Unshielded instrument cable for flame-retardant fireproof boat and manufacturing method thereof

A flame-retardant and fire-resistant, instrument cable technology, used in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc. Eliminates voids, facilitates stretch transfer, enhances impregnation against moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

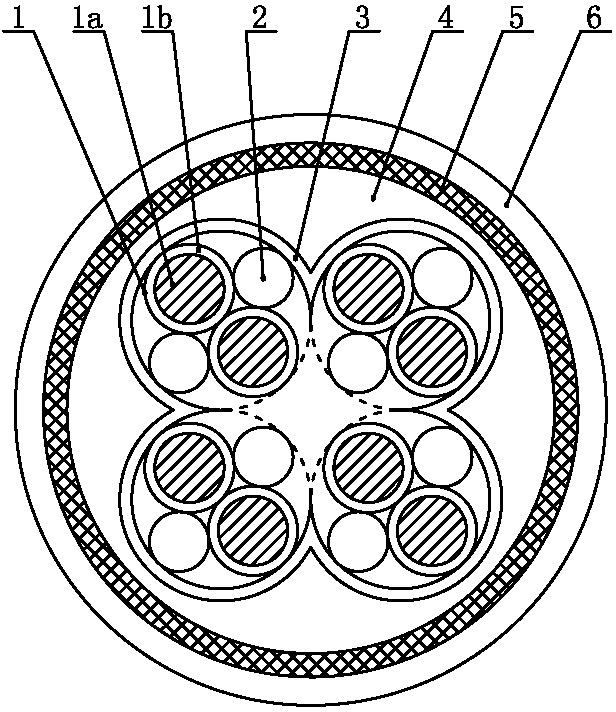

[0023] Such as figure 1 As shown, the flame-retardant and fire-resistant marine unshielded instrument cable of the present invention includes the following steps in turn: uniformly extruding a flame-retardant and fire-resistant ethylene-propylene rubber insulating layer 1b on the outer periphery of the stranded copper conductor 1a to form an insulating core 1, and the insulating core 1 is two Two pairs of twisted wires are twisted to form a pair of twisted wires, and the gap between the pair of twisted wires is filled with a flame-retardant non-hygroscopic fiber core 2. Each pair of twisted wires adopts a different twisting pitch, and multiple pairs of twisted wires are twisted Compose the cable core, then wrap the low-strength non-woven longitudinal cladding 3 on the outer periphery of the cable core, extrude the inner sheath 4 on the outer periphery of the low-strength non-woven longitudinal cladding 3, and braid the armor on the outer periphery of the inner sheath 4 Dress t...

Embodiment 2

[0028] Such as figure 1 As shown, the flame-retardant and fire-resistant marine unshielded instrument cable of the present invention includes the following steps in turn: uniformly extruding a flame-retardant and fire-resistant ethylene-propylene rubber insulating layer 1b on the outer periphery of the stranded copper conductor 1a to form an insulating core 1, and the insulating core 1 is two Two pairs of twisted wires are twisted to form a pair of twisted wires, and the gap between the pair of twisted wires is filled with a flame-retardant non-hygroscopic fiber core 2. Each pair of twisted wires adopts a different twisting pitch, and multiple pairs of twisted wires are twisted Compose the cable core, then wrap the low-strength non-woven longitudinal cladding 3 on the outer periphery of the cable core, extrude the inner sheath 4 on the outer periphery of the low-strength non-woven longitudinal cladding 3, and braid the armor on the outer periphery of the inner sheath 4 Dress t...

Embodiment 3

[0033] Such as figure 1 As shown, the flame-retardant and fire-resistant marine unshielded instrument cable of the present invention includes the following steps in turn: uniformly extruding a flame-retardant and fire-resistant ethylene-propylene rubber insulating layer 1b on the outer periphery of the stranded copper conductor 1a to form an insulating core 1, and the insulating core 1 is two Two pairs of twisted wires are twisted to form a pair of twisted wires, and the gap between the pair of twisted wires is filled with a flame-retardant non-hygroscopic fiber core 2. Each pair of twisted wires adopts a different twisting pitch, and multiple pairs of twisted wires are twisted Compose the cable core, then wrap the low-strength non-woven longitudinal cladding 3 on the outer periphery of the cable core, extrude the inner sheath 4 on the outer periphery of the low-strength non-woven longitudinal cladding 3, and braid the armor on the outer periphery of the inner sheath 4 Dress t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com