Multi-wing centrifugal fan blade, vane wheel and multi-wing centrifugal fan

A centrifugal fan and airfoil blade technology, which is applied in the directions of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of small inlet impact loss, small separation loss of blade trailing edge, no small bending angle, etc., and achieve excellent aerodynamics. performance, the effect of reducing inlet impact loss and blade trailing edge separation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0034] The above is the first embodiment of a multi-blade centrifugal fan blade provided by the embodiment of the present application, and the following is the second embodiment of a multi-blade centrifugal fan blade provided by the embodiment of the present application.

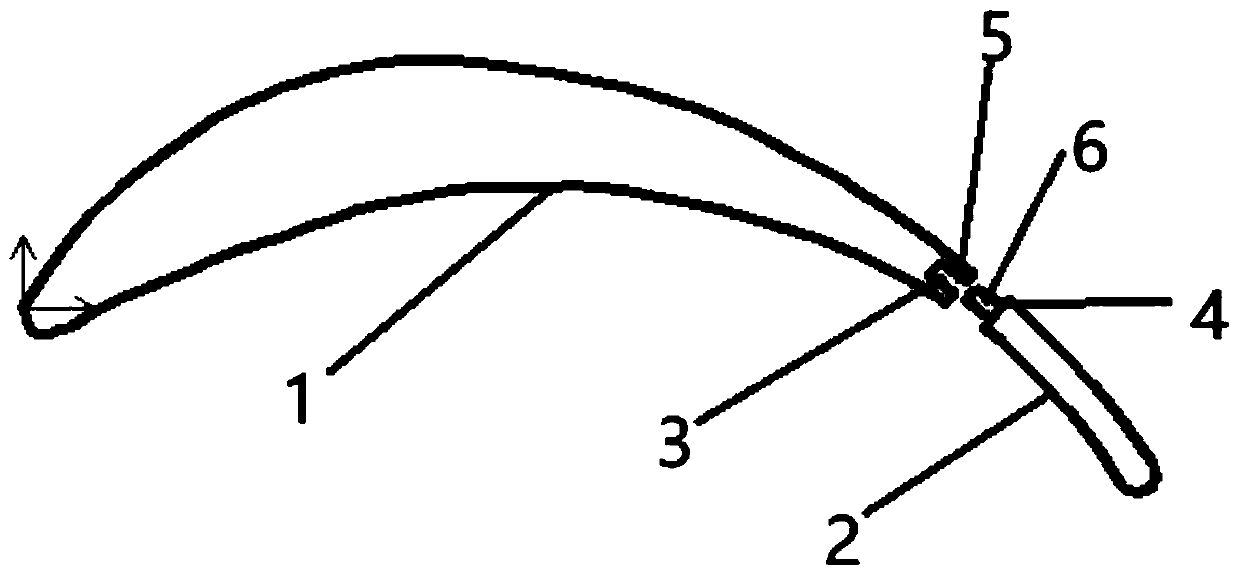

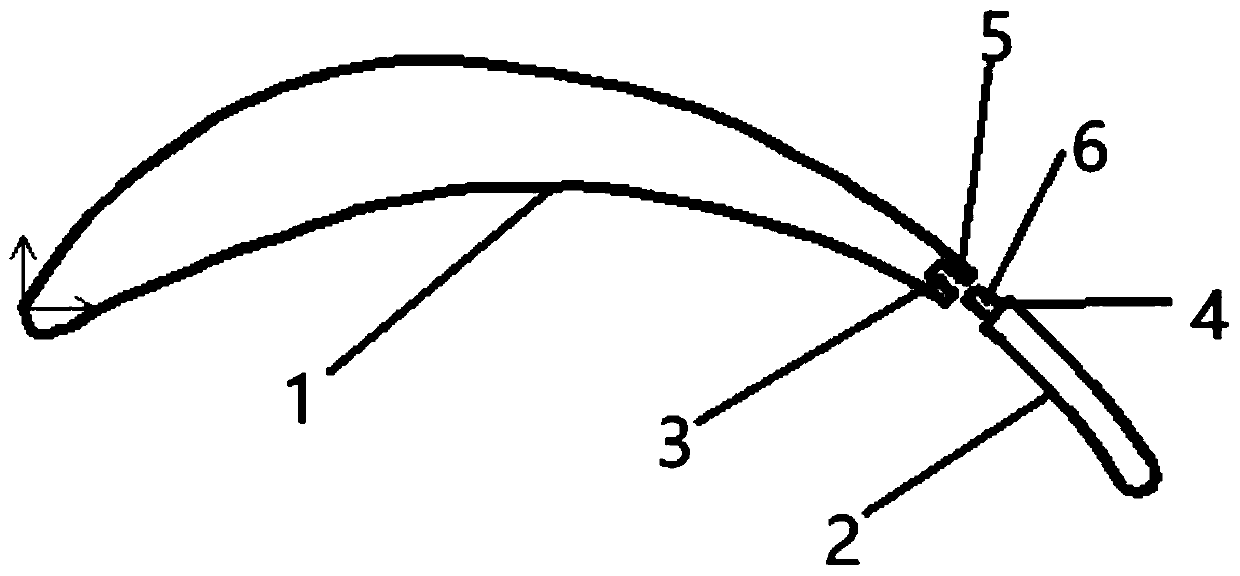

[0035] see figure 1 , a structural schematic diagram of a multi-blade centrifugal fan blade in an embodiment of the present application, including: an airfoil blade part 1 and an arc-shaped blade part 2; the tail end 3 of the airfoil blade part and the head end 4 of the arc-shaped blade part connect.

[0036] In order to make the performance of the blade better, the length d of the arc-shaped blade part 2 should not be too long, and the length d of the arc-shaped blade part 2 and the length D of the airfoil blade part 1 have the following relationship: h for

[0037] Further, h is specifically

[0038] Further, the airfoil blade part 1 and the arc-shaped blade part 2 are integrally formed.

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com