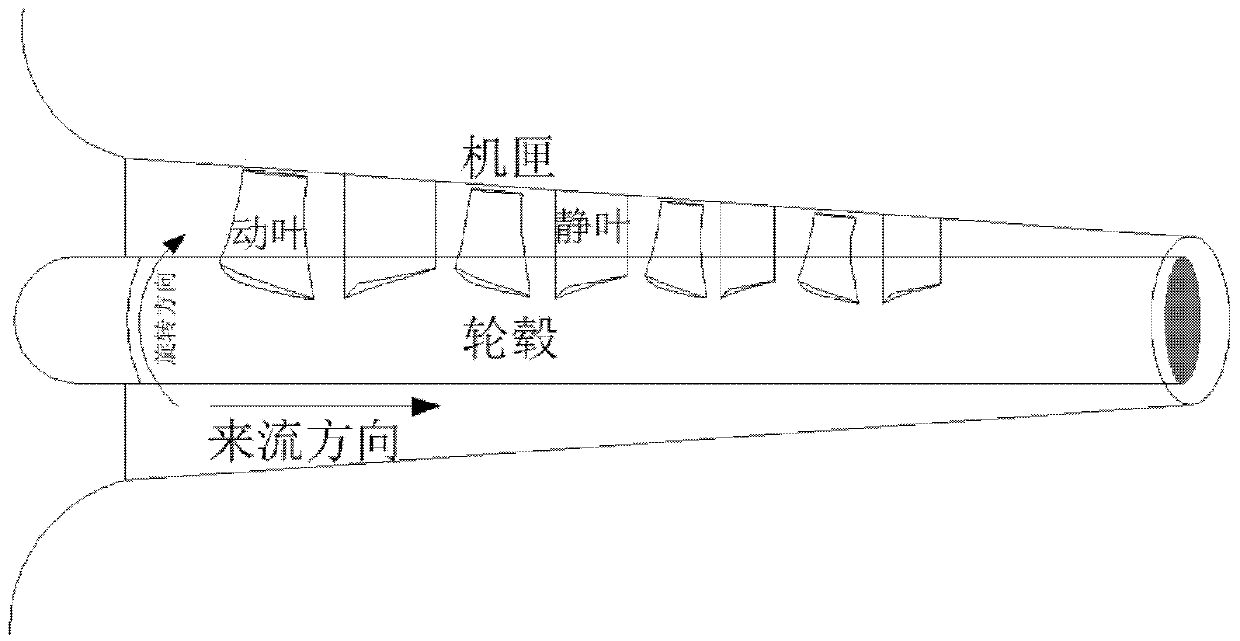

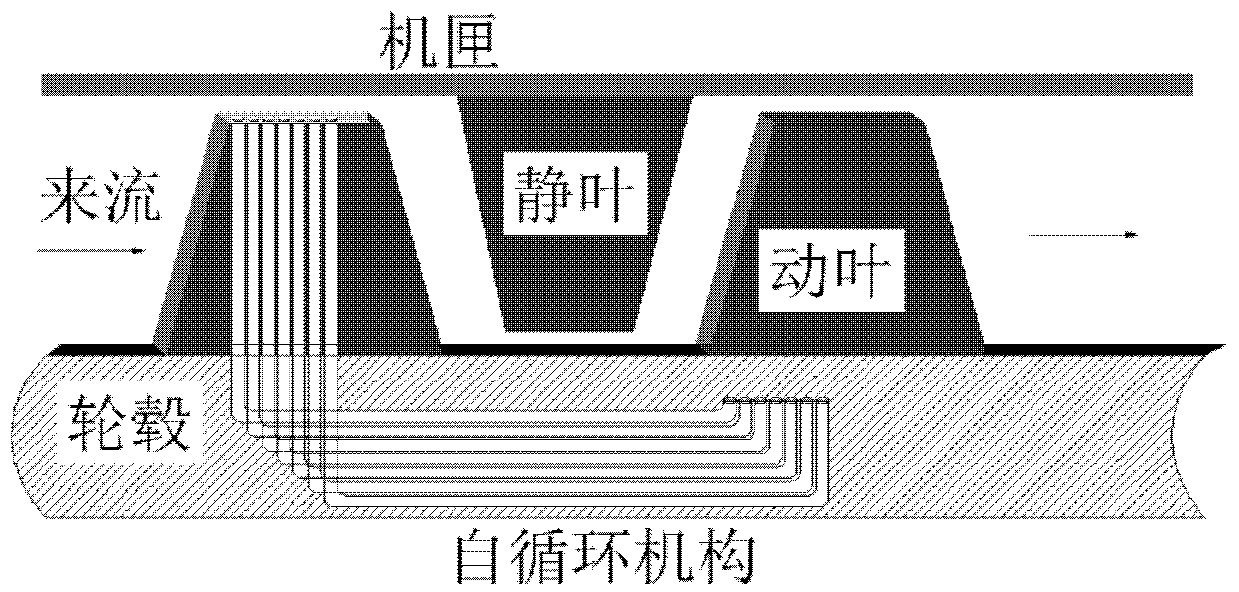

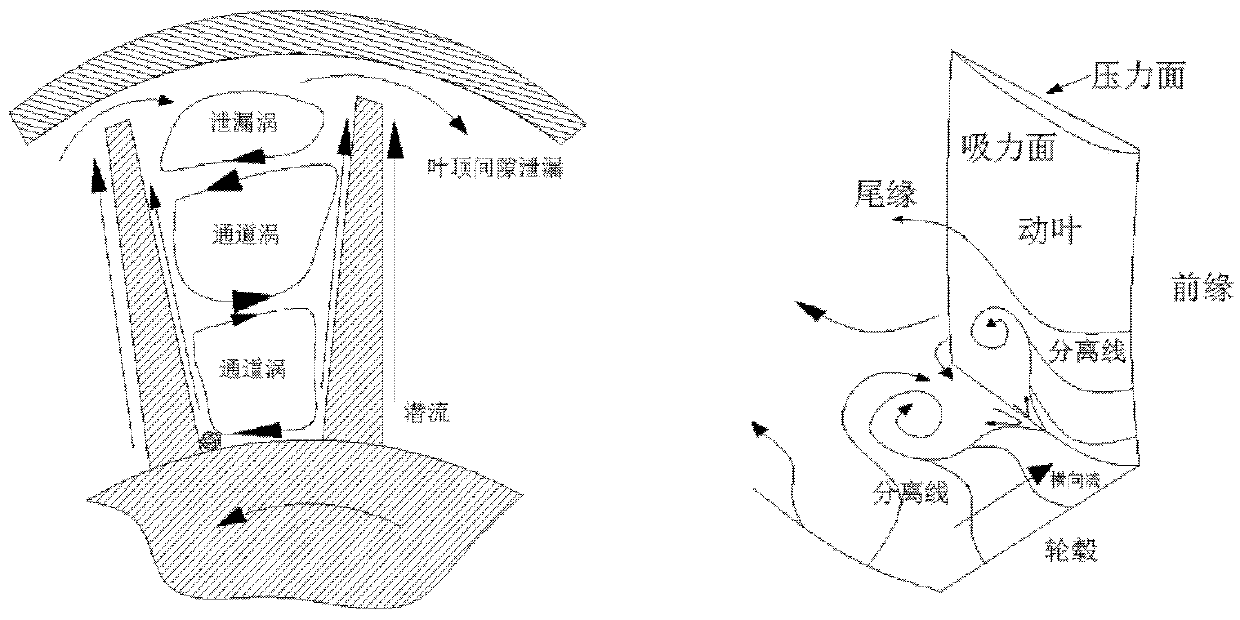

Self-circulating suction air injection device and method based on multi-stage axial flow compressor hub end wall

ActiveCN103994101BIncreased stability marginImprove efficiencyPump componentsGas turbine plantsAxial compressorEngineering

The invention discloses a hub end wall self-circulation suction jet device and method based on a multistage axial gas compressor. A self-circulation mechanism is arranged between a rear stage blade channel interior hub and a front stage movable blade top of the multistage axial gas compressor, the static pressure difference between the wall of the rear stage blade channel interior hub and the front stage movable blade top of the multistage axial gas compressor is utilized, and gas in the area of the rear stage blade channel interior hub is guided to the front stage movable blade top through the self-circulation mechanism for radial jetting accordingly. High-pressure eddy currents in the area of the rear stage blade channel interior hub of the multistage axial gas compressor can be fully utilized, radial jetting is carried out at the movable blade top, intensity of leakage currents in the area of the blade top is reduced, dual purposes of improving stall margin and efficiency are achieved, and the axial gas compressor can be operated under operating conditions with high-pressure ratios and wide stall margins.

Owner:青岛中科国晟动力科技有限公司

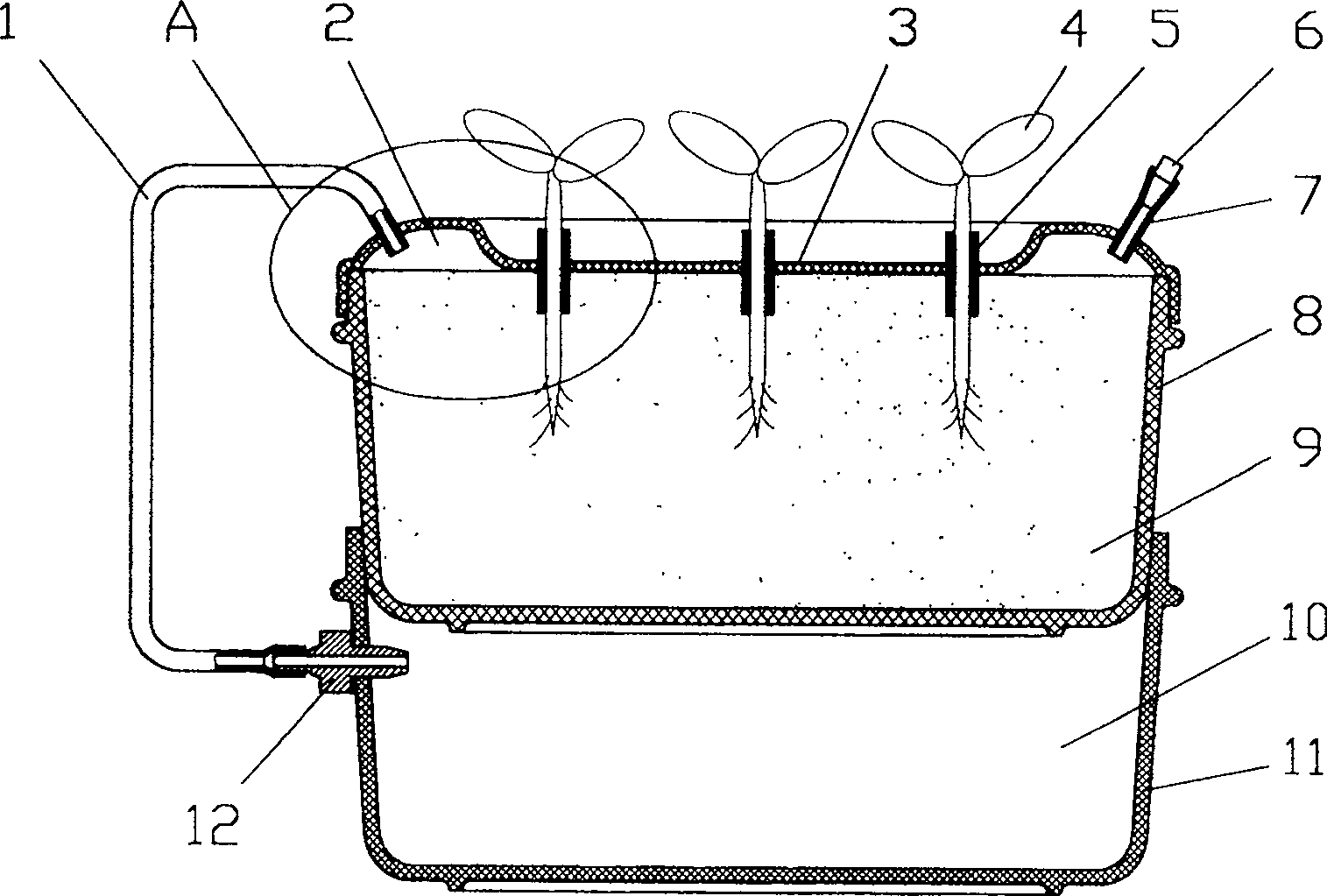

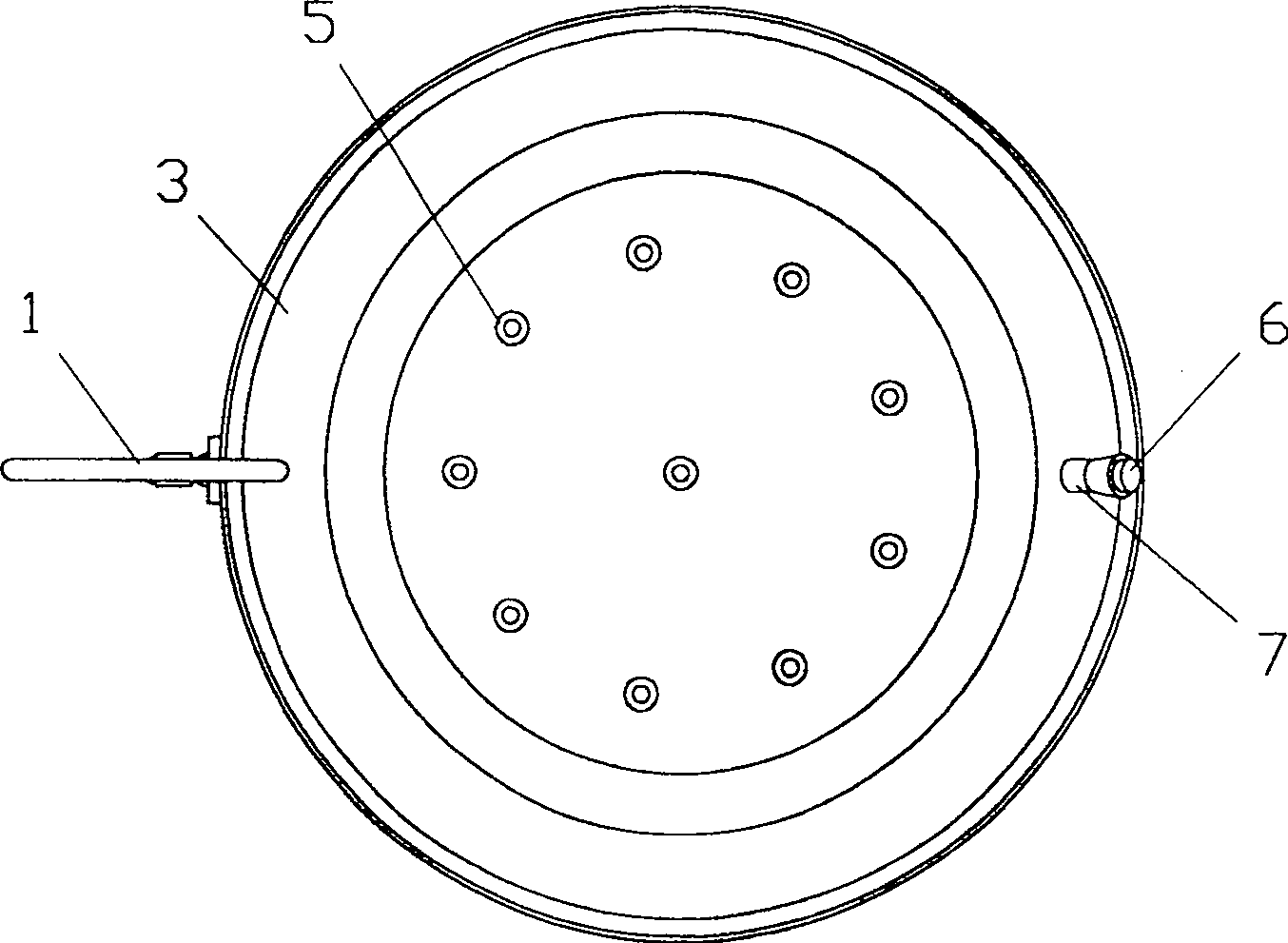

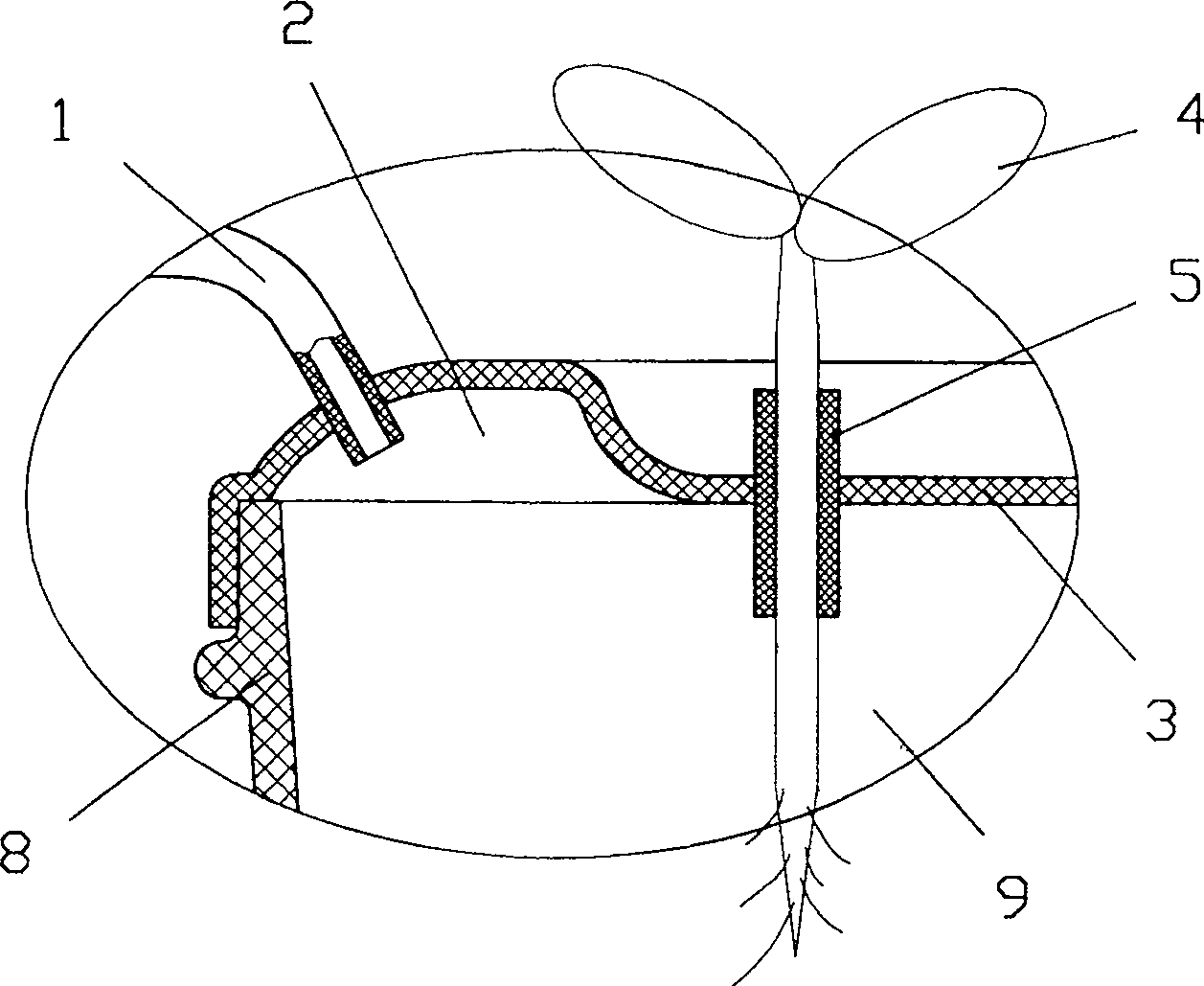

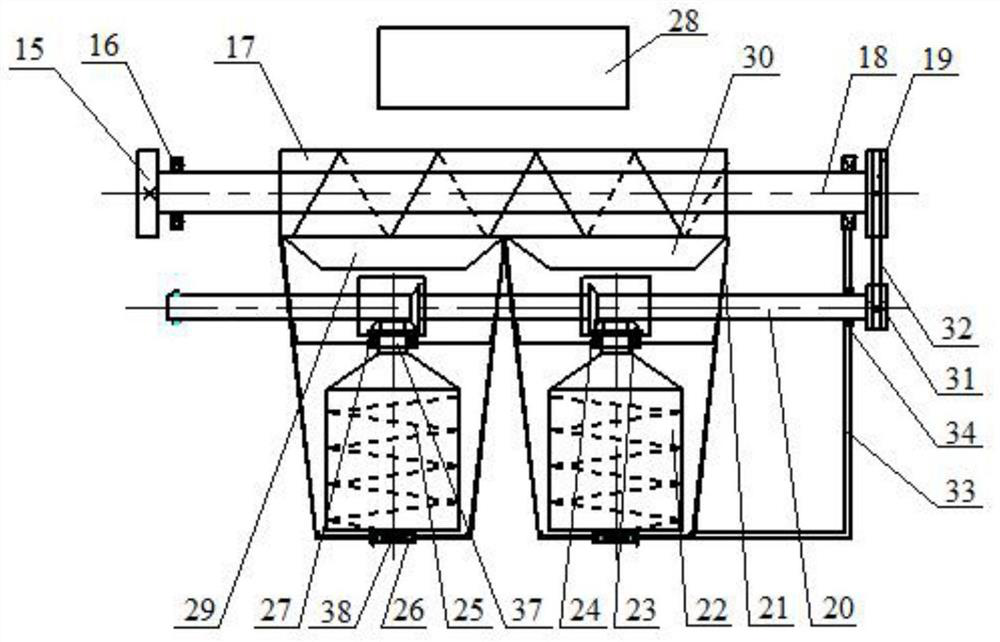

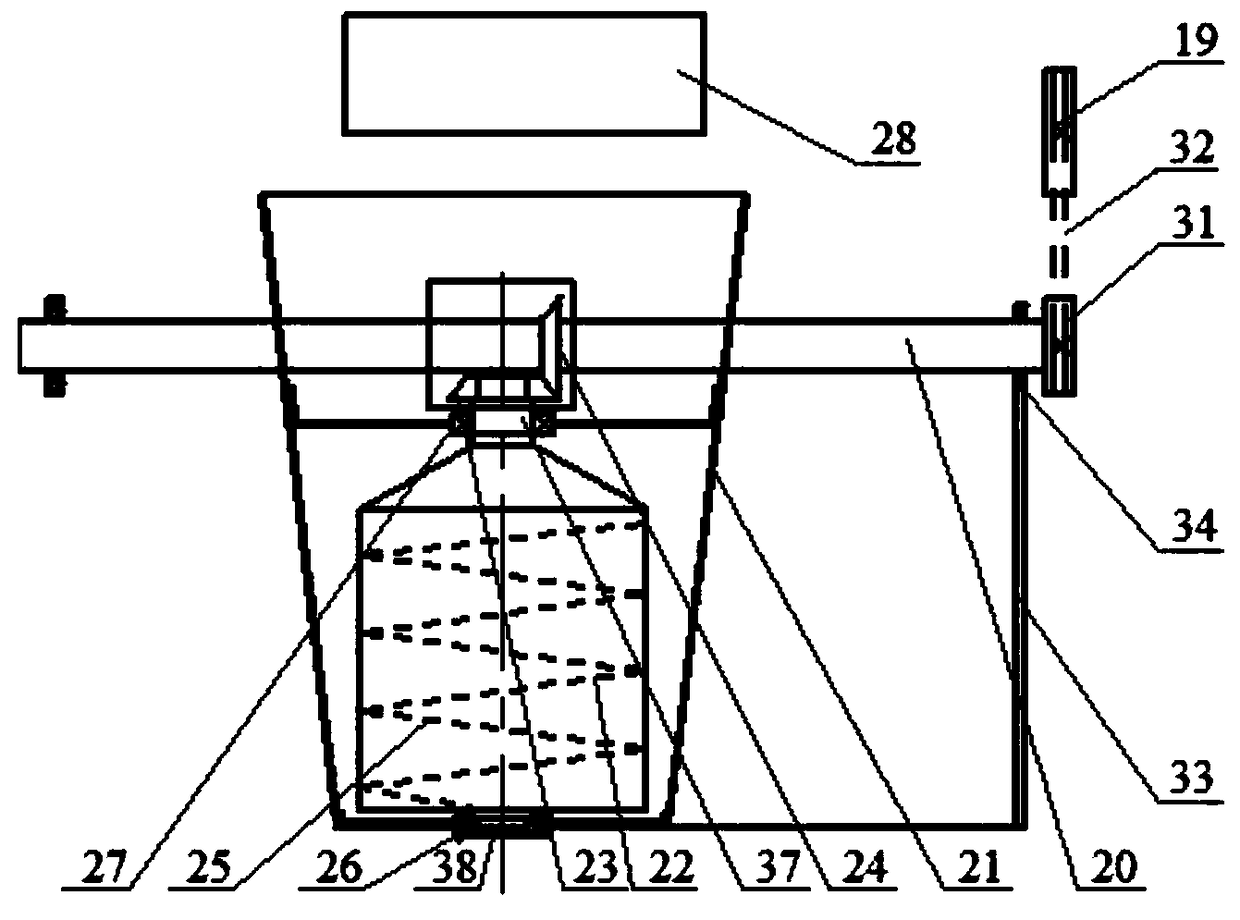

Method and device for determining plant transpiration efficiency precisely

InactiveCN100504346CInhibits moisture lossAdd Quantitatively AccurateWeighing by removing componentMicrobiological testing/measurementNutritionAgricultural engineering

The invention provides a method and device for accurately measuring the transpiration efficiency of plants. The basic principle is to use a sealed cover to suppress the surface evaporation of the cultivation container (box) (to make it approach "zero") moisture, and measure the weight change of the growing plant cultivation box Obtain transpiration water consumption, take plant samples to obtain dry matter accumulation, and then calculate plant transpiration efficiency. The measuring device used in the present invention comprises a closed incubator, a closed air pressure balance box and a connecting pipe arranged between the two boxes, and a seedling hole is arranged on the upper surface of the incubator. The main advantages of the present invention are: effectively suppressing the water loss caused by soil evaporation, solving the problem of root respiration and oxygen supply under sealed conditions and the problem of pressure change regulation under sealed conditions, the quantitative addition of nutrients and water is accurate, and the water consumption and biomass of transpiration are guaranteed accurate weighing. The measuring device has the advantages of low cost, good sealing performance, short measuring time, and less root separation loss, which is beneficial to batch testing.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

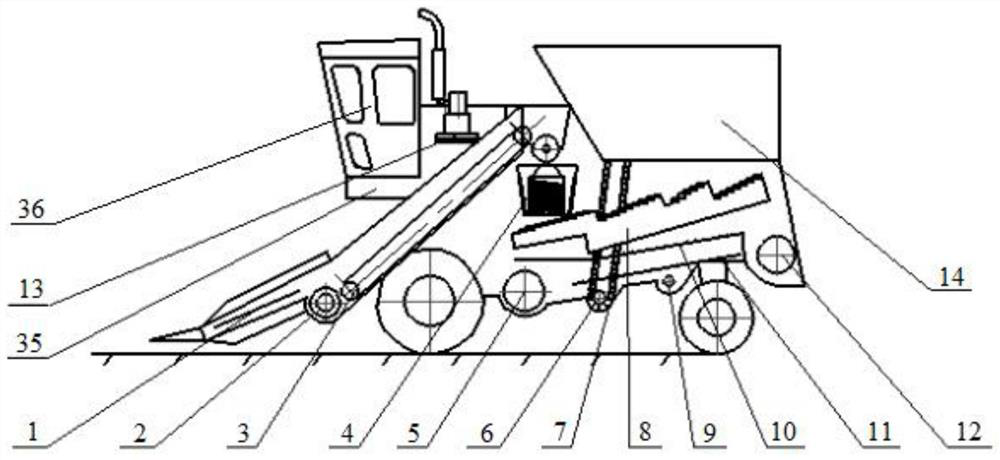

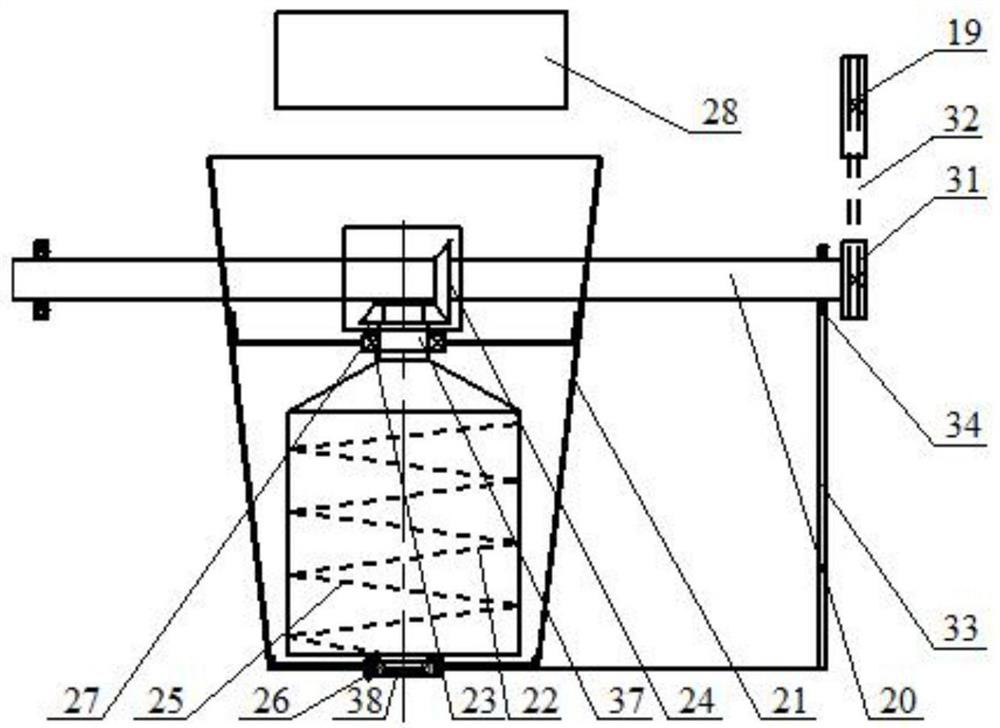

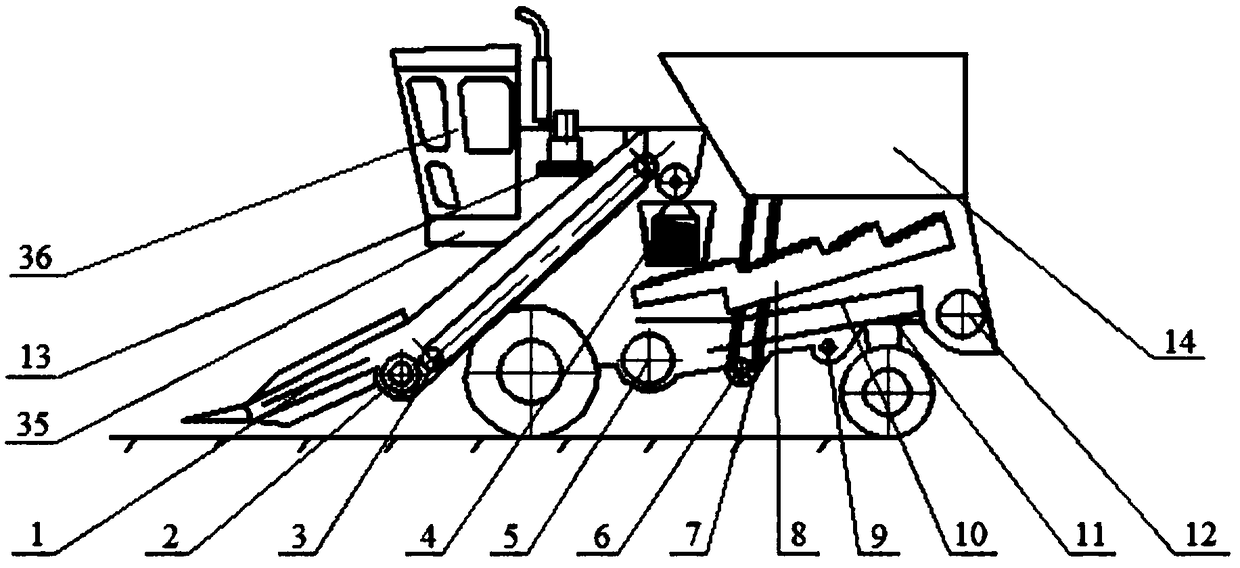

A vertical corn grain harvester

ActiveCN109005940BReduce breakageReduce power consumptionHarvestersThreshersDrive shaftAgricultural engineering

The invention discloses a vertical-type threshing device and a vertical-type threshing harvester employing the same. The threshing device comprises a small belt pulley, a drive shaft, a vertical-typethreshing roller outer cylinder, a vertical-type threshing roller inner cylinder, a driving bevel gear, a driven bevel gear, and an obtuse angle threshing element. The drive shaft is fixedly connectedto a frame, and the small belt pulley is fixedly connected to the right end of the drive shaft. The vertical-type threshing roller outer cylinder is installed at the central part of the drive shaft,and the driving bevel gear is disposed at the central part of the drive shaft. The vertical-type threshing roller outer cylinder is fixedly connected with the frame, and the vertical-type threshing roller inner cylinder is disposed in the vertical-type threshing roller outer cylinder. The driven bevel gear is disposed in the vertical-type threshing roller inner cylinder. The driving bevel gear isengaged with the driven bevel gear. The obtuse angle threshing element is fixed on the external surface of the vertical-type threshing roller inner cylinder. The threshing device enables the overall length to be effectively reduced, effectively improves the threshing performance, effectively improves the distribution uniformity of threshed objects on a sifter, remarkably reduces the harvesting loss, and improves the harvesting quality.

Owner:SHANDONG UNIV OF TECH

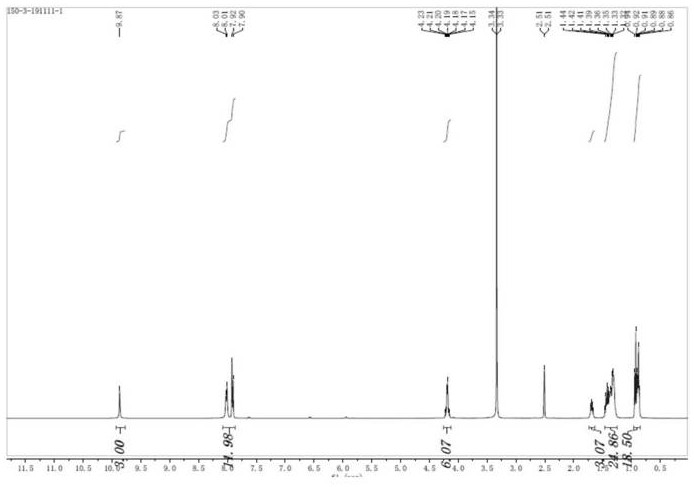

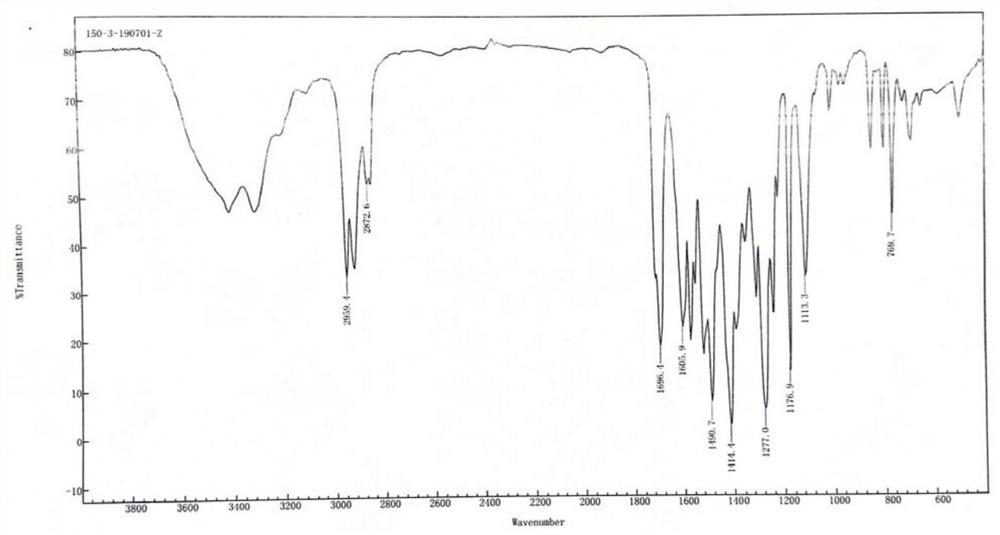

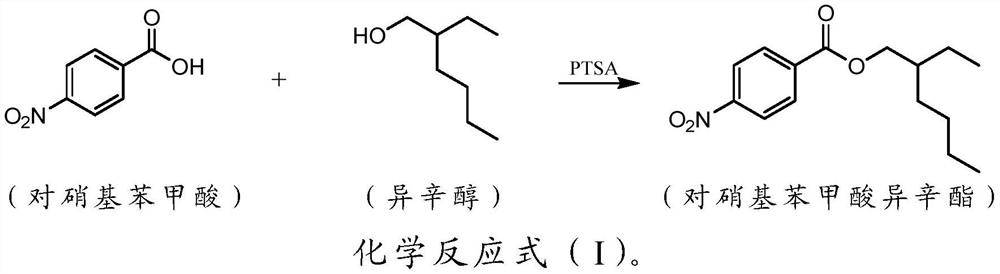

A kind of preparation method of sunscreen agent octyl triazone

ActiveCN112321522BReduce the difficulty of separation and recoveryReduce usageOrganic chemistryBenzoic acidOctyl triazone

The invention discloses a preparation method of sunscreen octyl triazone and the prepared octyl triazone and its application. The method comprises: step 1, carrying out esterification reaction between p-nitrobenzoic acid and isooctyl alcohol, Product I is obtained; step 2, product I undergoes hydrogenation reaction in the presence of a catalyst, after the reaction is completed, filter and distill under reduced pressure to obtain product II; step 3, add solvent to product II, and heat up to reflux, add solution A , to react, after post-treatment, to obtain octyl triazone. In the present invention, the sunscreen agent octyl triazone is efficiently prepared by using cheap and easily available p-nitrobenzoic acid as a raw material through esterification, hydrogenation, and coupling, and at the same time, isooctyl p-aminobenzoate is obtained, and the obtained octyl The triazone has high chromatographic purity and high yield, and has the advantages of less three wastes, low cost, environmental protection, simple operation, easy control, and easy realization of industrial production.

Owner:马鞍山科思化学有限公司

A multi-blade centrifugal fan blade, impeller and a multi-blade centrifugal fan

ActiveCN109973427BImprove aerodynamicsReduced separation lossPump componentsPumpsImpellerStructural engineering

The application discloses a multi-blade centrifugal fan blade, an impeller and a multi-blade centrifugal fan, wherein the multi-blade centrifugal fan blade includes: an airfoil blade part and an arc-shaped blade part; the tail end of the airfoil blade part and The head ends of the arc-shaped blade parts are connected. In this application, the multi-wing centrifugal fan blades are designed as airfoil blades and arc-shaped blades. By adjusting the arc-shaped blades, the blade inlet and outlet angles can be adjusted freely. The bending angle of the blade will not be too large, and the airfoil blade part can reduce the inlet impact loss and blade trailing edge separation loss of the arc-shaped blade part, thereby reducing the inlet impact loss and blade trailing edge separation loss of the entire blade, The blade satisfies the optimal aerodynamic performance, and solves the technical problems of existing blades with no small bending angle, small inlet impact loss and small separation loss of the blade trailing edge.

Owner:FANS TECH ELECTRIC CO LTD

Method for preparing sulfur ether intermediates of proton pump inhibitor

ActiveCN102702173BReasonable designPrevent oxidative deteriorationOrganic chemistryNitrobenzeneAbdomen diseases

The invention relates to a method for preparing a proton pump inhibitor sulfide intermediate of a drug for treating stomach diseases. The o-nitroaniline compound undergoes a continuous reduction-cyclization-condensation three-step process using water and lower alcohols as solvents under alkaline conditions. A series of proton pump inhibitor thioether intermediates (I) can be prepared with high efficiency through a one-pot reaction procedure, wherein X and Y are nitrogen atoms or carbon atoms, and R1 is selected from hydrogen, methoxy, pyrrol-1-yl and One of difluoromethoxy; R2, R3 and R4 are respectively selected from hydrogen, methyl, methoxy, 3-methoxy n-propoxy, 2,2,2-trifluoroethoxy and methyl One of the base sec-butylamine groups. The invention has the advantages of adopting a one-pot cooking synthesis process, reasonable process route design, simple and convenient operation, environment-friendly, avoiding separation loss in the synthesis process, and high yield of the target product. The general structural formula of (I) is:.

Owner:WUTONG AROMA CHEM CO LTD

Reflux condenser pipe special for microwave chemistry

InactiveCN101780423BIncreased separation lossReduced separation lossSteam/vapor condensersLaboratory glasswaresRefluxOrganic solvent

The invention discloses a reflux condenser pipe special for microwave chemistry, which mainly comprises an external layer water sleeve (3), a standard ground (4), a barrel-shaped pipe (5), baffle stabs (6), an inner core pipe (7), a coil pipe (8), a water distribution head (10) and a serial ball pipe (11). The reflux condenser pipe special for the microwave chemistry is characterized in that: thestandard ground (4) at the upper end of the external layer water sleeve (3) is welded with the barrel-shaped pipe (5) together; the baffle stabs (6) are uniformly distributed at the periphery of the inner wall of the barrel-shaped pipe (5); the lower end of the barrel-shaped pipe (5) is welded with the upper end of the serial ball pipe (11); the lower end of the inner core pipe (7) is connected with the water distribution head (10); and the coil pipe (8) is coiled outside the inner core pipe (7), and the lower end of the coil pipe (8) is connected with the water distribution head (10). Therefore, blasting explosion and high consumption of an organic solvent can be effectively prevented.

Owner:王锦化

Turbine capable of achieving direct backing and with primary-secondary moving blade structure

ActiveCN113513368AGuaranteed structural strengthReduced flow separationHybrid vehiclesBlade accessoriesTurbine bladeClassical mechanics

The invention aims to provide a turbine capable of achieving direct backing and with a primary-secondary moving blade structure. The turbine comprises a hub, a backing turbine primary blade and a backing turbine secondary blade, the backing turbine primary blade and the backing turbine secondary blade are uniformly mounted between a casing and the hub in a staggered manner in the circumferential direction, the hub is an ahead turbine last-stage moving blade tip connecting ring, and the trailing edge point of the backing turbine secondary blade and the trailing edge point of the backing turbine primary blade are located at the same axial position; and the distance b2 between the leading edge point and the leading edge frontal line of the backing turbine primary blade is changed by the backing turbine secondary blade according to the flowing working condition, and b2 does not exceed 65% of the axial chord length b1 of the backing turbine primary blade. The primary blade and the secondary blade are arranged in an axial flow turbine moving blade cascade in a staggered manner, the binding capacity of the backing turbine blade cascade on airflow is improved, large-scale separation is reduced, the turbine power and efficiency are improved, and good working reliability is achieved.

Owner:HARBIN ENG UNIV

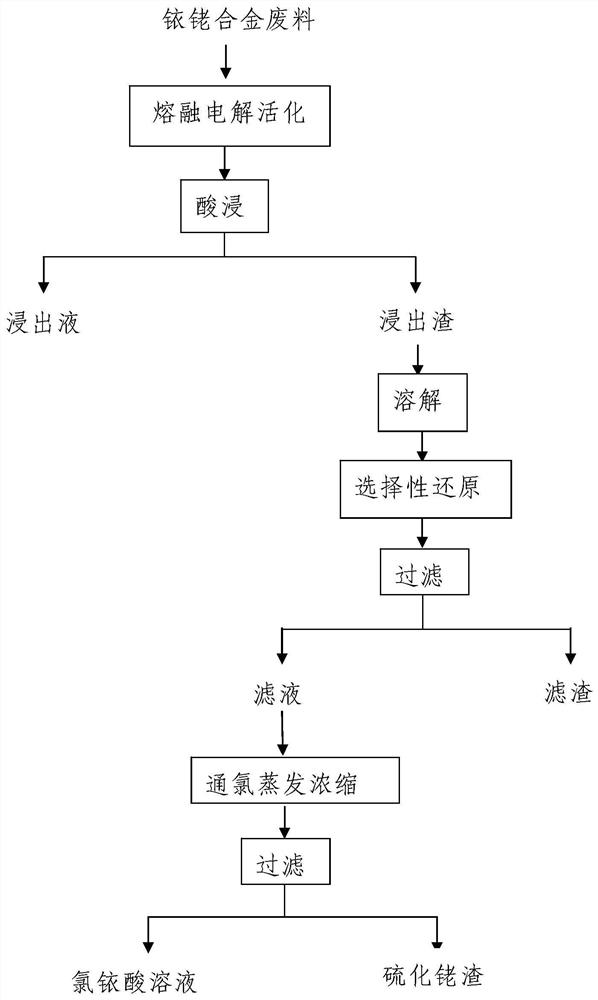

A kind of method that reclaims iridium, rhodium from iridium-rhodium alloy scrap

ActiveCN108505069BImprove the activation effectImprove conversion rateProcess efficiency improvementIridiumElectrolysis

The invention discloses a method for recovering iridium and rhodium from iridium-rhodium alloy waste. The method comprises: 1. mixing the iridium-rhodium alloy waste with alumina and then carrying out melting electrolysis to obtain highly active iridium-rhodium alloy waste; 2. Adding hydrochloric acid solution to the high-activity iridium-rhodium alloy waste material for leaching, then filtering and collecting the filter residue and washing; step 3, adding hydrochloric acid to the filter residue and introducing chlorine gas for dissolution, and then introducing hydrogen sulfide gas for reduction reaction to obtain slurry; Step 4, feed chlorine gas into the filtrate obtained after filtering the slurry, and carry out evaporation and concentration, and obtain chloroiridic acid solution and rhodium sulfide slag through filtration. The invention adopts molten electrolysis method to activate the iridium-rhodium alloy waste material doped with alumina, and the melted solution of alumina melt penetrates and corrodes the iridium-rhodium alloy, thereby improving the activation performance of the iridium-rhodium alloy, thereby improving the solution conversion rate of iridium-rhodium, The recovery rate of iridium and rhodium in the subsequent treatment is further improved, and there is no need to use expensive intermediate frequency furnace equipment in the activation process.

Owner:XIAN RAREALLOYS

Vertical-type threshing device and vertical-type threshing harvester

The invention discloses a vertical-type threshing device and a vertical-type threshing harvester employing the same. The threshing device comprises a small belt pulley, a drive shaft, a vertical-typethreshing roller outer cylinder, a vertical-type threshing roller inner cylinder, a driving bevel gear, a driven bevel gear, and an obtuse angle threshing element. The drive shaft is fixedly connectedto a frame, and the small belt pulley is fixedly connected to the right end of the drive shaft. The vertical-type threshing roller outer cylinder is installed at the central part of the drive shaft,and the driving bevel gear is disposed at the central part of the drive shaft. The vertical-type threshing roller outer cylinder is fixedly connected with the frame, and the vertical-type threshing roller inner cylinder is disposed in the vertical-type threshing roller outer cylinder. The driven bevel gear is disposed in the vertical-type threshing roller inner cylinder. The driving bevel gear isengaged with the driven bevel gear. The obtuse angle threshing element is fixed on the external surface of the vertical-type threshing roller inner cylinder. The threshing device enables the overall length to be effectively reduced, effectively improves the threshing performance, effectively improves the distribution uniformity of threshed objects on a sifter, remarkably reduces the harvesting loss, and improves the harvesting quality.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for efficiently separating cucurbit [n] uril Method for efficiently separating cucurbit [n] uril](https://images-eureka.patsnap.com/patent_img/1ca06637-867d-414c-9116-5fc4bbf69931/HDA0002513068980000011.png)

![Method for efficiently separating cucurbit [n] uril Method for efficiently separating cucurbit [n] uril](https://images-eureka.patsnap.com/patent_img/1ca06637-867d-414c-9116-5fc4bbf69931/HDA0002513068980000012.png)

![Method for efficiently separating cucurbit [n] uril Method for efficiently separating cucurbit [n] uril](https://images-eureka.patsnap.com/patent_img/1ca06637-867d-414c-9116-5fc4bbf69931/BDA0002513068970000011.png)