Method for unfolding and locking small-caliber projectile body-large wingspan space folding empennage

A small-caliber, tail fin technology, applied in the direction of offensive equipment, projectiles, weapon types, etc., can solve the problems of small deployment torque, inconvenient use of large torsion springs, complex structure, etc., to achieve reliable locking and self-locking, prevent back and forth swing, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

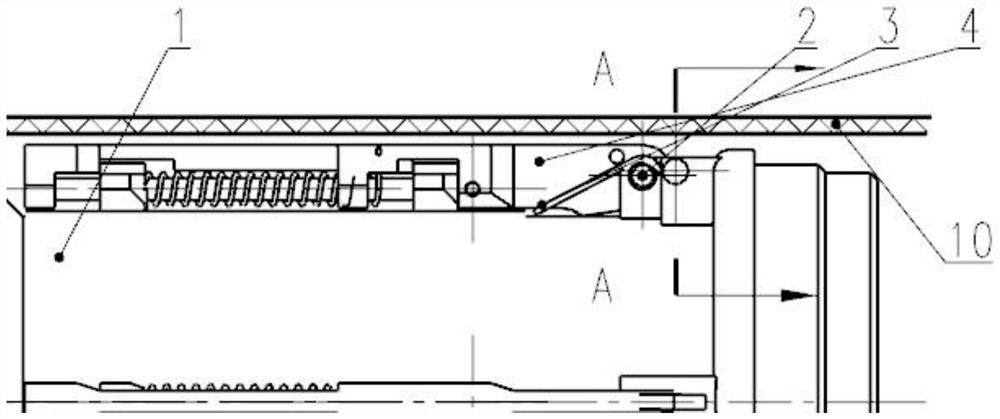

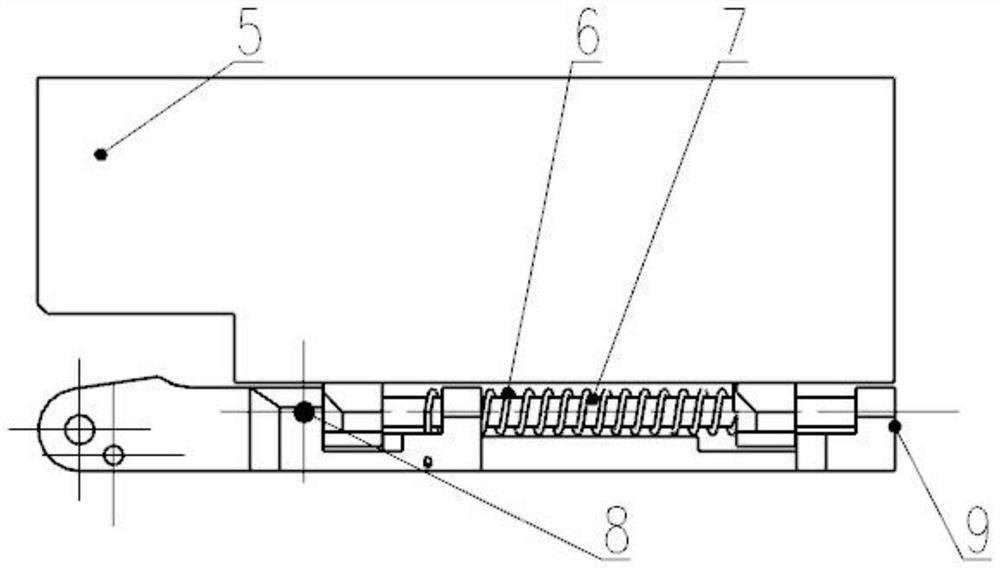

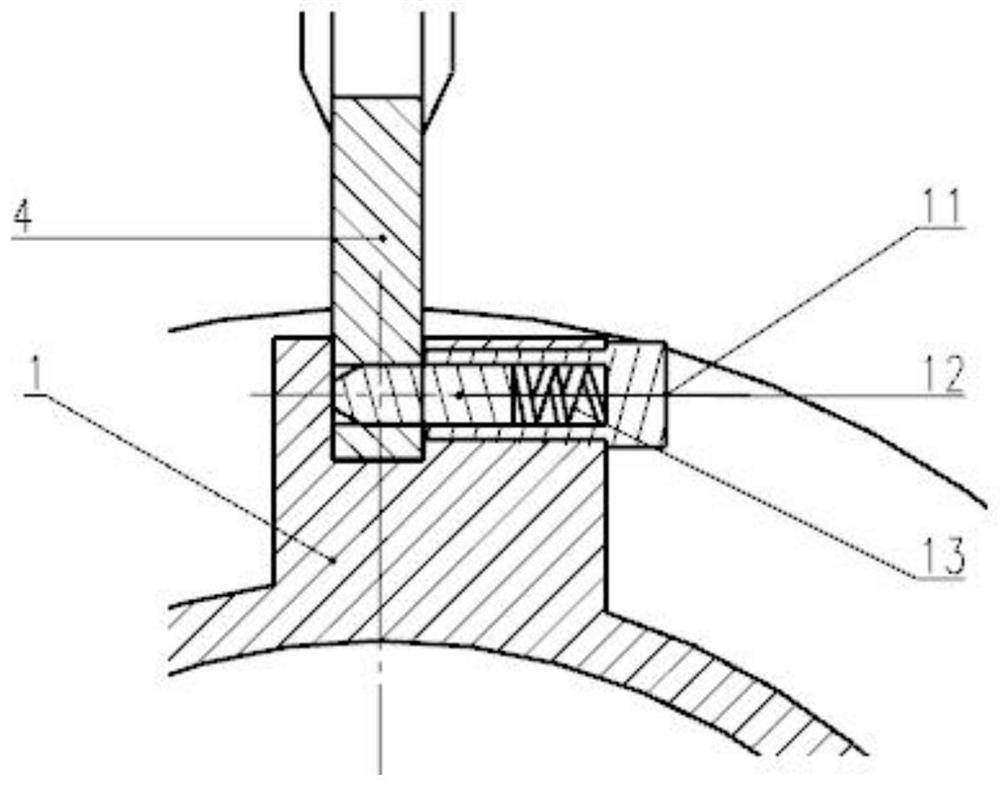

[0030] The small-caliber projectile provided by the preferred embodiment of the present invention-the rapid deployment and reliable locking method of the large-aspect-ratio empennage mechanism, the empennage mechanism is arranged in the lug groove at the middle and rear part of the nozzle, and the torsion spring and the wing torsion spring generate The spring force acts on the middle position of the empennage in the span direction, and the deployment moment is increased by adjusting the torsion spring, the stiffness of the wing torsion spring, and the position and height of the wing shaft.

[0031] The locking mechanism is divided into two parts: longitudinal locking and transverse locking; the longitudinal locking mechanism is built inside the nozzle, and the conical pin locking method is used to position and self-lock the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com