Self-circulating suction air injection device and method based on multi-stage axial flow compressor hub end wall

An axial flow compressor and jet device technology, which is applied in the directions of jet propulsion devices, gas turbine devices, and components of pumping devices for elastic fluids, etc., can solve the problems of channel blockage, increase total pressure loss, etc. Loss, improved efficiency, small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

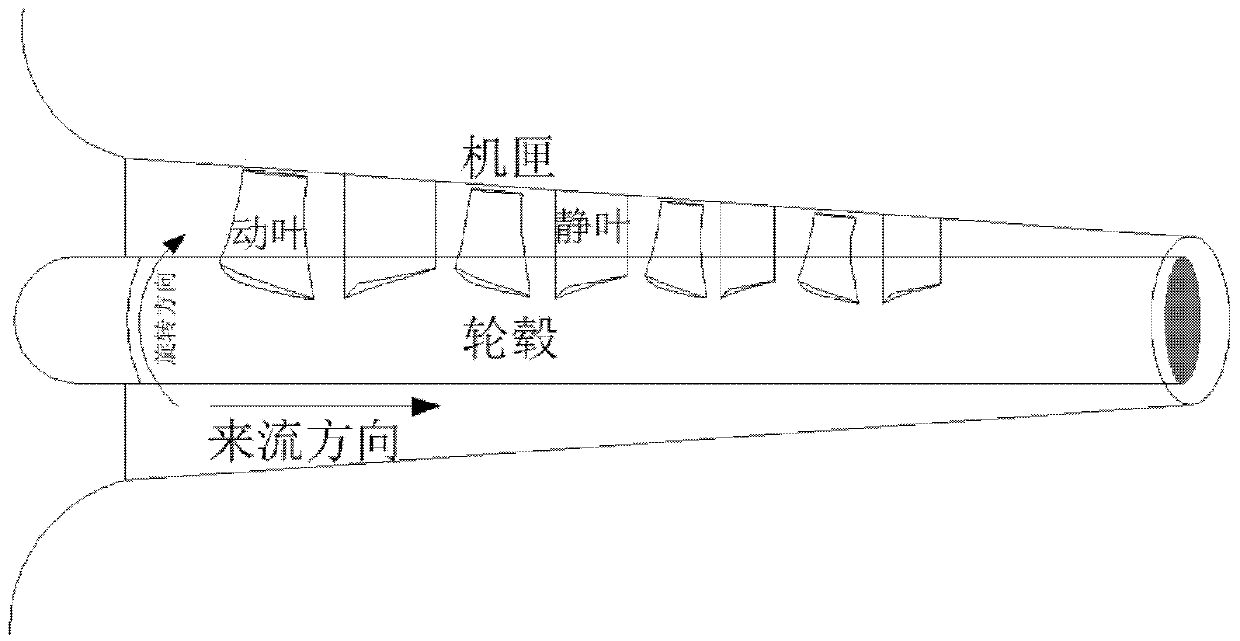

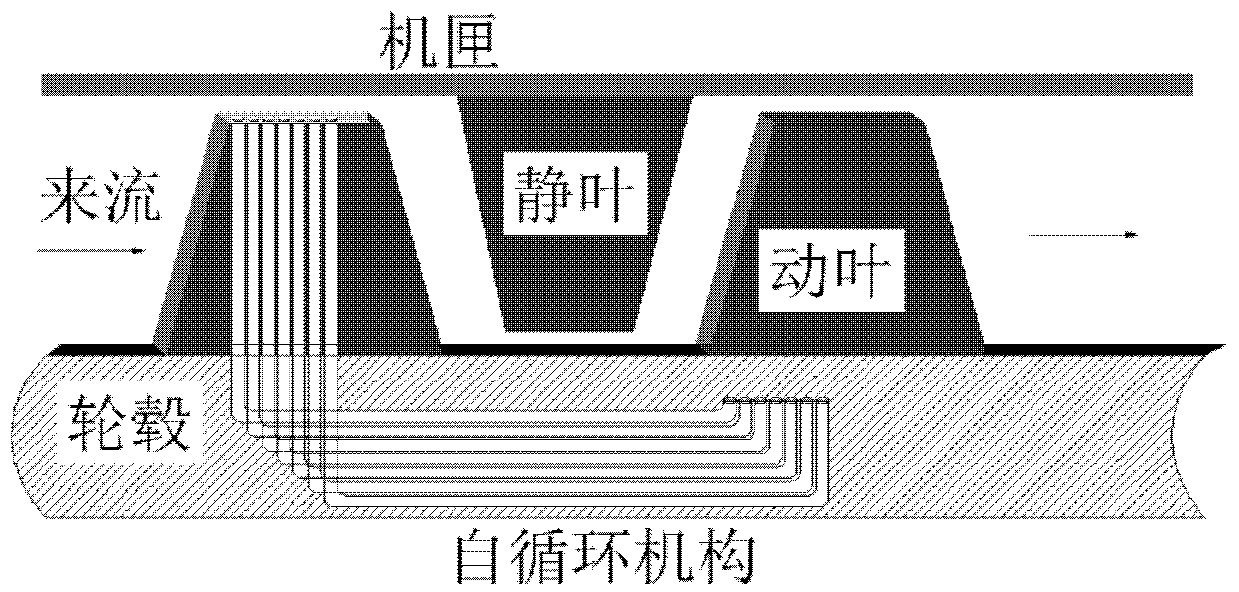

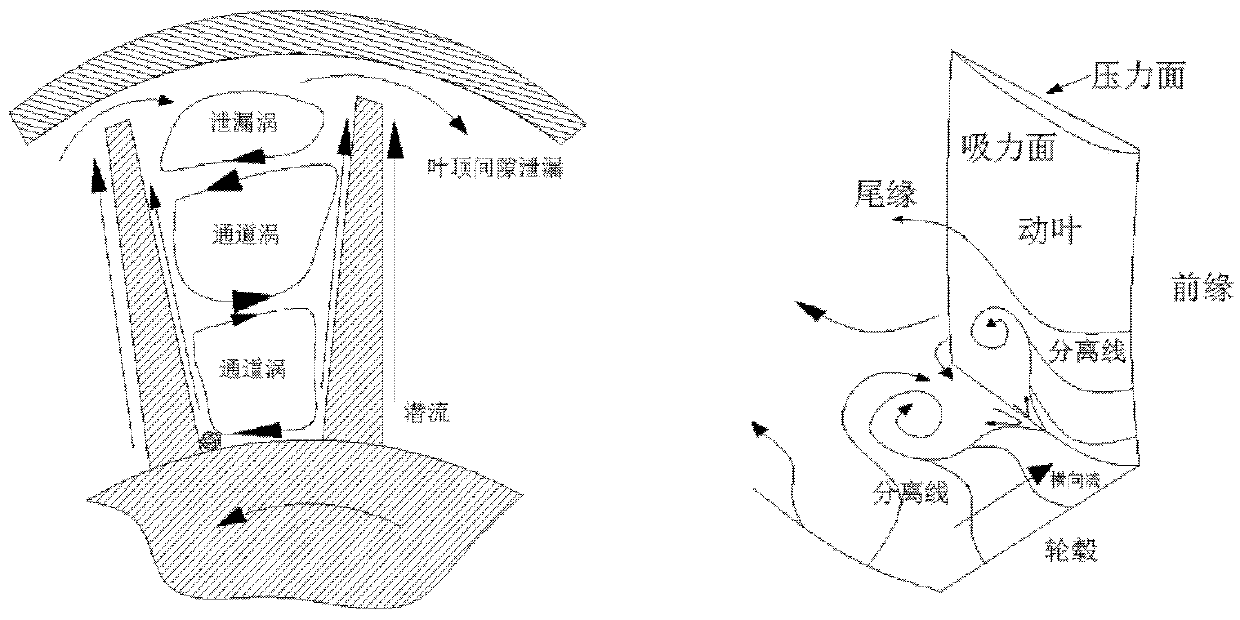

[0037] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a multi-stage axial flow compressor in the prior art. The multi-stage axial flow compressor includes: moving blades, stationary blades, casing and hub, wherein the moving blades are installed on the hub, and the stationary blades are installed on the casing. . During the rotation of the multi-stage axial flow compressor, the rotor blades rotate together with the hub, and then do work on the incoming flow to increase the pressure and speed of the intake air. When the gas passes through the stator blades, the static pressure increases According to the law of conservation of energy, the pressure increases and the velocity decreases. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com