Patents

Literature

53results about How to "Reduced current carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

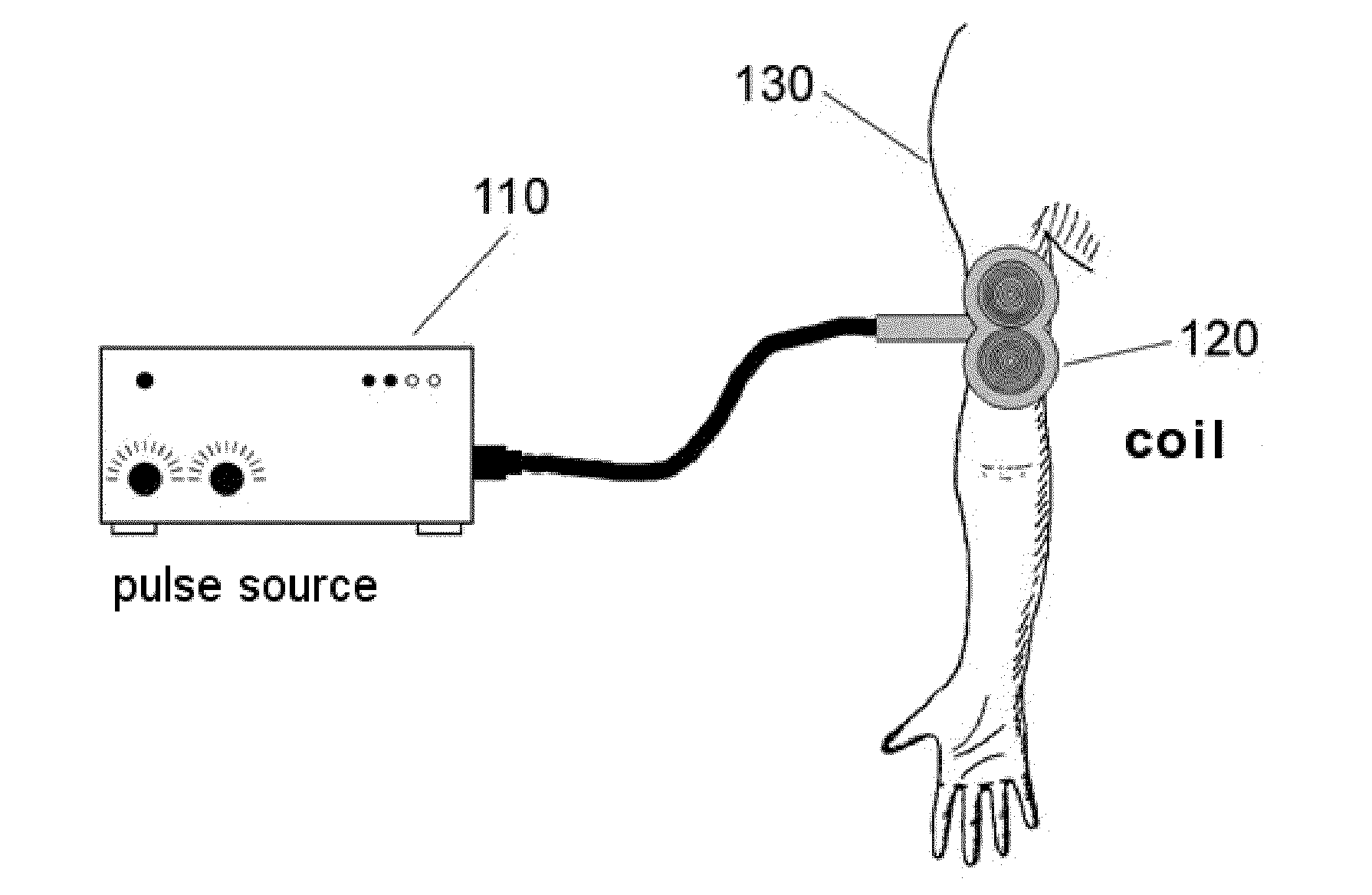

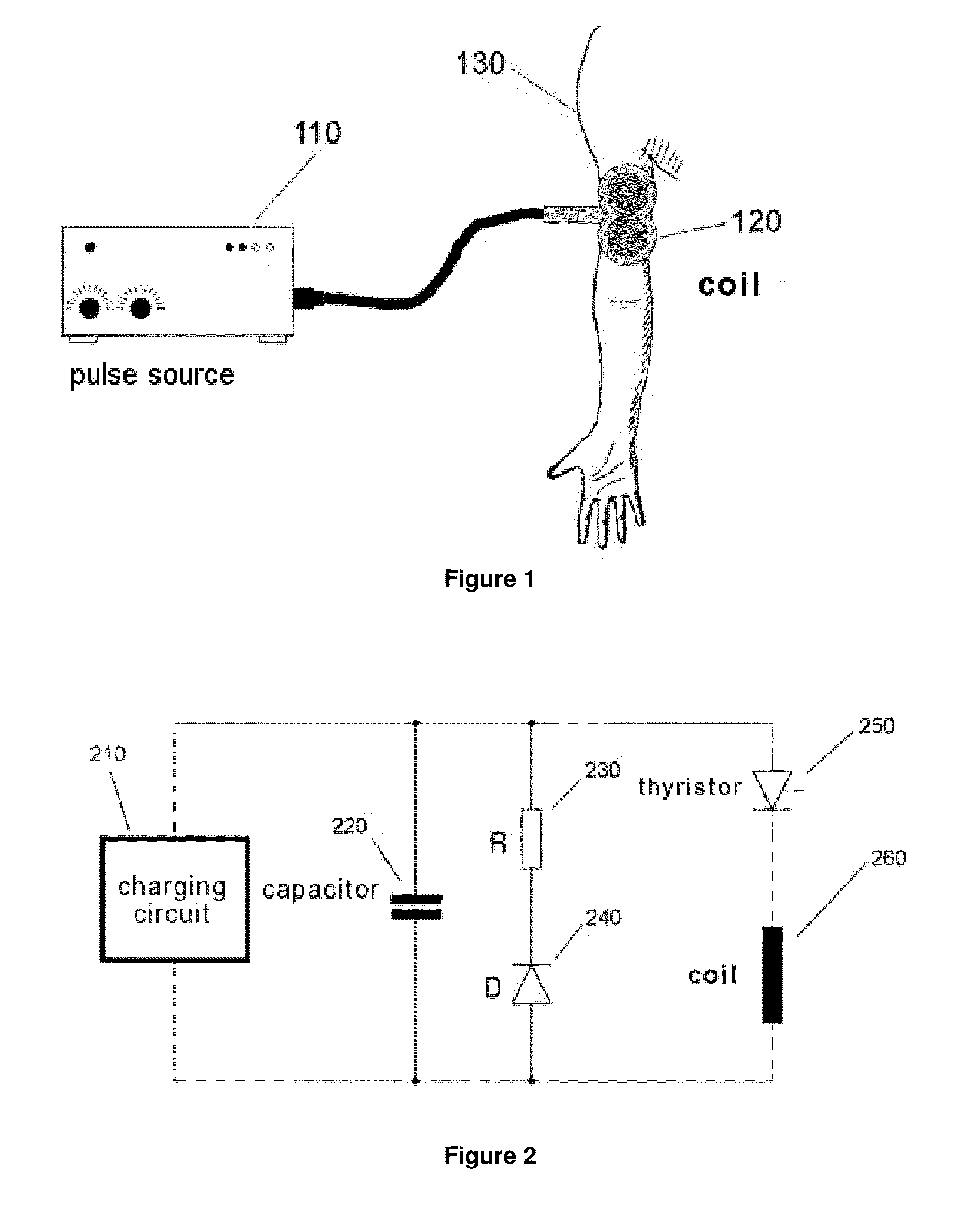

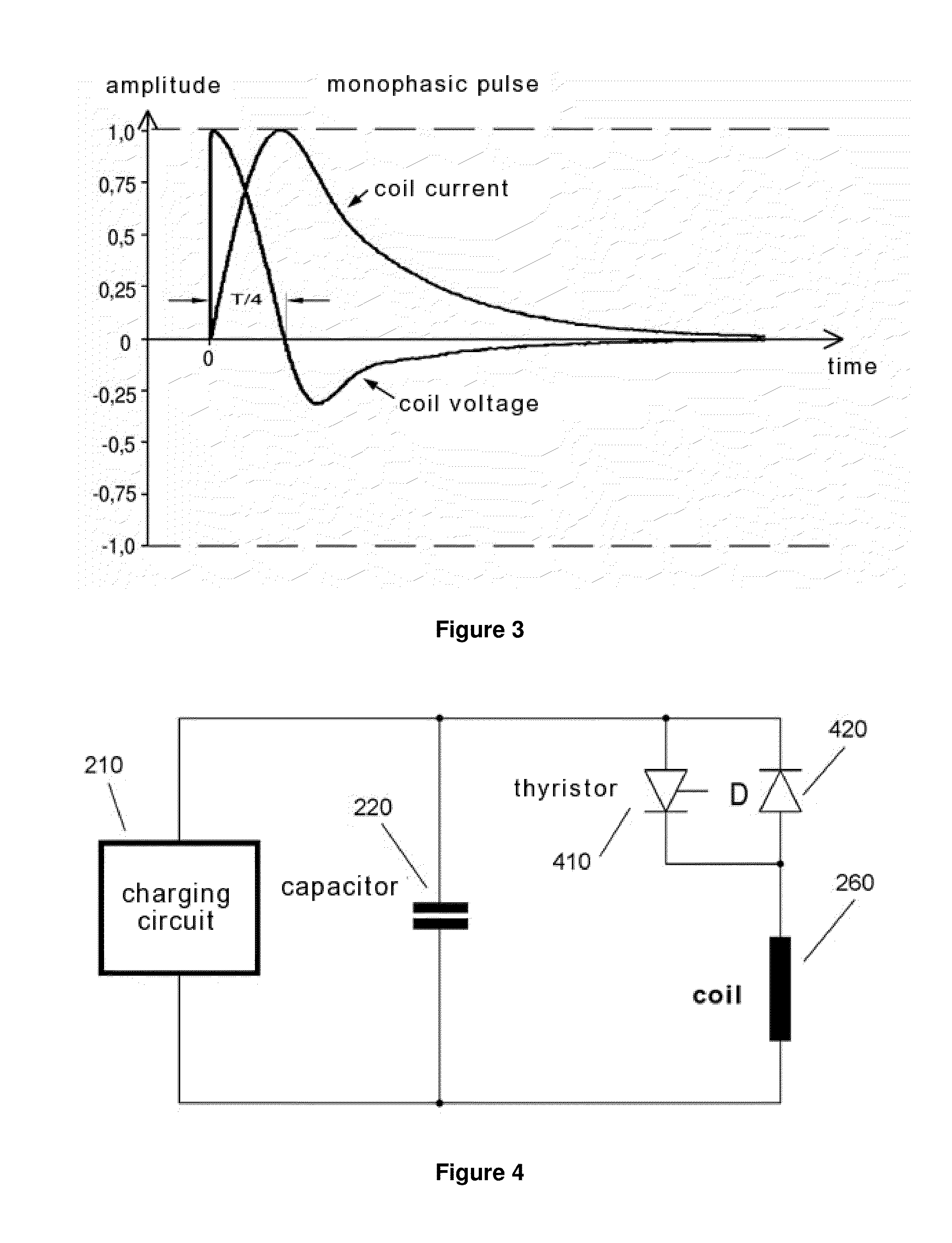

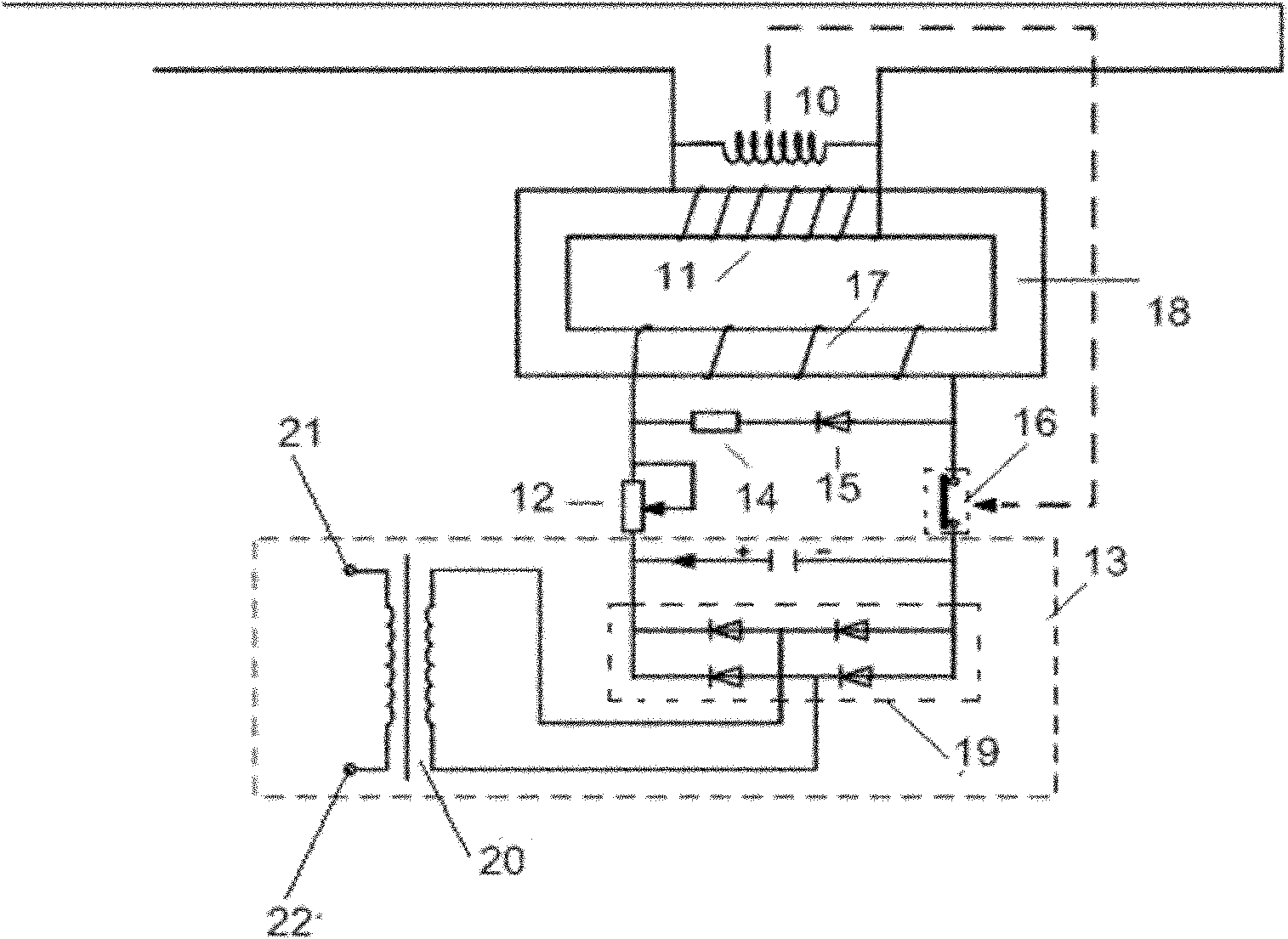

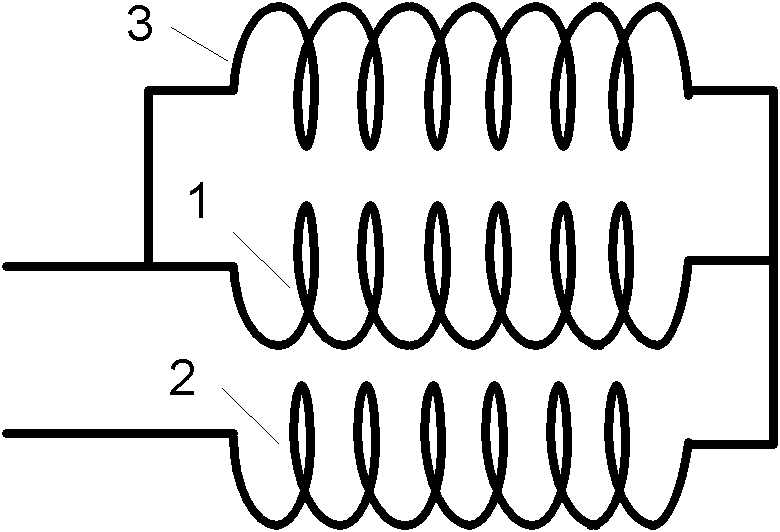

Magnetic stimulation having a freely selectable pulse shape

ActiveUS20130030239A1Low field energyField strengthElectrotherapyThyristorPulse shapingElectromagnetic induction

Device and method for generating brief strong current pulses in a coil for generating magnetic field pulses which according to the electromagnetic induction principle induce stimulation currents in the body tissue triggering an action potential of the nerve and / or muscle cells, where the coil is positionable close to the body tissue to be stimulated so that its magnetic field passes through the body tissue, and where the device comprises a power generating unit that can generate a freely selectable temporal course of the current through the coil during the current pulse. A method for determining an optimized temporal course of a brief strong current pulse through the coil, where the temporal course of the current pulse is calculated using a method which numerically simulates the electrical behavior of nerve and / or muscle cells and the coil and optimizes the course of the current pulse regarding at least one parameter, or which by means of stimulating the nerve and / or muscle cells with predetermined current pulses optimizes the temporal course of the current pulse regarding at least one parameter and therefrom determines essential parameters of nerve and / or muscle cells.

Owner:TECH UNIV MUNCHEN

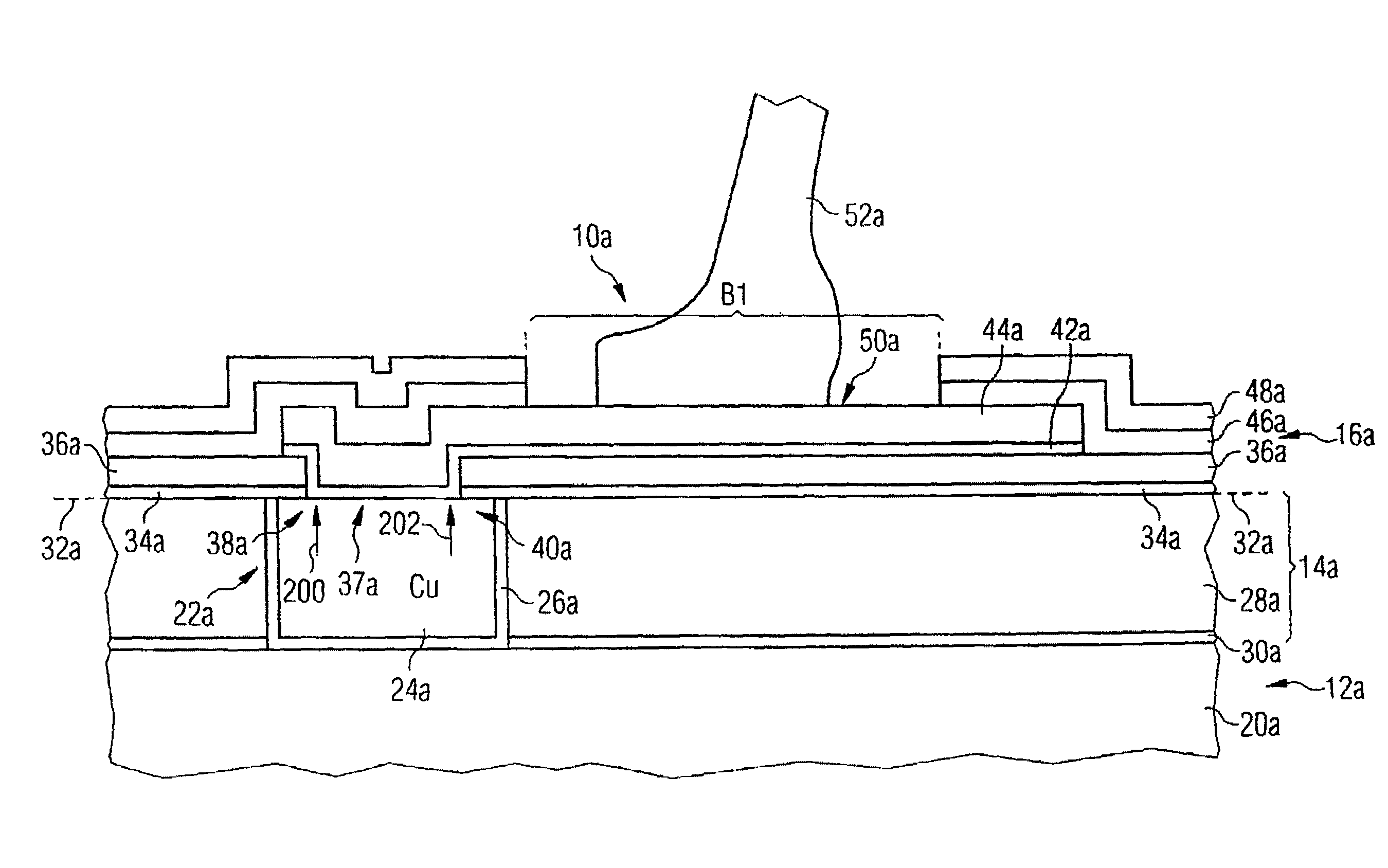

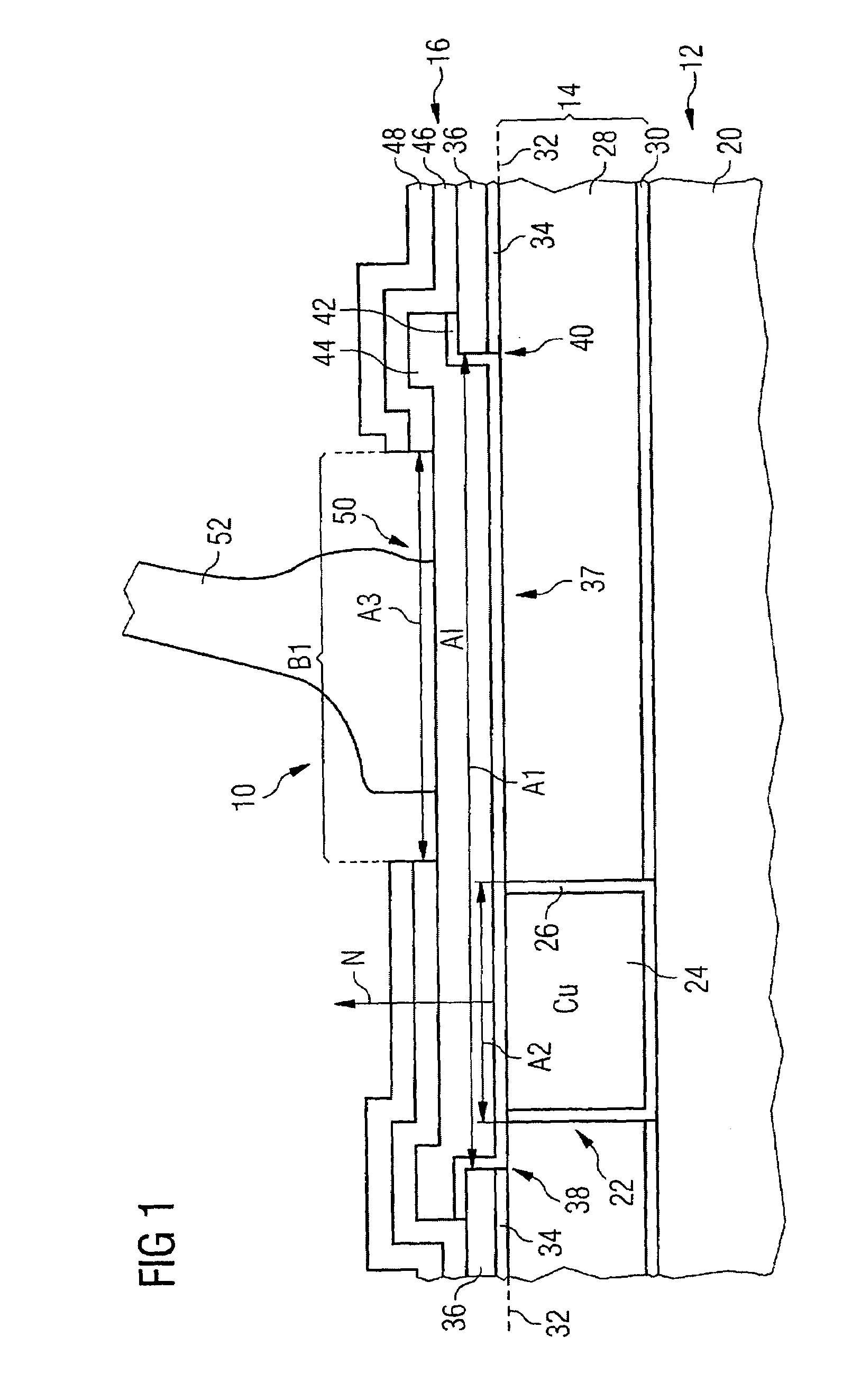

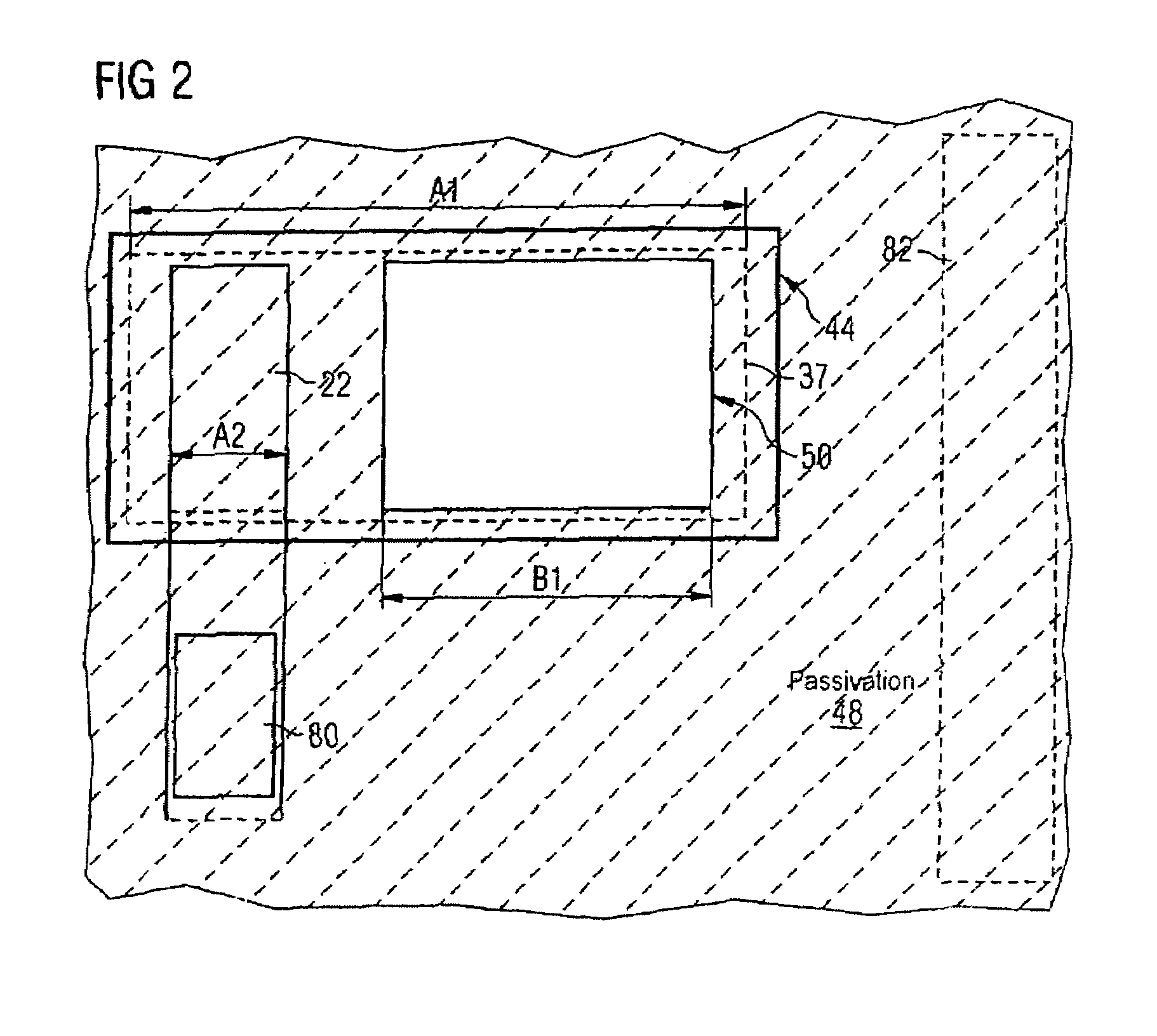

Integrated connection arrangements

ActiveUS7619309B2Reduce thicknessReduced current carrying capacitySemiconductor/solid-state device detailsSolid-state devicesInsulation layerContact zone

Owner:INFINEON TECH AG

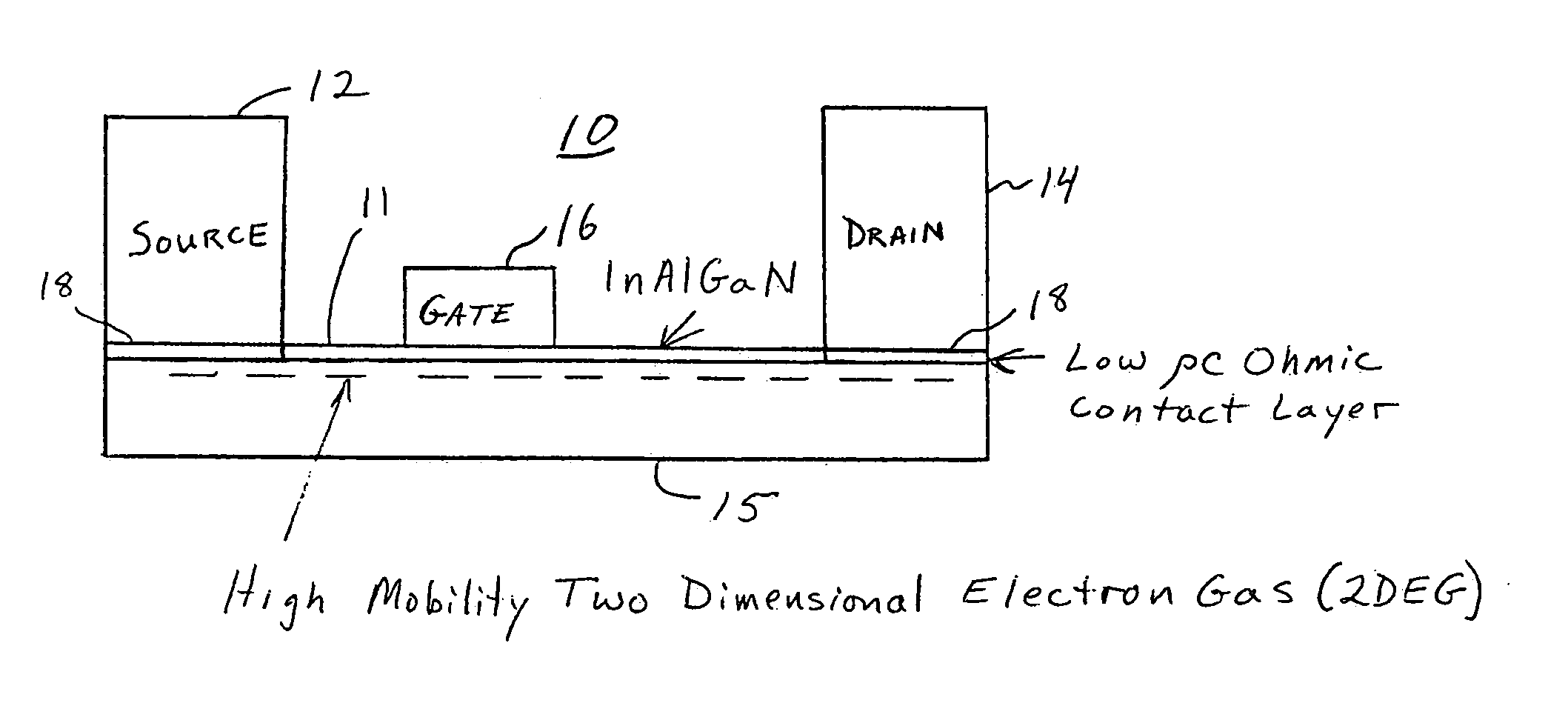

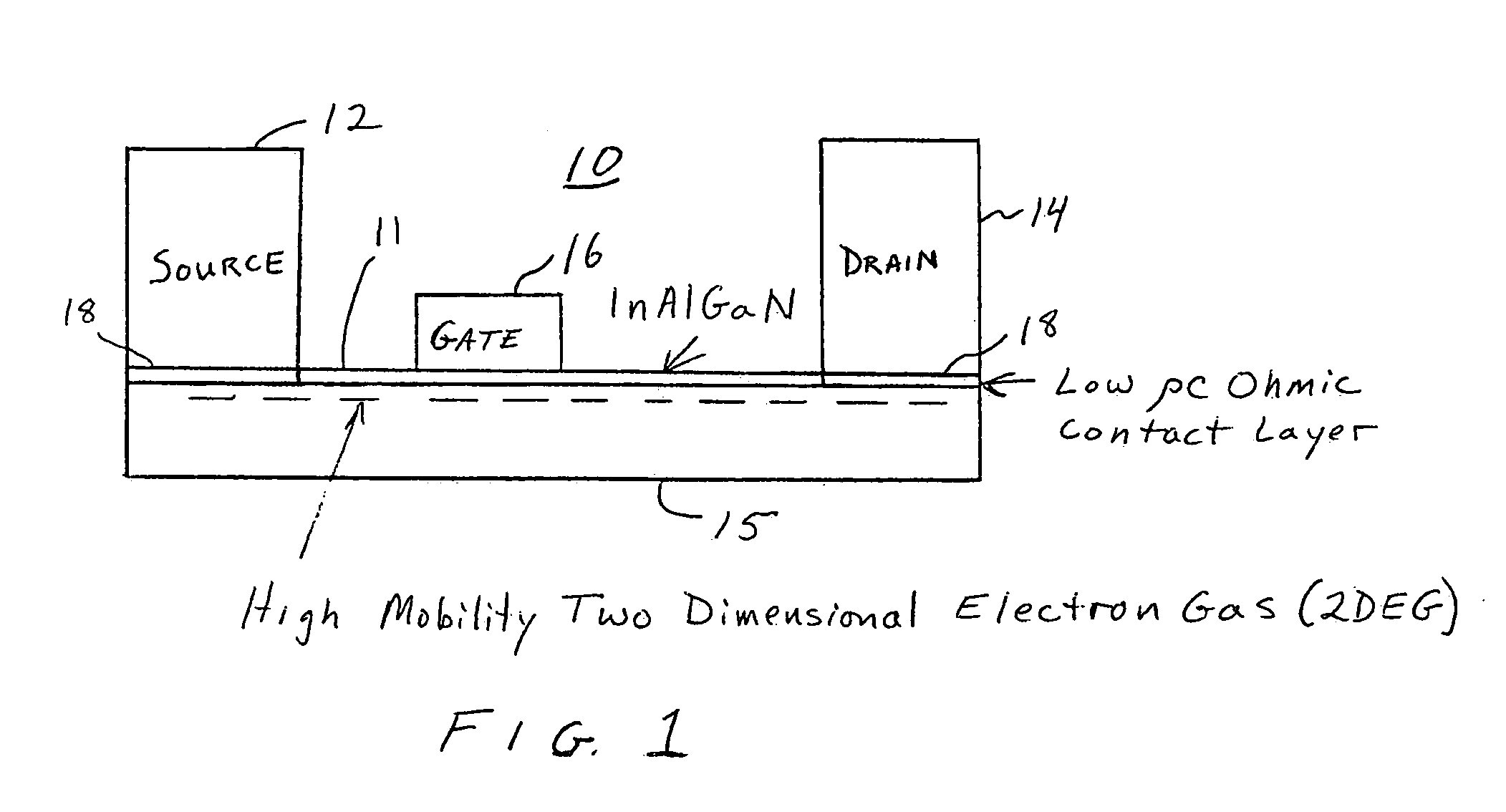

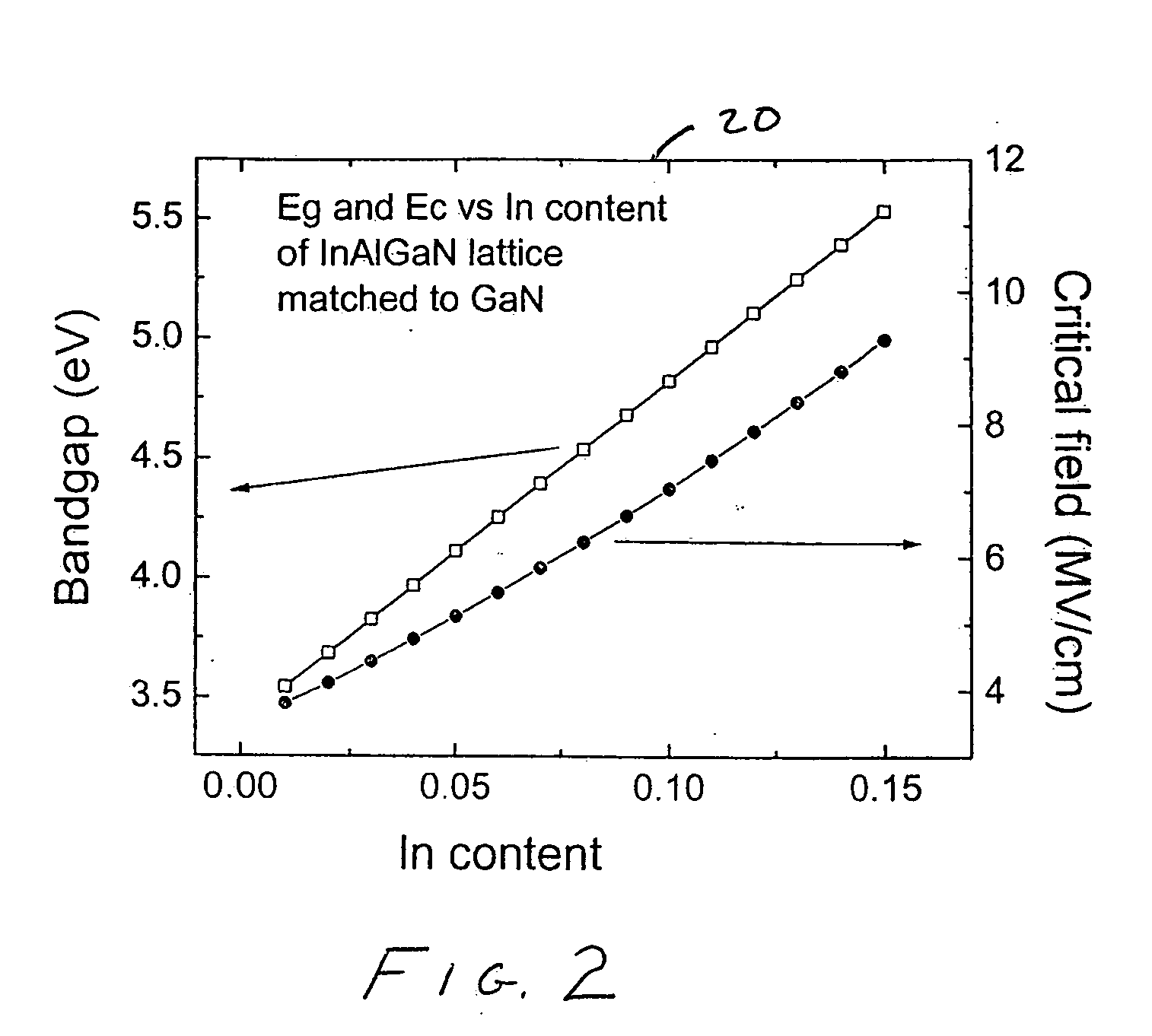

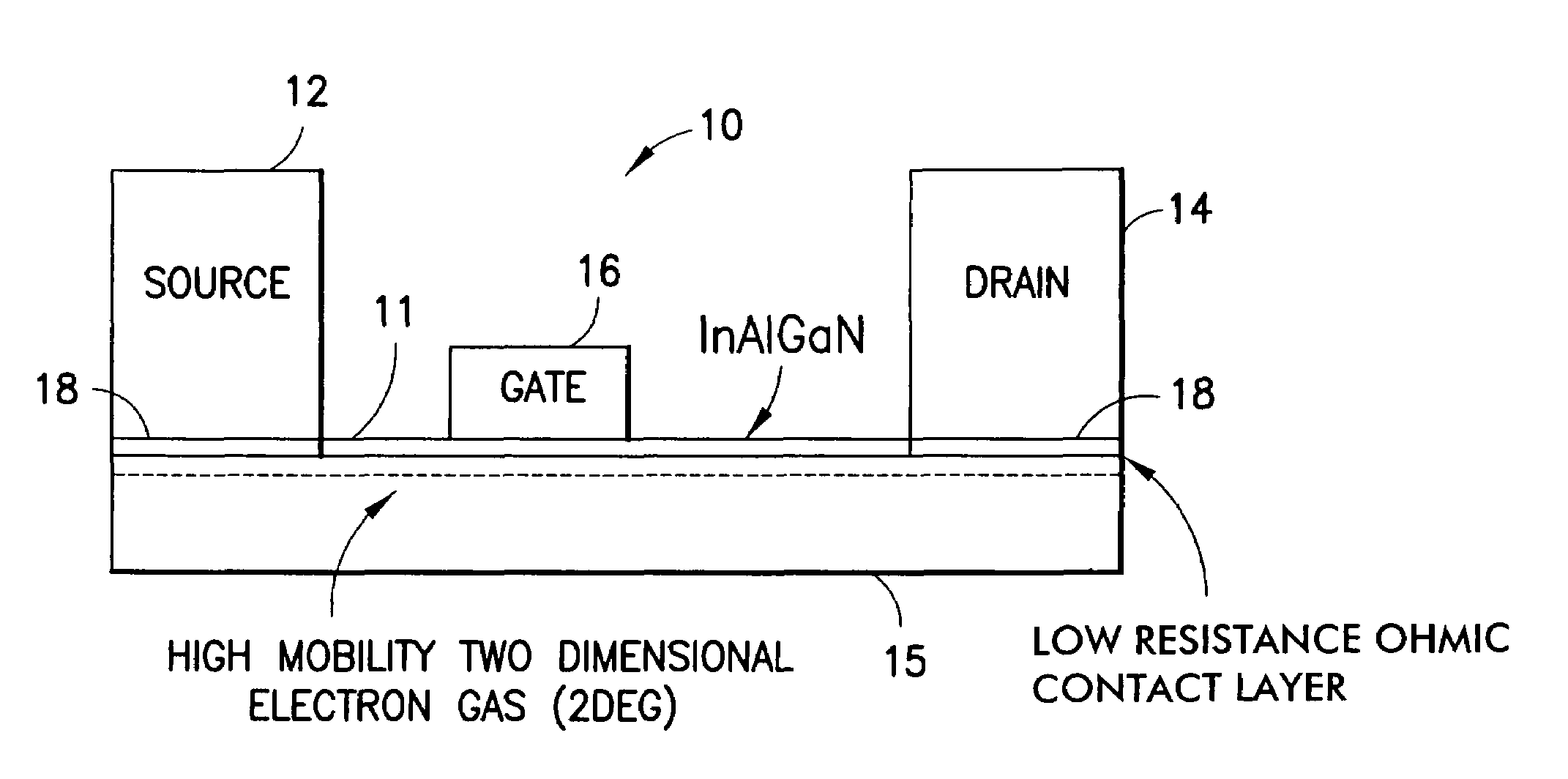

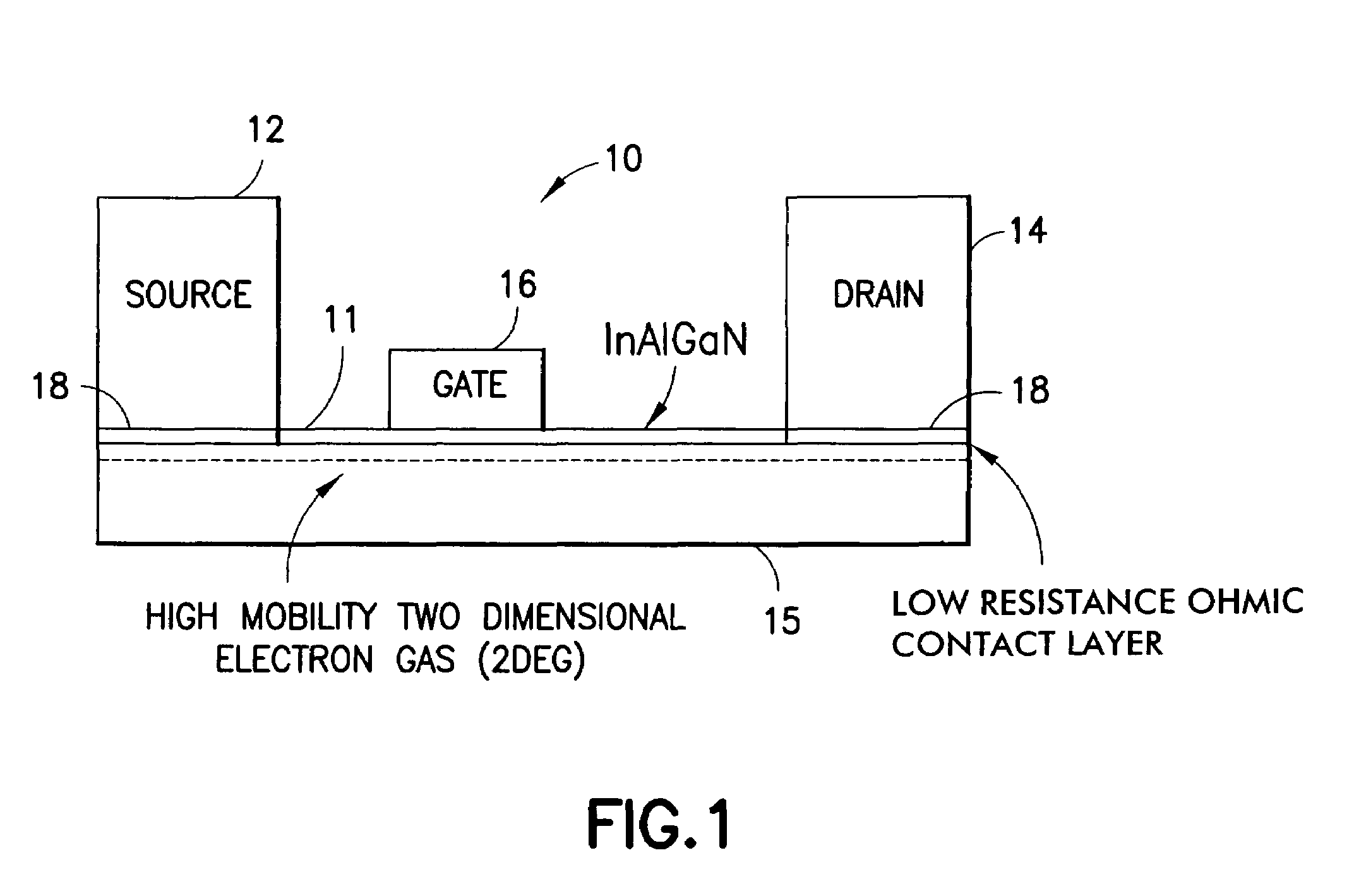

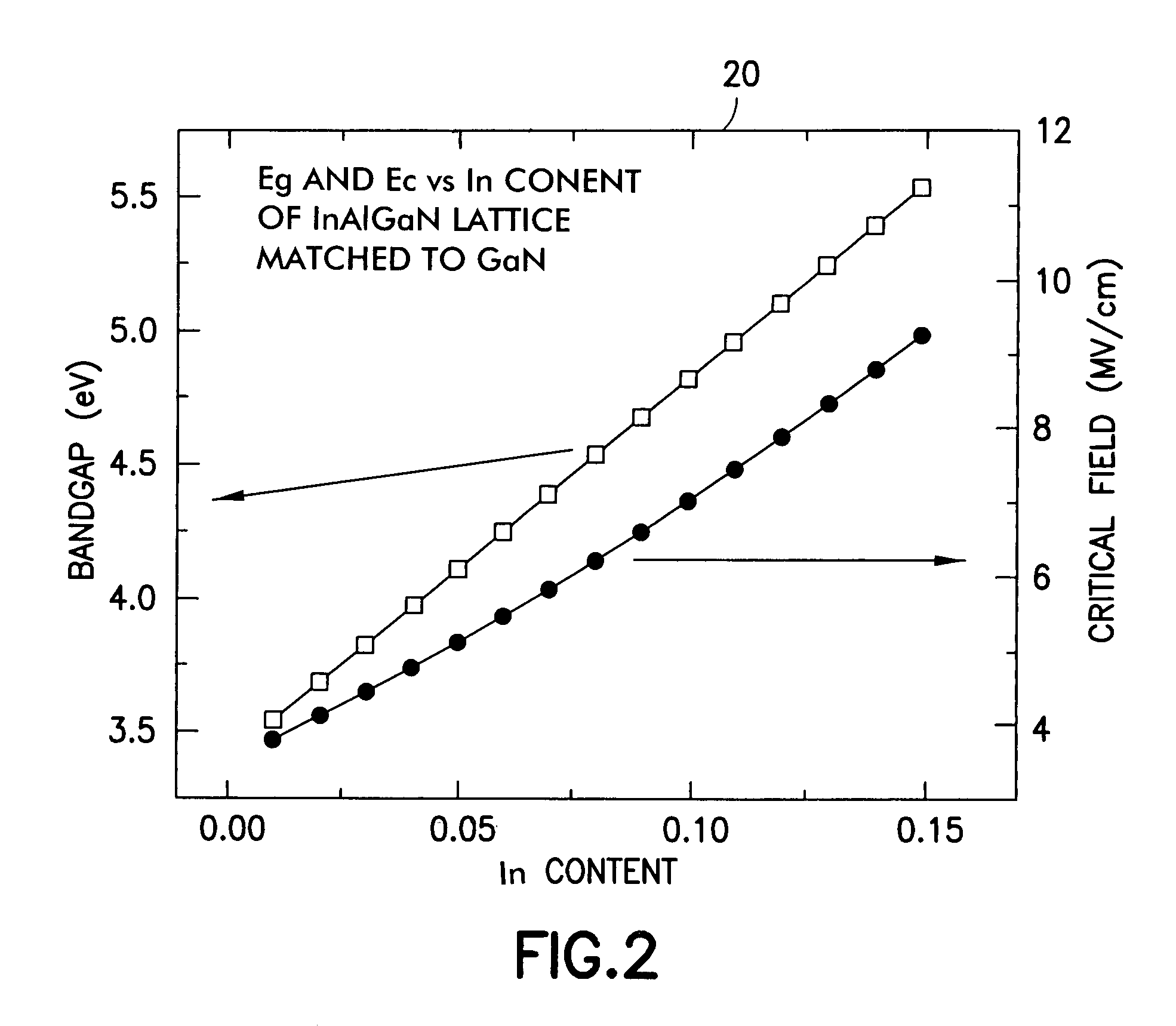

Field effect transistor with enhanced insulator structure

ActiveUS20050121661A1Reduce and eliminate strain generated fieldHigh densitySemiconductor/solid-state device manufacturingSemiconductor devicesIn planeField-effect transistor

A III-nitride based field effect transistor obtains improved performance characteristics through manipulation of the relationship between the in-plane lattice constant of the interface of material layers. A high mobility two dimensional electron gas generated at the interface of the III-nitride materials permits high current conduction with low ON resistance, and is controllable through the manipulation of spontaneous polarization fields obtained according to the characteristics of the III-nitride material. The field effect transistor produced can be made to be a nominally on device where the in-plane lattice constants of the material forming the interface match. A nominally off device may be produced where one of the material layers has an in-plane lattice constant that is larger than that of the other layer material. The layer materials are preferably InAlGaN / GaN layers that are particularly tailored to the characteristics of the present invention.

Owner:INFINEON TECH AMERICAS CORP

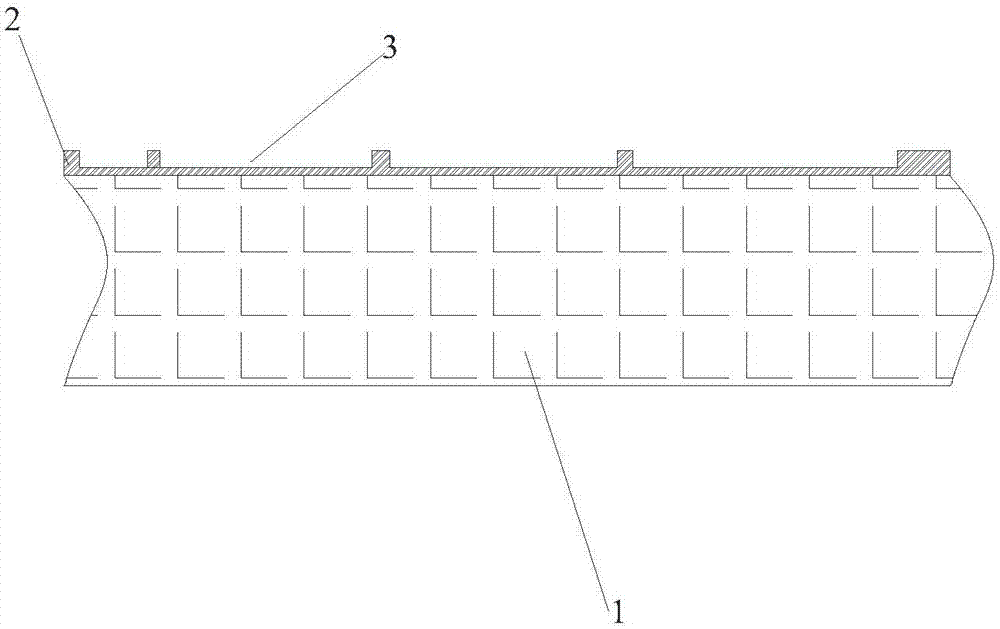

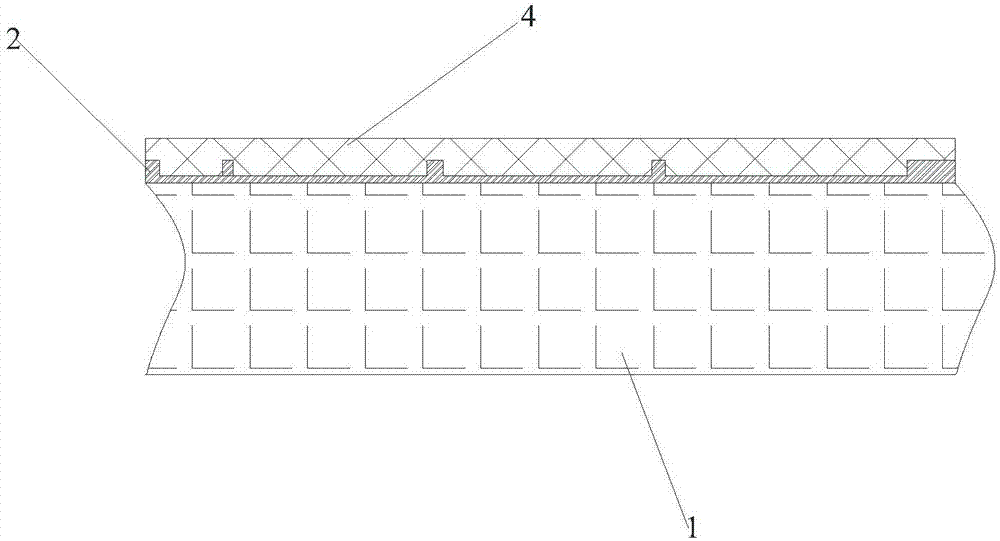

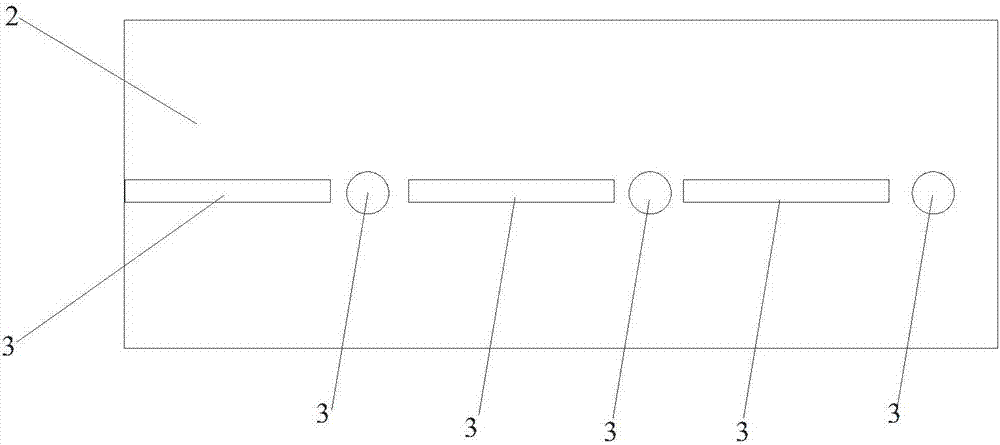

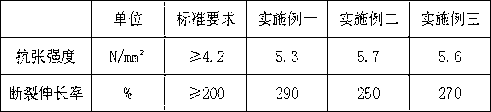

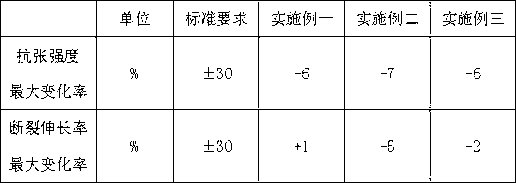

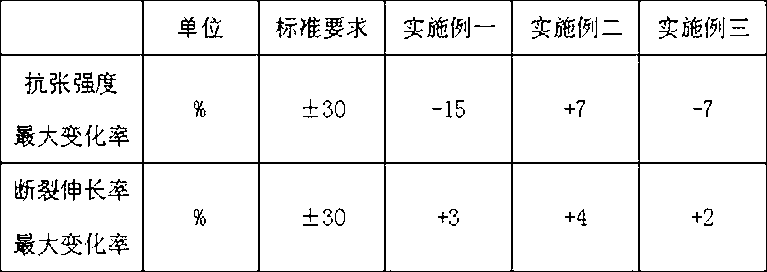

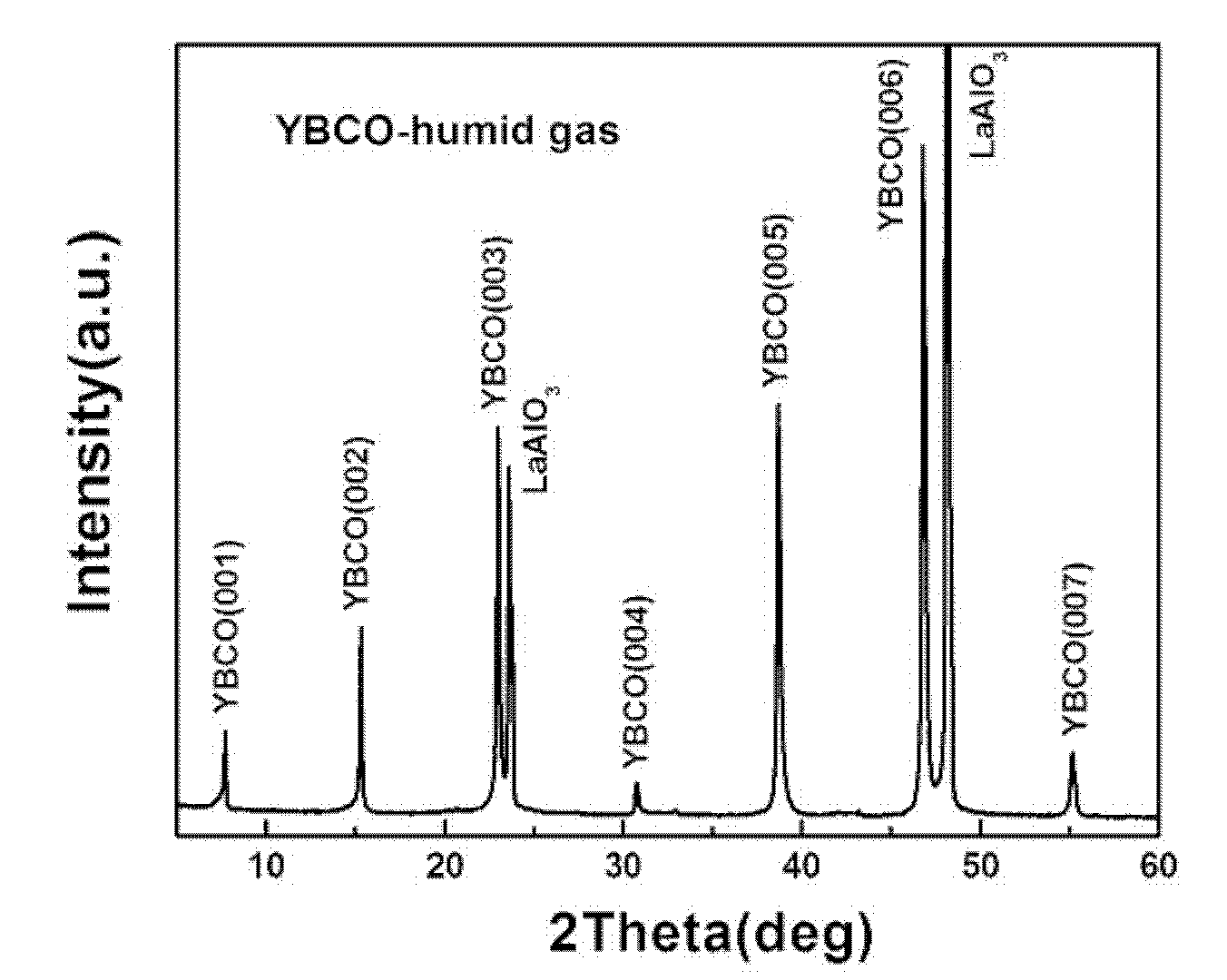

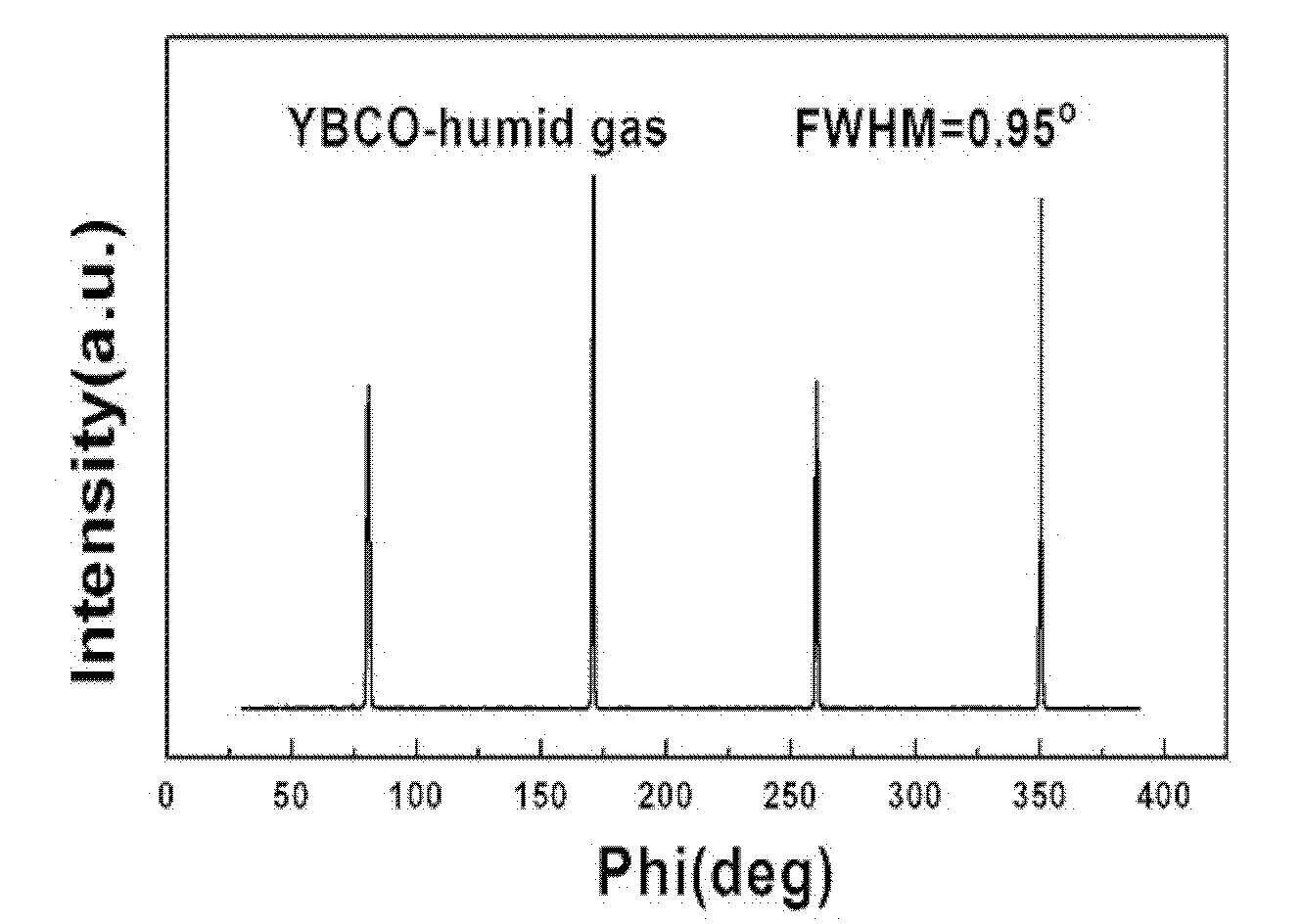

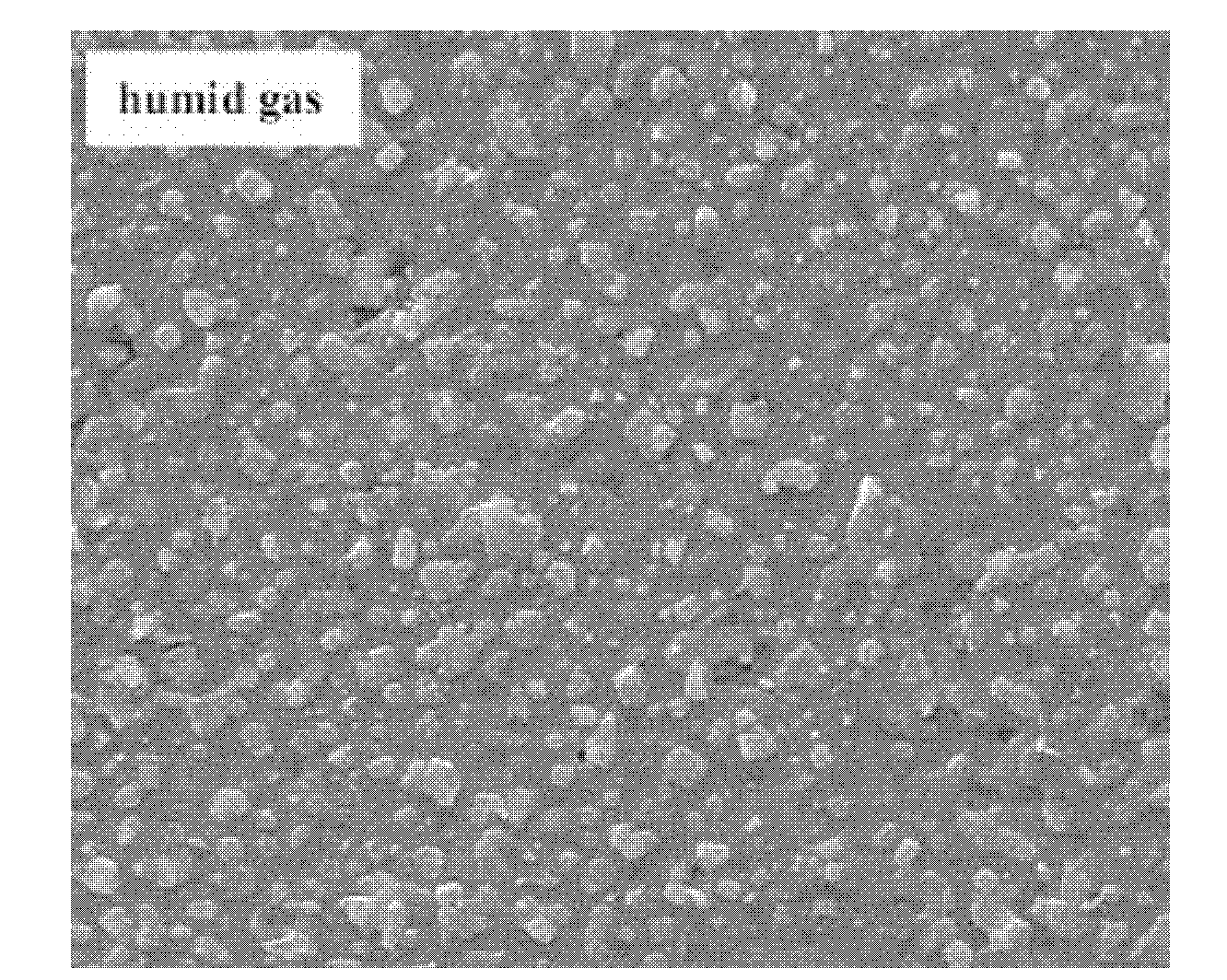

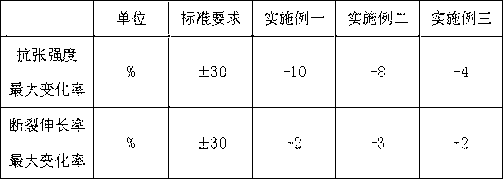

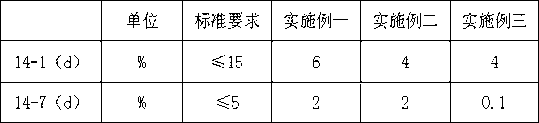

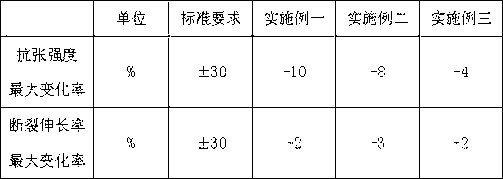

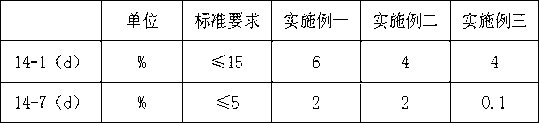

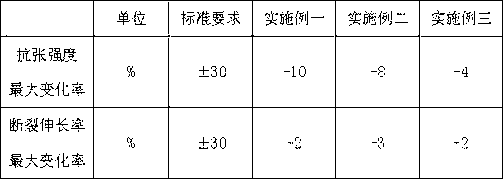

Processing method for improving second generation high-temperature super-conducting strip interlayer binding force

ActiveCN107103957AImprove bindingReduced current carrying capacitySuperconductors/hyperconductorsApparatus for manufacturing conducting/semi-conducting layersState of artUltrasound attenuation

The invention provides a processing method for improving second generation high-temperature super-conducting strip interlayer binding force. The processing method comprises the following steps of taking a textured flexible strip as the base material, performing etching on an oxide layer on the surface of the strip, and controlling etching depth, width and patterns; and adopting the etched textured flexible strip to perform superconducting thin film deposition. Compared with the prior art, the processing method has the following beneficial effects: 1, the interlayer binding force of the second generation high-temperature super-conducting strip obtained by the preparation method is improved by more than one time, while the current-carrying capability attenuation is less than 20%; and 2, the second generation high-temperature super-conducting strip prepared by the preparation method has no influence to the structure and the preparation process of the subsequently prepared superconducting thin film.

Owner:上海翌曦科技发展有限公司

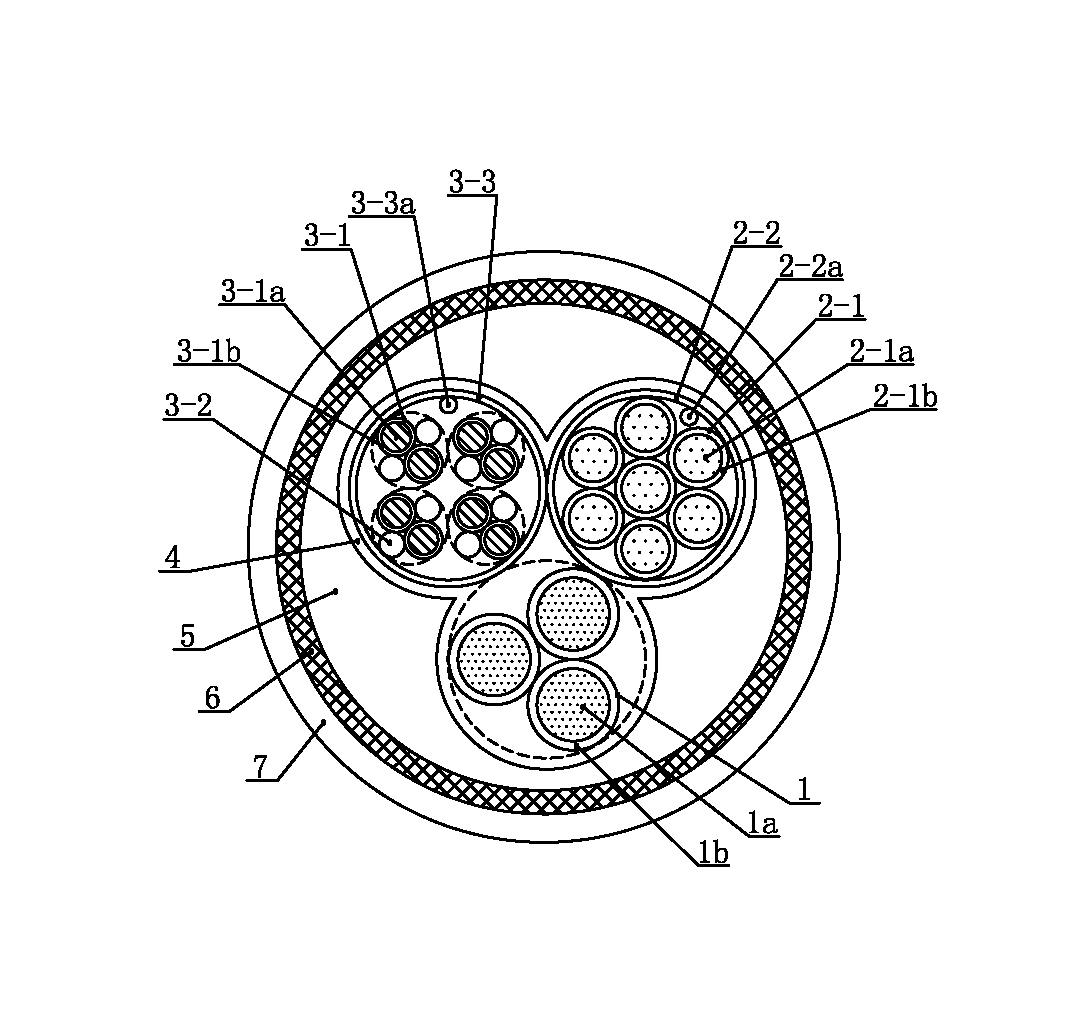

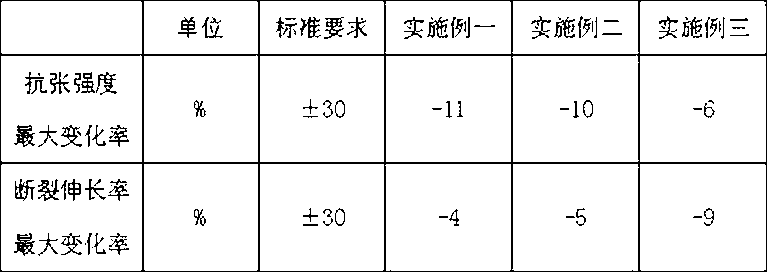

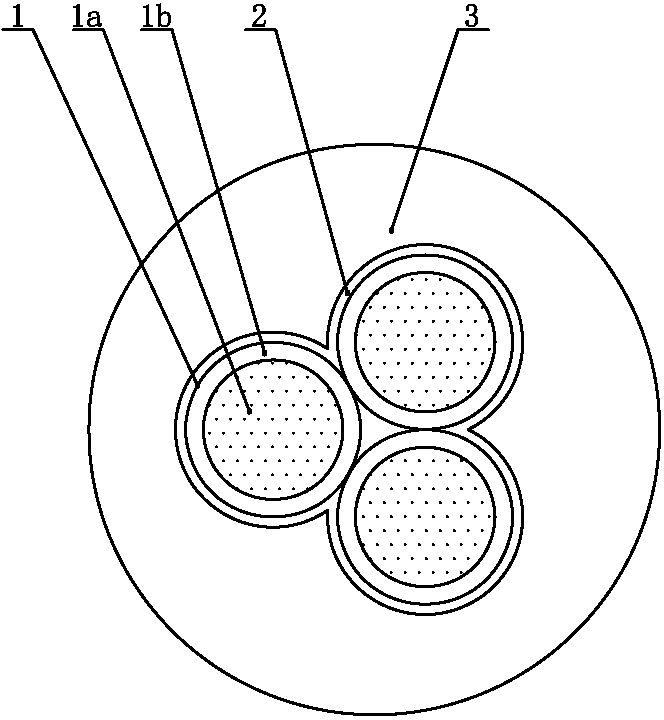

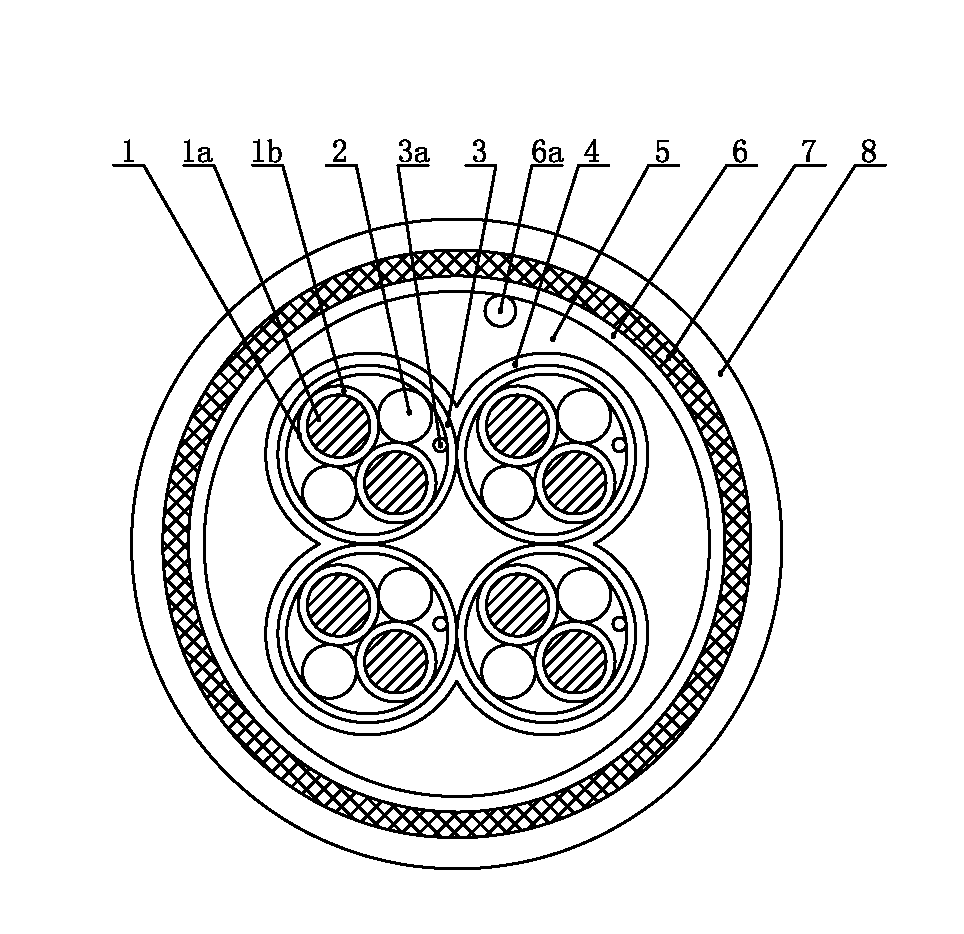

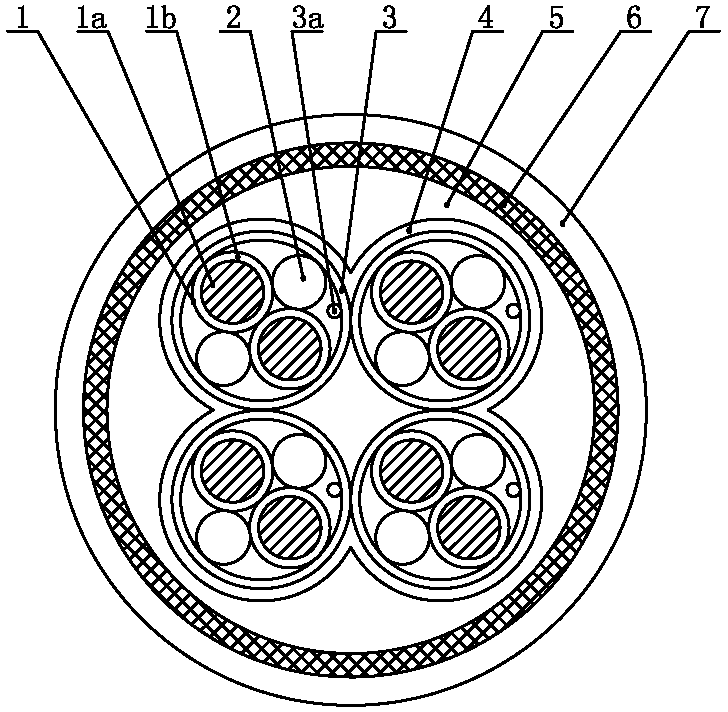

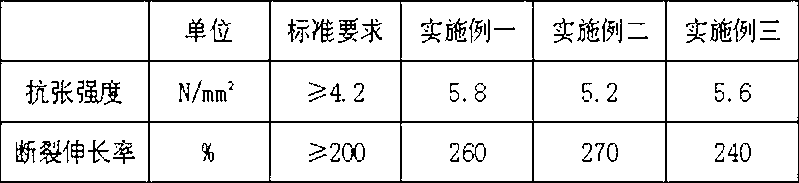

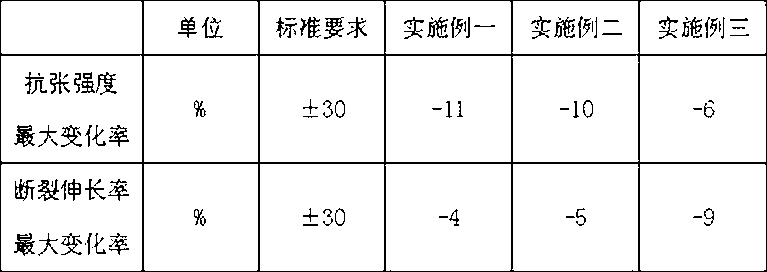

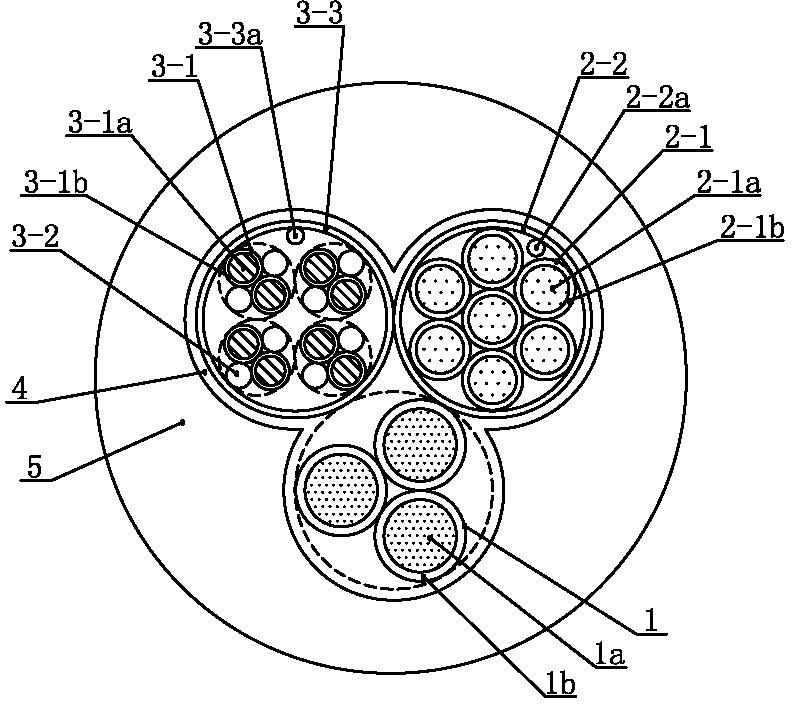

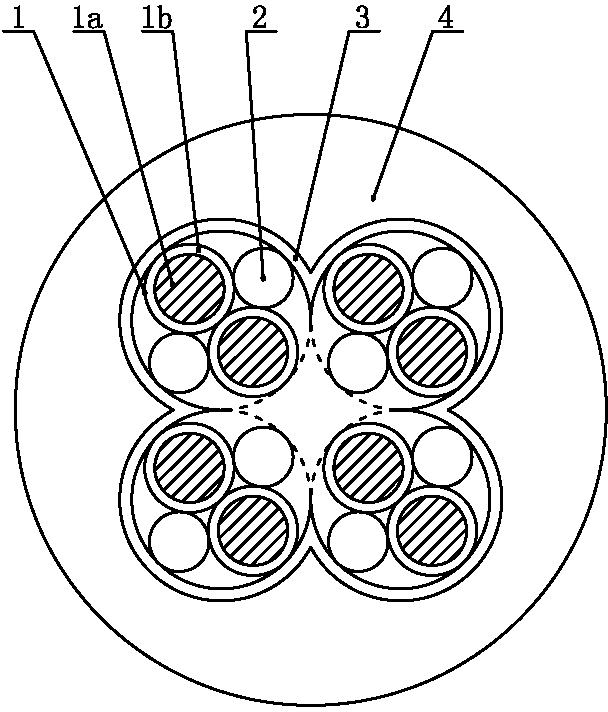

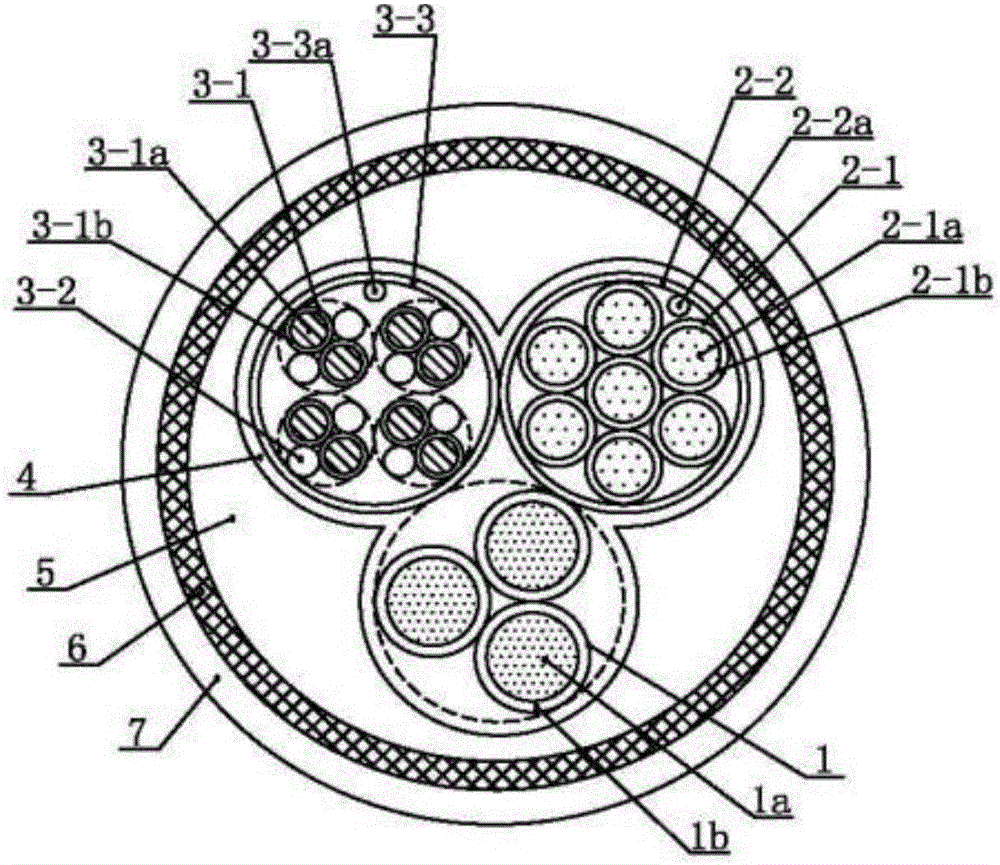

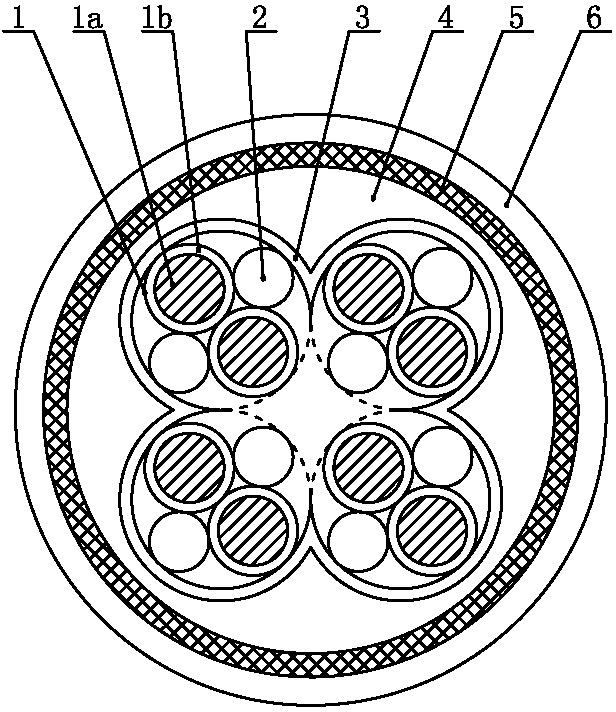

Composite cable for flame-retardant fireproof boat and manufacturing method thereof

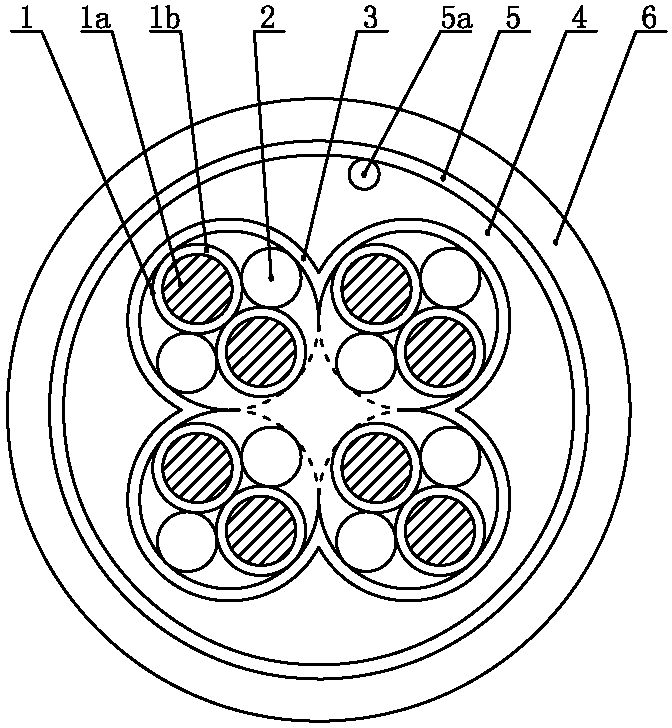

ActiveCN103226992AIncrease working temperatureEliminate voidsInsulated cablesInsulated conductorsPower cableEngineering

The invention relates to a composite cable for a flame-retardant fireproof boat and a manufacturing method thereof. A power cable core, a control cable core and an instrument cable core are stranded into a composite cable core; the periphery of the composite cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; an inner jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way; the periphery of the inner jacket is coated with an armor braid; and an outer jacket is extruded on the periphery of the armor braid in a wrapping way. The low-intensity non-woven fabric longitudinally-covered layer is completely in fit with each insulated conductor in shape, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated cores are eliminated, and flame can be conveniently prevented from being spread inwards; and meanwhile, the inner jacket and the insulated cores are guaranteed not to be adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:浙江华威设备制造有限公司

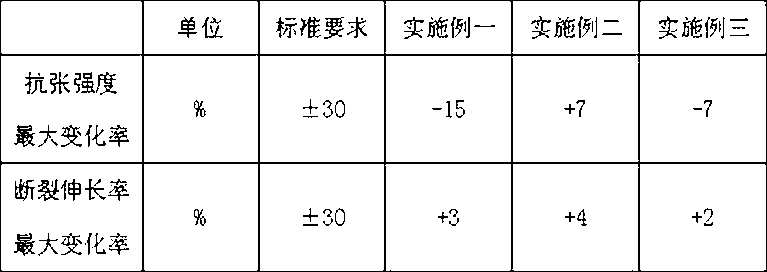

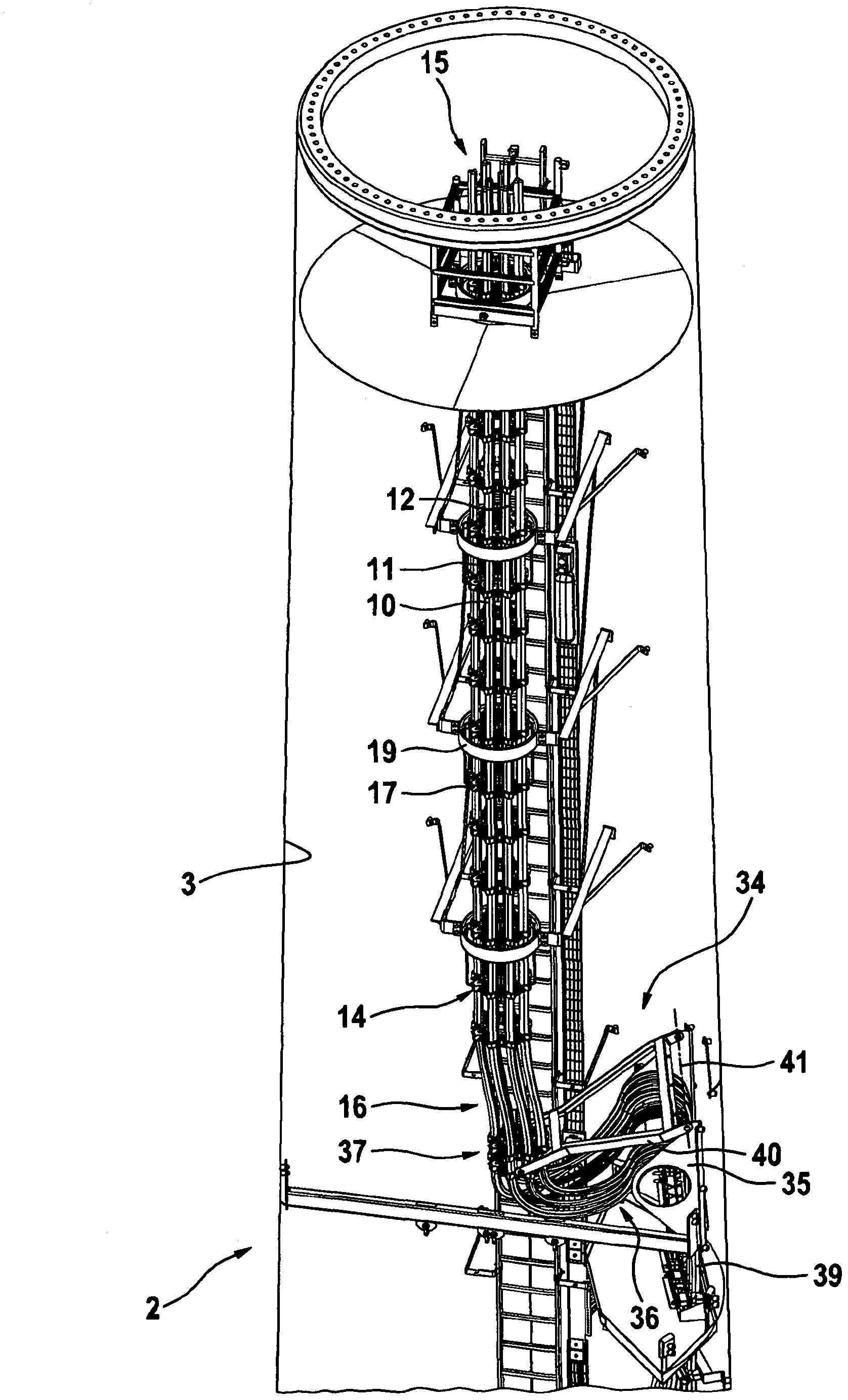

Tower for a wind turbine

InactiveCN102933845AGuaranteed current carrying capacityReduced current carrying capacityWind motor supports/mountsPower cables for overhead applicationWind forceThree-phase

The invention relates to a tower for a wind turbine and to a cable guide for a tower of a wind turbine, wherein a machine housing for the wind turbine is arranged on the tower such that it can rotate by means of the azimuth bearing about a vertical axis which runs in the longitudinal direction of the tower. Current-carrying cables, such as power cables, are routed in the tower of the wind turbine out of the machine housing from electrical components to the ground. These comprise a multiplicity of cables, for example a plurality of cables for electrically carrying individual phases of alternating current, in particular three-phase alternating current, cables for ground conductors and / or signal and control cables. One object of the invention is to specify improved routing of the cables which, inter alia, avoids the disadvantages of the prior art.; One particular aim is to ensure that the current load capacity of the cables is ensured, and / or that wear between the cables is reduced. According to the invention, the object is achieved by the features of the main claim 1, by arranging a guide apparatus effectively between the cable loom and the tower, in the tower, for at least partial fixing of the area of the cable loom to the tower, wherein the guide apparatus has means for supporting the lower area of the cable loom in a radial direction, and for support with respect to the tower in a circumferential direction. In this case, the guide apparatus is designed such that the lower area of the cable loom is mounted such that it can move in the axial direction with respect to the tower, but is essentially fixed with respect to the tower in the circumferential and radial directions.

Owner:SUZLON ENERGY LTD

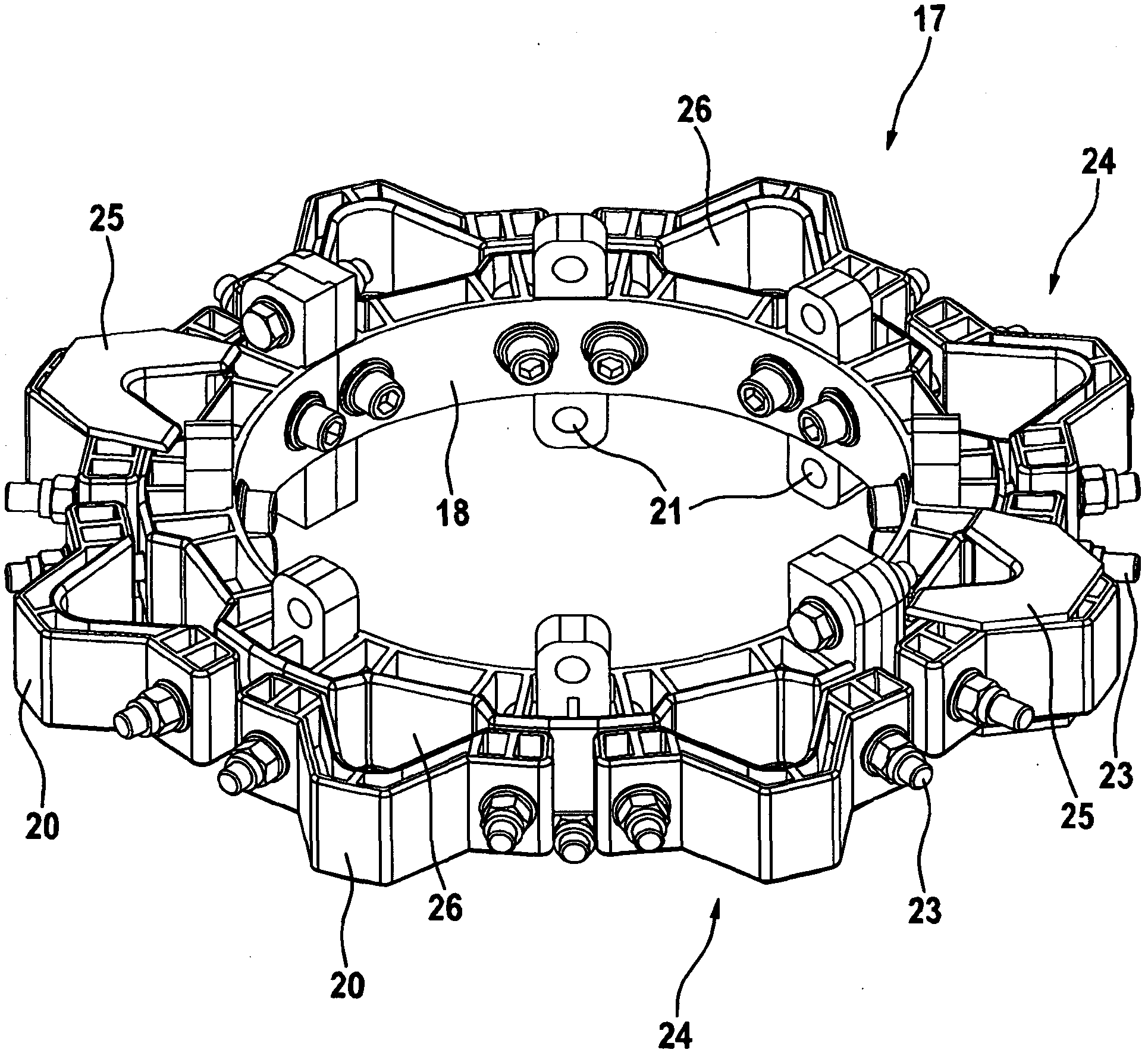

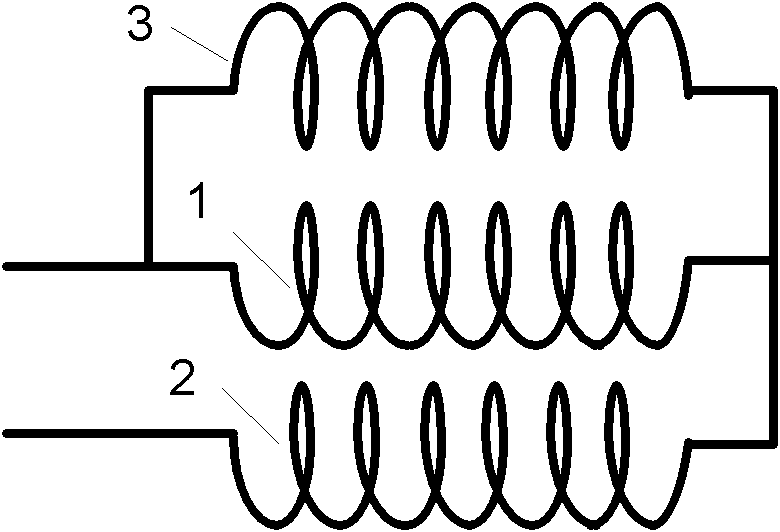

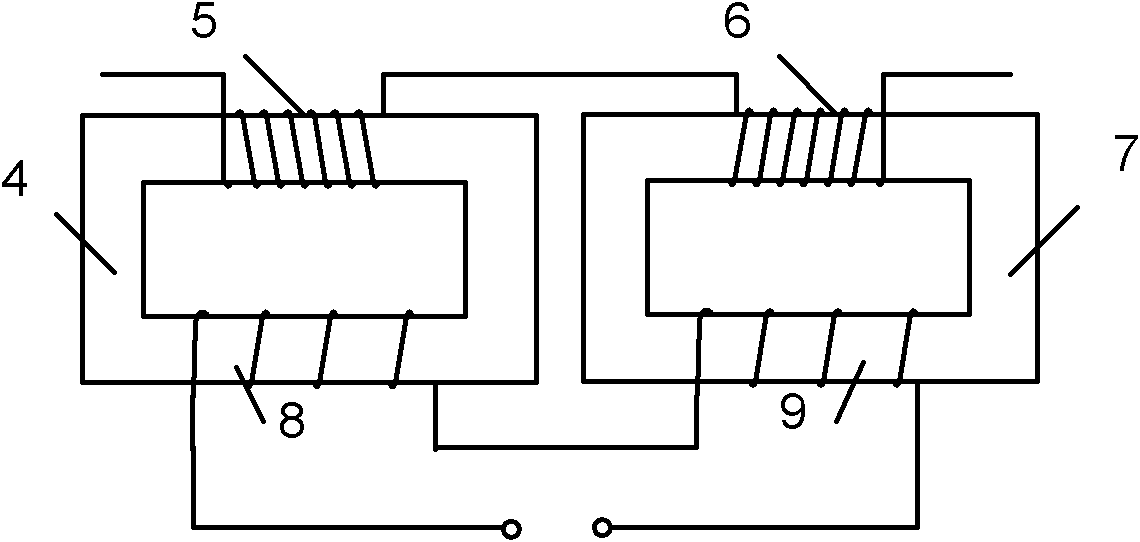

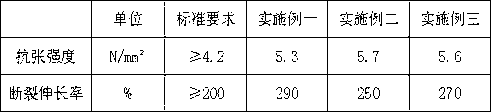

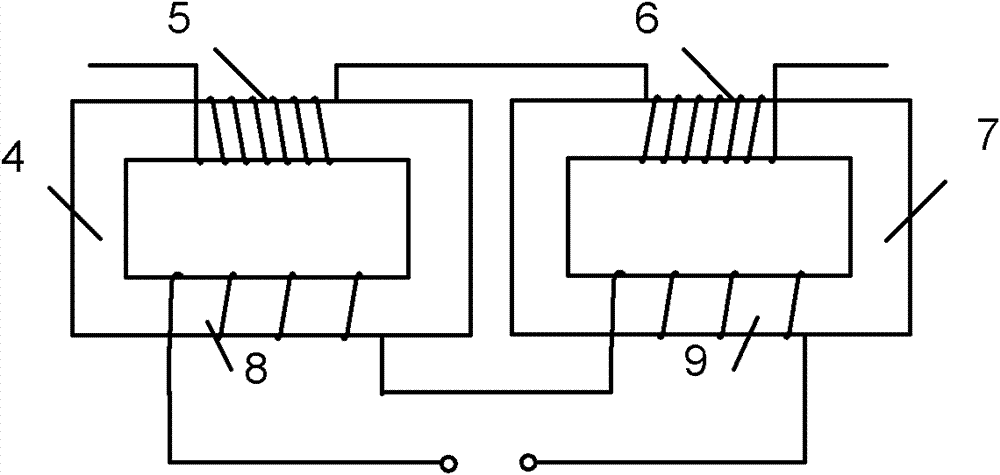

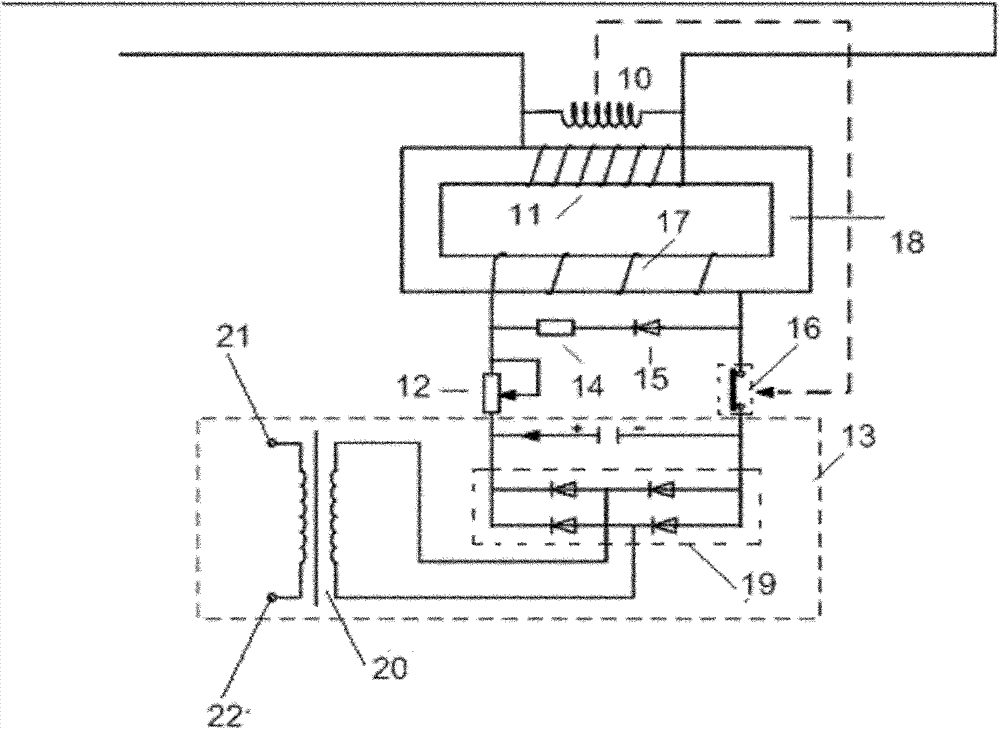

Impedance composite superconducting fault current limiter based on novel superconducting material

InactiveCN102064542AReduce manufacturing costEasy to makeSuperconducting magnets/coilsEmergency protective arrangements for limiting excess voltage/currentMagnetic tension forceVoltage source

The invention discloses an impedance composite superconducting fault current limiter based on a novel superconducting material. The superconducting fault current limiter comprises a square iron core (18), wherein an MgB2 superconducting winding (11) is arranged on the upper side of the iron core (18) and connected with a reactor (10) in parallel; a high temperature superconducting winding (17) isarranged on the lower side of the iron core (18) and connected with a direct current voltage source (13) in series; and a magnetic switch (16) and a value adjustable first resister (12) are connectedin series between the high temperature superconducting winding (17) and the direct current voltage source (13) to form a first circuit. Under the condition of satisfying the line current-carrying capacity, the superconducting fault current limiter uses the fewest superconductors, can improve the inductive impedance level in case of fault, and also can reduce voltage loss in normal operation and ensure the reliability of operation.

Owner:SOUTHEAST UNIV +1

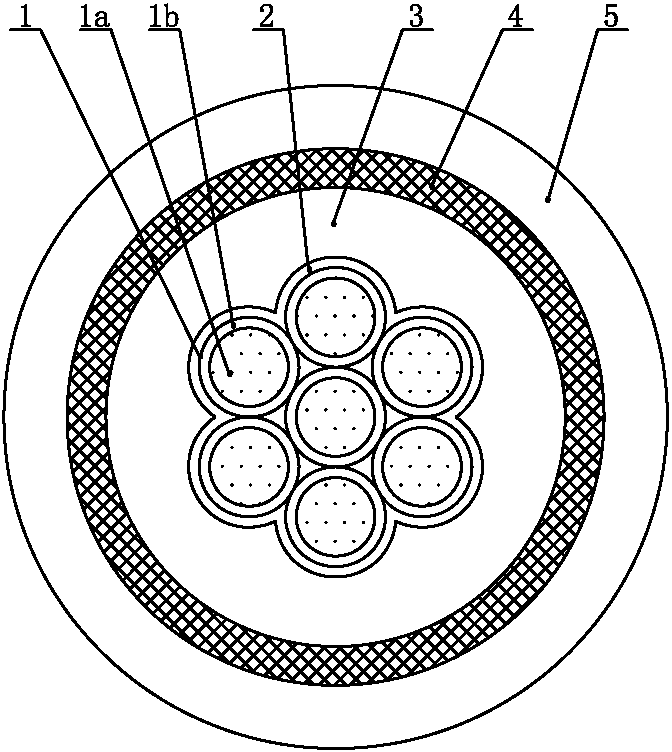

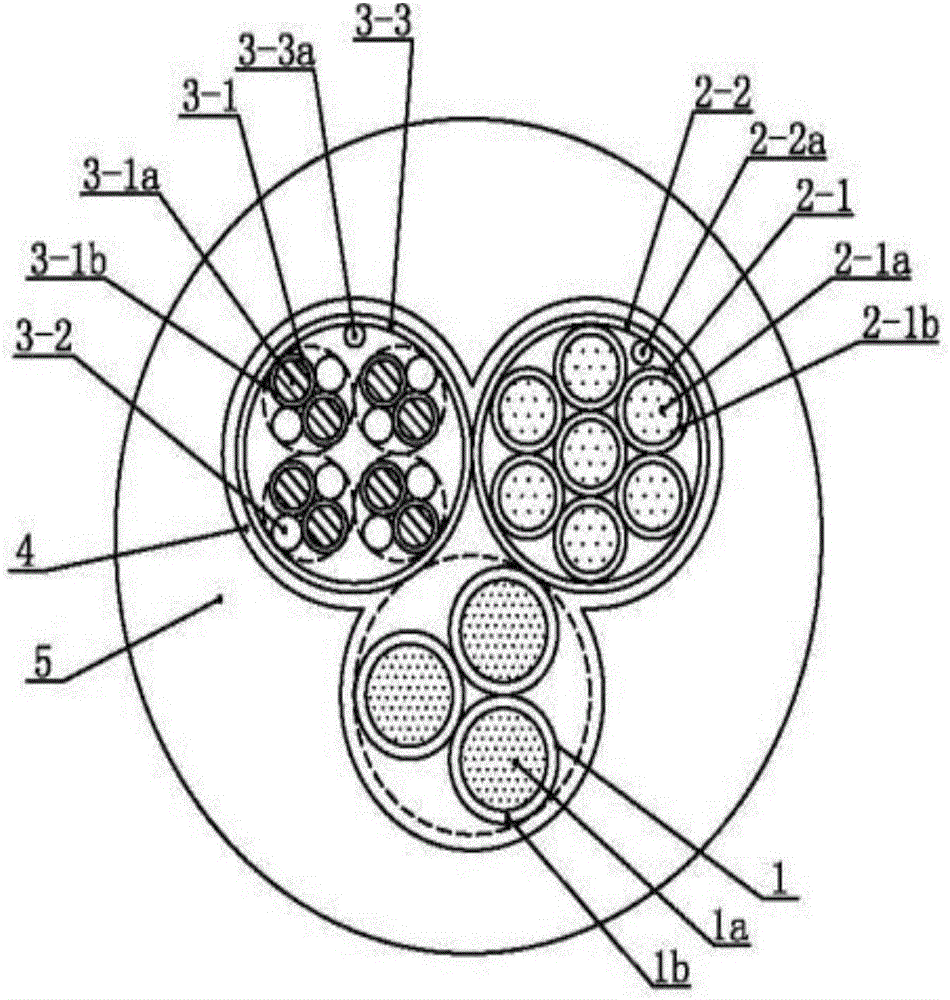

Salt corrosion resistant and twisting resistant power cable for ocean wind power and manufacturing method of power cable

ActiveCN103227008AReduce tensionEliminate voidsPower cablesInsulating conductors/cablesCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant power cable for ocean wind power and a manufacturing method of the power cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a power cable insulated core; a plurality of power cable insulated cores are mutually stranded to form a power cable core; the power cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The power cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the power cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the power cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

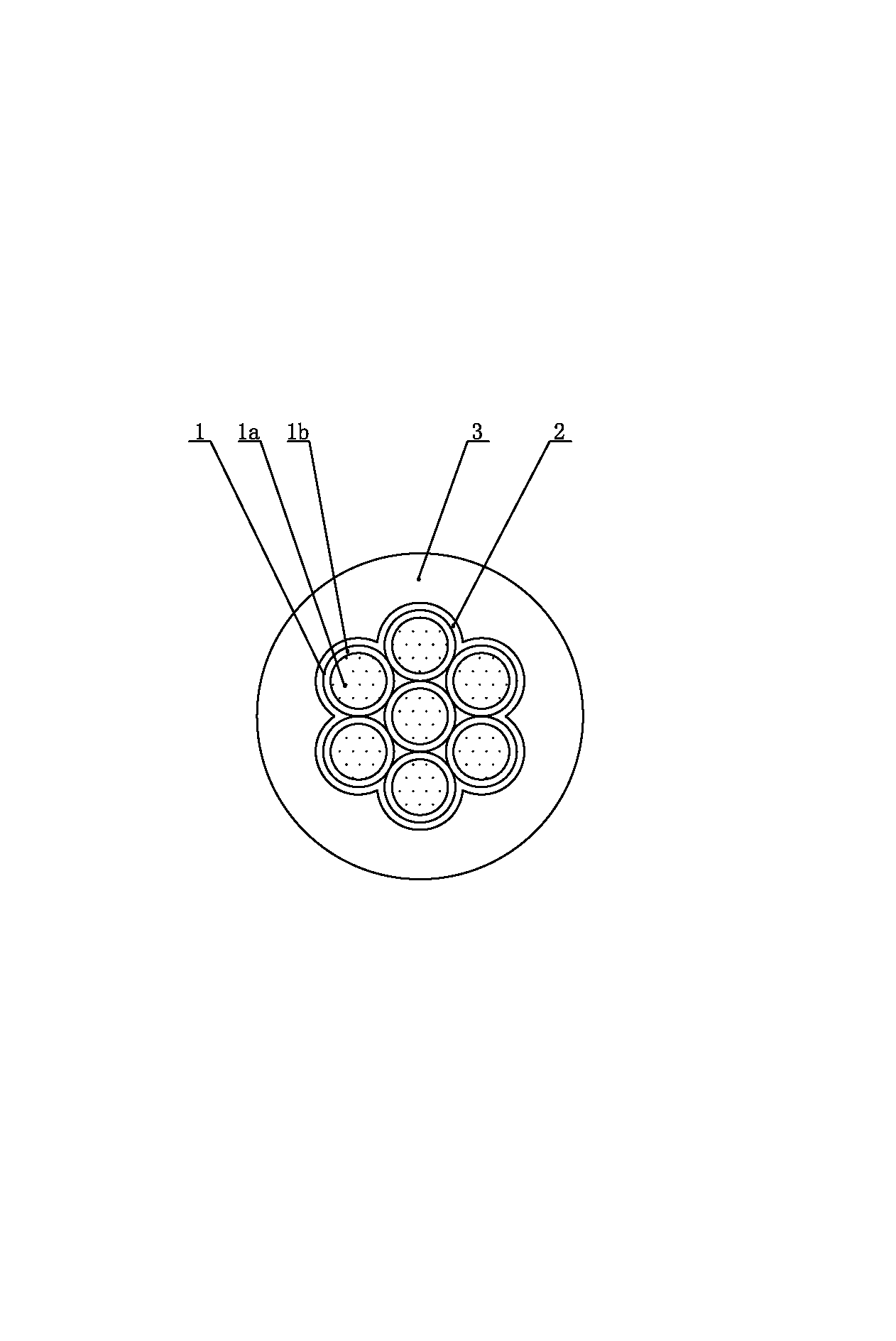

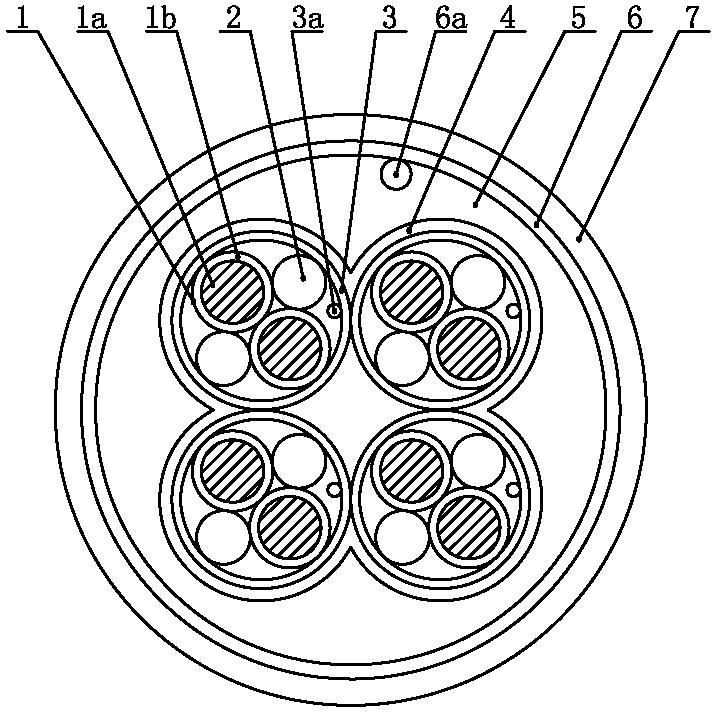

Double-shielded instrument cable for flame-resistant and fire-resistant ship and manufacture method thereof

ActiveCN103187126AIncrease working temperatureEliminate voidsInsulated cablesInsulated conductorsFiberCopper conductor

The invention relates to a double-shielded instrument cable for a flame-resistant and fire-resistant ship and a manufacture method of the double-shielded instrument cable. The periphery of a twisted copper conductor is extruded and packed with a flame-resistant and fire-resistant ethylene propylene rubber insulating layer to form insulated cable cores, the insulated cable cores are twisted with one another two by two to form a twisted conductor pair, a gap of each twisted conductor pair is filled with a flame-resistant non-absorbent fiber filling core, and the periphery of each set of the twisted conductor pairs is warped with twisted conductor pair copper foil shield layers to form pair twist sets; and the plurality of sets of pair twist sets are twisted with one another to form a cable core, and the periphery of the cable core is sequentially packed with a low-intensity non-woven fabric lengthways-packed layer, an inner jacket, a cable core copper foil shield layer, an armor weaving layer and an outer jacket. The low-intensity non-woven fabric lengthways-packed layer is completely matched with the shape of the insulated cable core, so that gaps between the low-intensity non-woven fabric lengthways-packed layer and the insulated cable core can be eliminated, and the flame can not inwards extend conveniently; and the non-stickiness between the inner jacket and the insulated cable core can be guaranteed, and the insulated cable core can be hardly damaged when the jackets are stripped during construction.

Owner:嘉兴君宏汽车配件有限公司

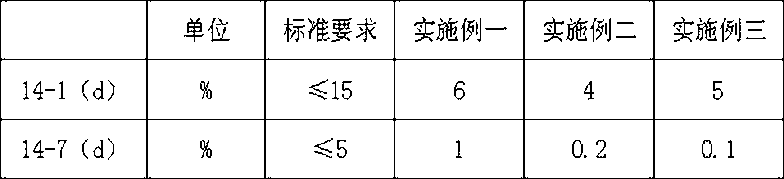

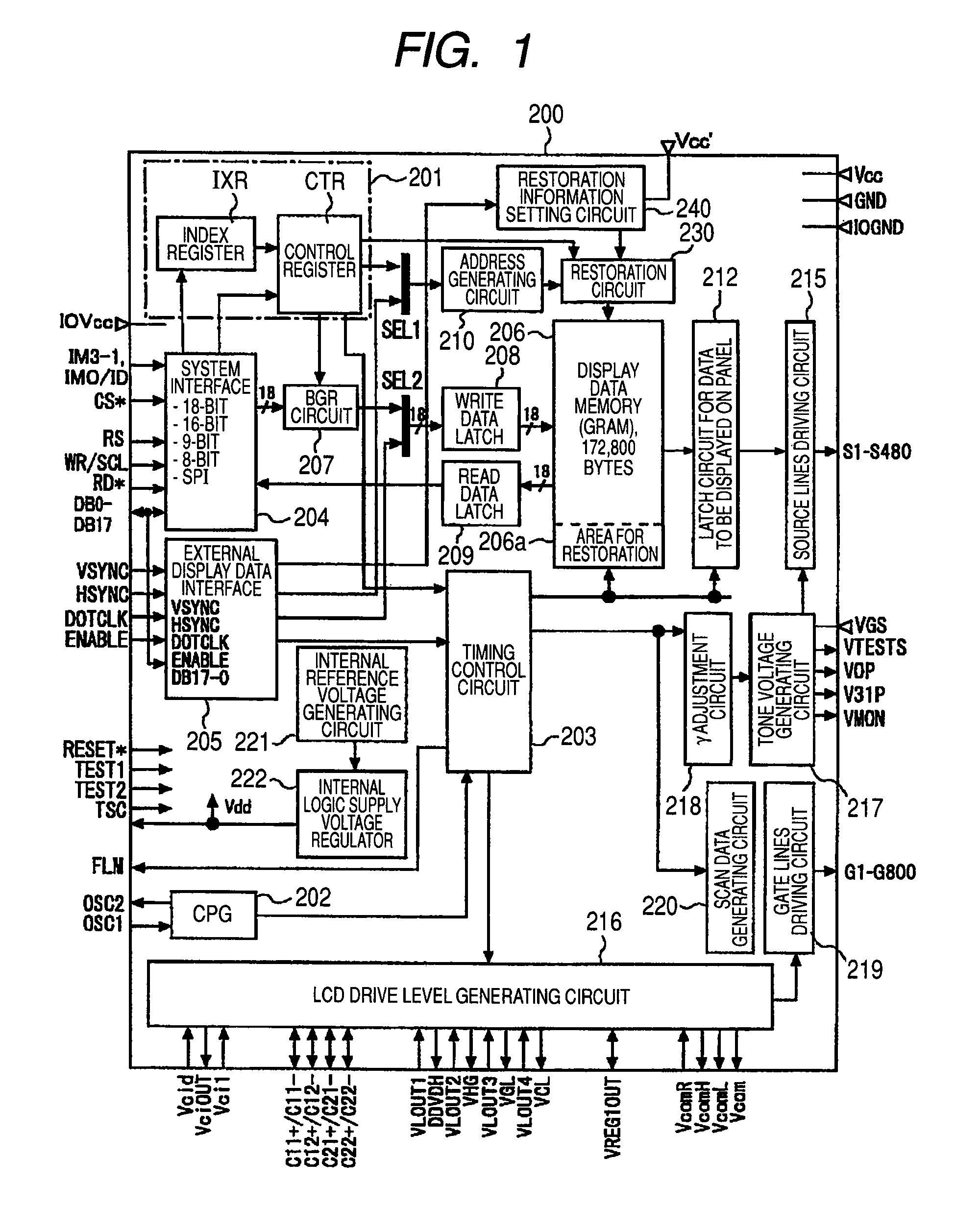

Semiconductor integrated circuit device for display controller

ActiveUS20080122855A1Increase chanceReduced current carrying capacityCathode-ray tube indicatorsImage data processing detailsHigh rateStorage cell

The semiconductor IC device for display control disclosed herein aims to achieve a higher rate of memory access cycles without enhancing the current carrying capability of the memory device. The IC device is provided with a memory cell array capable to store display data, peripheral circuits to enable writing and reading of display data, and a control circuit which is able to control read and write operations from / to the memory cell array. The memory cell array comprises a plurality of memory blocks. The control circuit comprises a control logic which enables parallel processing of write operations in such a manner that, before completion of writing of data to one of the memory blocks, writing of data to another memory block is started. Write cycles are shortened by the parallel processing of write operations.

Owner:SYNAPTICS JAPAN GK

Field effect transistor with enhanced insulator structure

ActiveUS7279697B2Improve current carrying capacityLower resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesIn planeField-effect transistor

Owner:INFINEON TECH AMERICAS CORP

Method for preparing superconducting layer of high-temperature superconducting coated conductor by depositing fluorine-free chemical solution

InactiveCN101857429AReduced current carrying capacityStable stateSuperconductors/hyperconductorsSuperconductor devicesElectrical conductorPhase formation

The invention discloses a method for preparing a superconducting layer of a high-temperature superconducting coated conductor by depositing fluorine-free chemical solution. The method comprises the following steps of: a, preparation of precursor solution; b, the preparation of coating colloid; c, coating and drying; d, wet-type decomposition heat treatment, namely placing a substrate with a film into a tubular finance; rising the temperature to be between 100 and 150 DEG C from room temperature at the speed of 1-5DEG C / min under the protection of an argon atmosphere; introducing a mixed gas of water vapor and argon with the dew point of between 10 to 20 DEG C into the furnace to form a wet argon protective atmosphere; rising the temperature to be between 450 and 500 DEG C at the speed of 0.25 to 1.5DEG C / min; keeping the temperature for 0.5 to 2 hours; cooling to the room temperature in the argon atmosphere; and e, phase formation and heat treatment to obtain the superconducting layer. The critical current density of the superconducting layer of the high-temperature superconducting coated conductor prepared by the method is up to the same magnitude order as the that of the superconducting layer prepared by a fluorine-containing method; the superconducting layer has a high-degree biaxially texture and a flat and dense surface; and the method is easy to prepare a thicker superconducting layer and has the characteristics of low cost, simple process and suitability of large-scale industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

Salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and manufacturing method thereof

ActiveCN103187127AEliminate voidsExcellent impregnationRubber insulatorsInsulating conductors/cablesCopper conductorFiber

The invention relates to a salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and a manufacturing method thereof. A salt corrosion and torsion resisting type rubber insulating layer is uniformly extruded to wrap the peripheries of stranded copper conductors in order to form insulating wires, the insulating wires are stranded in pairs to form a stranded wire pair, the gap of the stranded wire pair is filled with a flame-retardant non-hygroscopic fiber filling core, the periphery of each group of stranded wire pair is wound with a copper foil polyester compounding belt shielding layer to form a stranded group, multiple stranded groups are mutually stranded to form a cable core, and the periphery of the cable core is wrapped with low strength non-woven fabrics, and is extruded with a protective sleeve. According to the salt corrosion and torsion resisting type shielding telecommunication cable, a longitudinal low strength non-woven fabric wrapping layer is adopted, and is completely matched with the insulating wire core in shape, so that the gap between the longitudinal low strength non-woven fabric wrapping layer and the insulating wire core is eliminated, a flame can be favorably prevented from being continuously transmitted to the inside under the combustion condition, and the humidity steeping resistance is improved. Meanwhile, the longitudinal low strength non-woven fabric wrapping layer can ensure that the protective sleeve does not adhere to the insulating wire core, and facilitates the stripping of the protective sleeve in the construction process without damages on the insulating wire core.

Owner:浙江华威设备制造有限公司

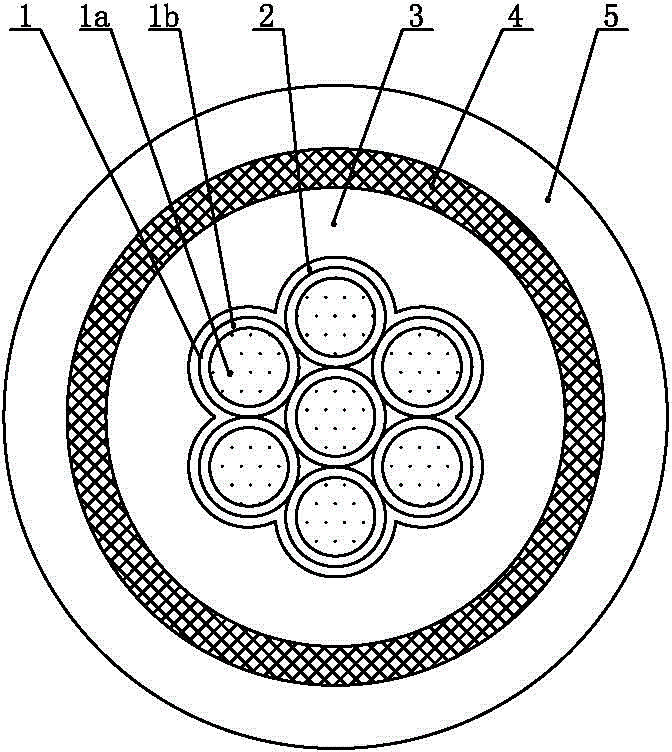

Control cable for flame-retardant fireproof boat and manufacturing method thereof

ActiveCN103226999AReduce tensionEliminate voidsInsulated cablesInsulated conductorsCopper conductorEngineering

The invention relates to a control cable for a flame-retardant fireproof boat and a manufacturing method thereof. Flame-retardant fireproof ethylene propylene rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form control cable insulated cores; a plurality of control cable insulated cores are stranded mutually to form a control cable core; the periphery of the control cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; an inner jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way; the periphery of the inner jacket is coated with an armor braid; and an outer jacket is extruded on the periphery of the armor braid in a wrapping way. The cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each control cable insulated core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the control cable insulated cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated cores are not adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:浙江华威设备制造有限公司

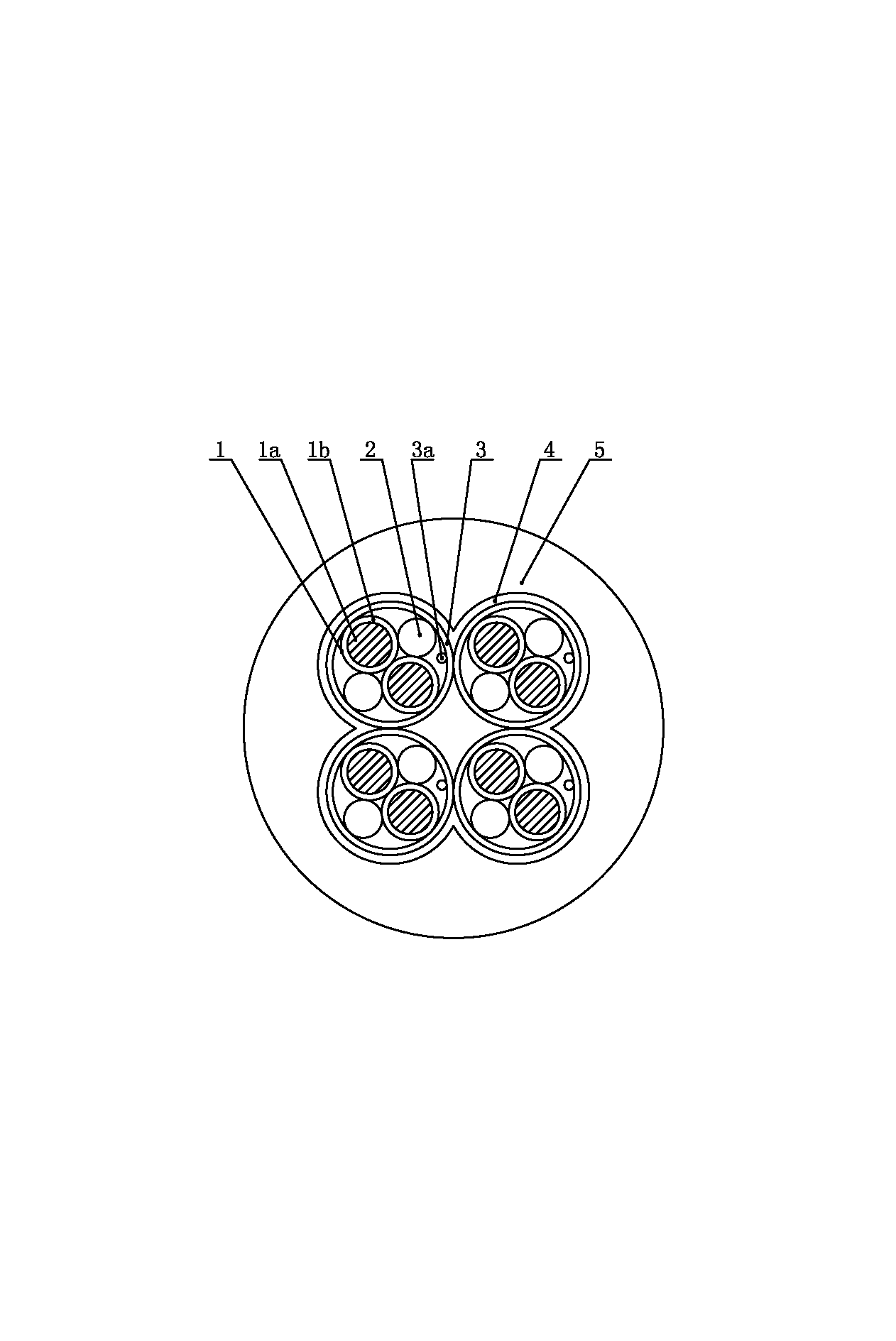

Pair-twist shielding instrument cable for flame-retardant fireproof boat and manufacturing method thereof

ActiveCN103227002AEliminate voidsEase of transmissionInsulated cablesInsulated conductorsCopper foilWoven fabric

The invention relates to a pair-twist shielding instrument cable for a flame-retardant fireproof boat and a manufacturing method thereof. Flame-retardant fireproof ethylene propylene rubber insulating layers are extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated cores; the insulated cores are stranded in pairs to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; the periphery of each group of pair-twist wire pairs is wrapped in a copper foil polyester composite belt shielding layer to form a pair-twist group; the copper foil surfaces of the copper foil polyester composite belt shielding layers are inward and tinned stranded copper-wire drainage wires are arranged inside the copper foil polyester composite belt shielding layers; a plurality of groups of pair-twist wire pairs are stranded to form a cable core; and the periphery of the cable core is sequentially coated with a low-intensity non-woven fabric longitudinally-covered layer, an inner jacket, an armor braid and an outer jacket sequentially from inside out. The low-intensity non-woven fabric longitudinally-covered layer is completely in fit with each insulated core in shape, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated cores are eliminated, and flame can be conveniently prevented from being spread inwards; and meanwhile, the inner jacket and the insulated cores are guaranteed not to be adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:嘉兴君宏光学有限公司

Salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and manufacturing method of integral shielding telecommunication cable

ActiveCN103227011AReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and a manufacturing method of the integral shielding telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; a plurality of groups of pair-twist wire pairs are stranded to form a cable core; and the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer, an inner jacket, a copper foil polyester composite belt shielding layer and an outer jacket sequentially from the inside out. The integral shielding telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the inner jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

Salt corrosion resistant and twisting resistant control cable for ocean wind power and manufacturing method of control cable

ActiveCN103227000AReduce tensionEliminate voidsRubber insulatorsInsulated cablesCopper conductorInsulation layer

The invention relates to a salt corrosion resistant and twisting resistant control cable for ocean wind power and a manufacturing method of the control cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a control cable insulated core; a plurality of control cable insulated cores are mutually stranded to form a control cable core; the control cable core is wrapped in a low-strength non-woven fabric longitudinal wrap; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The control cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the control cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the control cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

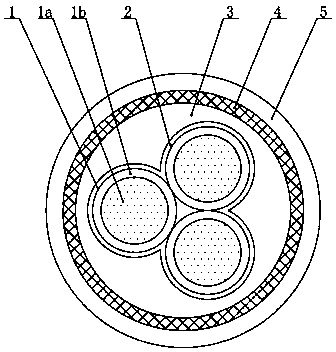

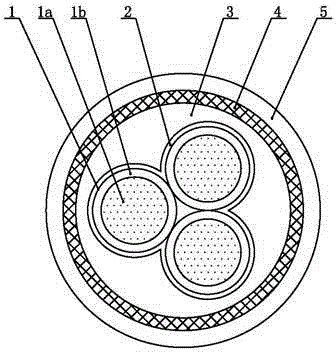

Power cable for flame-retardant fireproof boat and manufacturing method thereof

ActiveCN103227006AIncrease working temperatureEliminate voidsPower cablesInsulating conductors/cablesCopper conductorPower cable

The invention relates to a power cable for a flame-retardant fireproof boat and a manufacturing method thereof. Flame-retardant fireproof ethylene propylene rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form power cable insulated cores; a plurality of power cable insulated cores are stranded to form a power cable core; the periphery of the power cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; an inner jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way; the periphery of the inner jacket is coated with an armor braid; and an outer jacket is extruded on the periphery of the armor braid in a wrapping way. The cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each power cable insulated core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the power cable insulated cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated cores are not adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:浙江华威设备制造有限公司

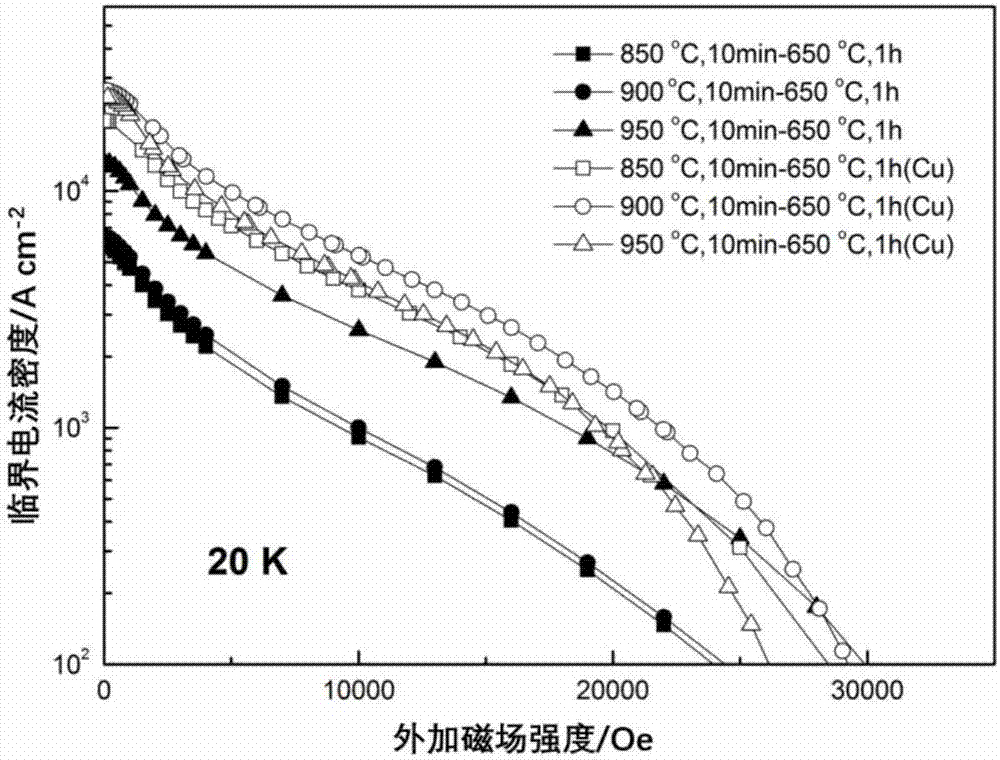

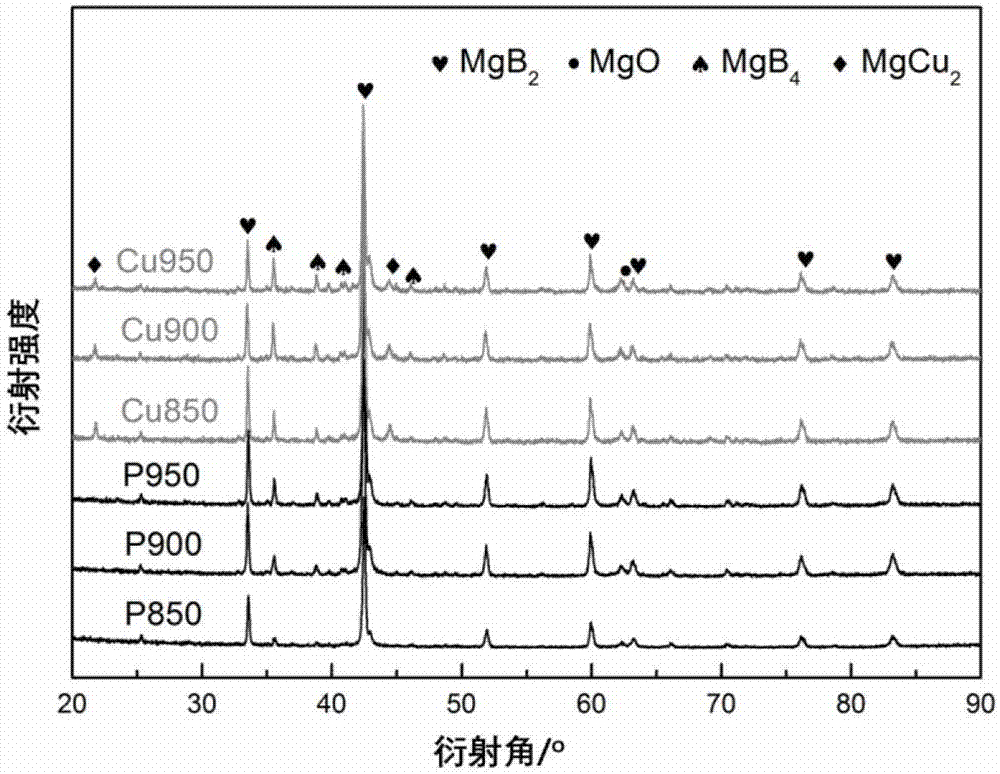

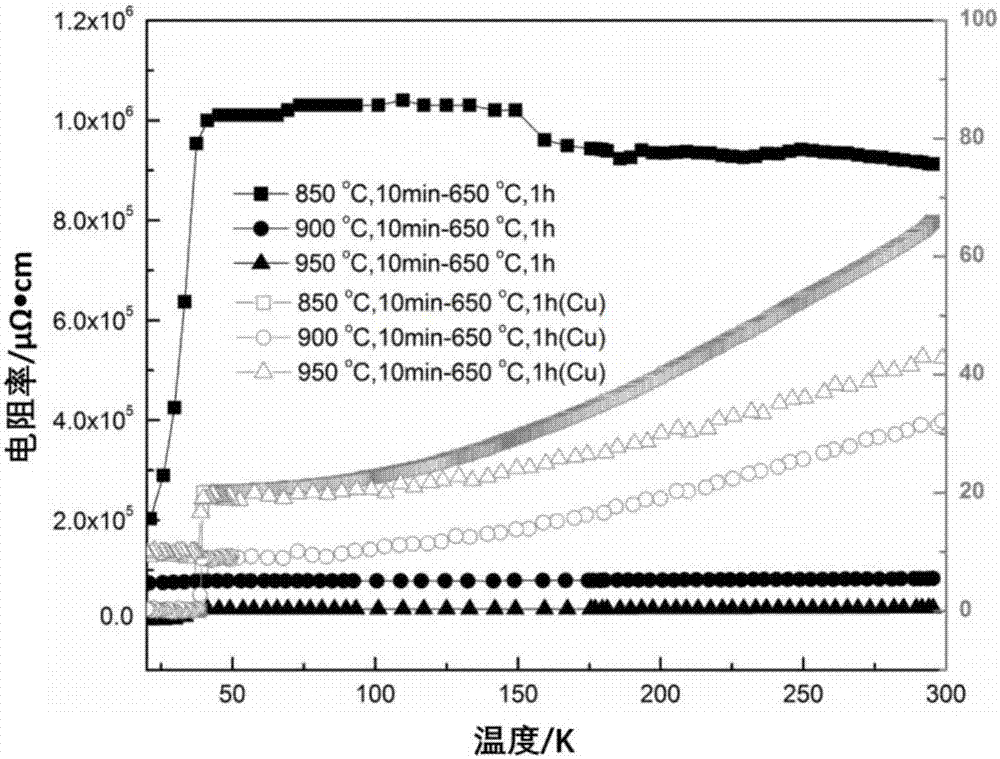

Method for pre-sintering copper-containing active magnesium diboride superconducting block

InactiveCN107244921AHigh critical transition temperatureReduced current carrying capacityArgon atmosphereMagnesium diboride

The invention belongs to a method for pre-sintering a copper-containing active magnesium diboride superconducting block. The method comprises the following steps: adding 1-5 wt% of copper powder to a precursor powder MgB2 powder, fully mixing the copper powder and the precursor powder in an agate mortar, and processing the obtained mixture under a pressure of 2-8 MPa to prepare a small cylindrical sheet; placing the small cylindrical sheet in a thermogravimetric-differential thermal analyzer, heating the small cylindrical sheet in a flowing highly-pure argon atmosphere to 800-1000 DEG C, keeping the temperature for 0-20 min, and sintering the small cylindrical sheet; and cooling the sintered small cylindrical sheet to 600-700 DEG C, keeping the temperature for 0-3 h, and cooling the cooled small cylindrical sheet to room temperature according to a speed of 10-40 DEG C / min. The above prepared MgB2 superconducting material with a high current carrier is obtained through introducing a copper adding technology to a pre-sintering technology, has a stable structure and a high critical conversion temperature, and is better than all MgB2 superconducting blocks prepared through the pre-sintering technology in the current carrying ability; and the preparation method ahs the advantages of simplicity, high controllability, no pollution, wide sources of raw materials, low preparation cost, and wide engineering application and promotion prospect.

Owner:TIANJIN UNIV

Salt corrosion resistant and twisting resistant composite cable for ocean wind power and manufacturing method of composite cable

ActiveCN103227007AReduce tensionEliminate voidsRubber insulatorsPower cables with screens/conductive layersElectricityCombustion

The invention relates to a salt corrosion resistant and twisting resistant composite cable for ocean wind power and a manufacturing method of the composite cable. Power cable insulation layers, control cable insulation layers and meter cable insulation layers are all salt corrosion resistant and twisting resistant rubber insulation layers and are mutually stranded to form a composite cable core; the composite cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The composite cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

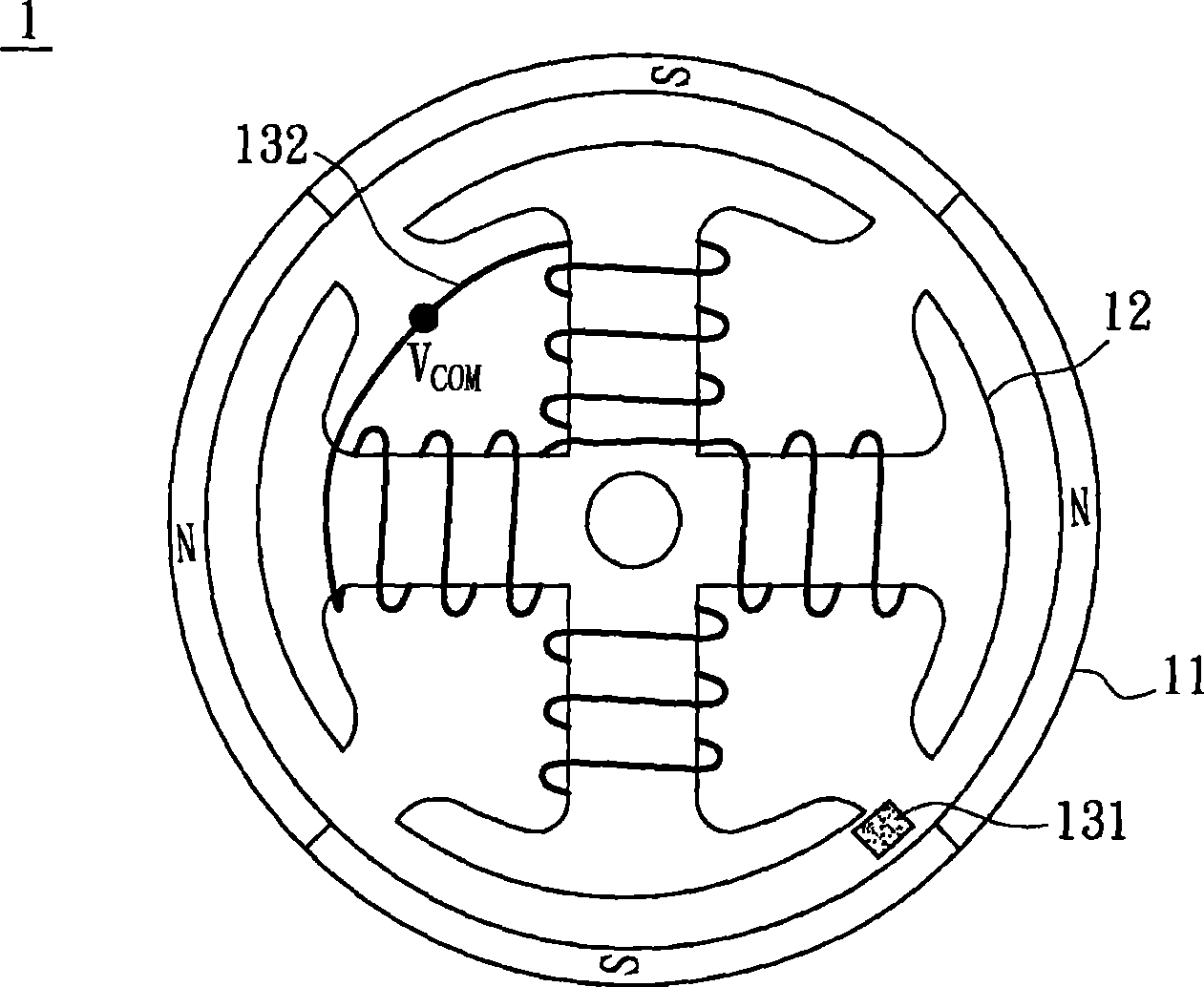

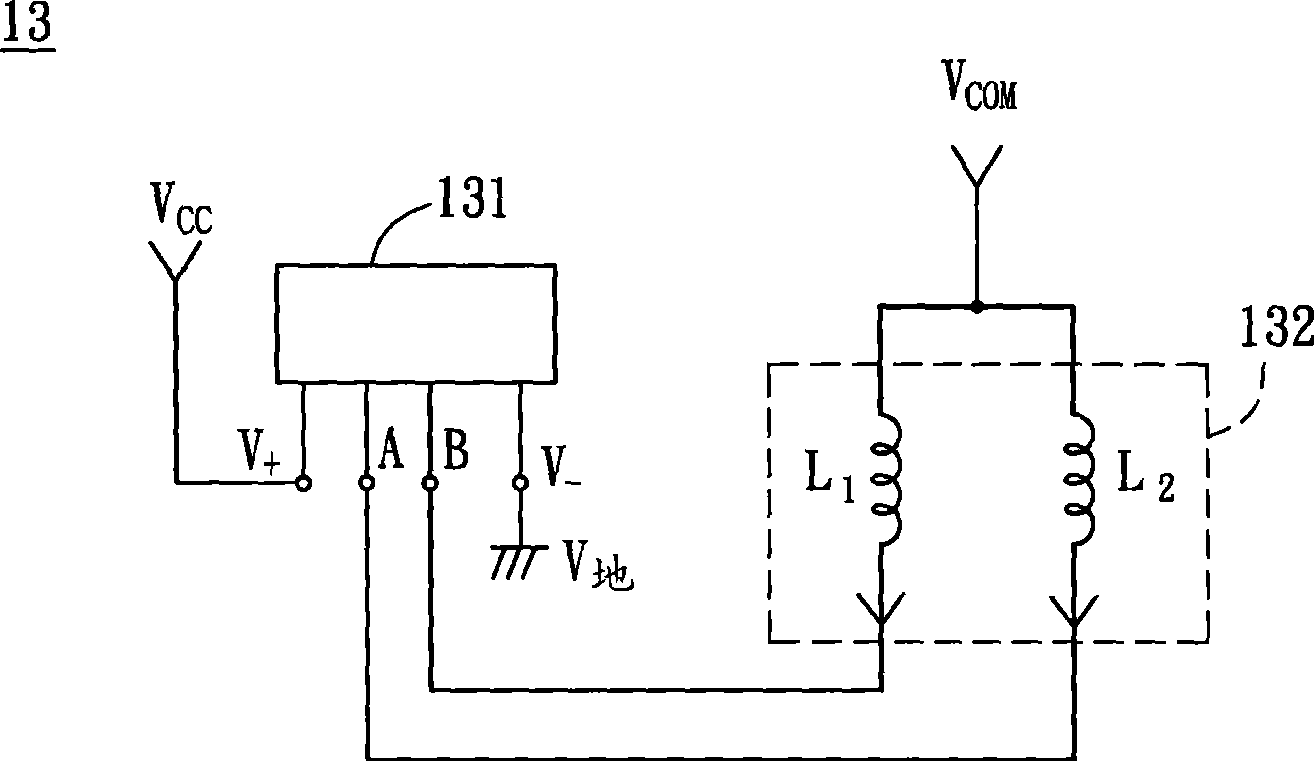

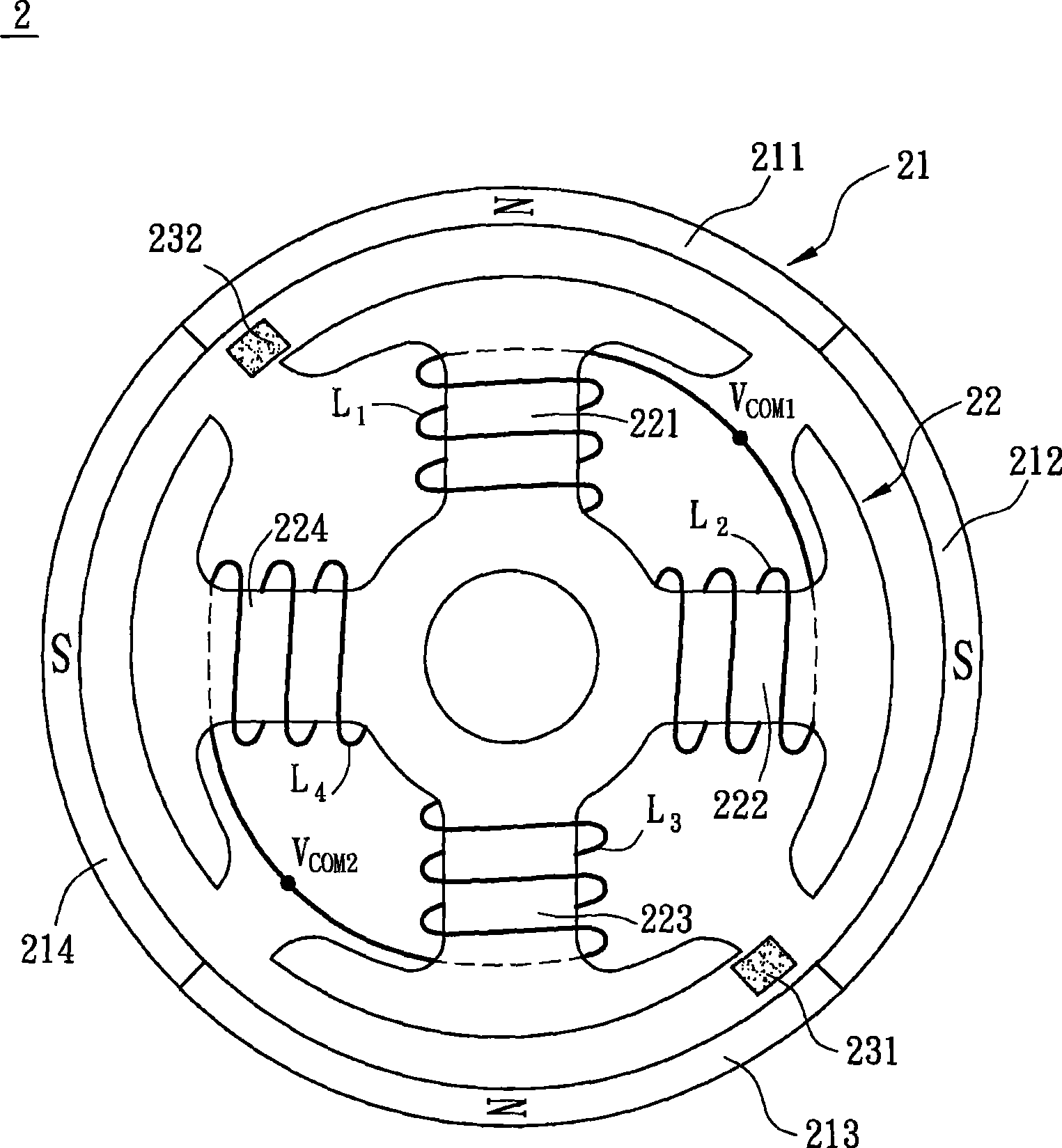

Motor and control circuit thereof

ActiveCN101291133BReduced current carrying capacityAC motor controlStructural associationEngineeringControl circuit

Owner:DELTA ELECTRONICS INC

Salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and manufacturing method of telecommunication cable

ActiveCN103227009AEliminate voidsEase of transmissionRubber insulatorsInsulating conductors/cablesEngineeringElectrical conductor

The invention relates to a salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and a manufacturing method of the telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; pair-twist wire pairs adopt different stranding pitches, a plurality of groups of pair-twist wire pairs are stranded to form a cable core; the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; and a jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way. The telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the jacket is stripped during construction.

Owner:嘉兴君宏光学有限公司

Impedance composite superconducting fault current limiter based on novel superconducting material

InactiveCN102064542BReduce manufacturing costEasy to makeSuperconducting magnets/coilsEmergency protective arrangements for limiting excess voltage/currentElectrical resistance and conductanceCarrying capacity

Owner:SOUTHEAST UNIV +1

Manufacturing method of composite cable

InactiveCN106548823AIncrease working temperatureEliminate voidsInsulated cablesCable/conductor manufacturePower cableEngineering

The invention relates to a manufacturing method of a composite cable. A power cable core, a control cable core and an instrument cable core are mutually twisted to form the composite cable; the periphery of the composite cable is coated with a low-intensity non-woven fabric longitudinal covering; an inner sheath is extruded on the periphery of the low-intensity non-woven fabric longitudinal covering; the periphery of the inner sheath is coated with an armored braid; and an outer sheath is extruded on the periphery of the armored braid. The low-intensity non-woven fabric longitudinal covering is completely coincided with the shape of an insulated conductor so as to eliminate a gap between the low-intensity non-woven fabric longitudinal covering and the insulated conductor and facilitate preventing inward spread of flame; and meanwhile, the inner sheath and the insulated conductor are guaranteed not to be adhered so as to facilitate not damaging the insulated conductor when the sheaths are stripped off in the construction process.

Owner:重庆三峡电线电缆科技股份有限公司

Salt corrosion-resistant and torsion-resistant composite cable and manufacturing method thereof

InactiveCN106653152AReduce tensionEliminate voidsRubber insulatorsPower cables including communication wiresInsulation layerCombustion

The invention relates to a salt corrosion-resistant and torsion-resistant composite cable and a manufacturing method thereof. A power cable insulation layer, a control cable insulation layer and an instrument cable insulation layer are salt corrosion-resistant and torsion-resistant rubber insulation layers. A power cable core, a control cable core and an instrument cable core are twisted into a composite core. The periphery of the composite core is coated with a low-intensity non-woven longitudinal cladding. A sheath is arranged at the periphery of the low-intensity non-woven longitudinal cladding by means of extrusion. The low-intensity non-woven longitudinal cladding which has a shape completely consistent with the appearance of an insulated wire core is adopted, and the gap between the low-intensity non-woven longitudinal cladding and the insulated wire core is eliminated, so that flame can be prevented from spreading to the inside under the condition of combustion, and the resistance to moisture impregnation can be enhanced. Moreover, the low-intensity non-woven longitudinal cladding can ensure that the sheath and the insulated wire core are not adhered together, and the insulated wire core is not damaged when the sheath is tripped in the process of construction.

Owner:重庆三峡电线电缆科技股份有限公司

Flame-retardant fire-resistant marine control cable and manufacturing method thereof

ActiveCN103226999BIncrease working temperatureEliminate voidsInsulated cablesInsulated conductorsCopper conductorEngineering

The invention relates to a control cable for a flame-retardant fireproof boat and a manufacturing method thereof. Flame-retardant fireproof ethylene propylene rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form control cable insulated cores; a plurality of control cable insulated cores are stranded mutually to form a control cable core; the periphery of the control cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; an inner jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way; the periphery of the inner jacket is coated with an armor braid; and an outer jacket is extruded on the periphery of the armor braid in a wrapping way. The cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each control cable insulated core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the control cable insulated cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated cores are not adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:浙江华威设备制造有限公司

Unshielded instrument cable for flame-retardant fireproof boat and manufacturing method thereof

ActiveCN103227001AReduce tensionEliminate voidsInsulated cablesInsulated conductorsCopper conductorFiber

The invention relates to an unshielded instrument cable for a flame-retardant fireproof boat and a manufacturing method thereof. Flame-retardant fireproof ethylene propylene rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated cores; the insulated cores are stranded in pairs to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; pair-twist wire pairs adopt different stranding pitches; a plurality of groups of pair-twist wire pairs are stranded to form a cable core; the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; an inner jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way; the periphery of the inner jacket is coated with an armor braid; and an outer jacket is extruded on the periphery of the armor braid in a wrapping way. The cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated cores are eliminated, and flame can be conveniently prevented from being spread inwards under the burning condition; and meanwhile, the inner jacket and the insulated cores can be guaranteed not to be adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:浙江华威设备制造有限公司

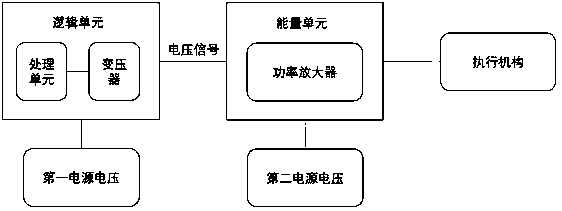

Device for supplying voltage to motor vehicle control equipment

PendingCN107650840AHigh operating costsLow running costElectric/fluid circuitMobile vehicleElectrical battery

Disclosed is a device for supplying voltage to motor vehicle control equipment. The device includes a logical unit used for processing information, an energy unit used for driving an actuator mechanism and a voltage supply system. The logic unit and the energy unit are individually connected with power supply voltage. A switch is arranged between the logical unit and the power supply voltage connected with the logical unit, and the operating cost of the control equipment is reduced. A specified signal is output to the energy unit to drive the actuator mechanism, it is ensured that the energy unit and the actuator mechanism are in a static state when a motor vehicle stops running, excessive discharge of a motor vehicle battery is avoided to improve the service life of the motor vehicle battery, and the device for supplying the voltage to the motor vehicle control equipment has the advantages of being convenient to design, simple in structure, low in cost and simple and easy to control.

Owner:佟林阳

Salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and manufacturing method of communication cable

ActiveCN103227012AReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorInsulation layer

The invention relates to a salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and a manufacturing method of the communication cable. Each stranded copper conductor is wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form an insulated core; each two insulated cores are stranded to form a twisted pair of which the gaps are filled with fillers; each twisted pair is wrapped in a twisted pair copper foil shielding layer to form a twisted-pair group; the twisted-pair groups are mutually stranded to form a cable core; and the cable core is wrapped in a low-strength non-woven fabric longitudinal wrap, an inner sheath, a cable core copper foil shielding layer and an outer sheath in sequence from inside to outside. The communication cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheaths are not stuck to the insulated cores, and provides convenience for stripping the sheathes in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Flame-retardant and fire-resistant marine power cable and manufacturing method thereof

ActiveCN103227006BIncrease working temperatureEliminate voidsPower cablesInsulating conductors/cablesCopper conductorPower cable

The invention relates to a power cable for a flame-retardant fireproof boat and a manufacturing method thereof. Flame-retardant fireproof ethylene propylene rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form power cable insulated cores; a plurality of power cable insulated cores are stranded to form a power cable core; the periphery of the power cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; an inner jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way; the periphery of the inner jacket is coated with an armor braid; and an outer jacket is extruded on the periphery of the armor braid in a wrapping way. The cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each power cable insulated core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the power cable insulated cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated cores are not adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:浙江华威设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com