Patents

Literature

141results about How to "Maintain purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

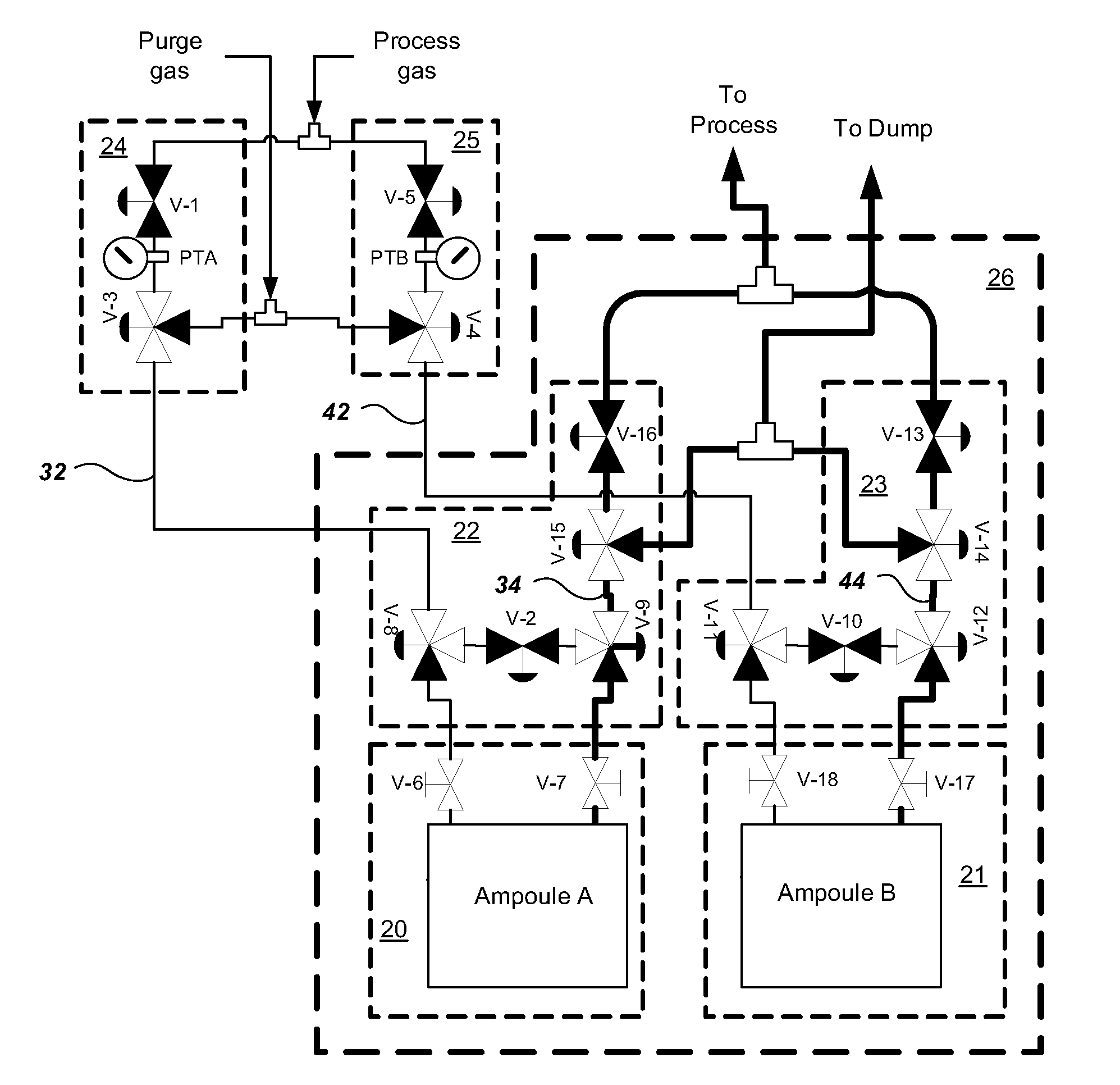

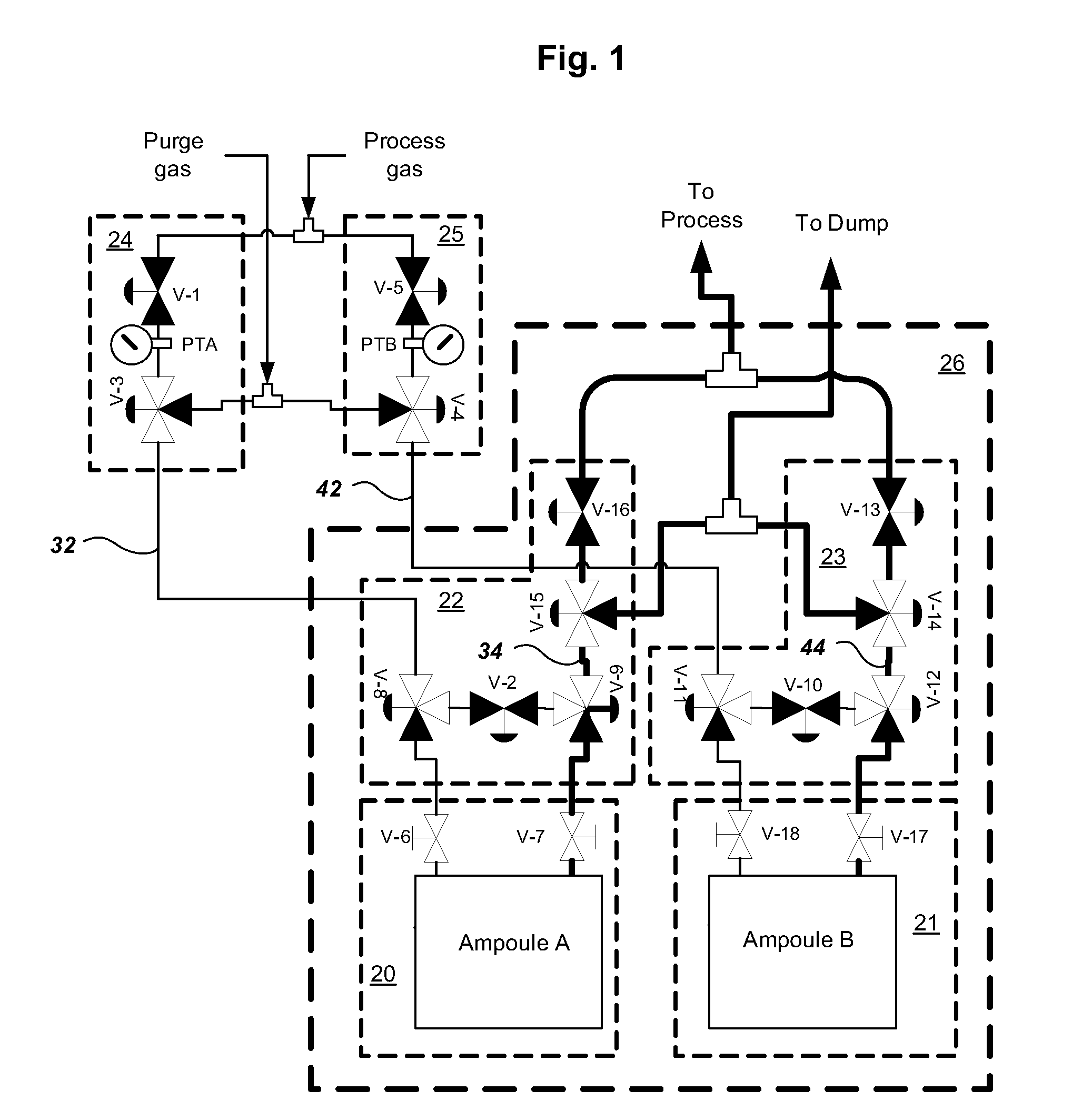

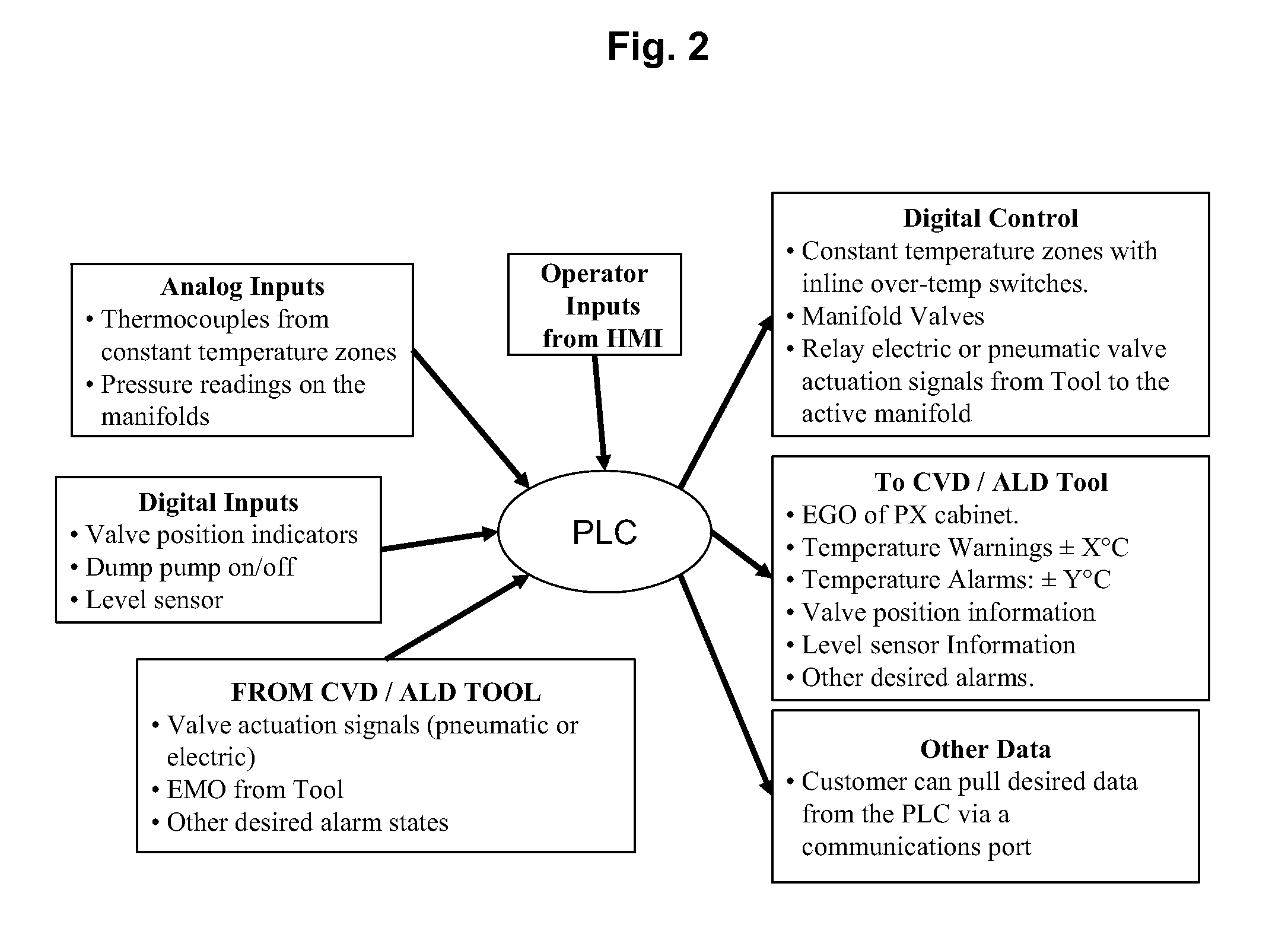

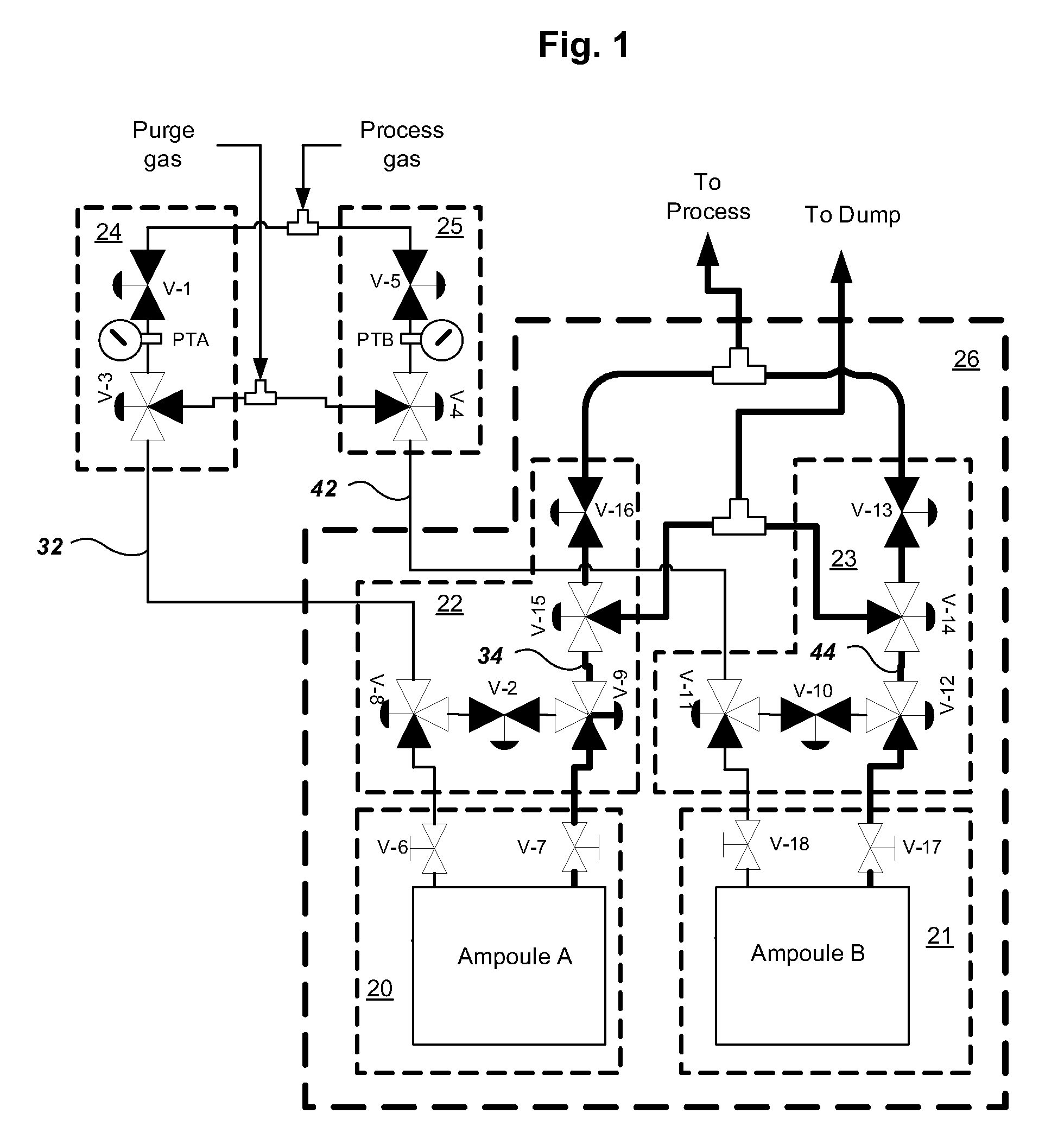

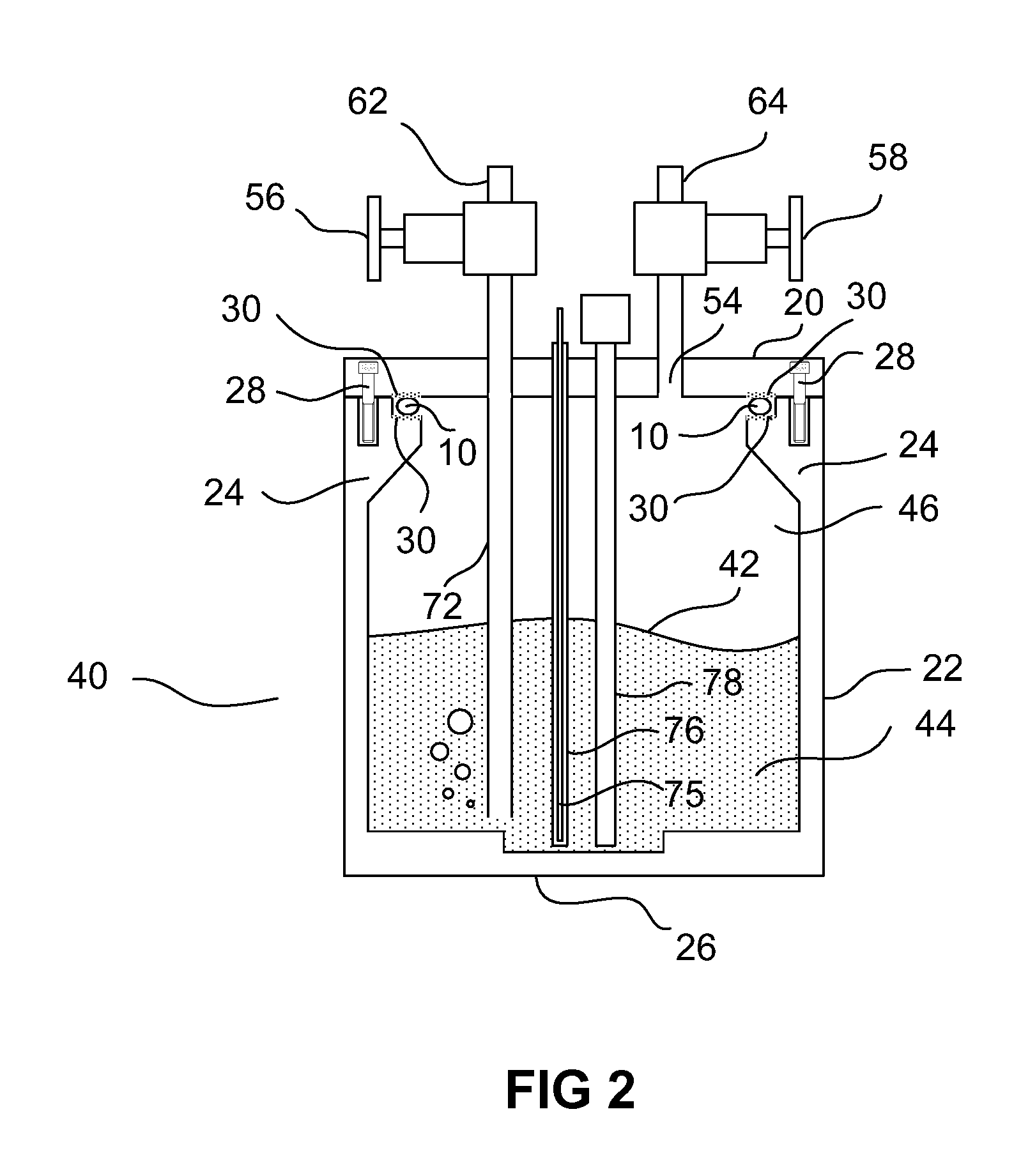

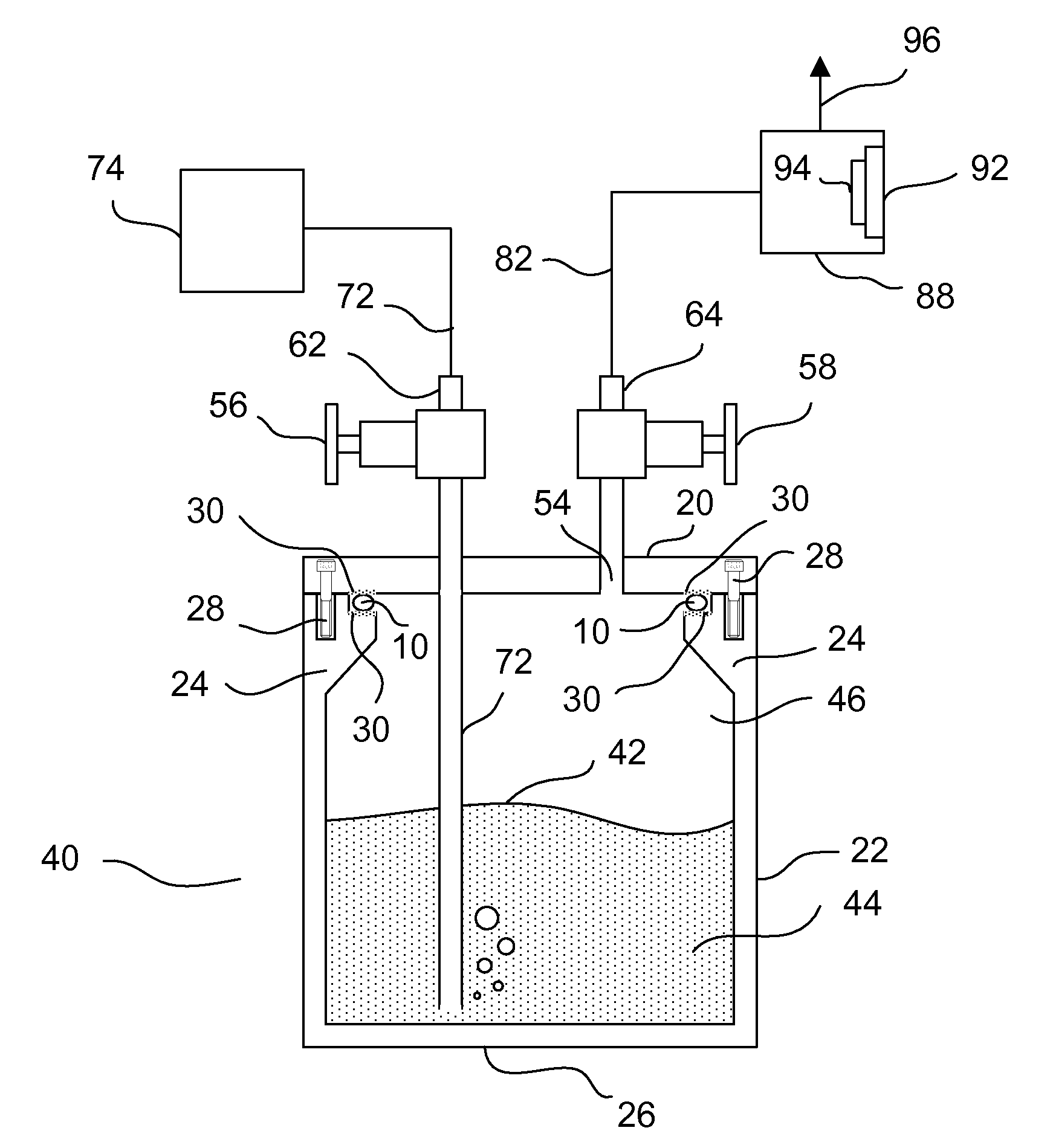

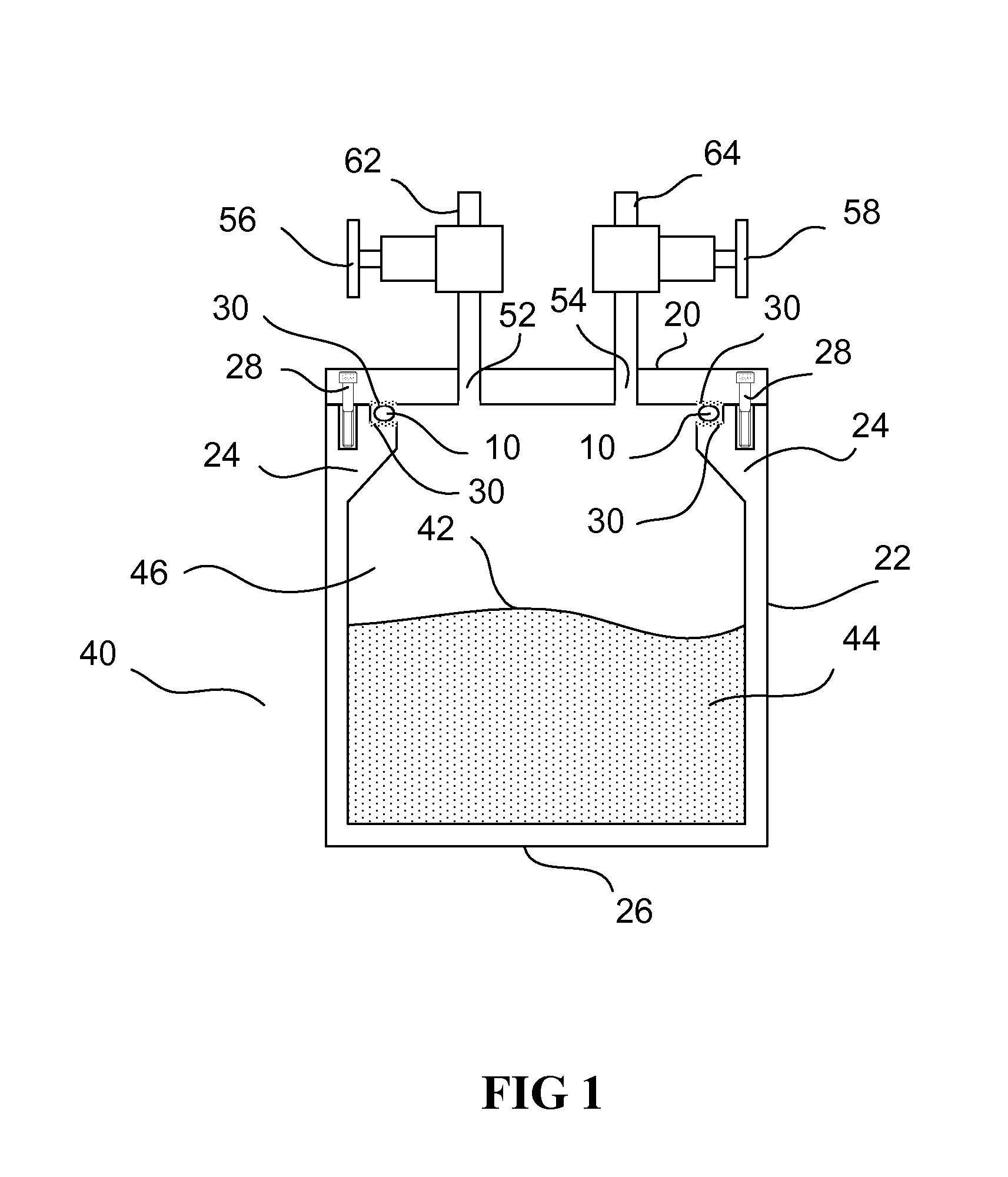

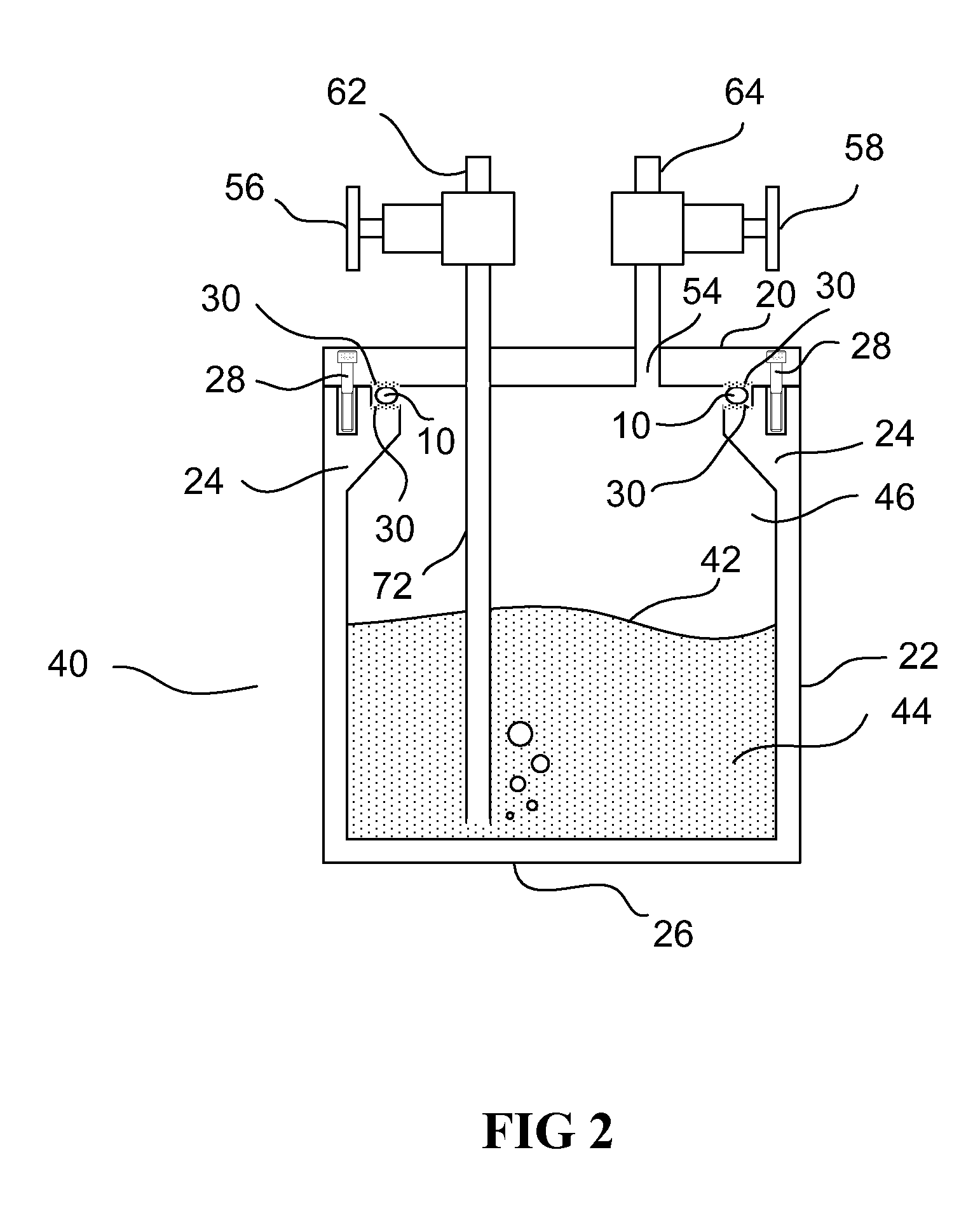

Multiple ampoule delivery systems

InactiveUS20090211525A1Easy to useReduce wasteLiquid surface applicatorsPipeline systemsSemiconductor materialsDelivery system

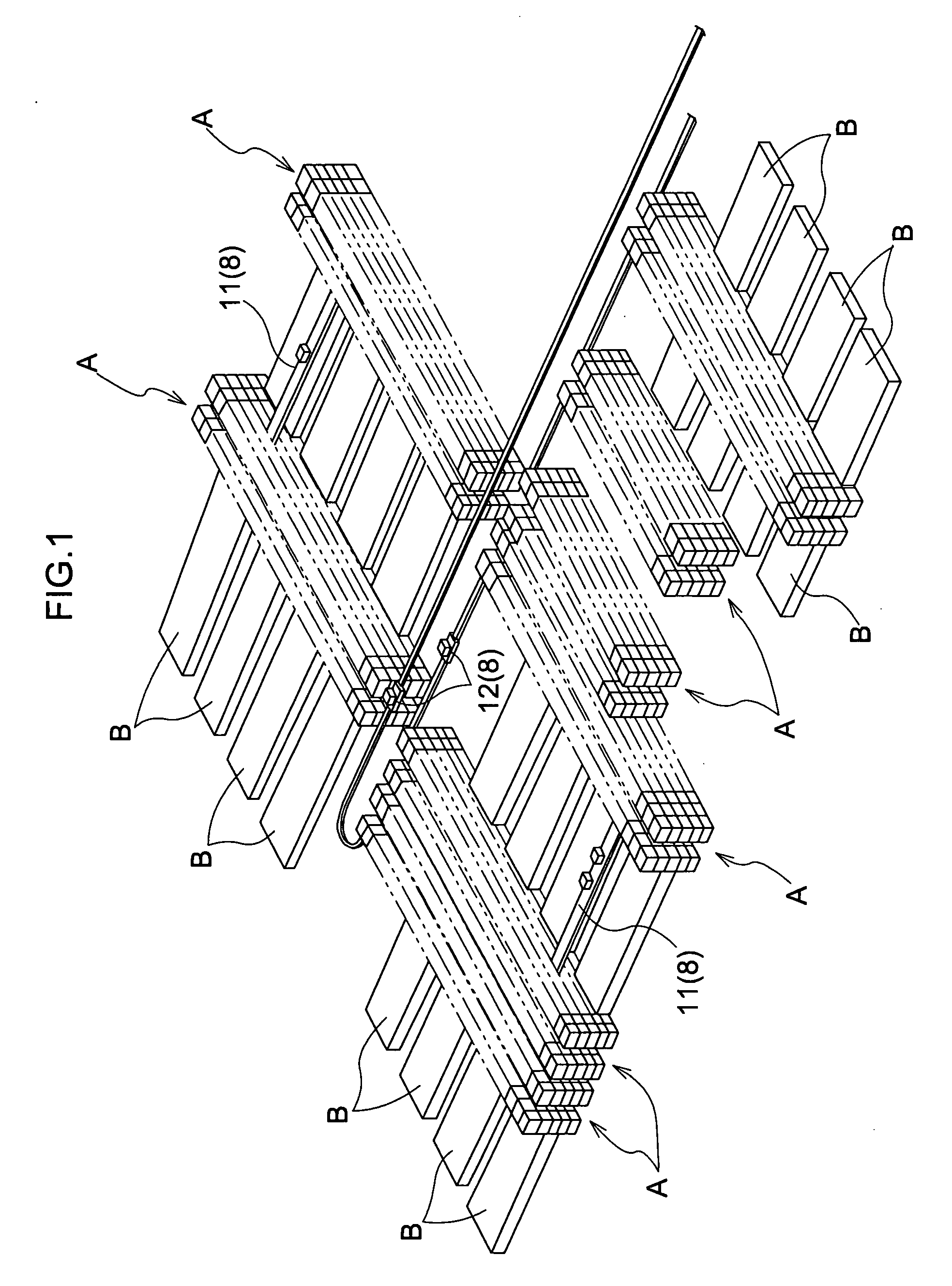

This invention relates to an integrated vapor or liquid phase reagent dispensing apparatus having a plurality of vessels and a plurality of carrier or inert gas feed / vapor or liquid phase reagent delivery manifolds, that may be used for continuously dispensing vapor or liquid phase reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

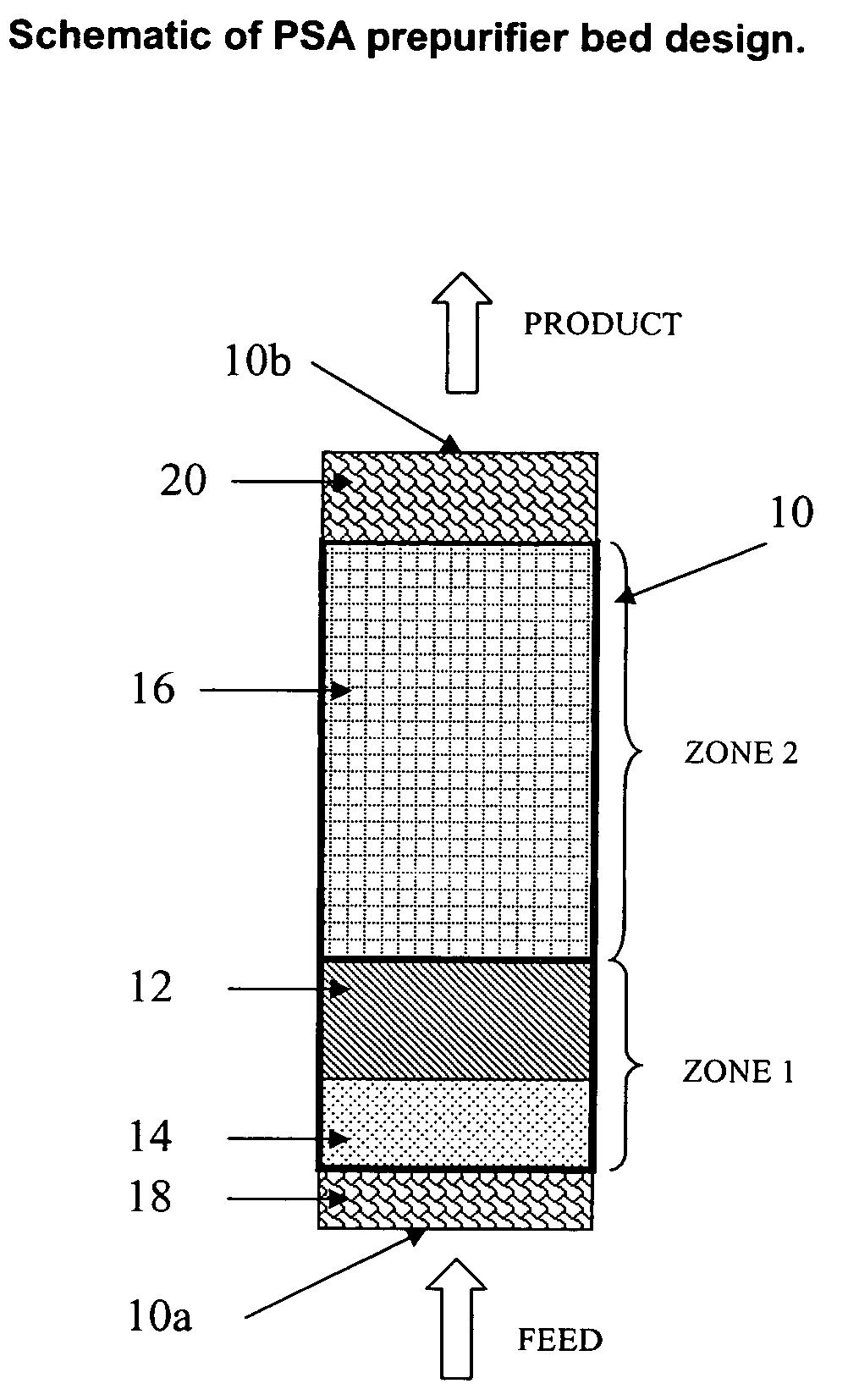

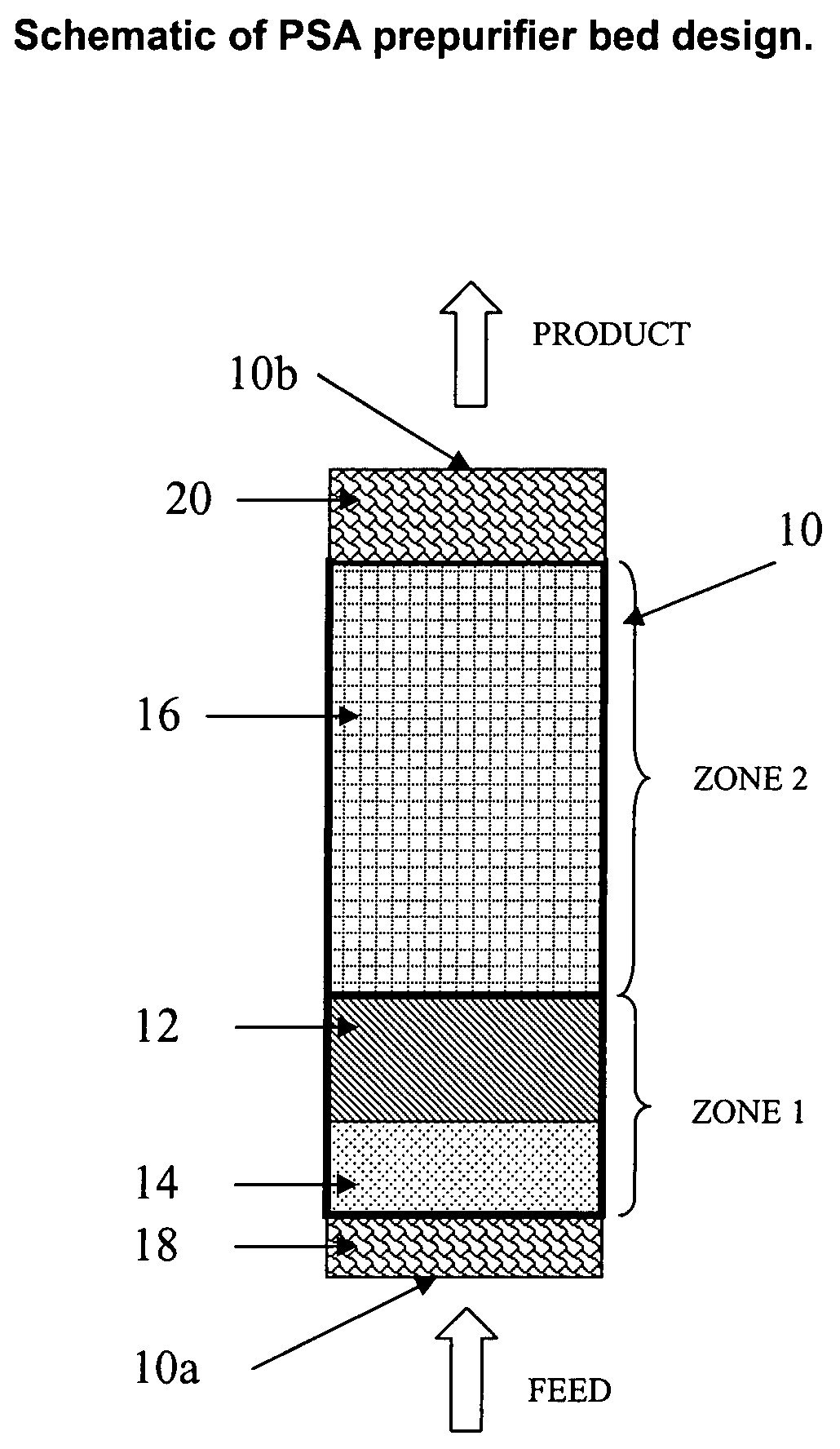

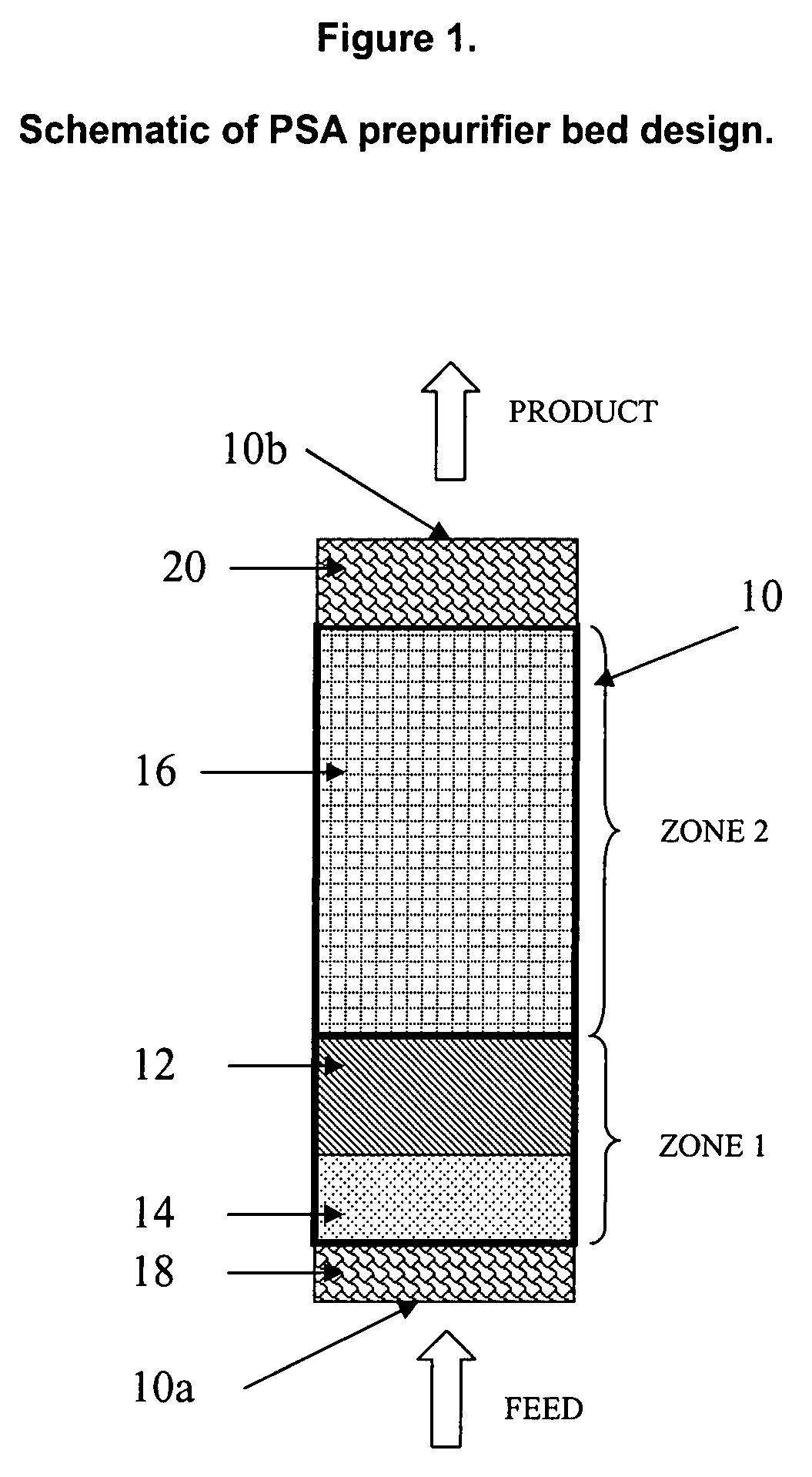

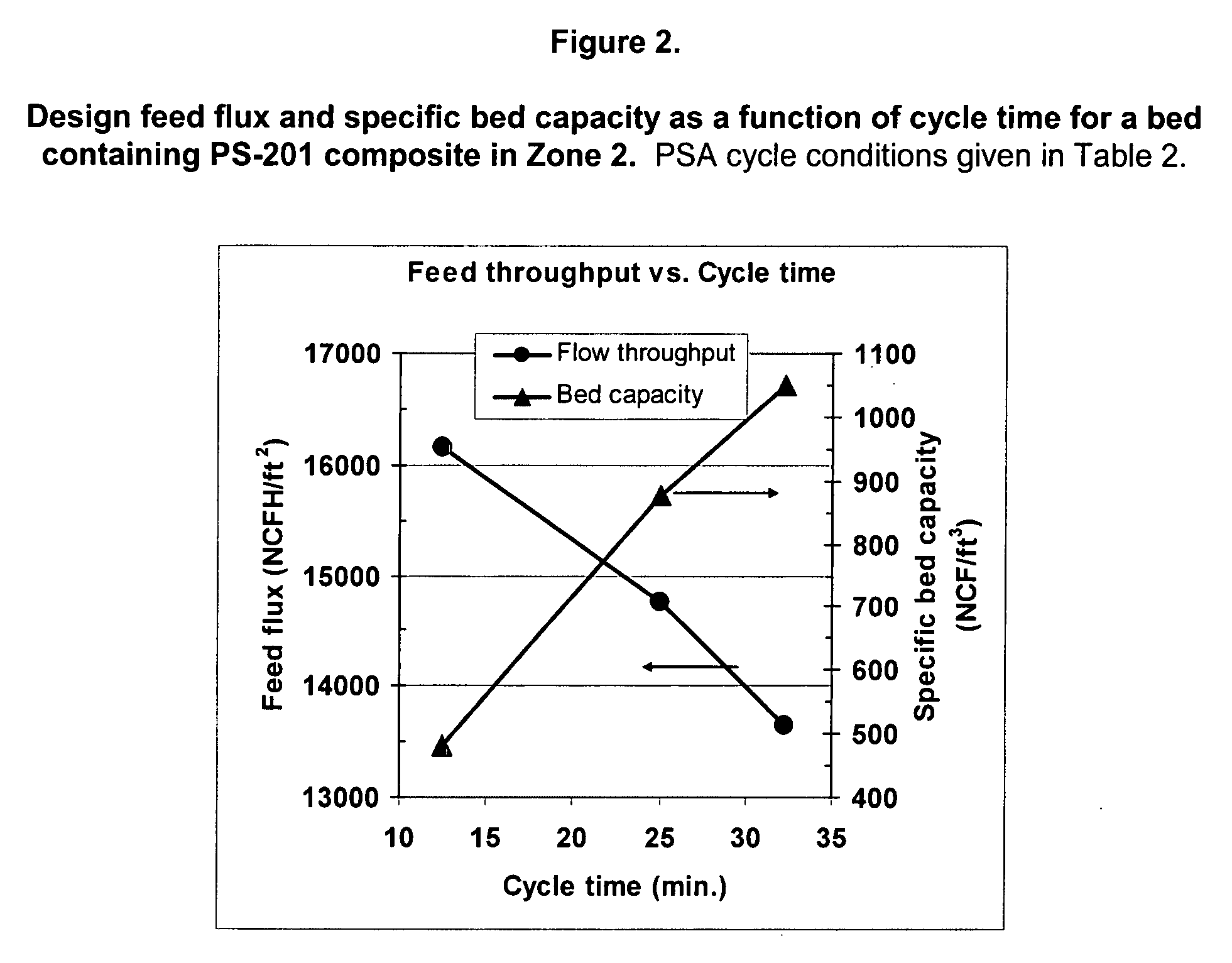

Adsorbents for pressure swing adsorption systems and methods of use therefor

InactiveUS7713333B2Reduce frequencyMaintain purityGas treatmentIsotope separationPurification methodsSorbent

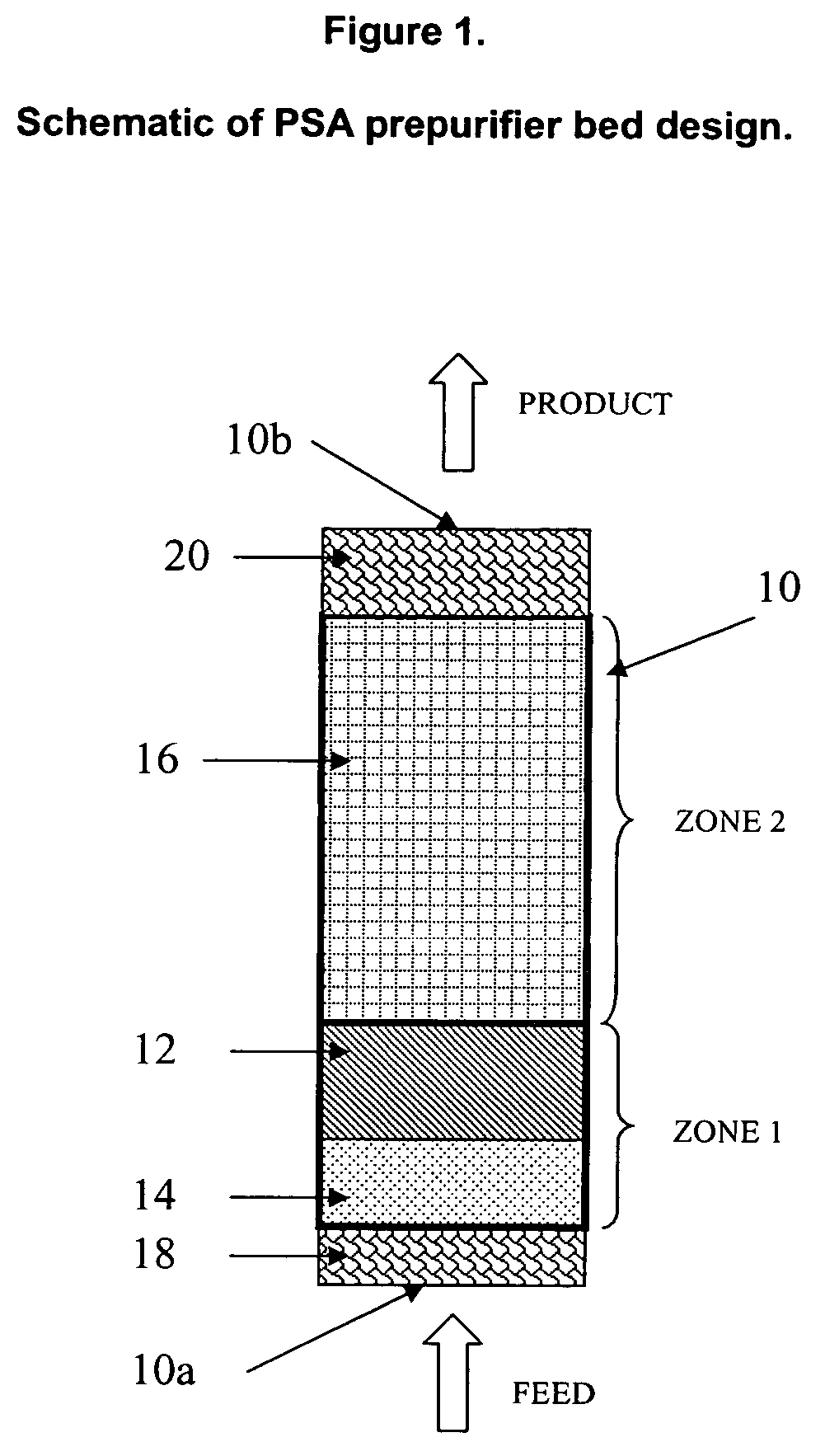

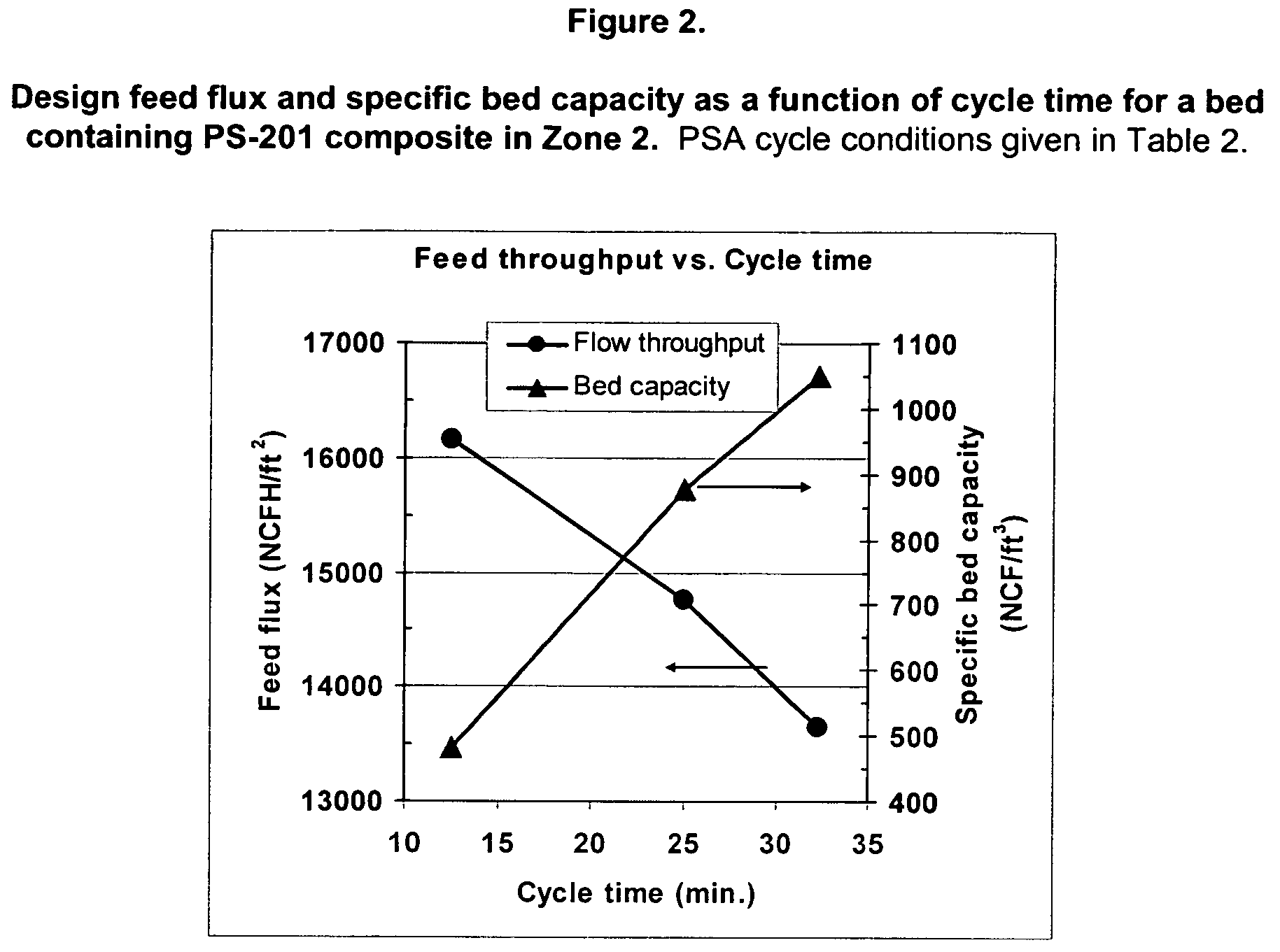

The present invention relates generally to adsorbents for use in pressure swing adsorption (PSA) prepurification processes. The invention more particularly relates to the design of adsorbent zones to be used in PSA prepurification processes that are expected to provide for extensions in PSA cycle time, thereby reducing blowdown loss and operating costs associated with the process. One particular embodiment of the present invention includes a first adsorption zone containing activated alumina and a second adsorption zone of an alumina-zeolite mixture or composite adsorbent in which the volume of the first zone does not exceed 50% of the total volume of the first and second zone.

Owner:PRAXAIR TECH INC

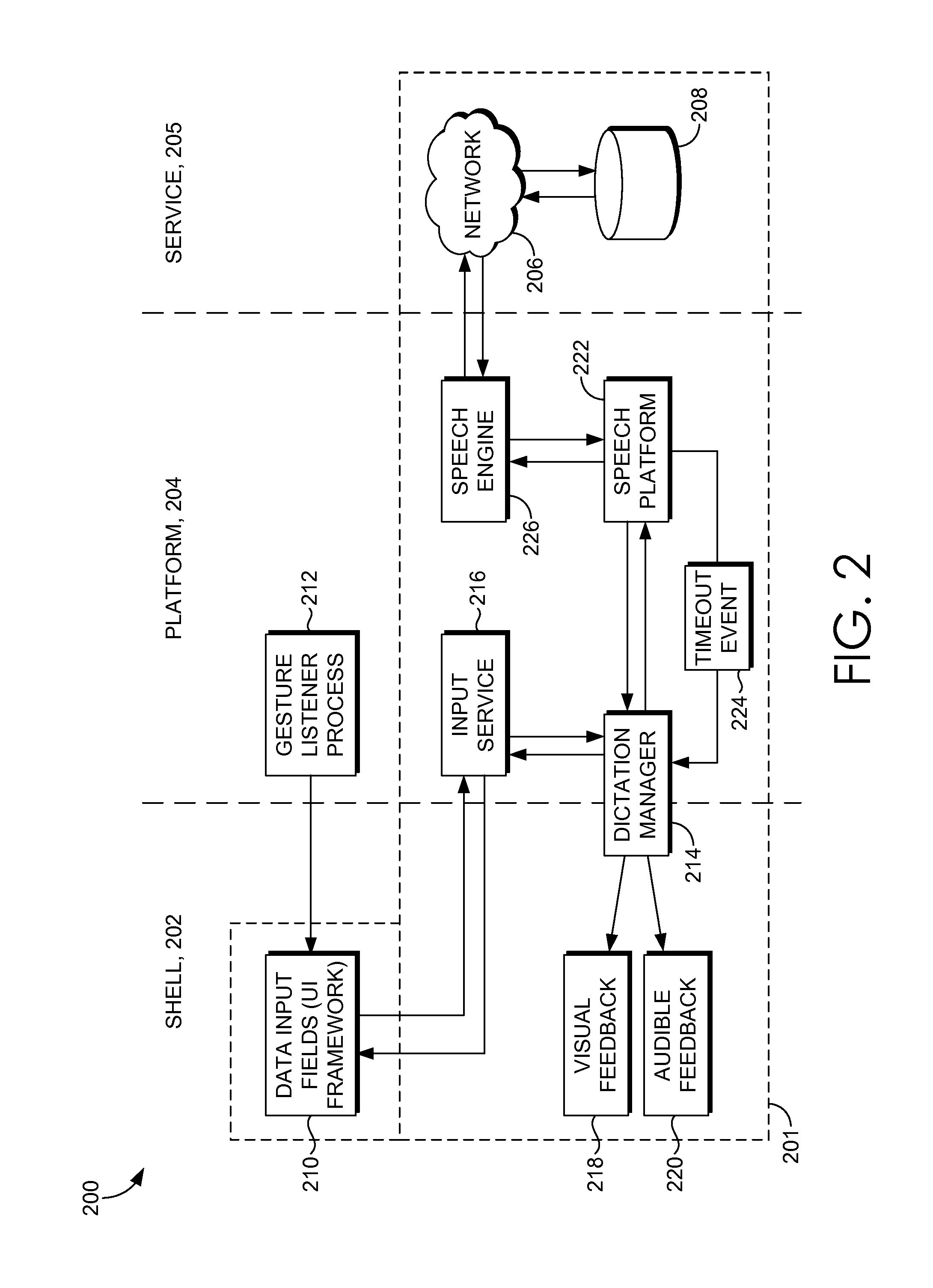

Gesture shortcuts for invocation of voice input

InactiveUS20160077793A1Maintain purityNatural language data processingSound input/outputApplication softwareSpeech sound

Systems, methods, and computer storage media are provided for initiating a system-wide voice-to-text dictation service in response to a preconfigured gesture. Data input fields, independent of the application from which they are presented to a user, are configured to at least detect one or more input events. A gesture listener process, controlled by the system, is configured to detect a preconfigured gesture corresponding to a data input field. Detection of the preconfigured gesture generates an input event configured to invoke a voice-to-text session for the corresponding data input field. The preconfigured gesture can be configured such that any visible on-screen affordances (e.g., microphone button on a virtual keyboard) are omitted to maintain aesthetic purity and further provide system-wide access to the dictation service. As such, dictation services are generally available for any data input field across the entire operating system without the requirement of an on-screen affordance to initiate the service.

Owner:MICROSOFT TECH LICENSING LLC

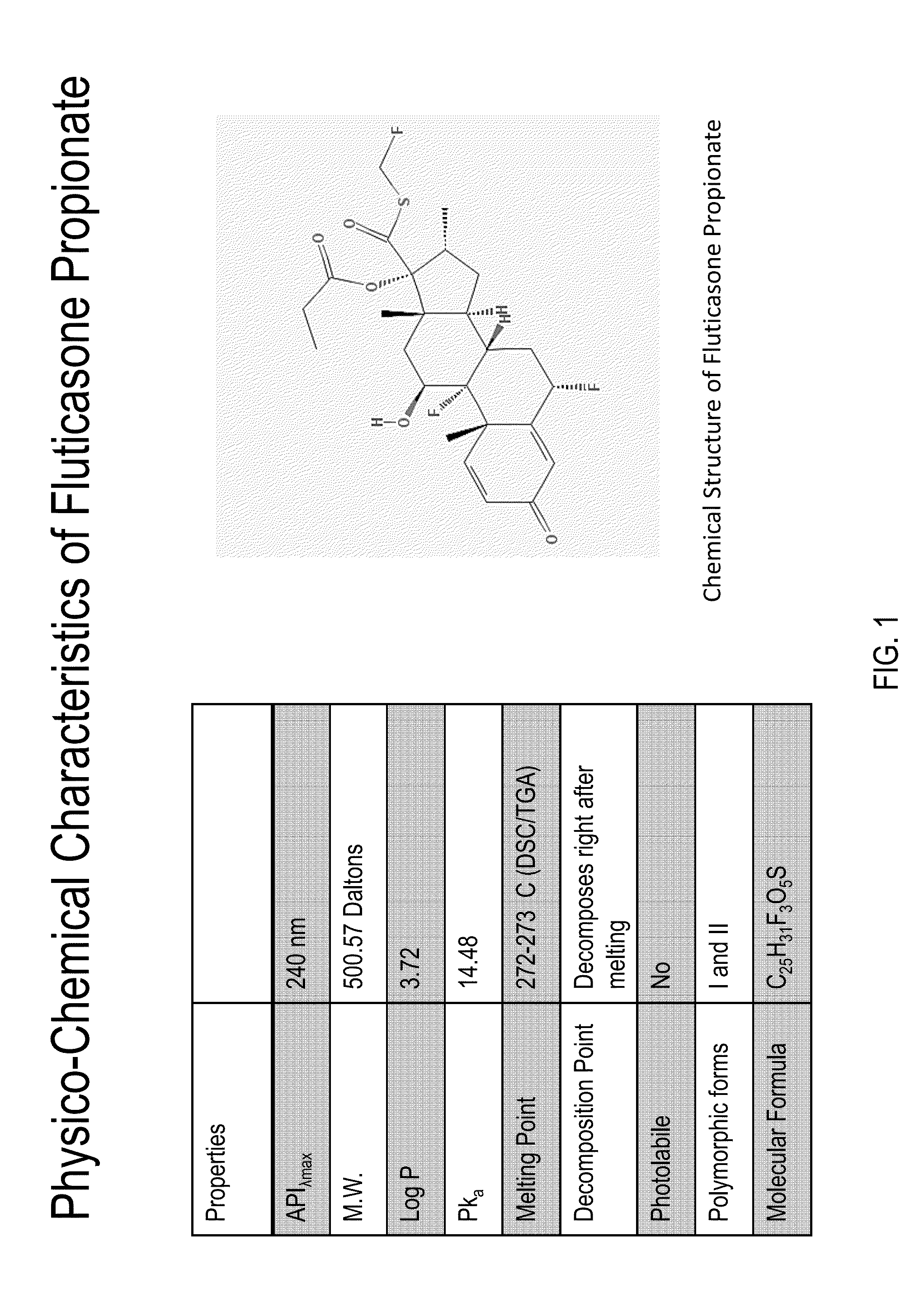

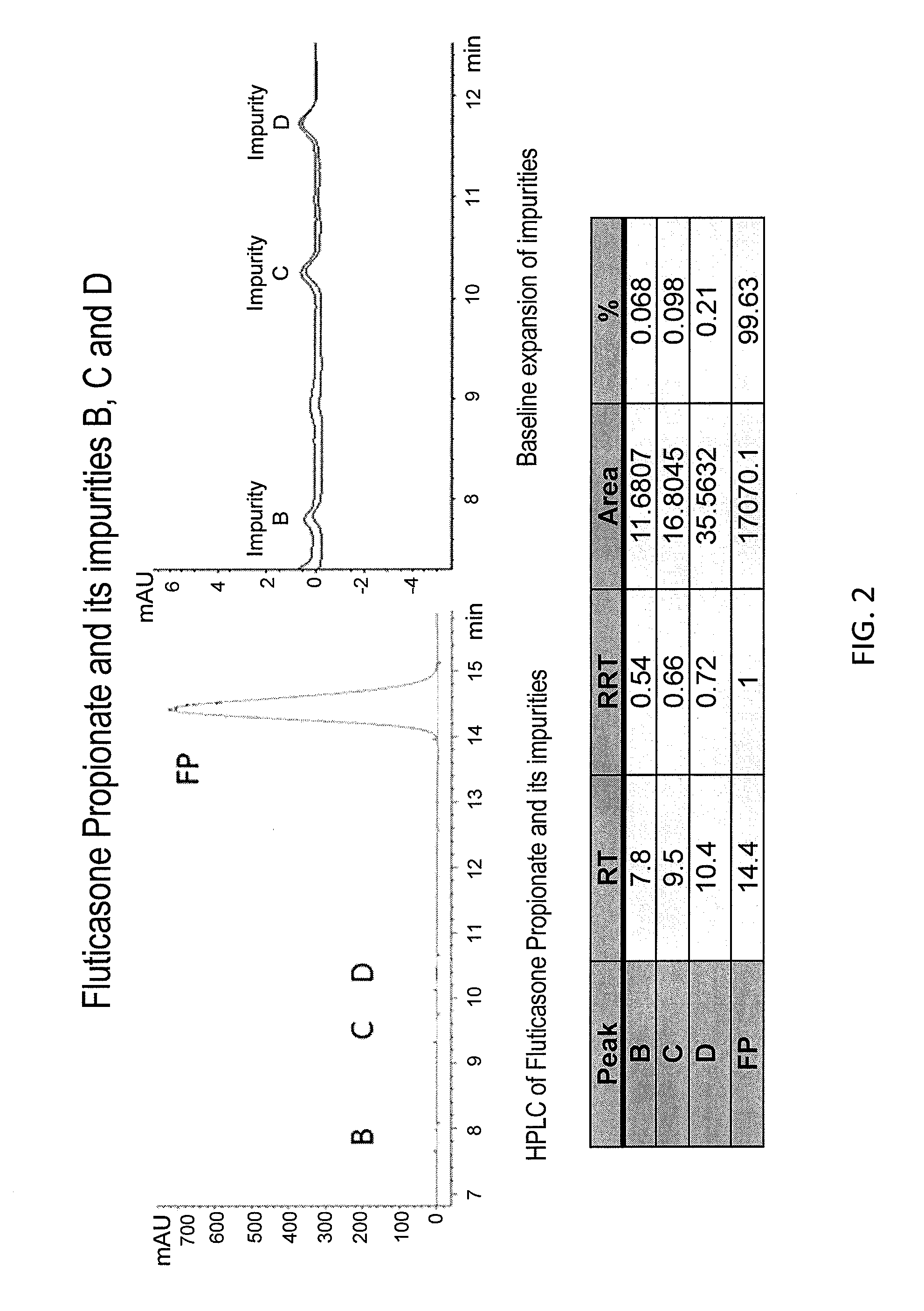

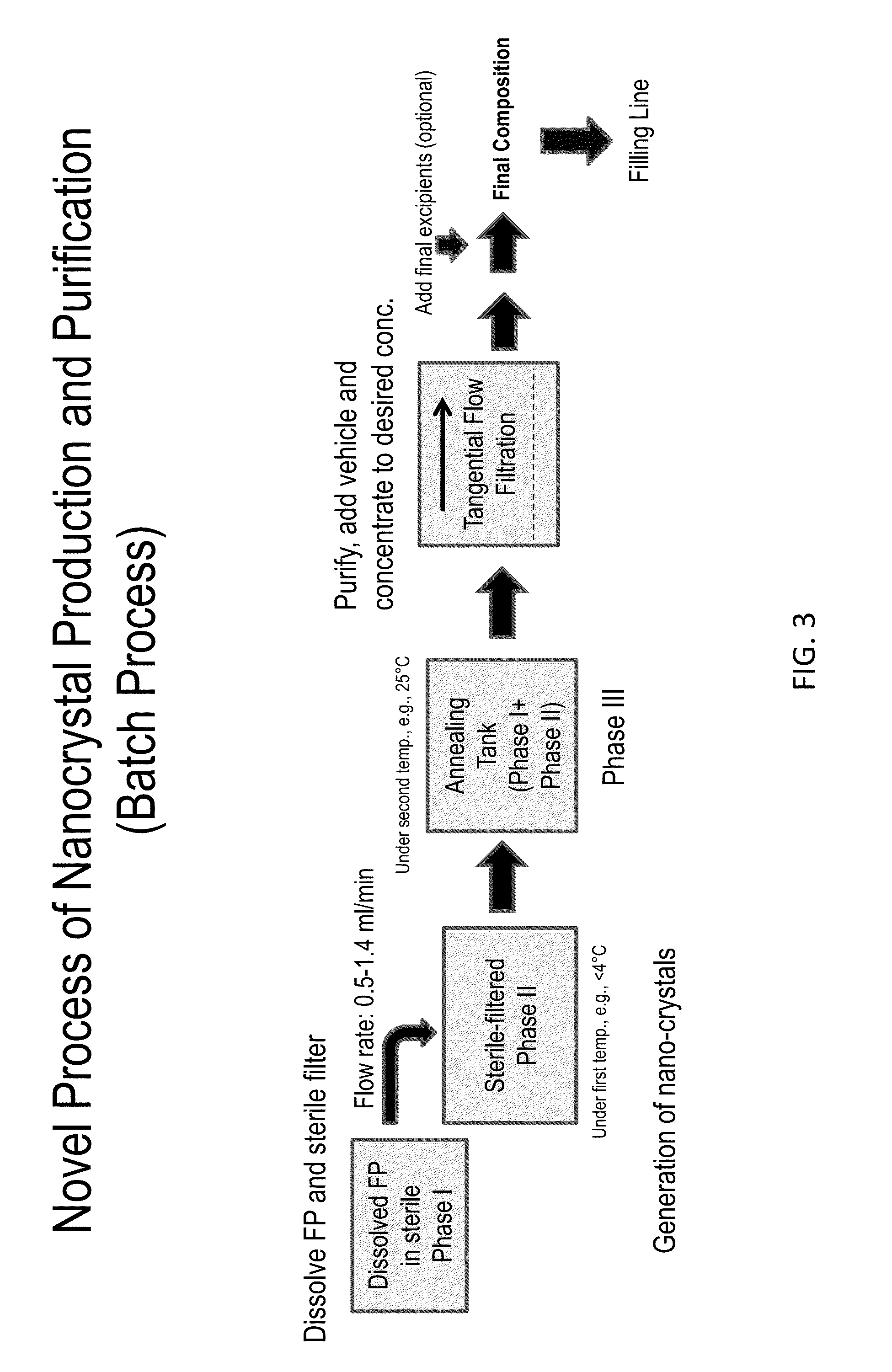

Preparations of Hydrophobic Therapeutic Agents, Methods of Manufacture and Use Thereof

ActiveUS20130303502A1Increase concentrationMaintaining osmolalityOrganic active ingredientsOrganic chemistry methodsDiseaseRespiratory disease

The present invention further provides method of preparing nanocrystals of a hydrophobic therapeutic agent such as fluticasone, pharmaceutical compositions (e.g., topical or intranasal compositions) thereof and methods for treating and / or preventing the signs and / or symptoms of disorders such as blepharitis, meibomian gland dysfunction or skin inflammation or a respiratory disease (e.g., asthma).

Owner:NICOX OPHTHALMICS

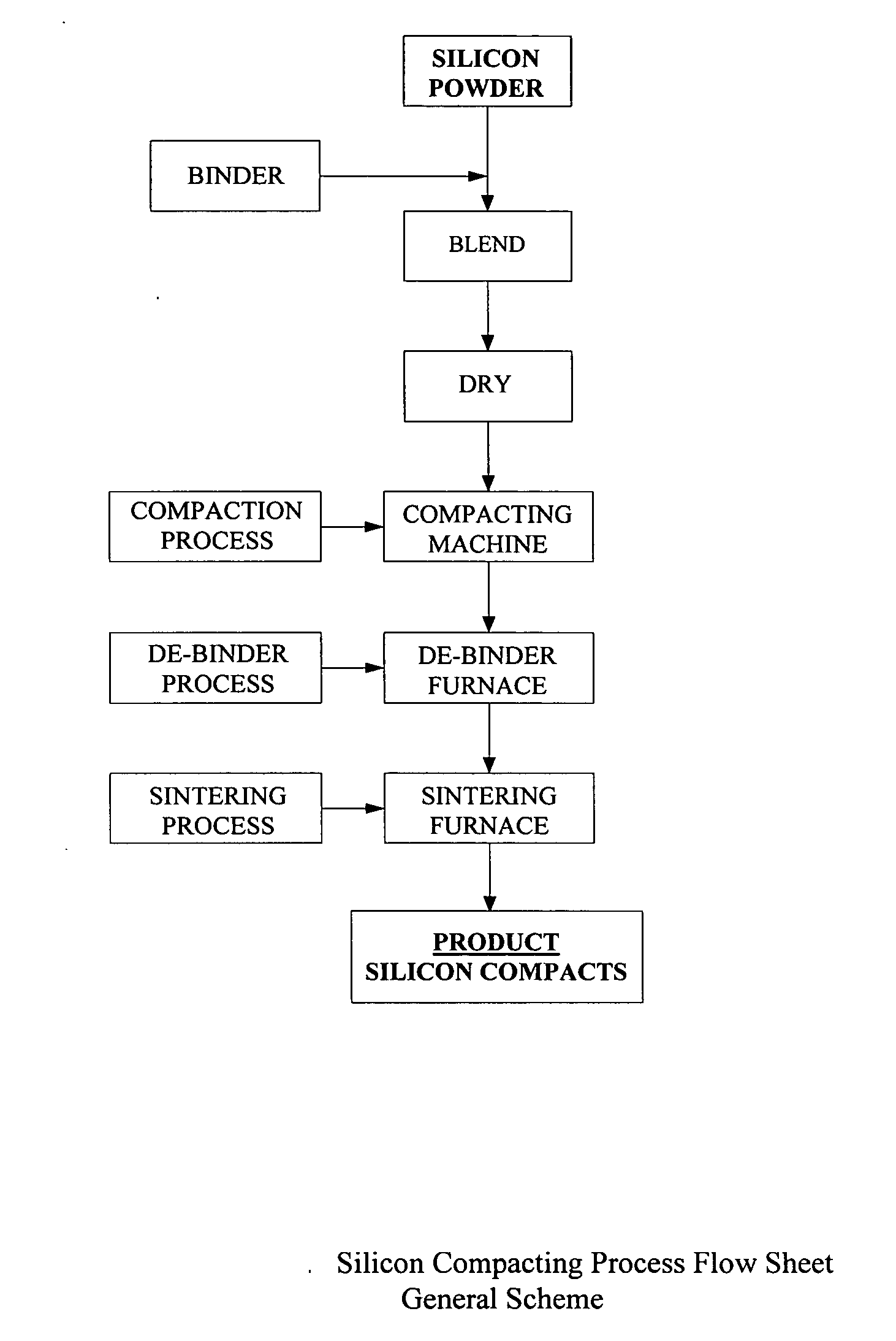

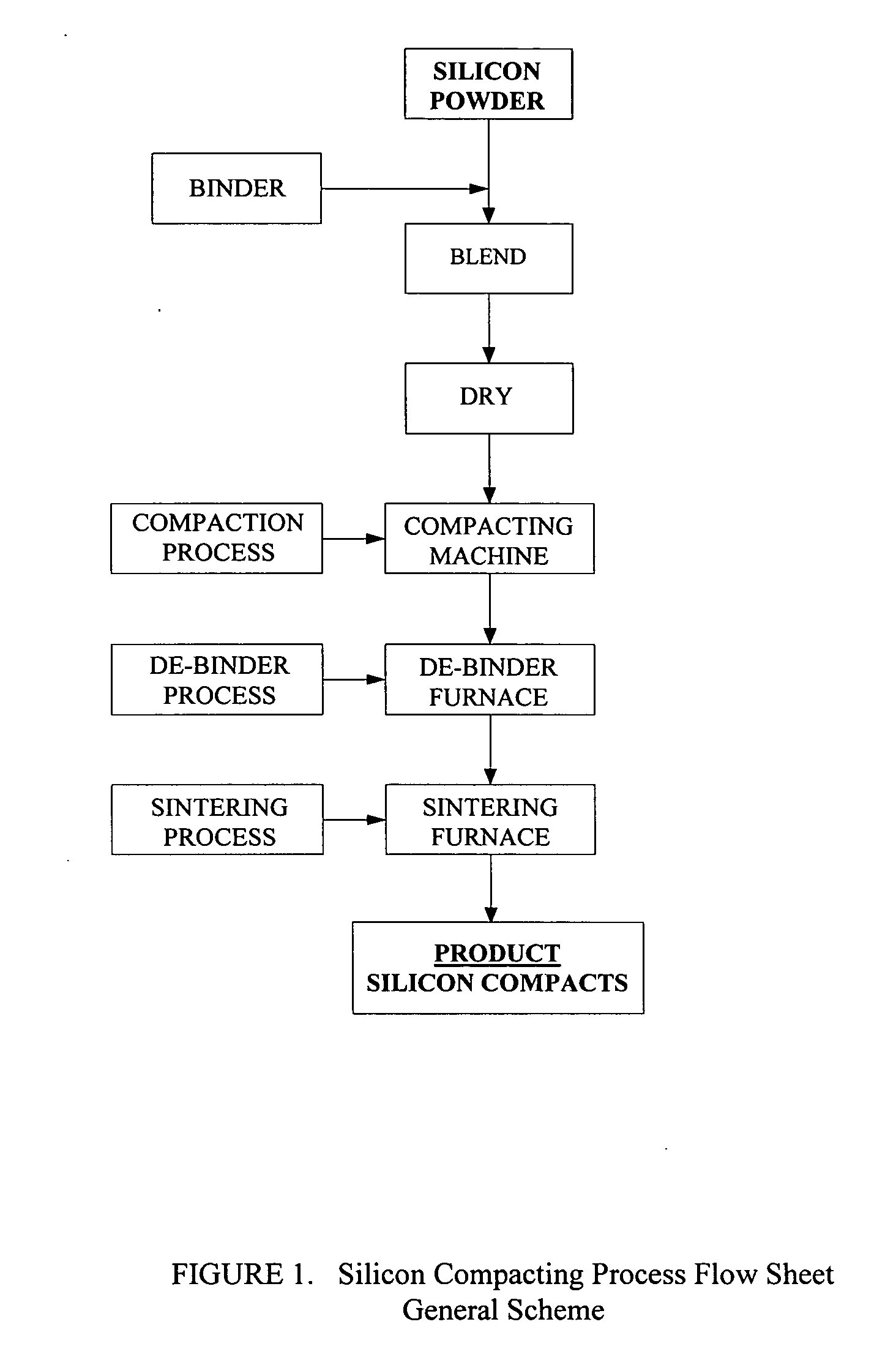

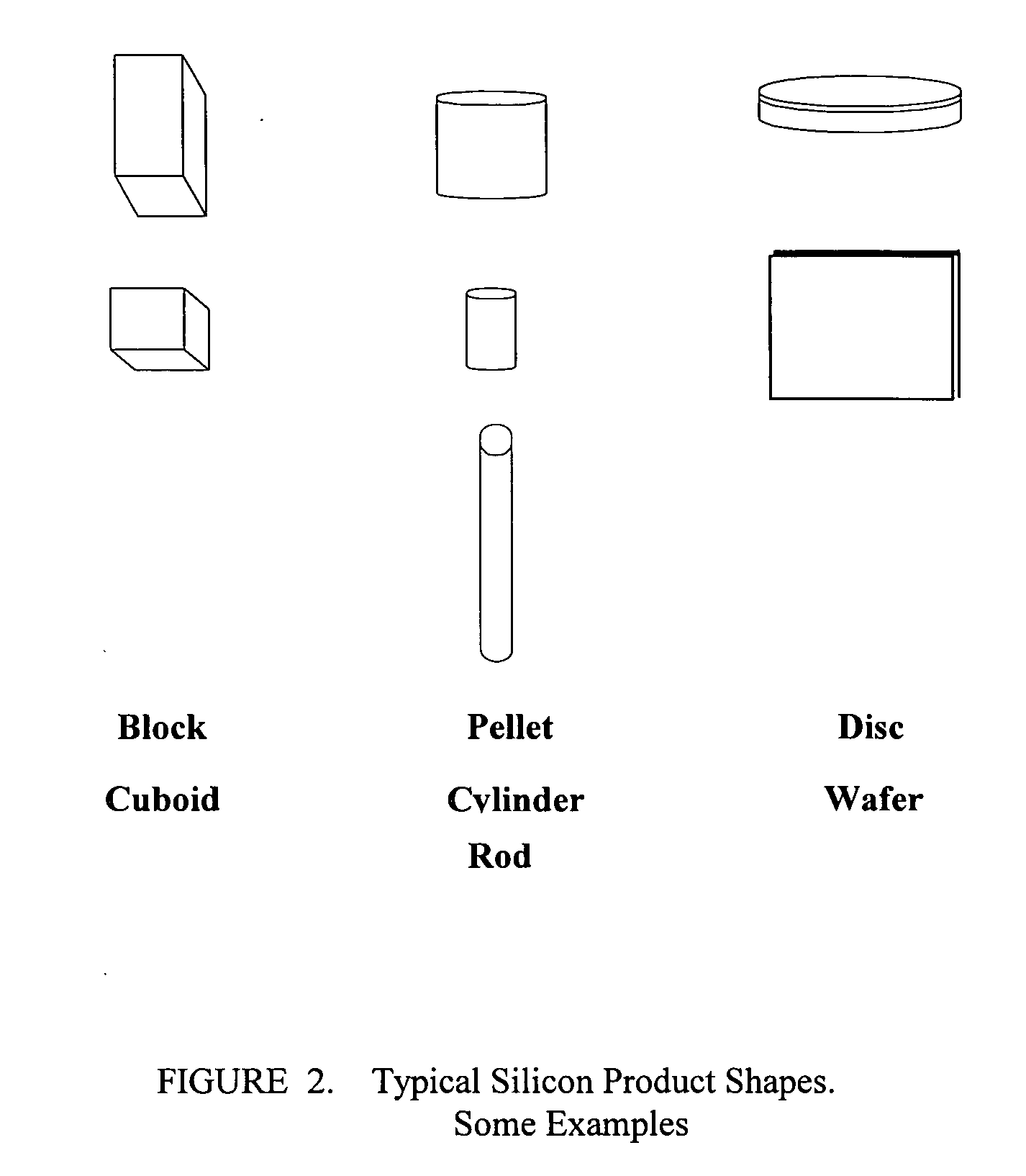

Conversion of high purity silicon powder to densified compacts

InactiveUS20070014682A1Maintain purityIncrease speedSiliconFinal product manufactureSilica fumeGeometric form

This invention describes methods of compacting and densifying high purity silicon powder to defined geometric forms and shapes. High purity silicon powder is first mixed with binder from a select group of binders and pressed into desired shapes in a mechanical equipment. The binder is removed either in a separate step or combined with a subsequent sintering operation. The binders and process conditions are chosen to make negligible change to the purity of the silicon in the end product. When high purity silicon powder is utilized in the process, the end use for the densified silicon compacts is primarily as feedstock for silicon-based photovoltaic manufacturing industries.

Owner:SEMLUX TECH

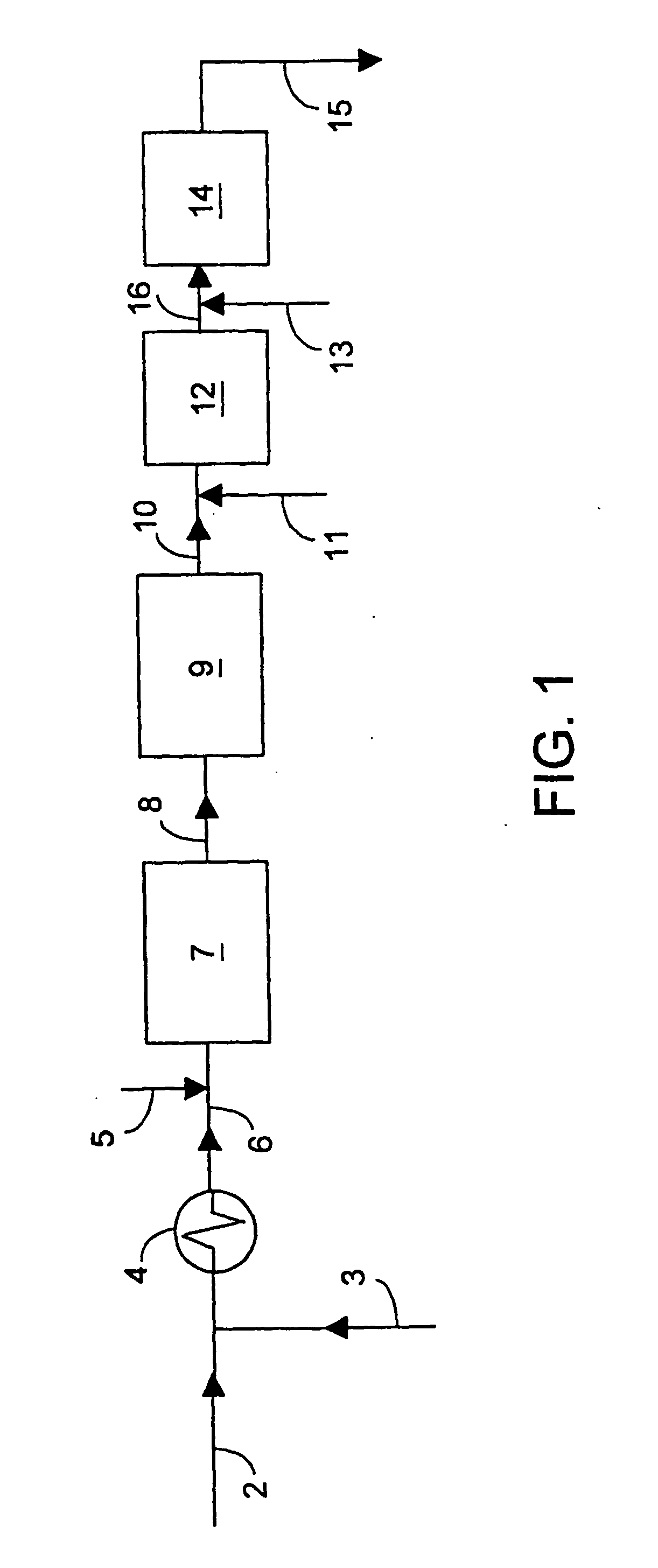

Feedforward control processes for variable output hydrogen generators

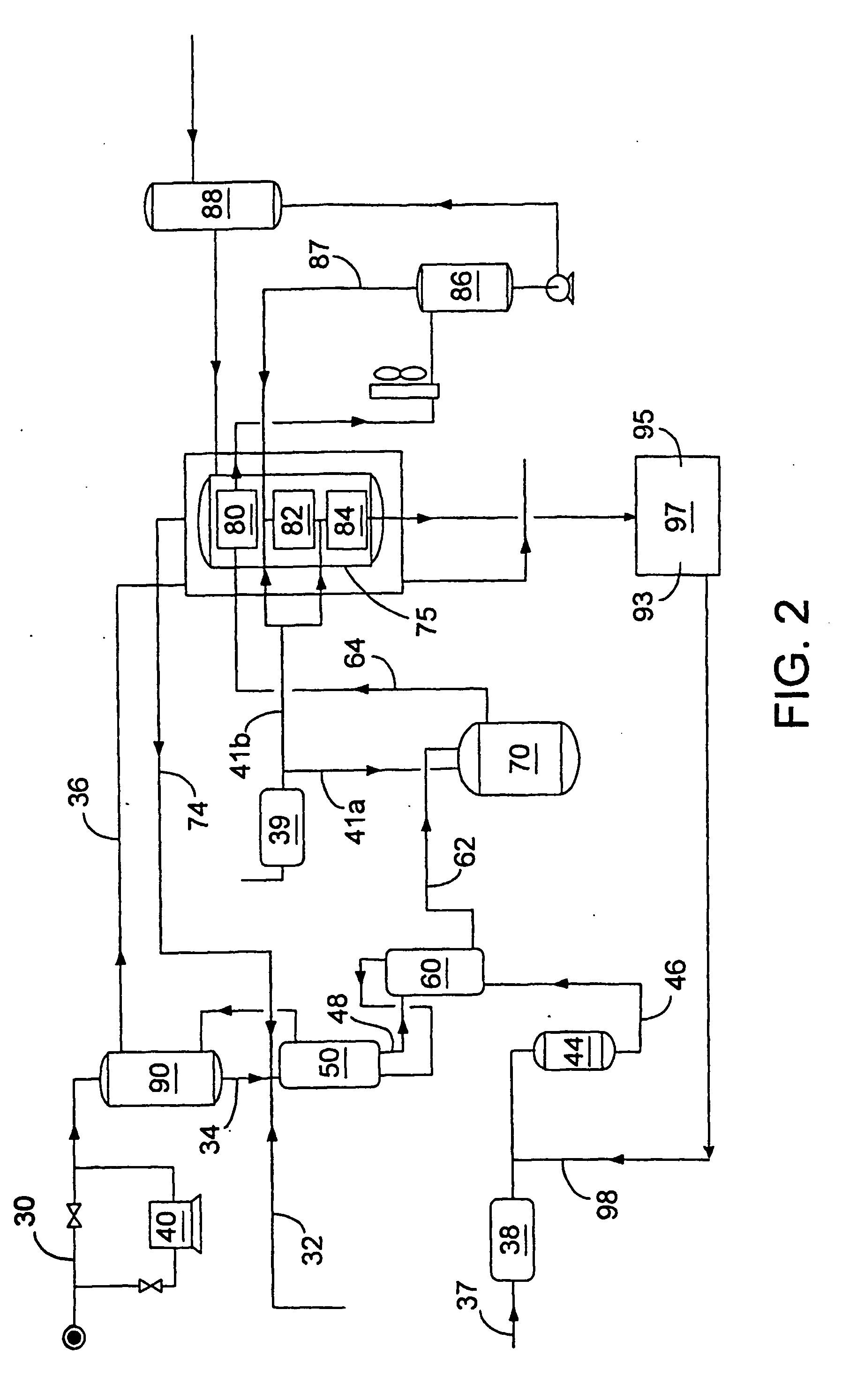

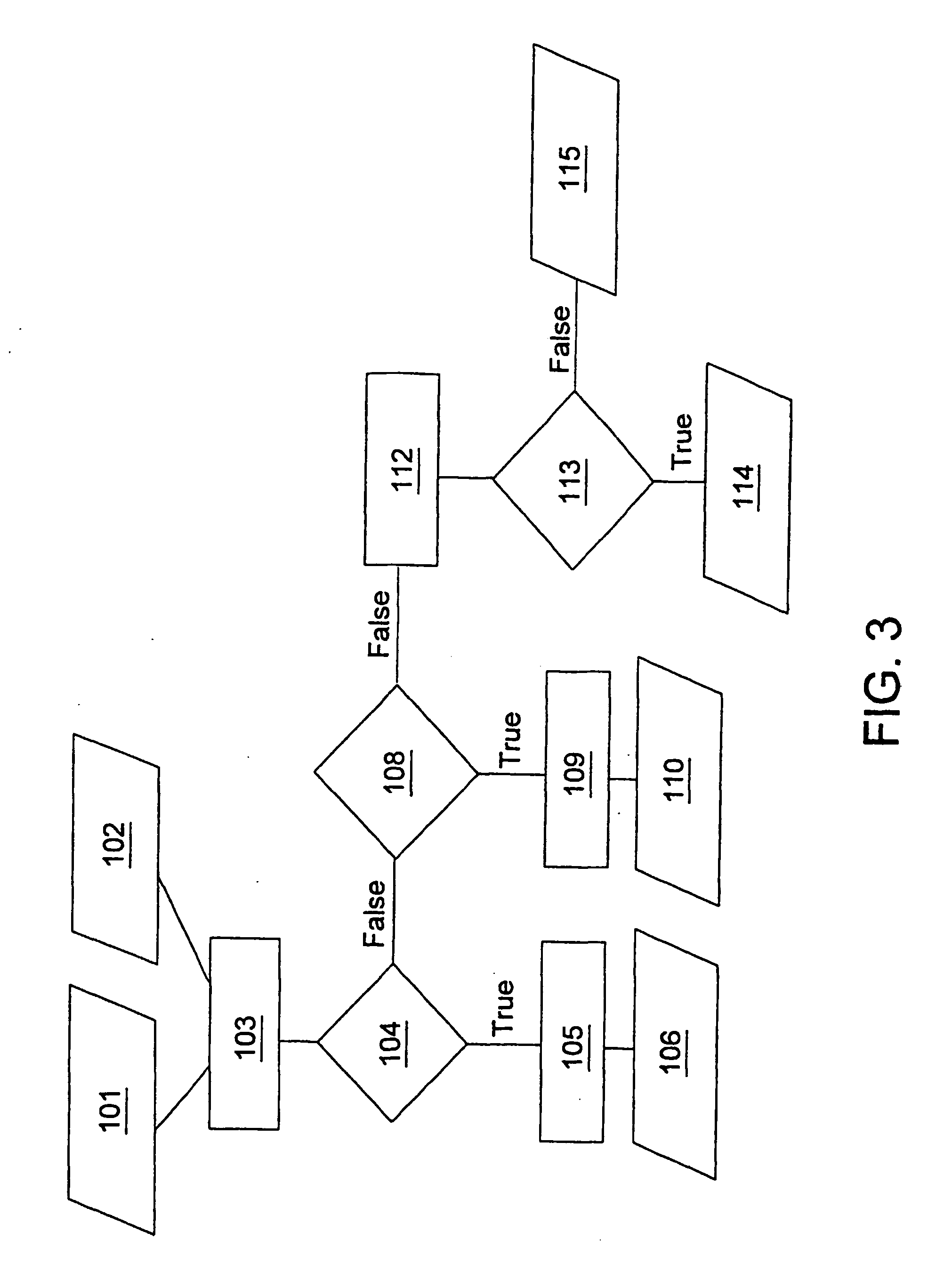

InactiveUS20060096175A1Improve efficiencyImprove stabilityProcess control/regulationExhaust apparatusFuel cellsProcess engineering

Hydrogen generators and integrated hydrogen generator / fuel cells systems are operated by determining the condition of the hydrogen generator and the condition of the fuel to the hydrogen generator for selection of predetermined flow rates for each of the externally-provided raw materials. The processes of the invention can provide rapid transitions between hydrogen production rates while enabling enhanced efficiency and stability during transient operations.

Owner:HYRADIX INC

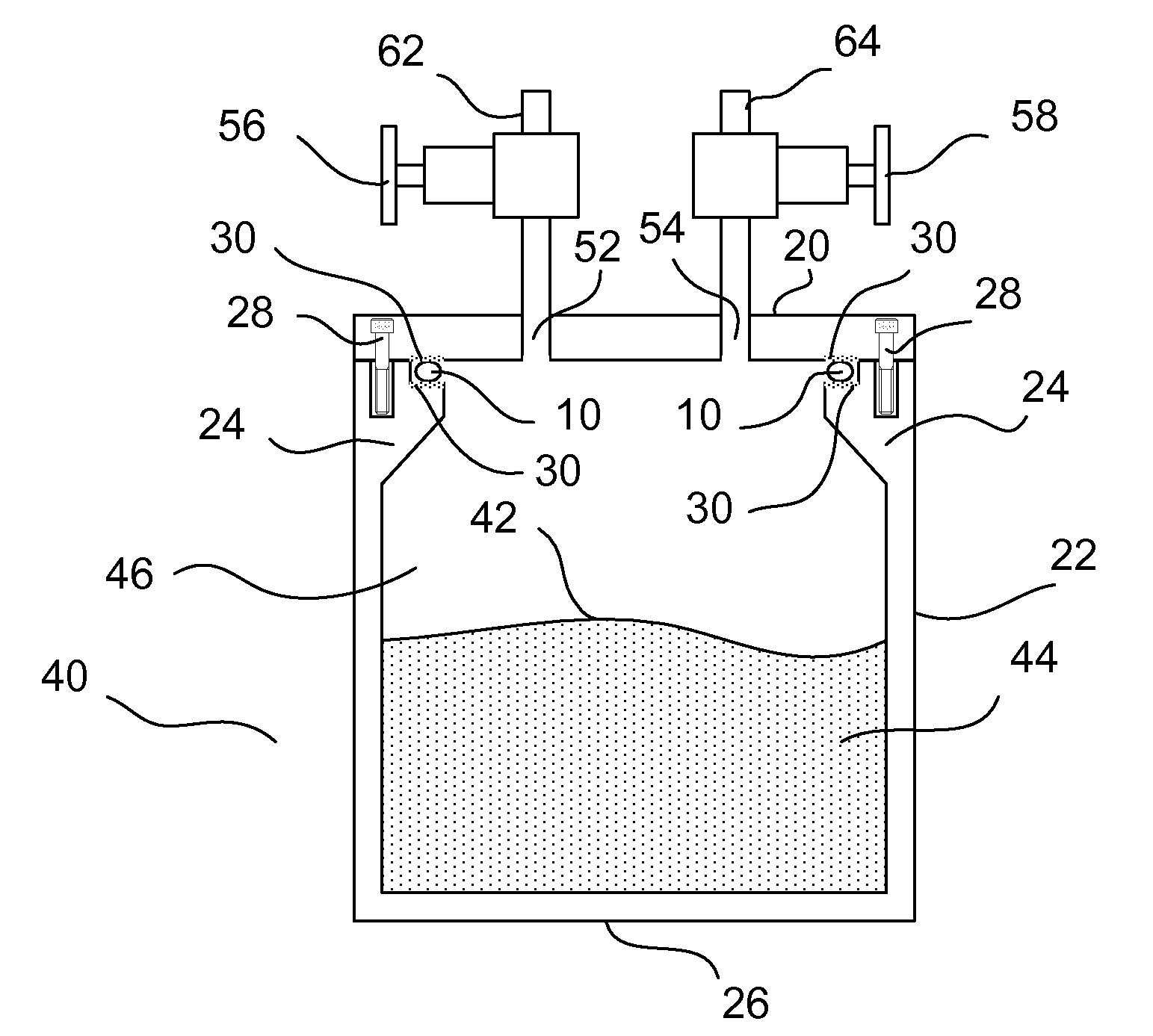

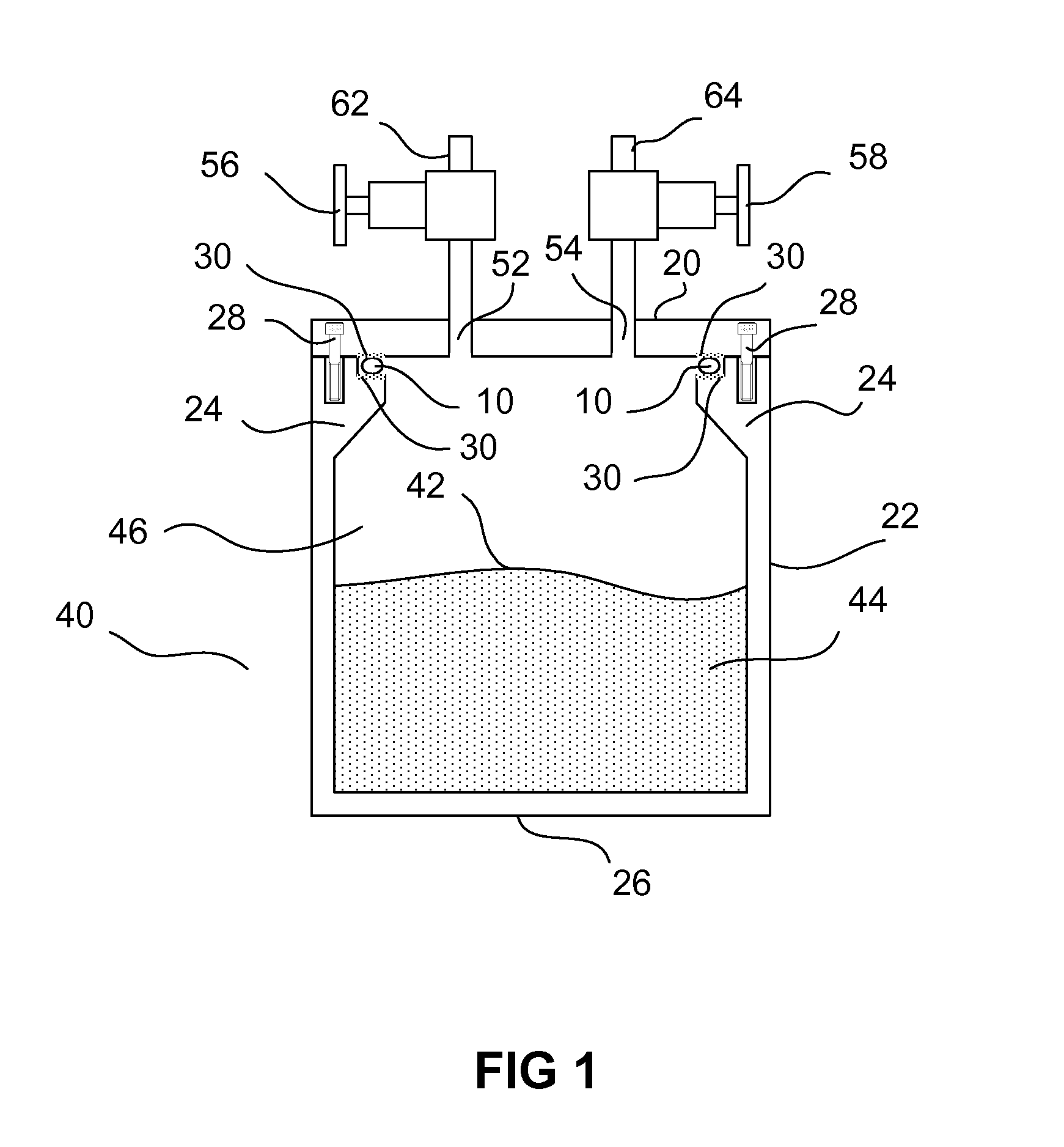

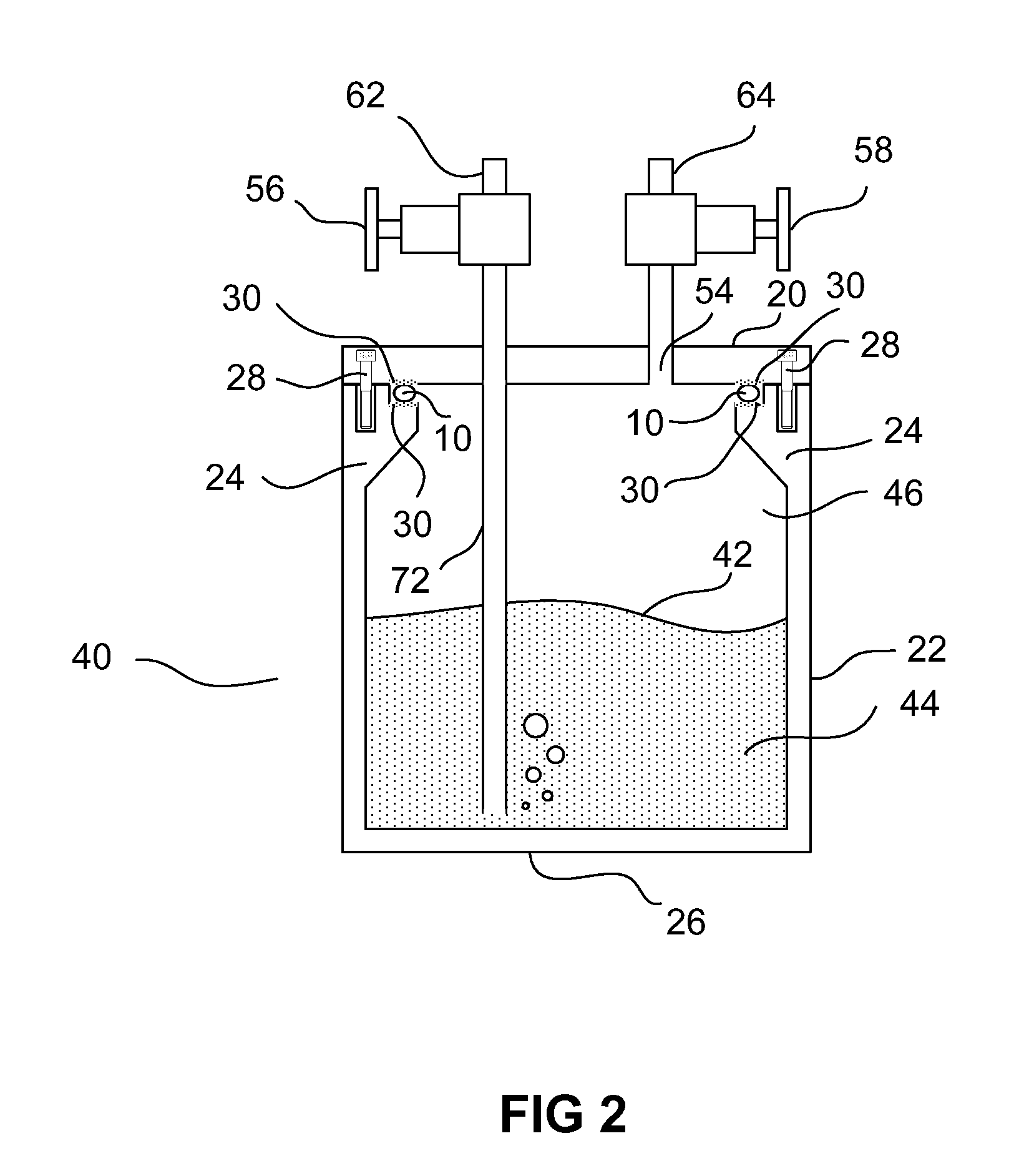

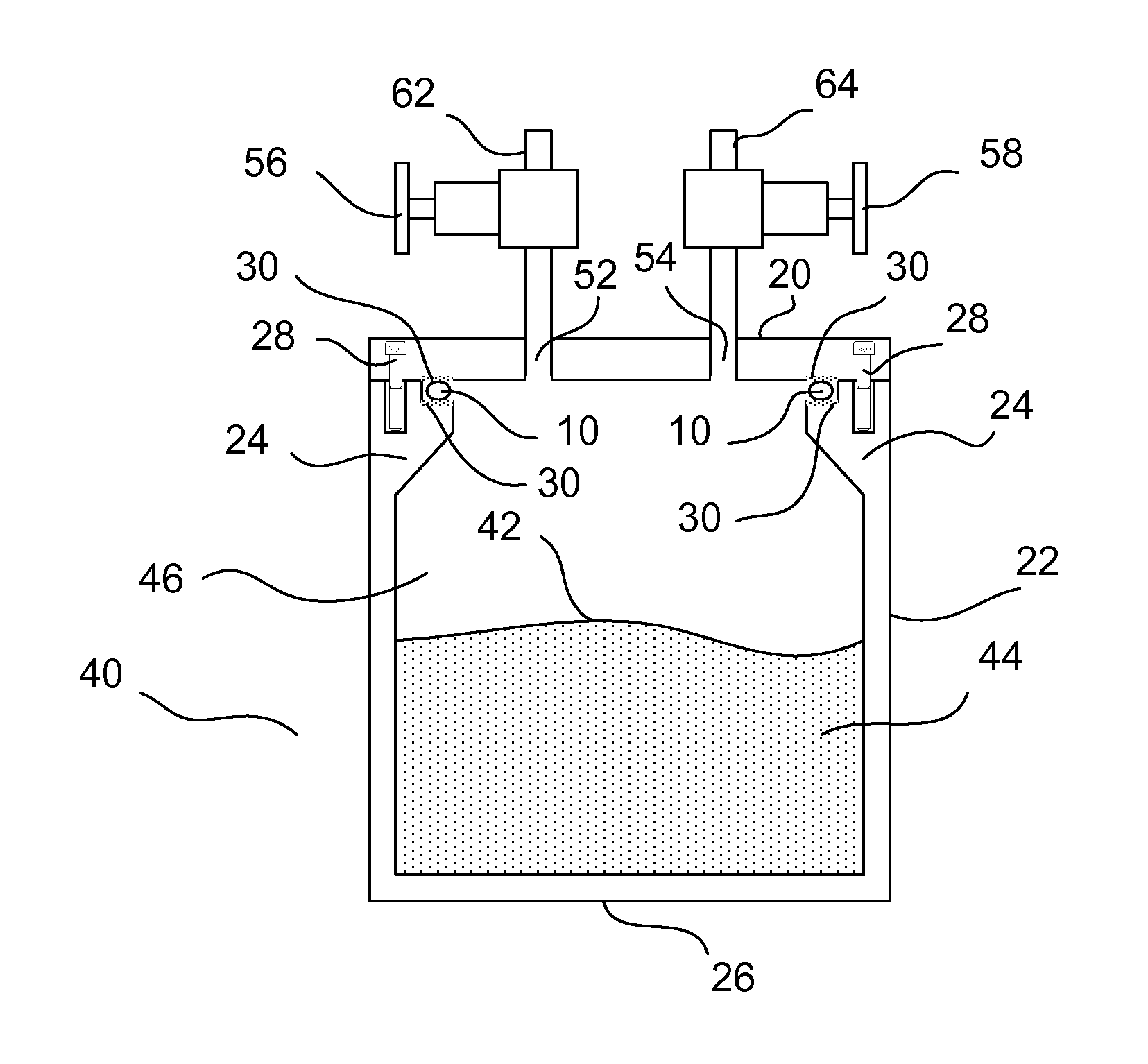

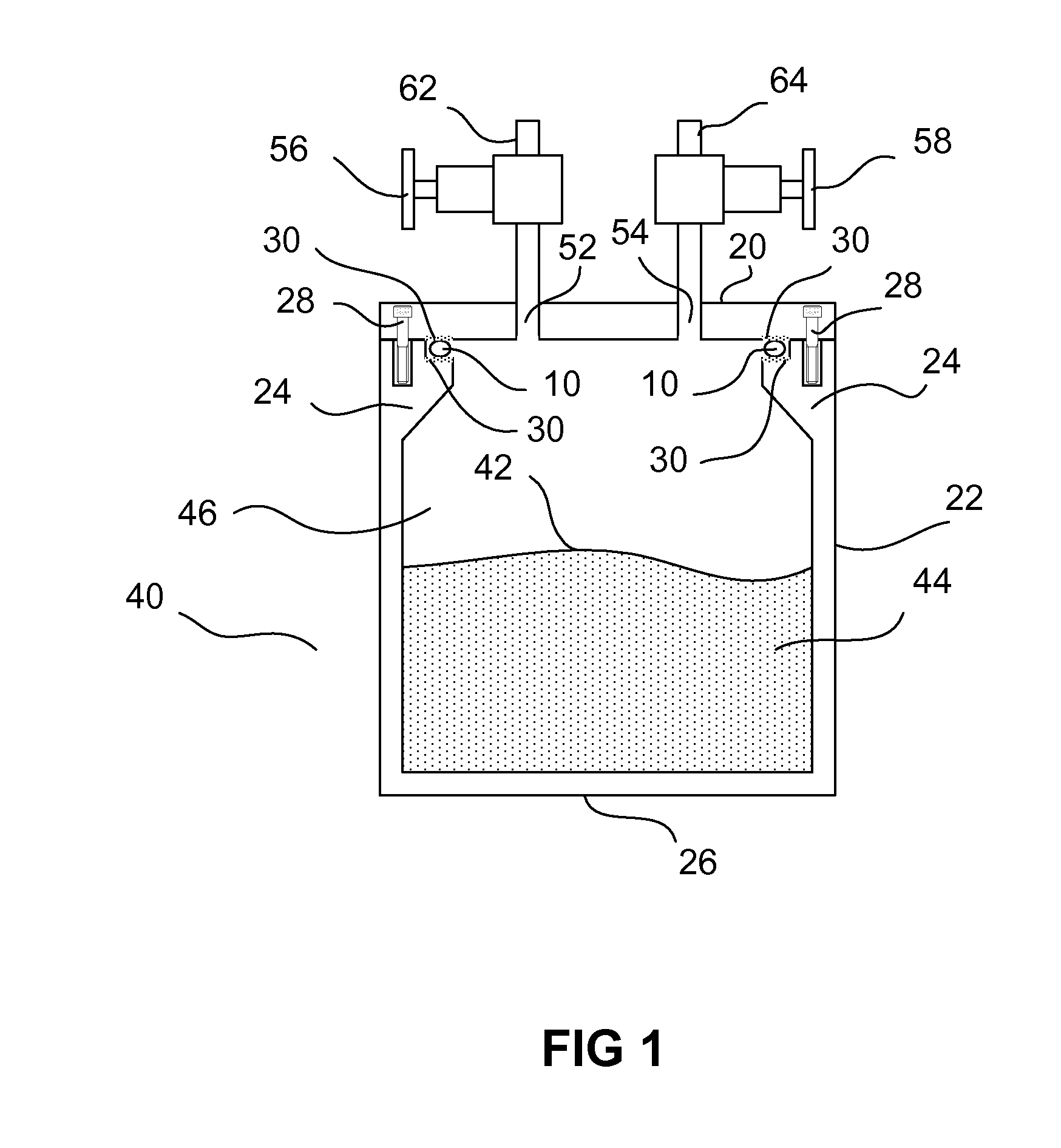

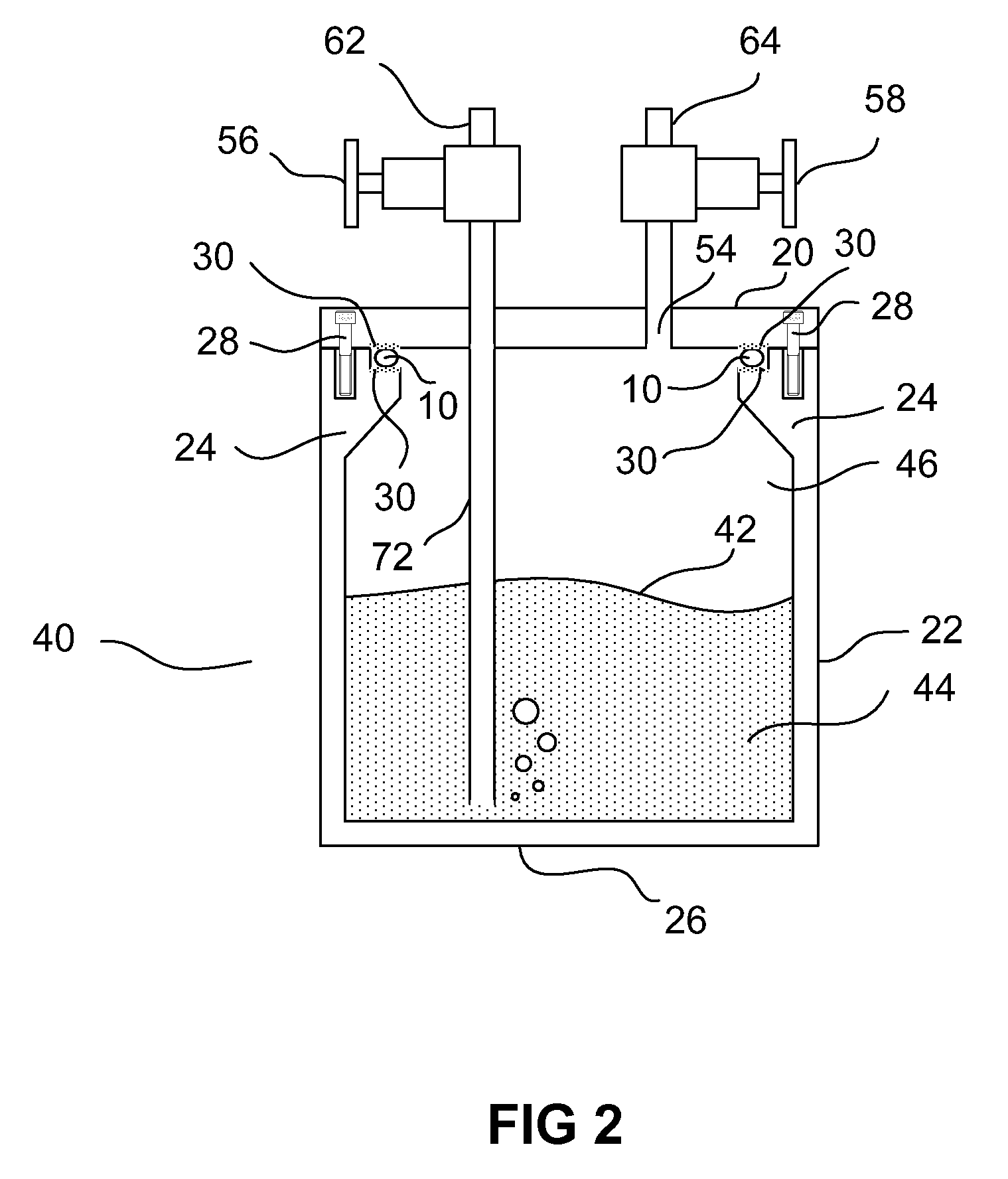

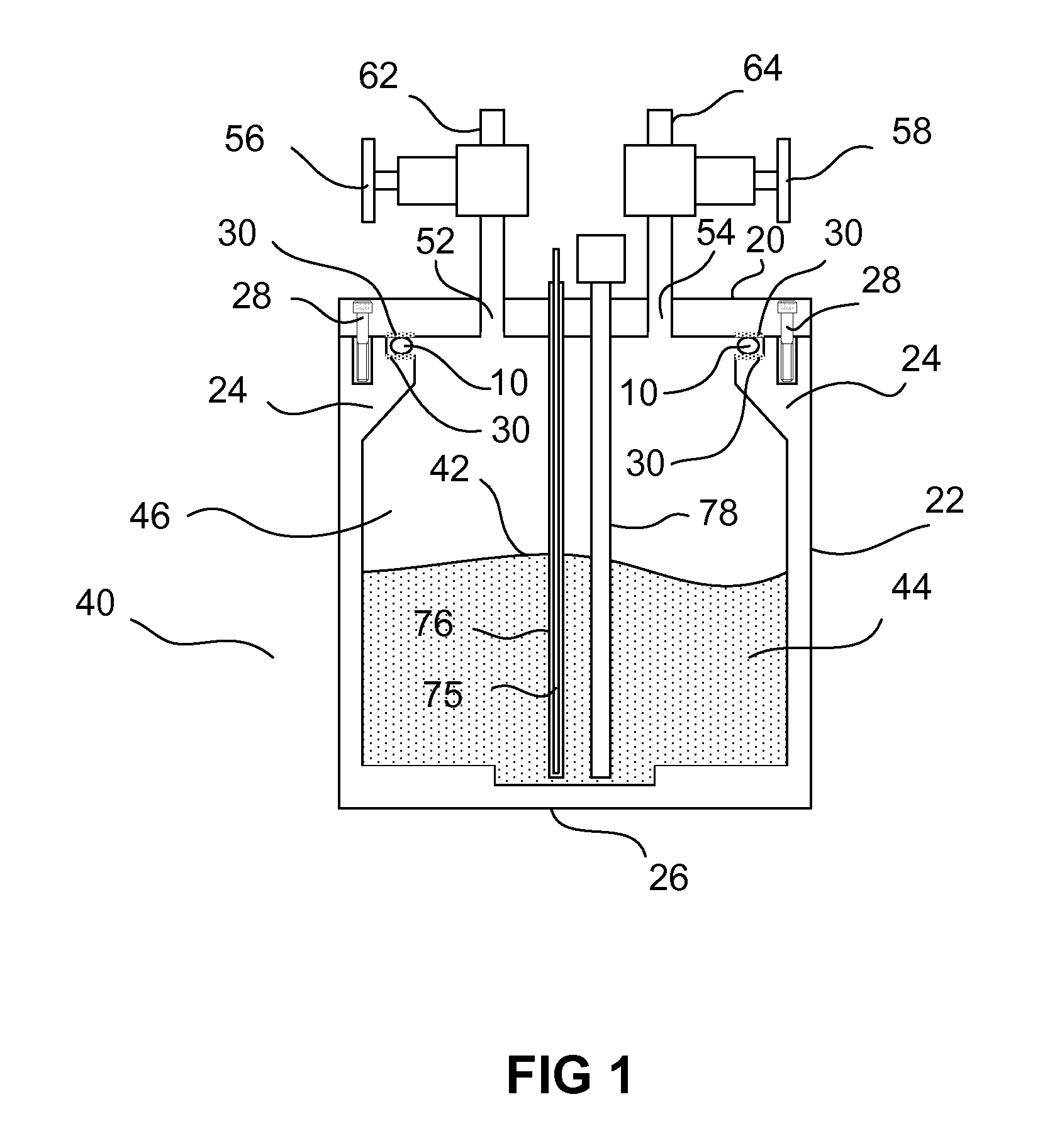

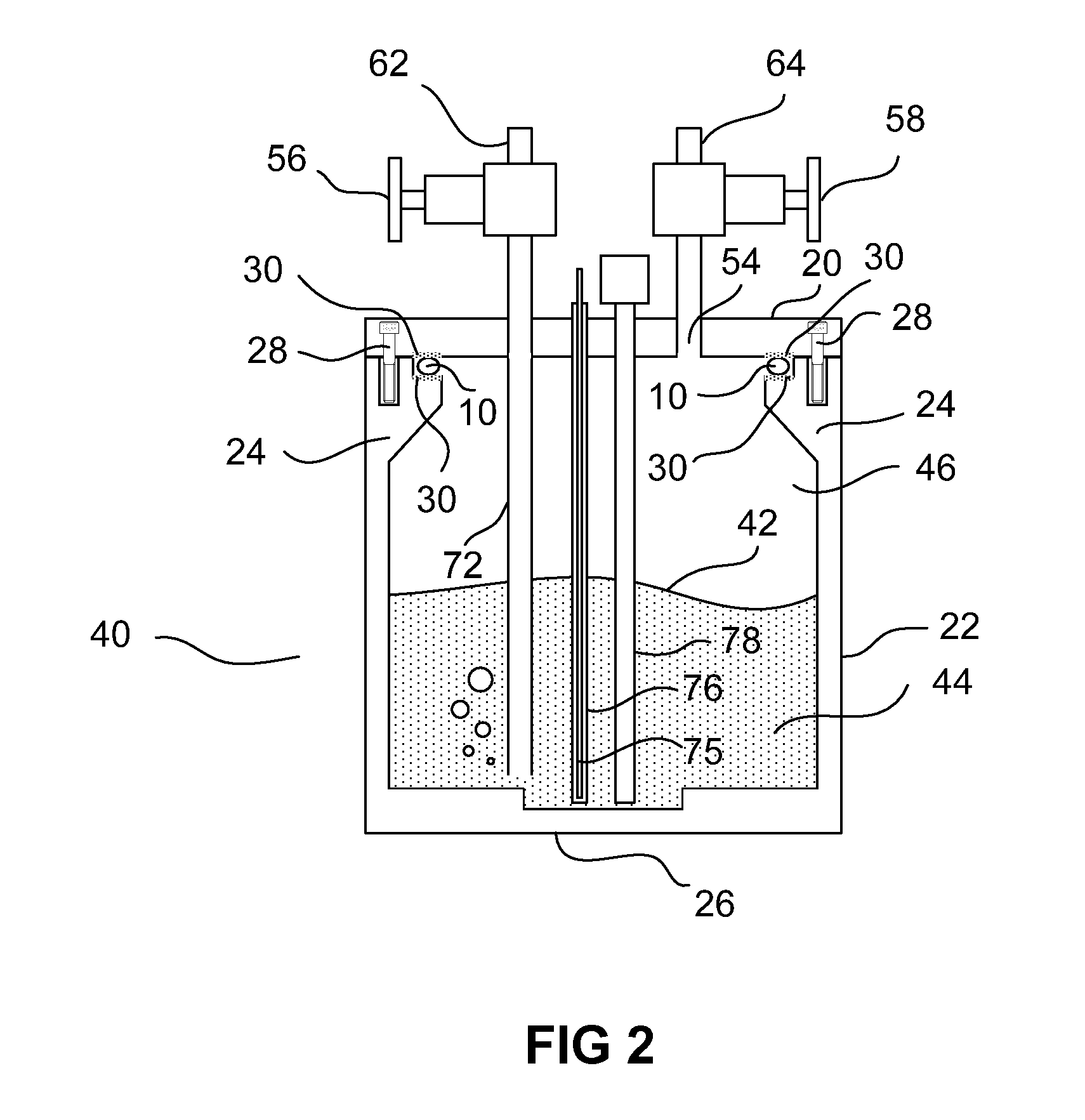

Multiple ampoule delivery systems

InactiveUS20090214779A1Easy to useReduce wasteLiquid surface applicatorsChemical vapor deposition coatingSemiconductor materialsDelivery system

This invention relates to an integrated vapor or liquid phase reagent dispensing apparatus having a plurality of vessels and a plurality of carrier or inert gas feed / vapor or liquid phase reagent delivery manifolds, that may be used for continuously dispensing vapor or liquid phase reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

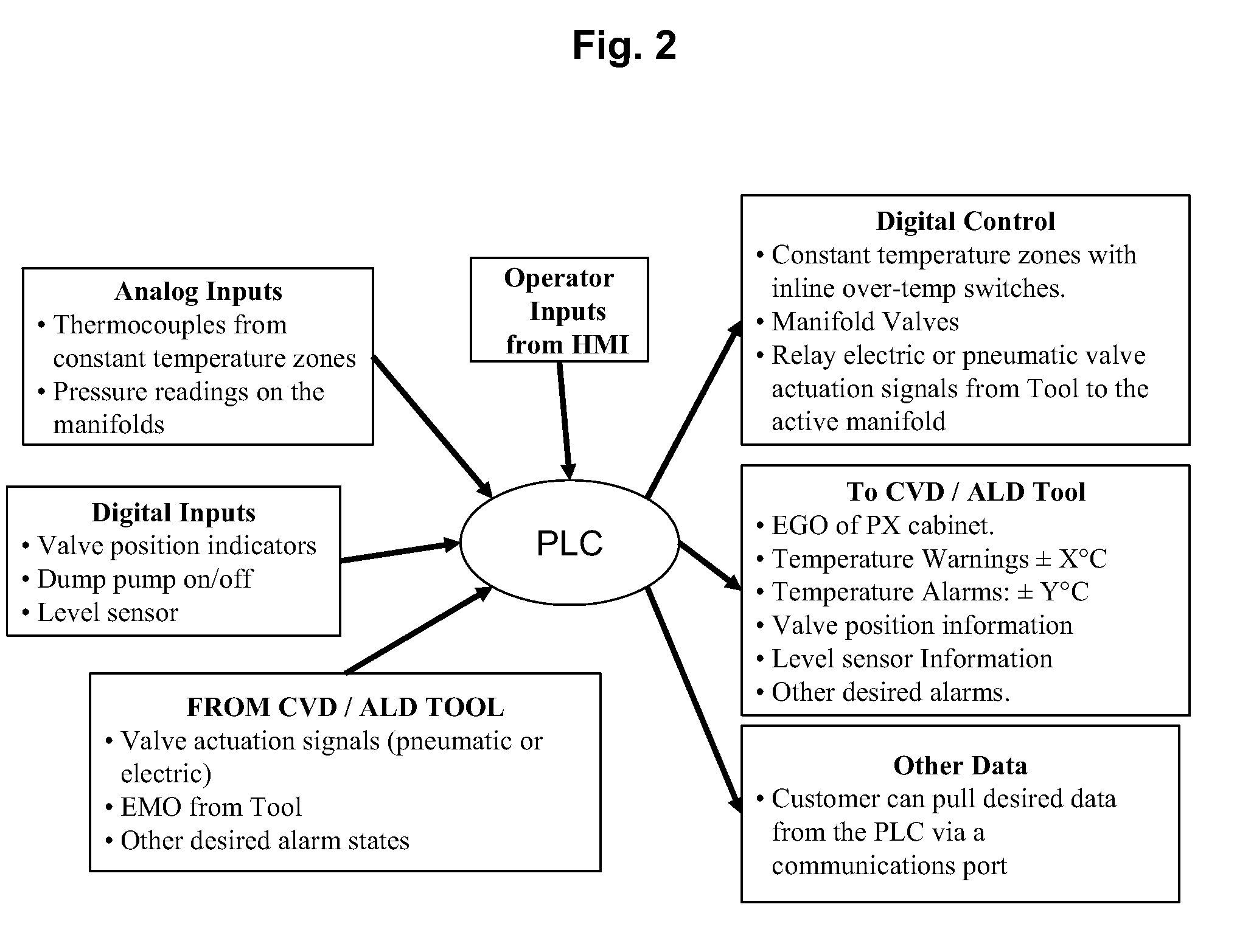

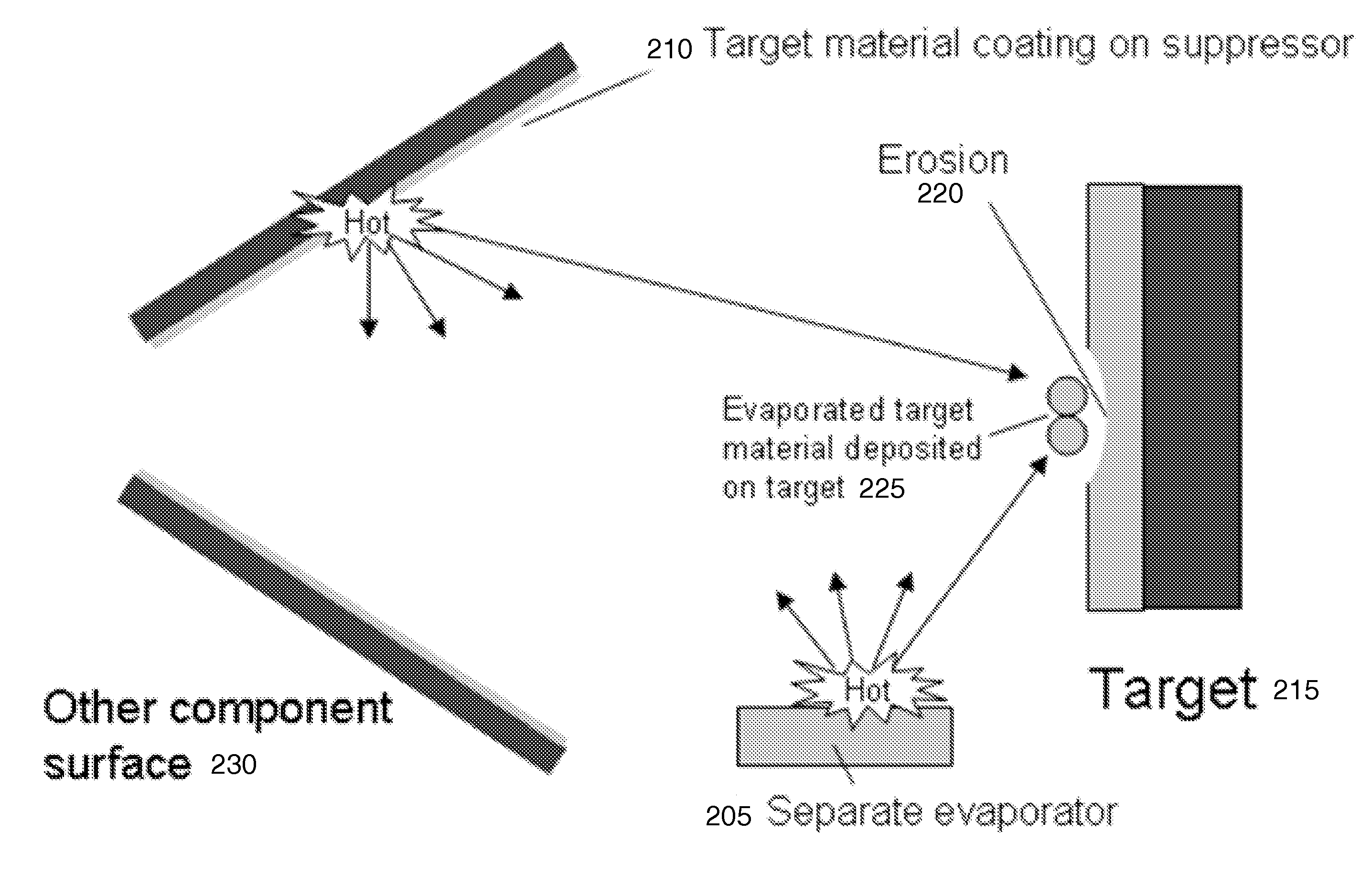

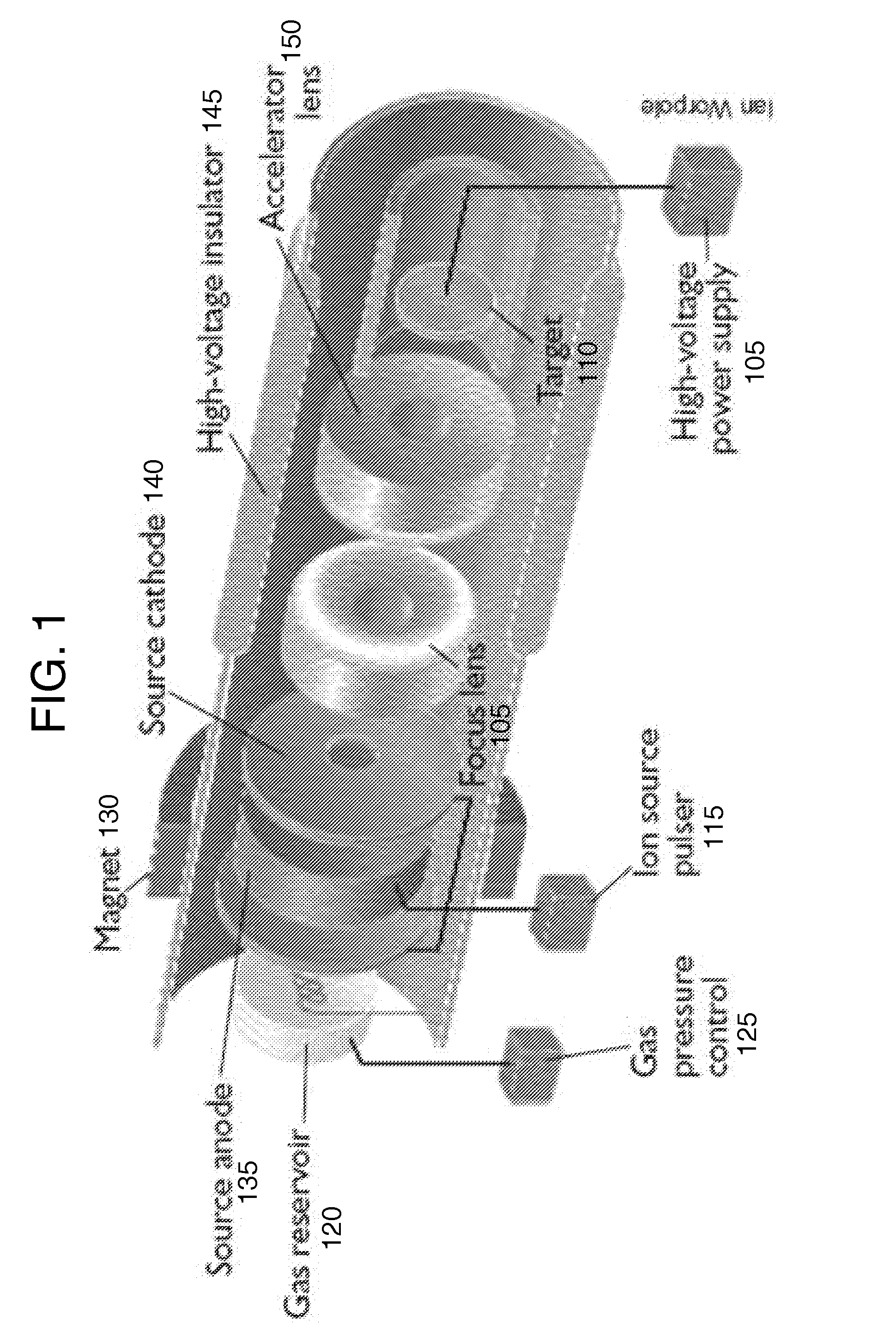

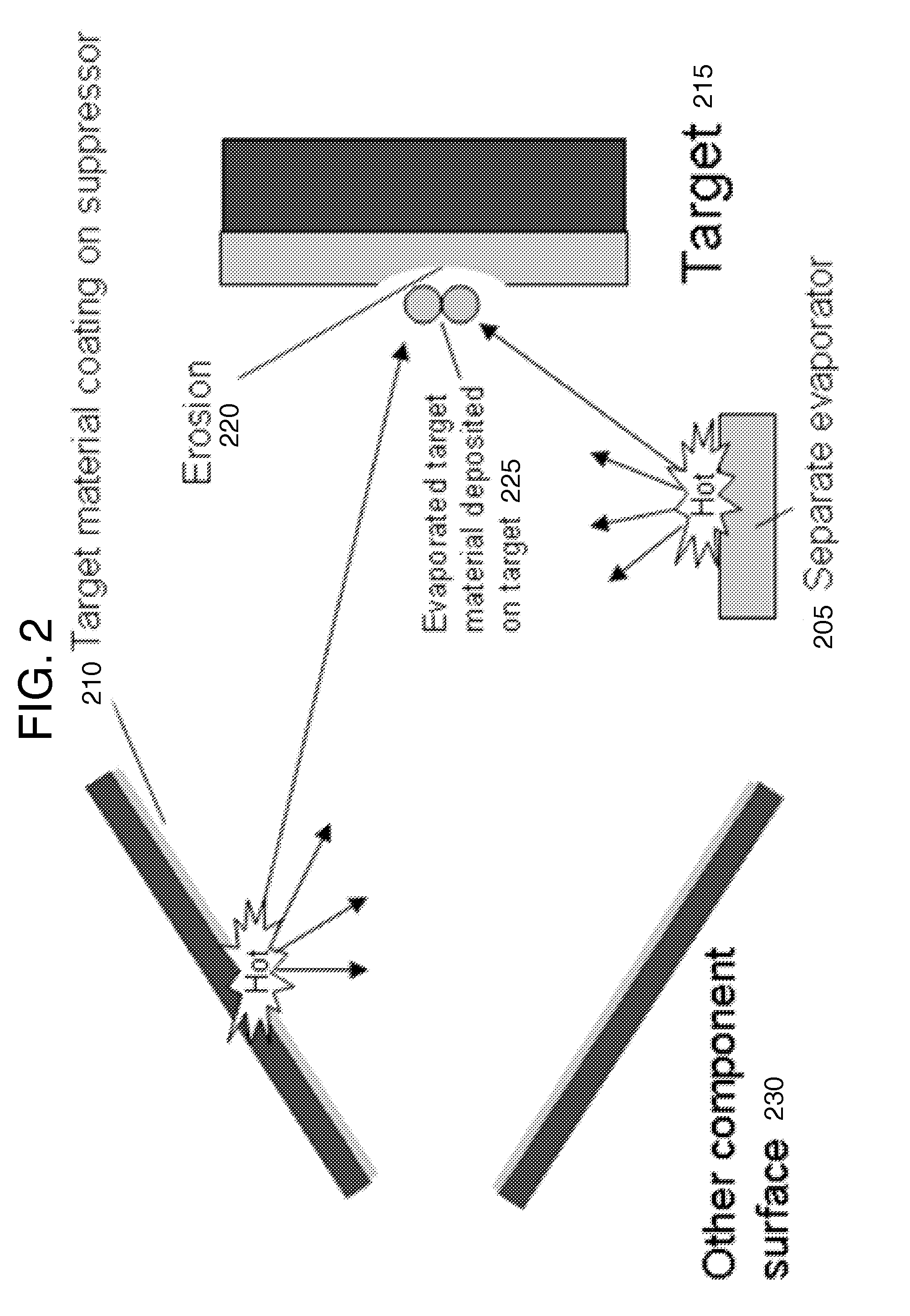

Method and system for in situ depositon and regeneration of high efficiency target materials for long life nuclear reaction devices

ActiveUS20110091000A1Maintain purityMinimize the numberNuclear energy generationDirect voltage acceleratorsNeutron energy spectrumNuclear reaction

Aspects of the invention relate to several methods to deposit and regenerate target materials in neutron generators and similar nuclear reaction devices. In situ deposition and regeneration of a target material reduces tube degradation of the nuclear reaction device and covers impurities on the surface of the target material at the target location. Further aspects of the invention include a method of designing a target to generate neutrons at a high efficiency rate and at a selected neutron energy from a neutron energy spectrum.

Owner:STARFIRE IND LLC

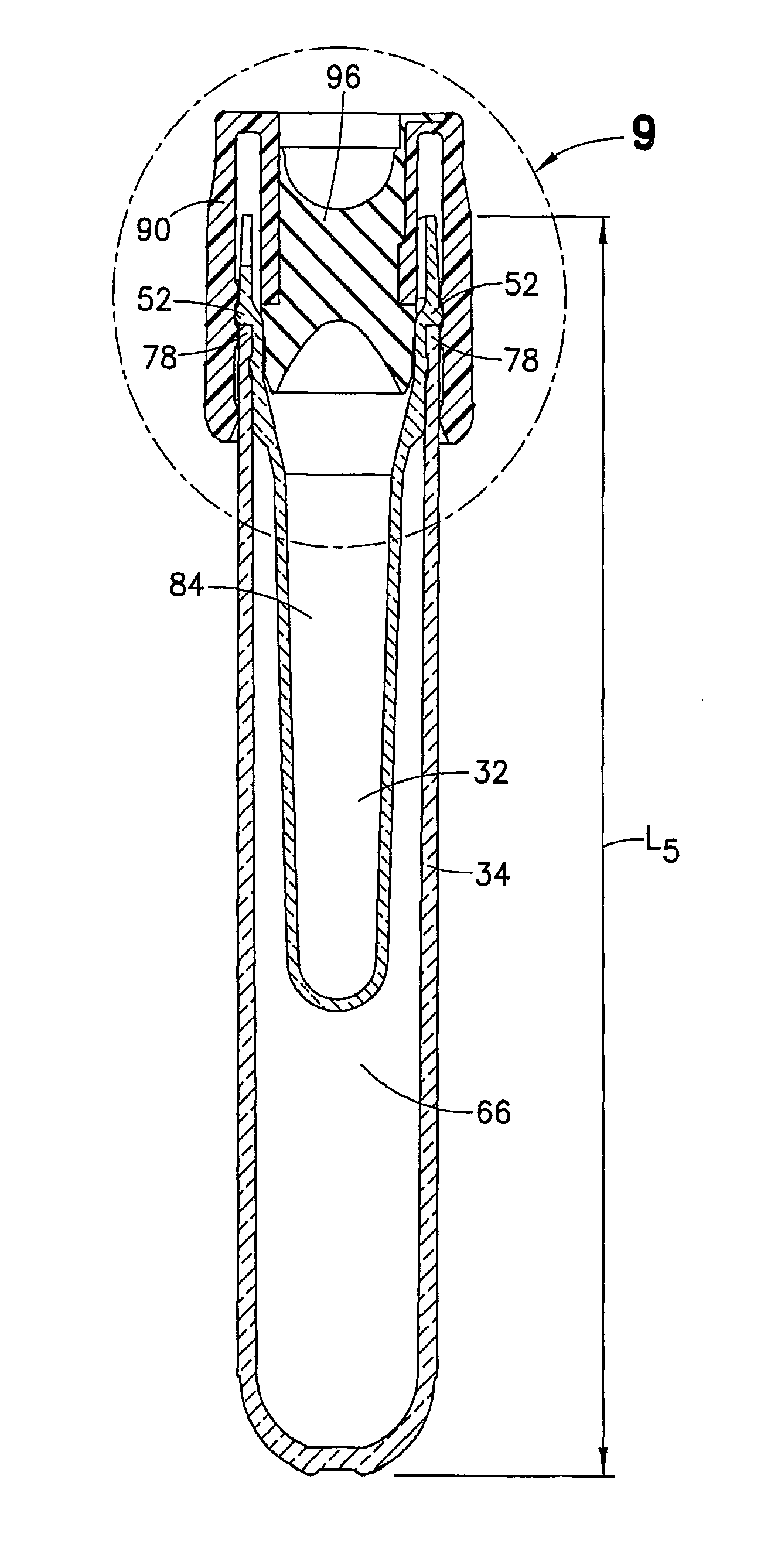

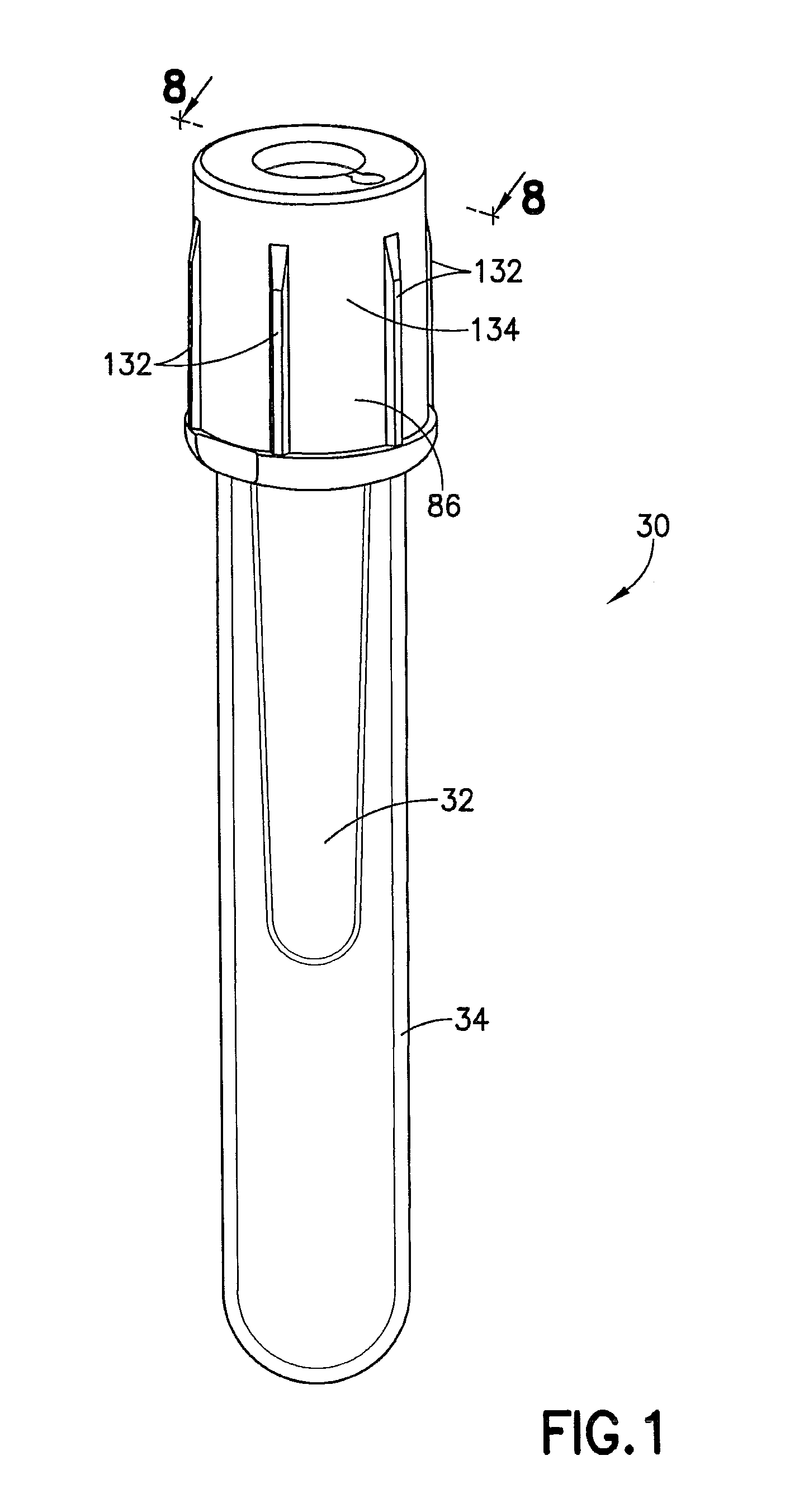

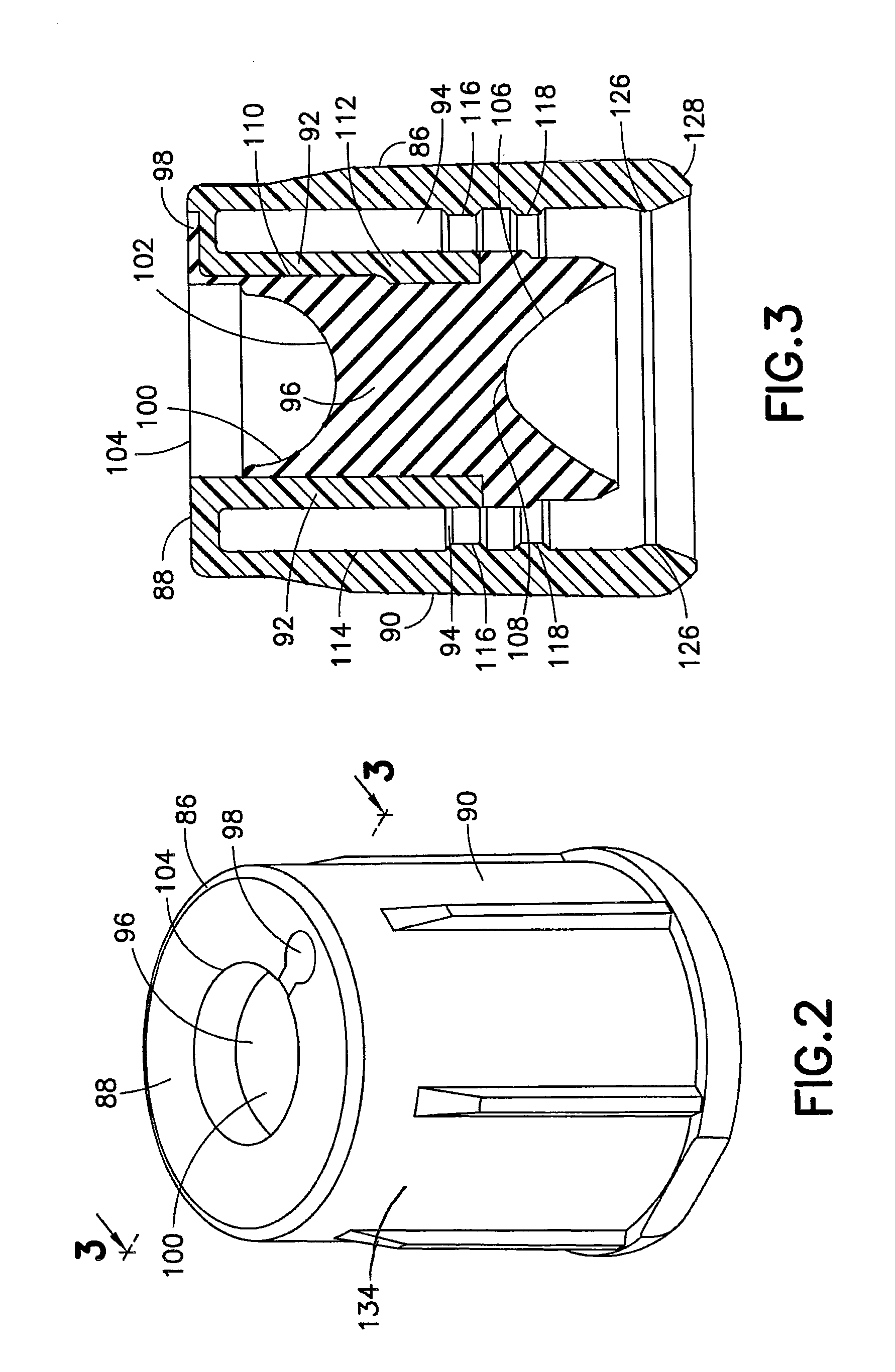

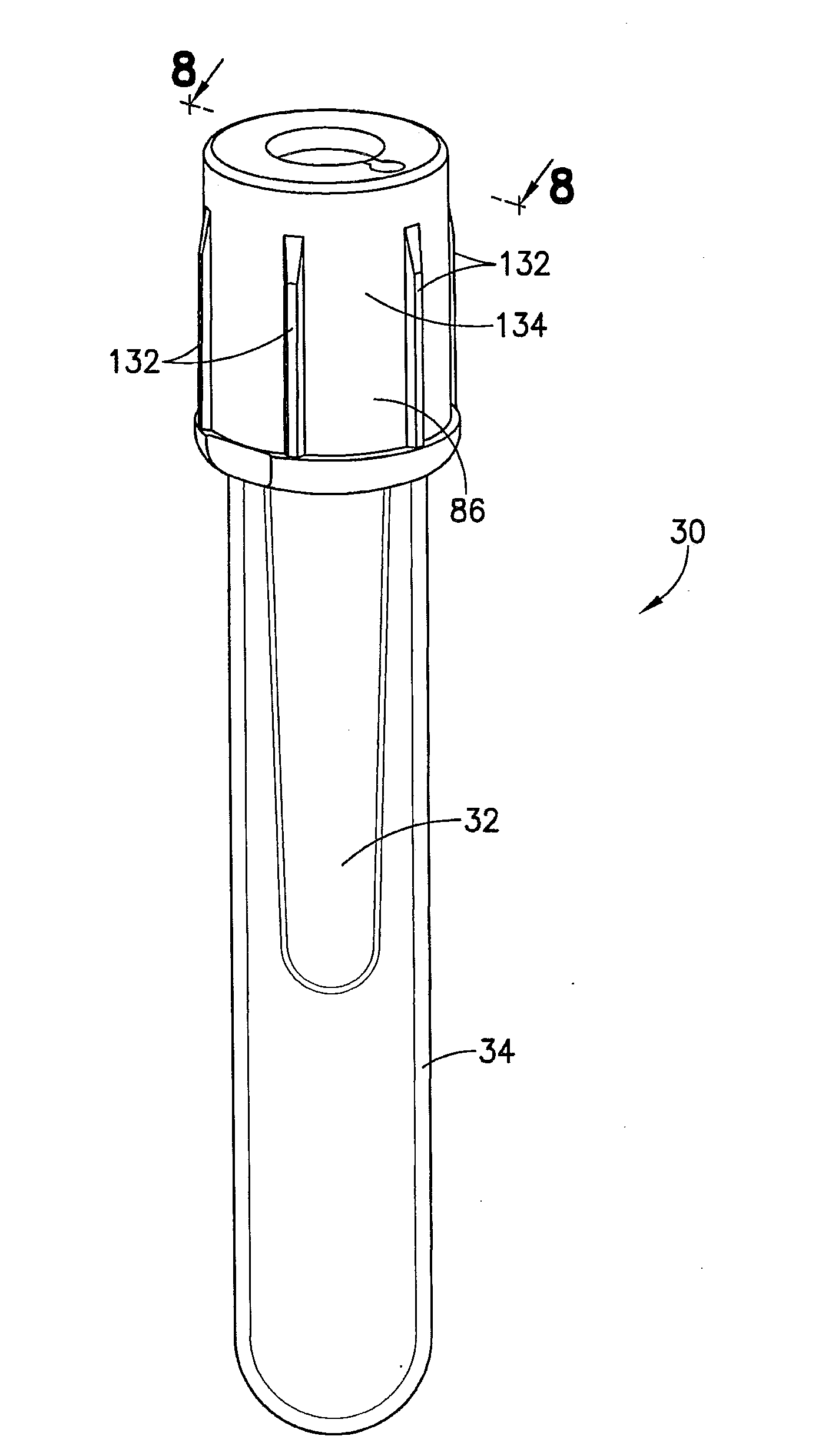

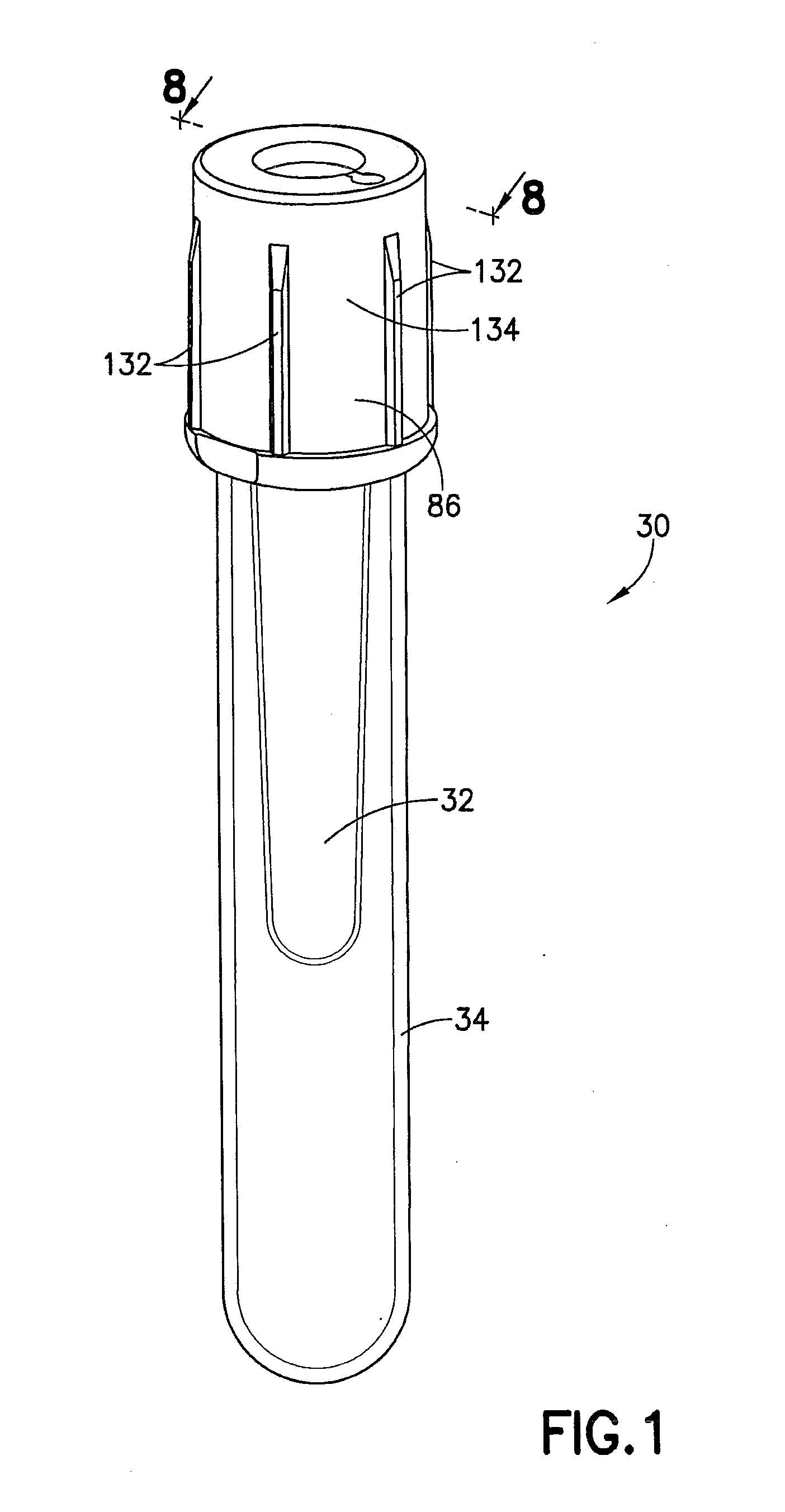

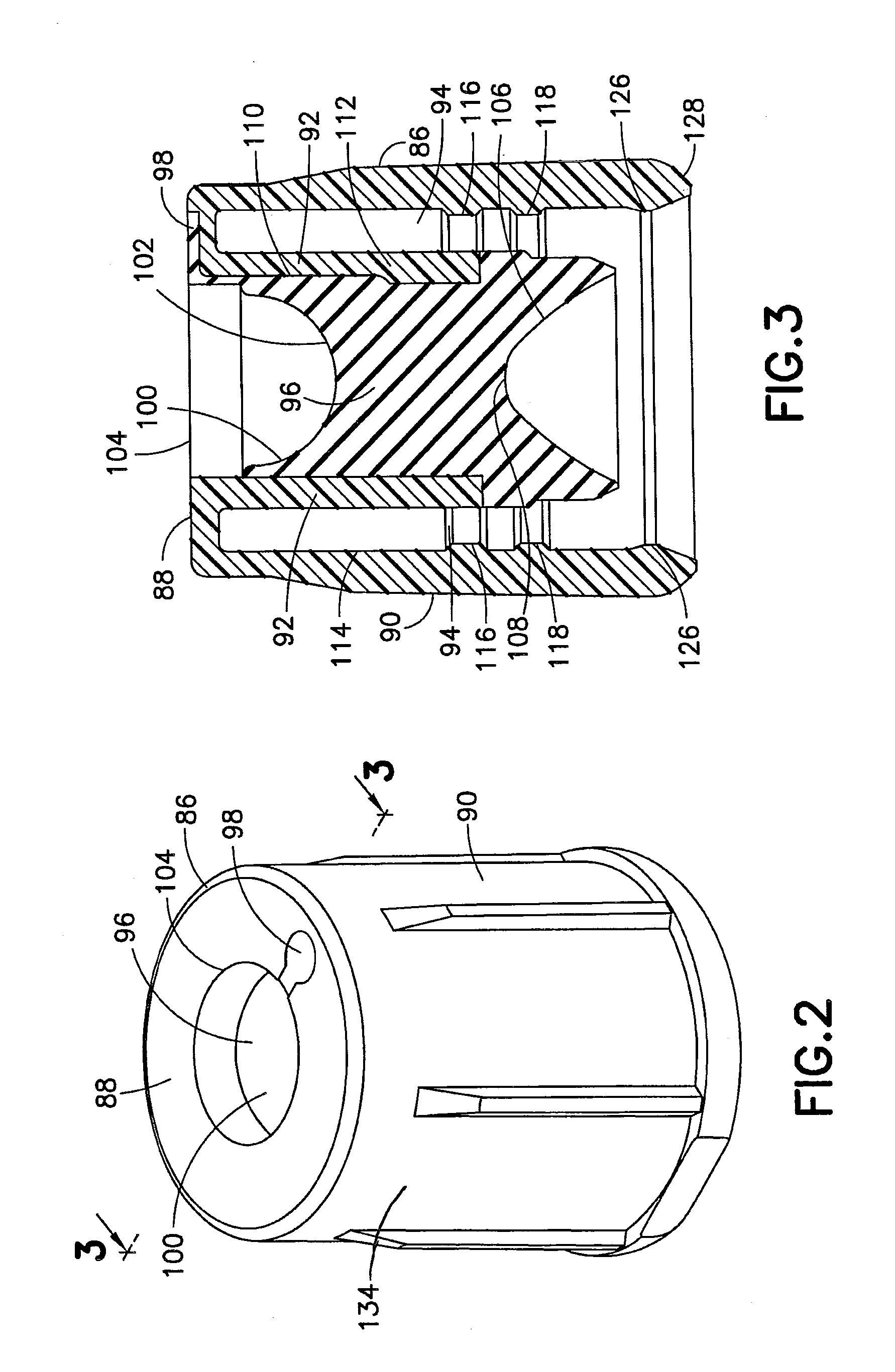

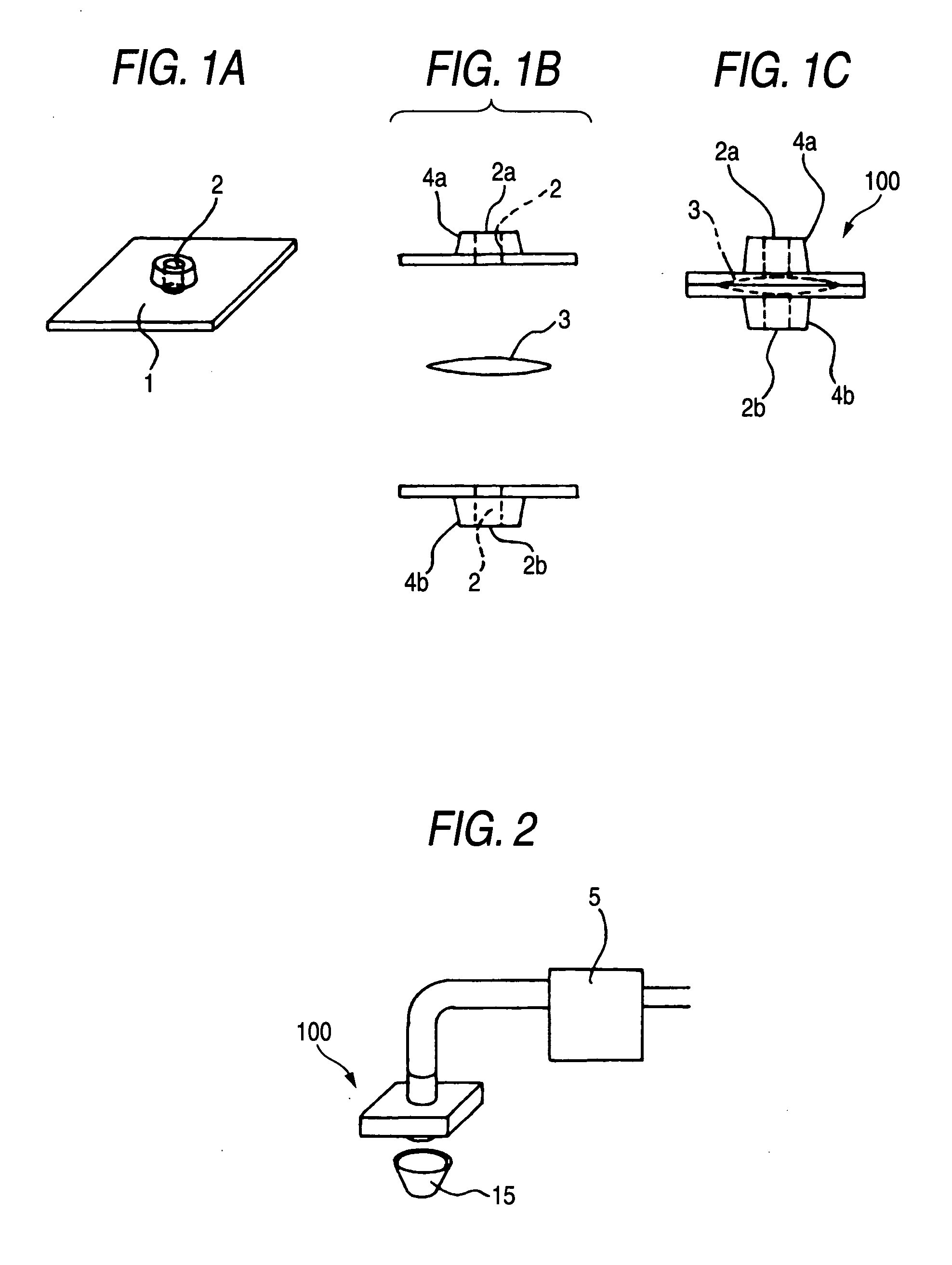

Specimen collection container assembly

ActiveUS8460620B2Optimization mechanismMaintaining the sterility of the interiorSurgeryVaccination/ovulation diagnosticsEngineeringMechanical engineering

A specimen collection container includes inner and outer tubes. The inner tube includes a bottom end, a top end, and a sidewall extending therebetween defining an interior. The sidewall includes an inner surface and an outer surface having at least one annular protrusion extending therefrom. The inner tube includes at least one funnel portion adjacent the top end for directing a specimen into the inner tube interior, and an annular ring disposed about a portion of the outer surface of the sidewall adjacent the top end. The outer tube includes a bottom end, a top end, and a sidewall extending therebetween, the sidewall having an outer surface and an inner surface defining an annular recess adapted to receive a portion of the annular protrusion therein. The inner tube is disposed within the outer tube and a portion of the top end of the outer tube abuts the annular ring.

Owner:BECTON DICKINSON & CO

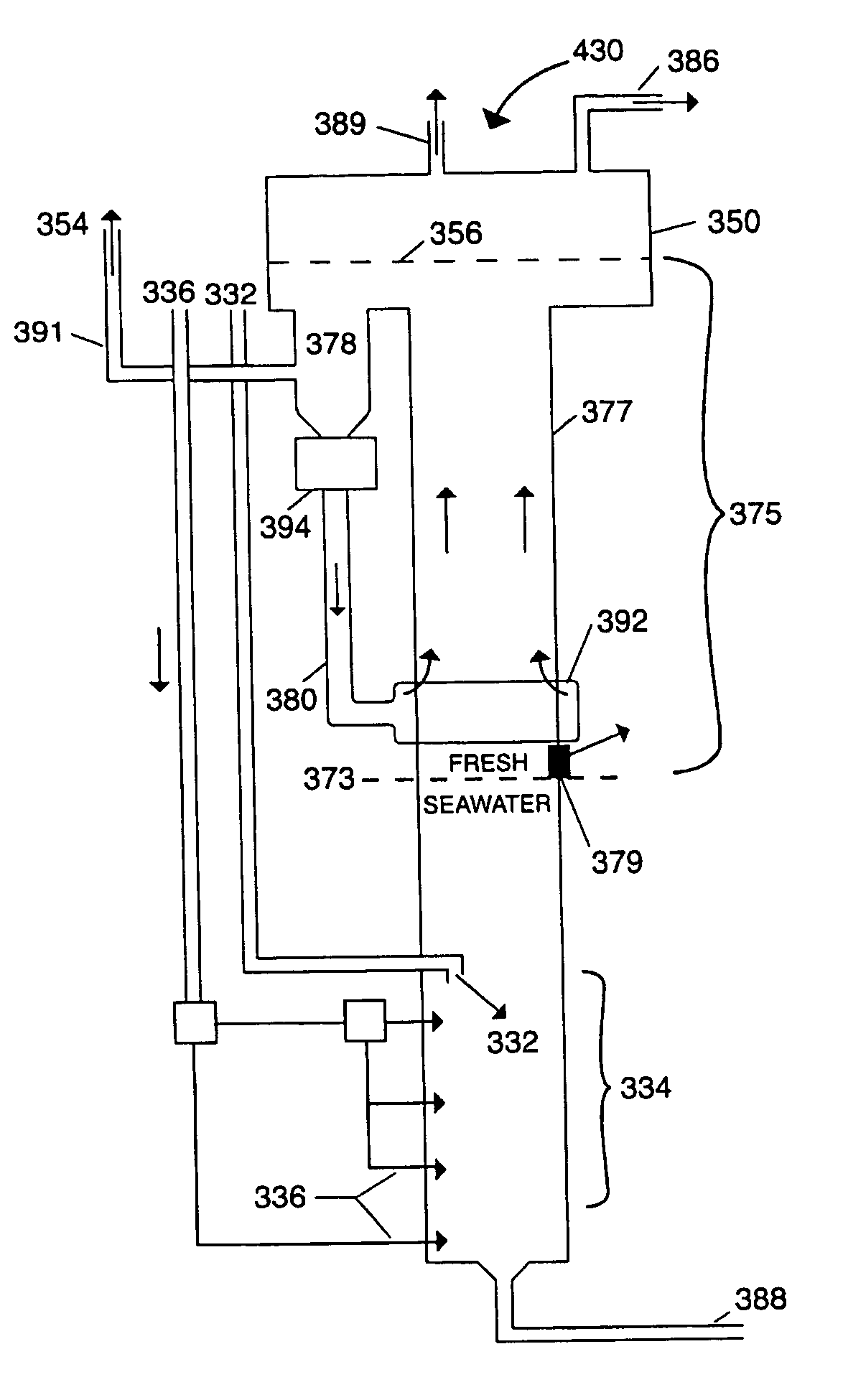

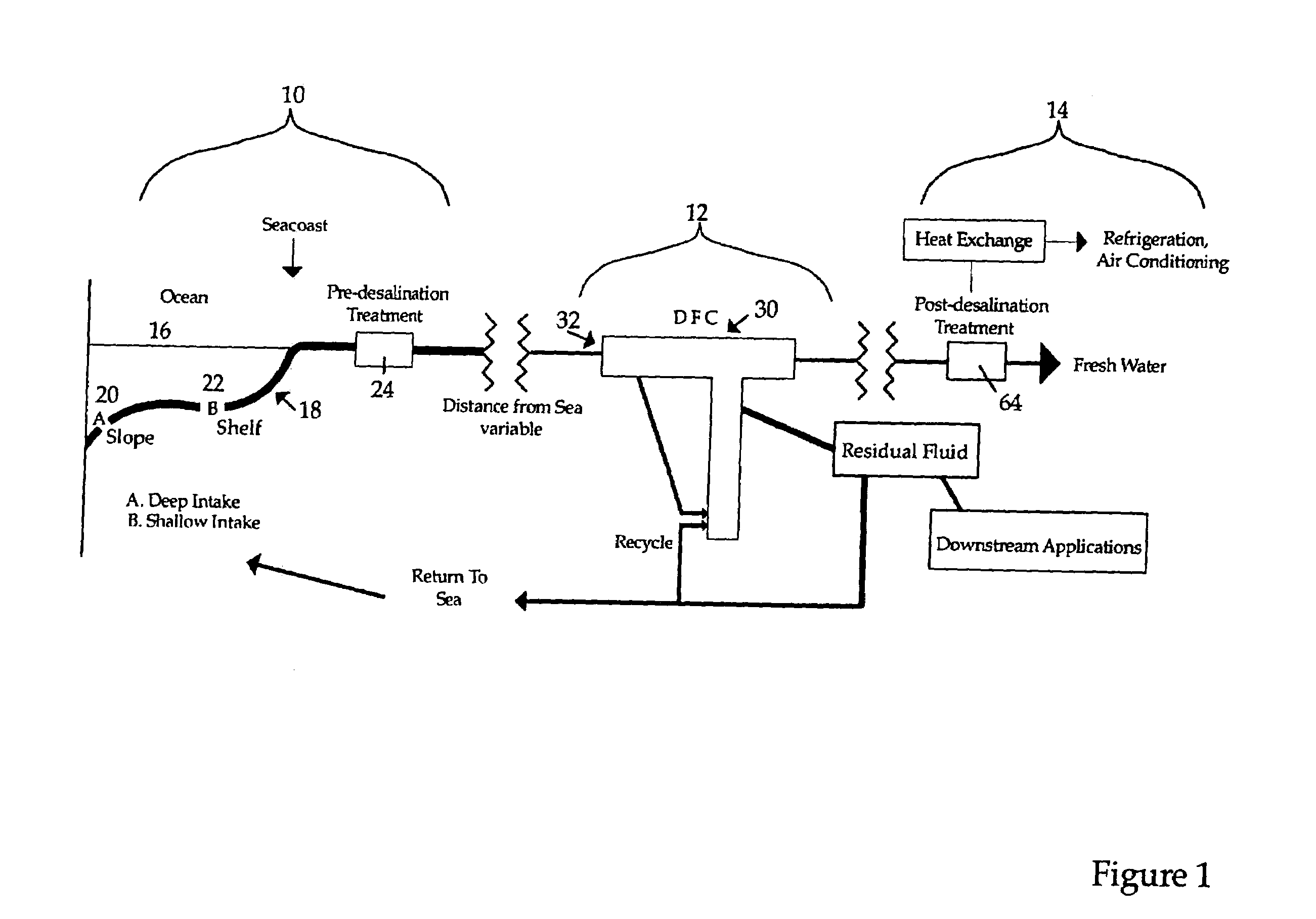

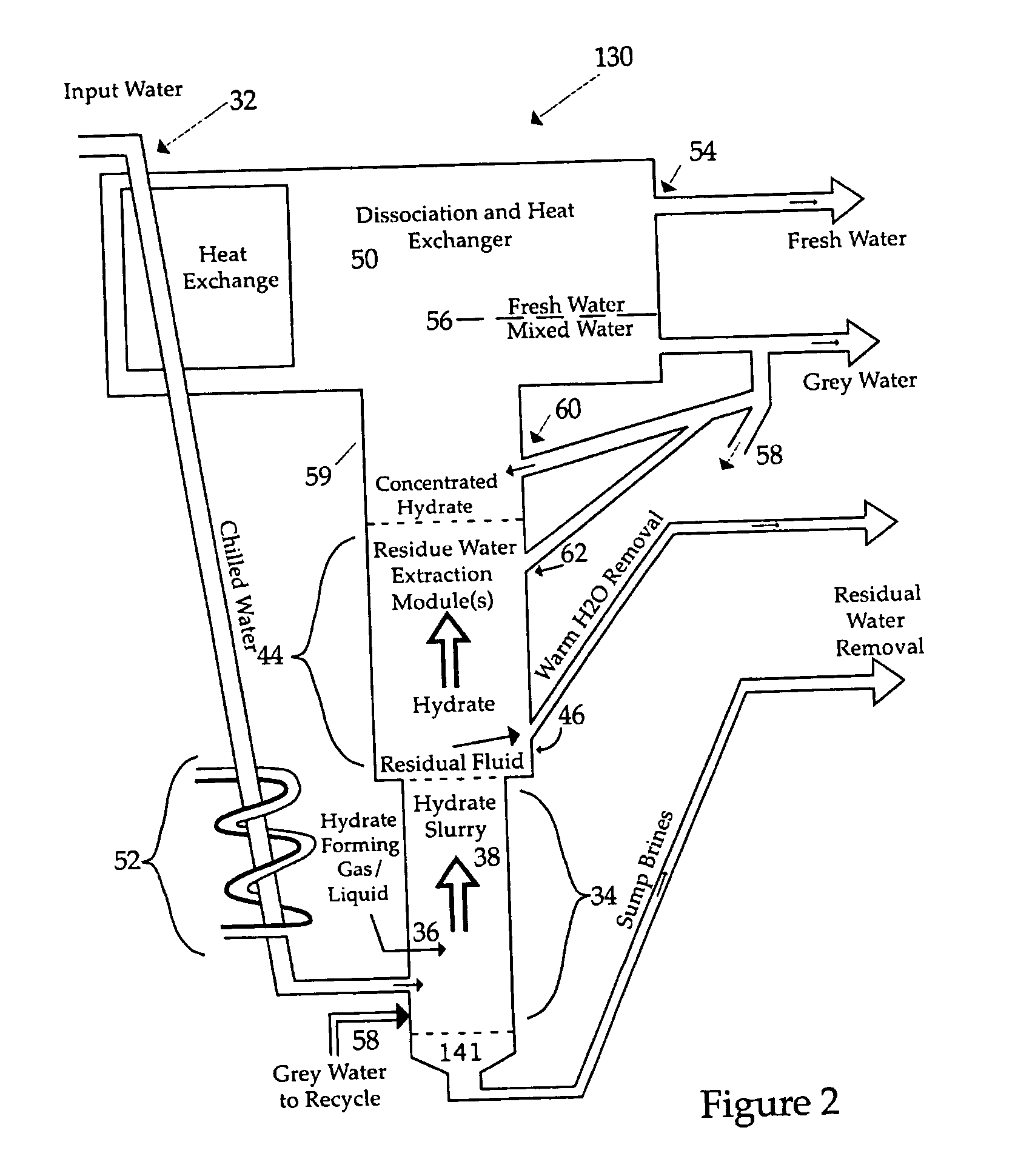

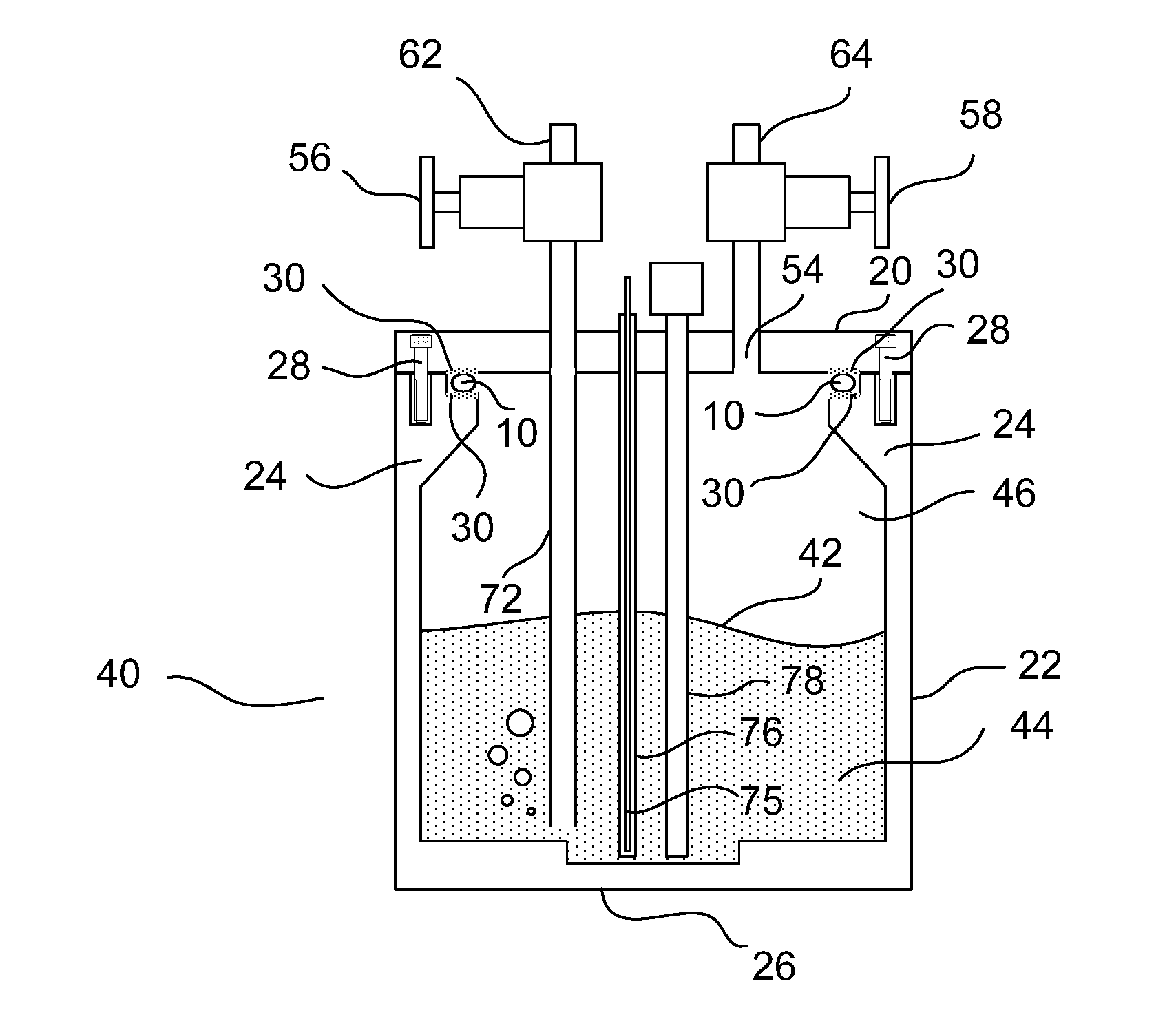

Hydrate-based desalination with hydrate-elevating density-driven circulation

InactiveUS6969467B1Increase ratingsMinimize the possibilityOrganic chemistryAuxillariesWater desalinationSaline water

In hydrate-based desalination or other water purification conducted using naturally buoyant or trapped-gas-assisted buoyancy hydrate in a hydrate fractionation column, a portion of fresh or purified product water is extracted from an upper, hydrate dissociation region of the fractionation column and reintroduced into a lower portion of the fractionation column at a point above but generally near a product water / saline water interface. The difference in density between the reintroduced product water and the fluid in the hydrate fractionation column above the point of reintroduction (water, hydrate, and gas) drives a natural circulation system which enhances the rate at which hydrate rises into the hydrate dissociation region.

Owner:WATER REGENERATION SYST

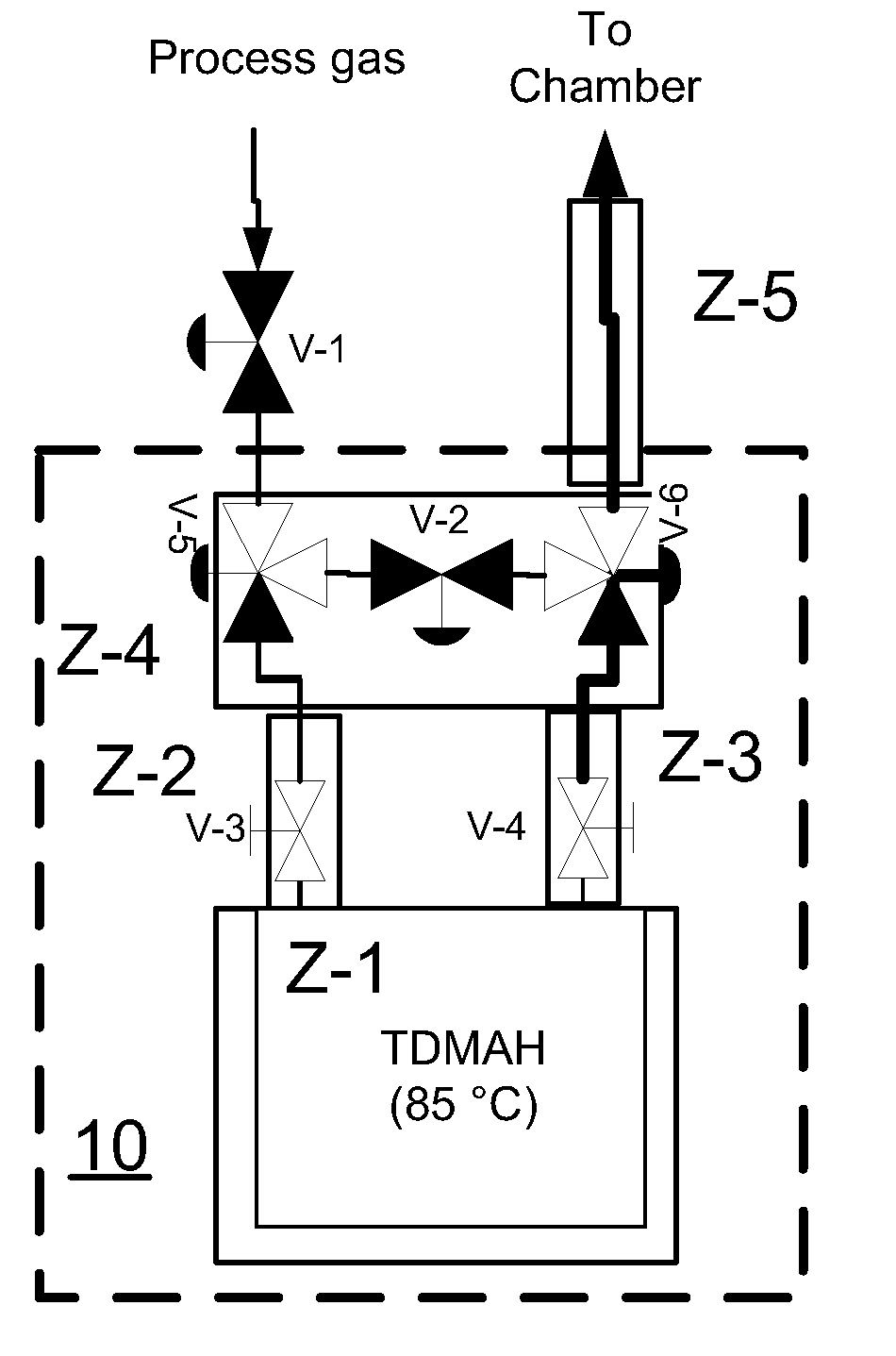

Diptube apparatus and method for delivering vapor phase reagent to a deposition chamber

InactiveUS20080178809A1Easy to cleanIncrease usageLiquid surface applicatorsContainer filling methodsSemiconductor materialsGas phase

This invention relates to a liquid phase reagent dispensing apparatus having a diptube and alsoa metal seal aligned and in contact with hardened opposing flat surfaces of top wall member and a protuberance[ [;]]on a side wall member, wherein said hardened opposing flat surfaces of said top wall member and said protuberance have a hardness greater than the hardness of said metal seal.The apparatus further has a temperature sensor and a source chemical level sensor extending through a centrally located portion of the top wall member and generally vertically downwardly to a cavity centrally located on the a bottom wall member [ [,]] . The dispensing apparatus may be used for dispensing of reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

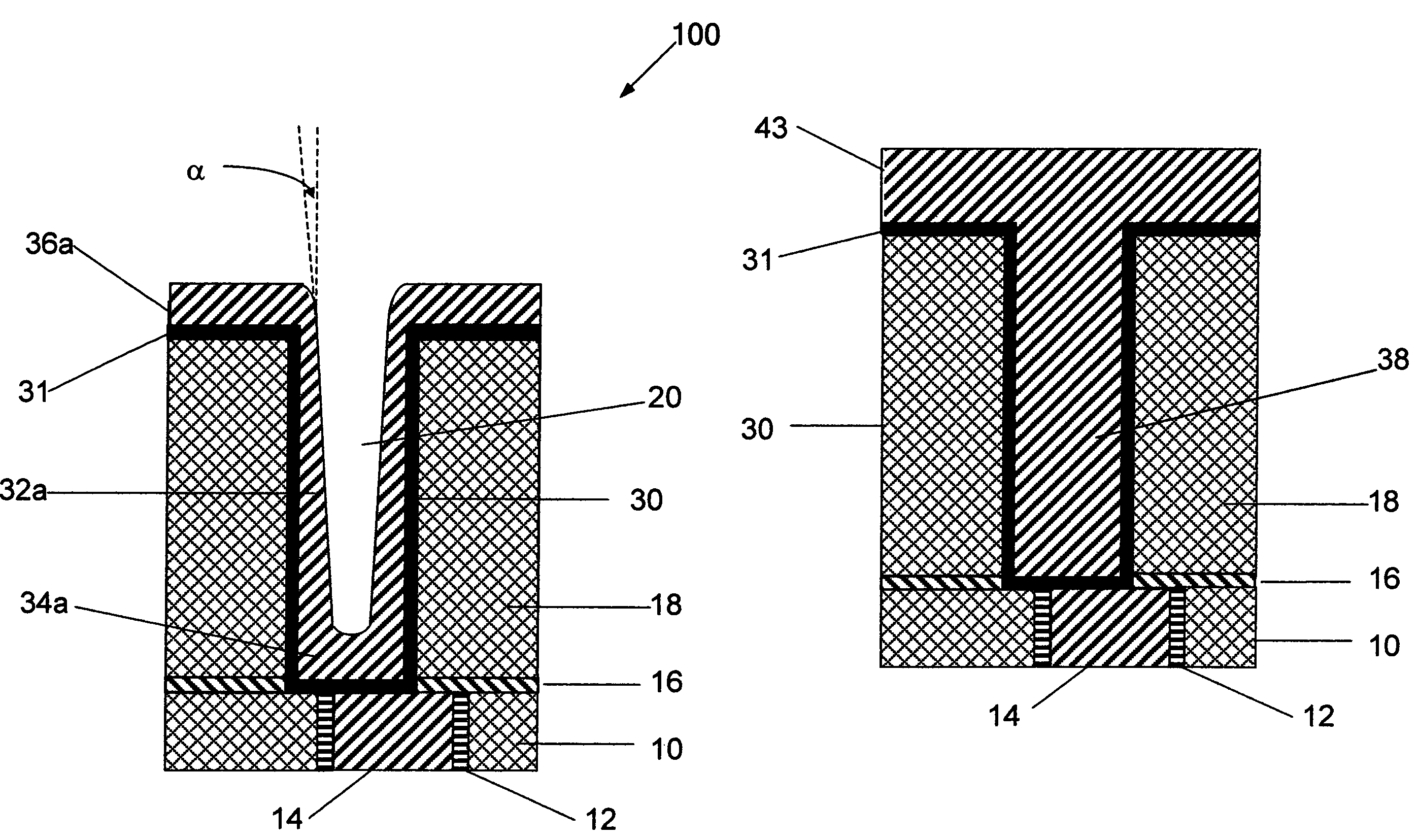

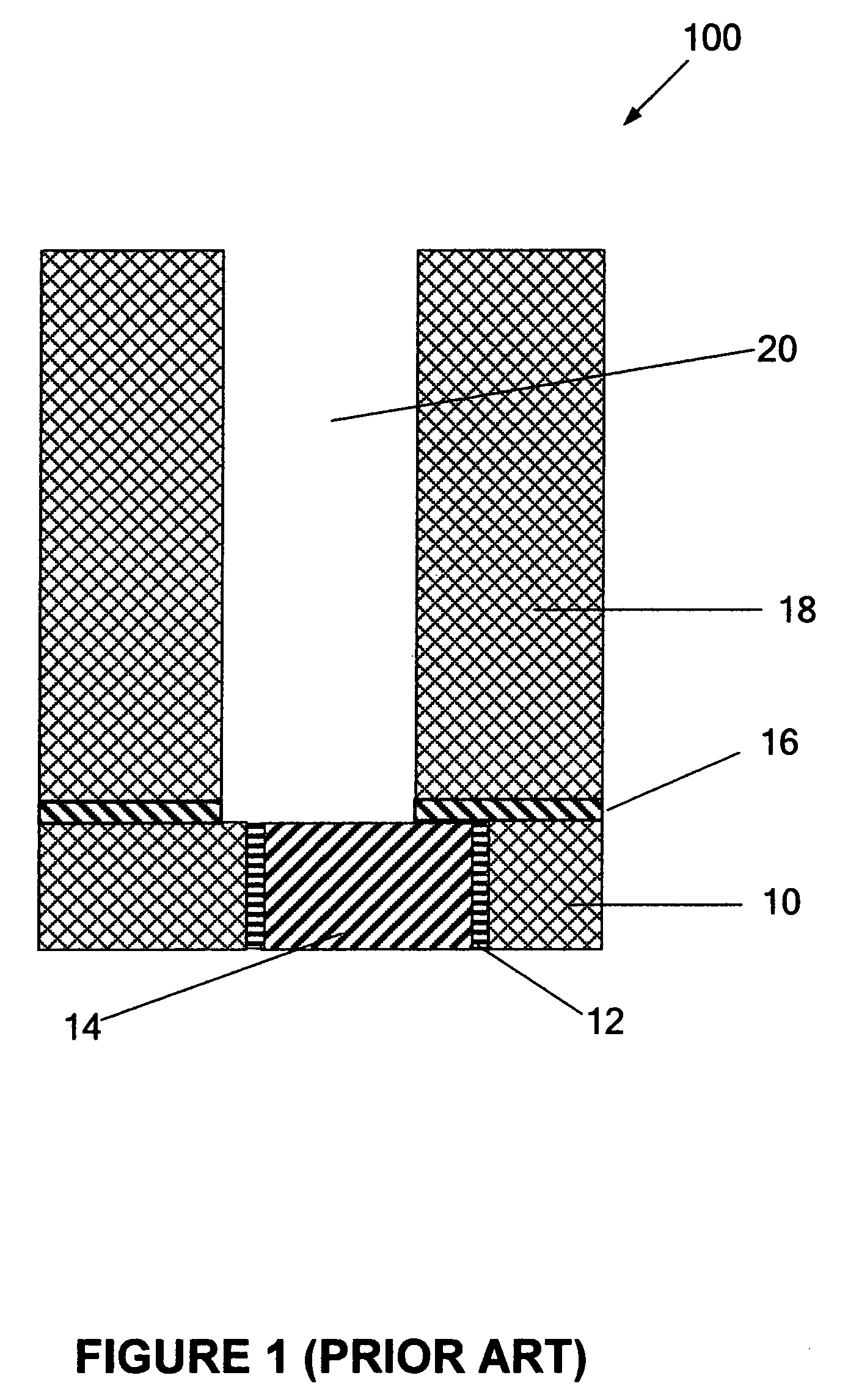

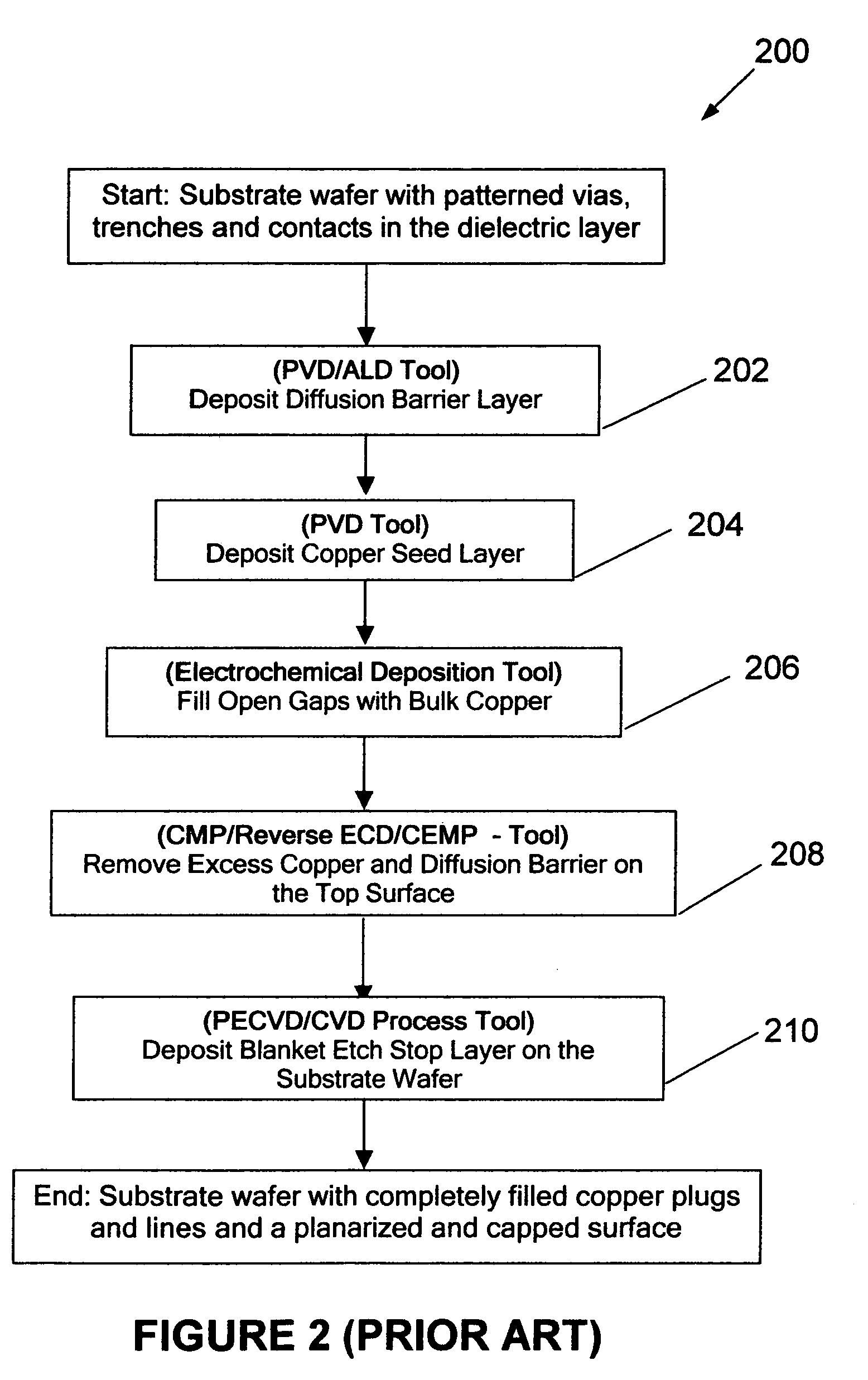

Method for filling of a recessed structure of a semiconductor device

InactiveUS7365005B1Quality improvementEasy to runSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialGas phase

This invention relates to process sequence by high-speed atomic layer chemical vapor processing that includes deposition for diffusion barriers in the etched features on substrate followed by gap fill and subsequent in-situ removal of the blanket films on the top by plasma enhanced vapor phase processes. The apparatus and process sequences employed in these processing scheme allows the practitioner to complete all vapor phase process sequences of diffusion barrier deposition, gap fill and planarization of copper and diffusion barrier planarization. In case of copper metallization scheme, vapor phase gap fill can be employed to replace electrochemical deposition of copper and removal of copper and the diffusion barrier by vapor phase reactions can replace chemical-mechanical-polishing. Furthermore, such a processing scheme can be employed to deposit gate level dielectric layer, shallow trench isolation and also to form first metal contact plugs with a suitable barrier at the front end of line processing.

Owner:GADGIL PRASAD N

Method for processing substrates

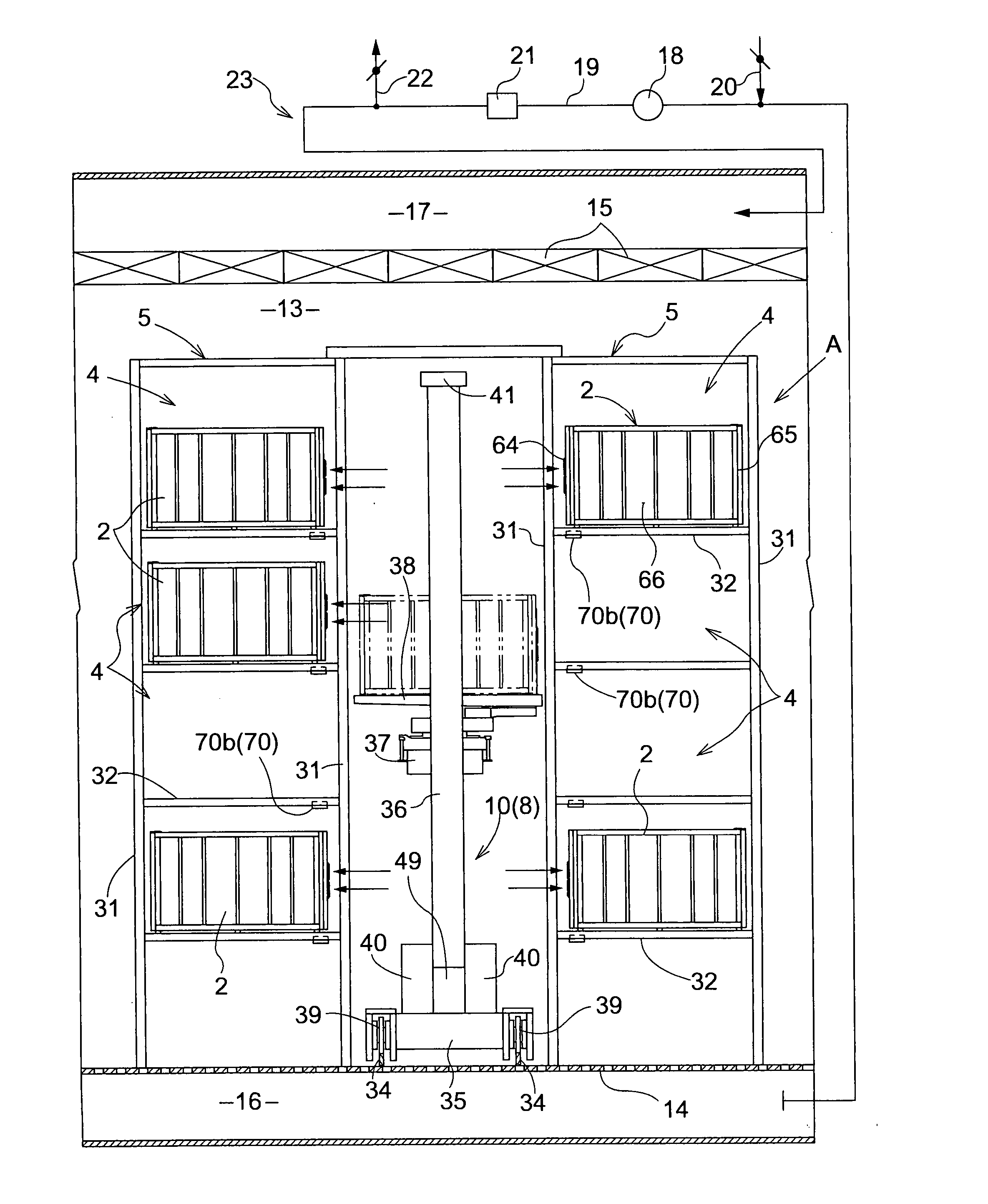

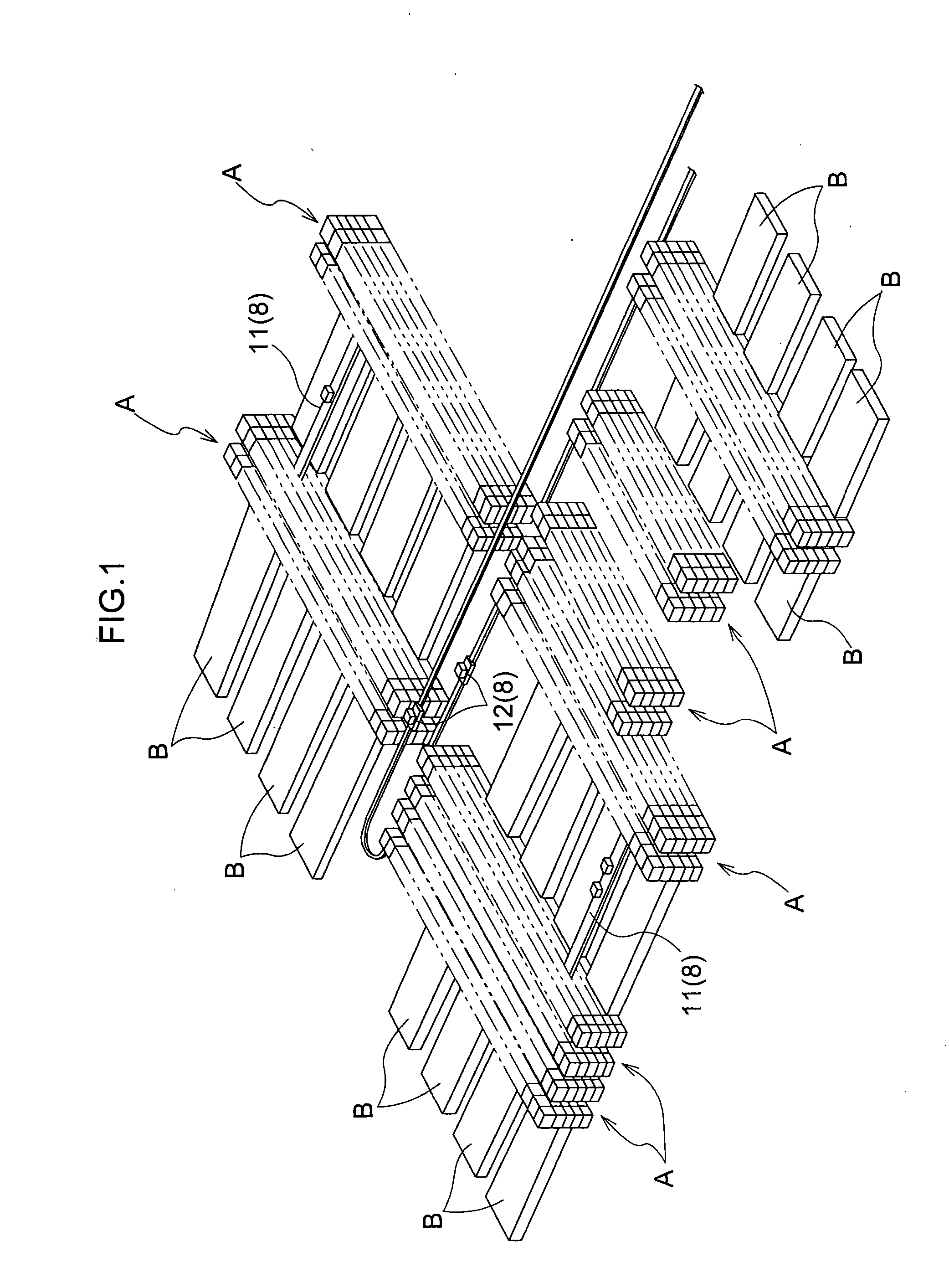

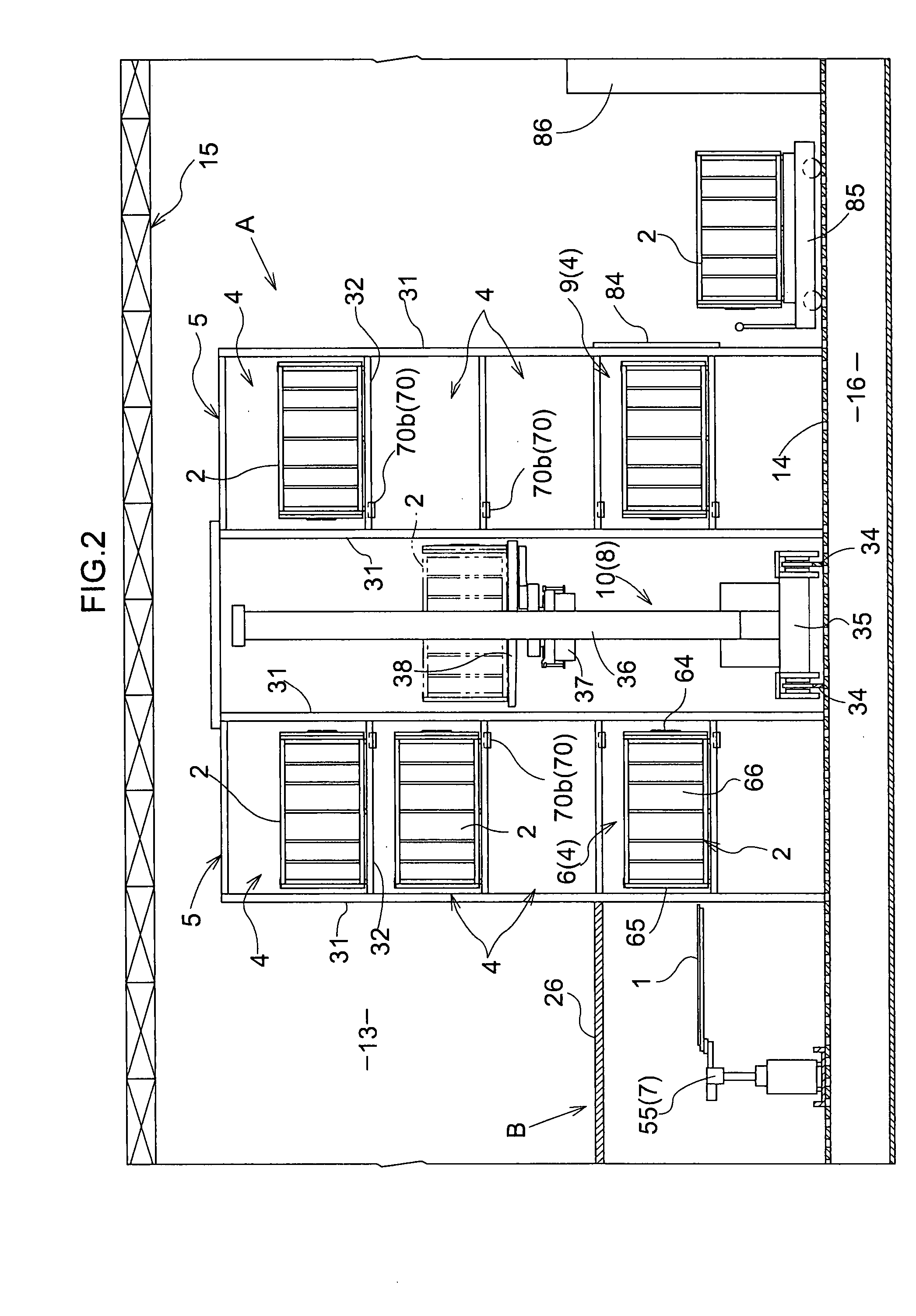

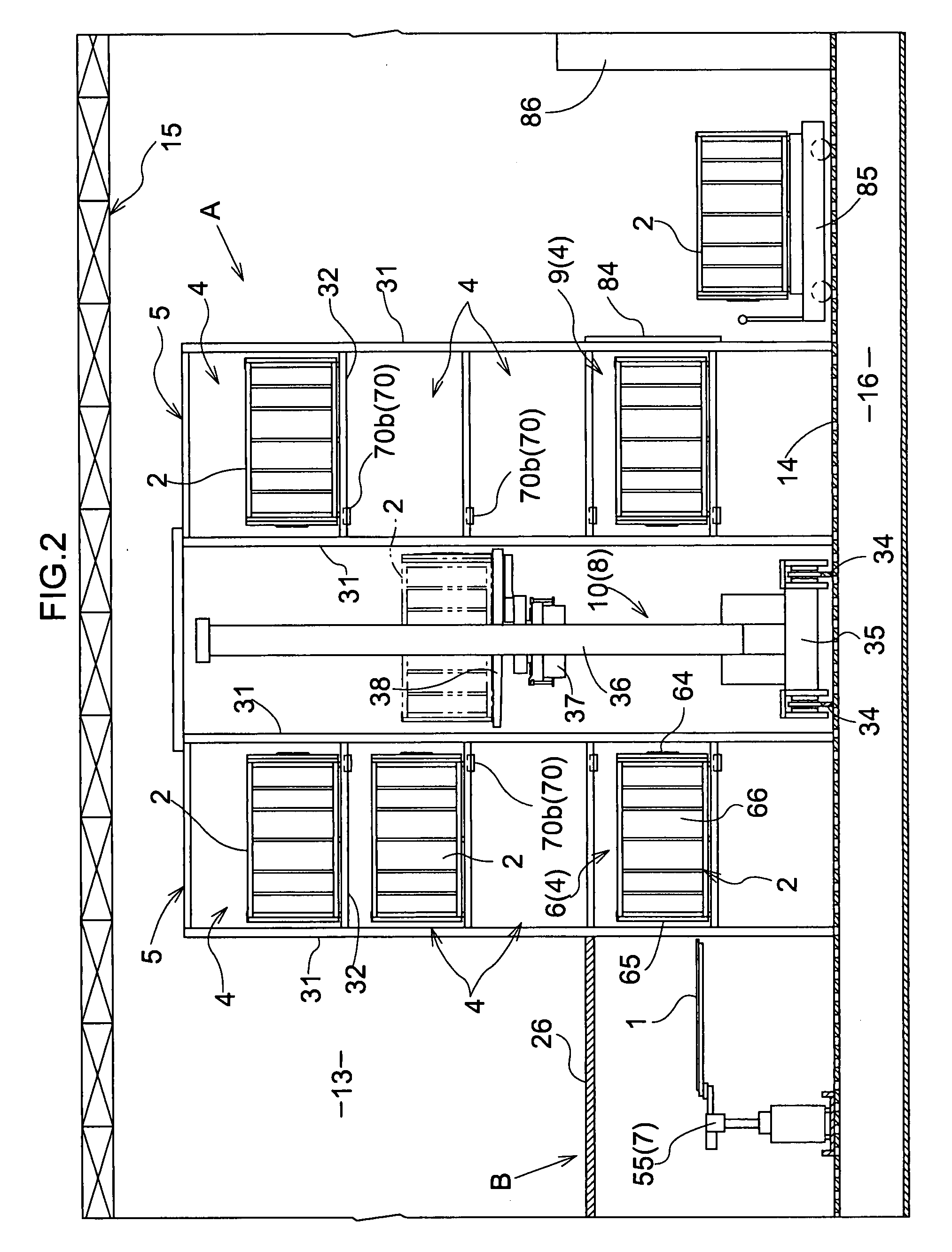

ActiveUS20080089765A1Maintain purityInhibition of attachmentLighting and heating apparatusLarge containersEngineeringClosed state

The method for processing substrates for substrate processing facility includes the steps of performing ventilation a the fan filter unit while putting a lid of a container in a closed state, when the container is stored in a storage shelf, and is transferred with a substrate transfer device, and ventilating the container with the fan filter with the lid of the container in an open state, when substrates are transferred in a substrate loading / unloading section with the substrate transfer device.

Owner:DAIFUKU CO LTD

Specimen Collection Container Assembly

ActiveUS20120141341A1Improved sealing mechanismOptimization mechanismLaboratory glasswaresDiagnostic recording/measuringMechanical engineeringSpecimen collection

A specimen collection container includes inner and outer tubes. The inner tube includes a bottom end, a top end, and a sidewall extending therebetween defining an interior. The sidewall includes an inner surface and an outer surface having at least one annular protrusion extending therefrom. The inner tube includes at least one funnel portion adjacent the top end for directing a specimen into the inner tube interior, and an annular ring disposed about a portion of the outer surface of the sidewall adjacent the top end. The outer tube includes a bottom end, a top end, and a sidewall extending therebetween, the sidewall having an outer surface and an inner surface defining an annular recess adapted to receive a portion of the annular protrusion therein. The inner tube is disposed within the outer tube and a portion of the top end of the outer tube abuts the annular ring.

Owner:BECTON DICKINSON & CO

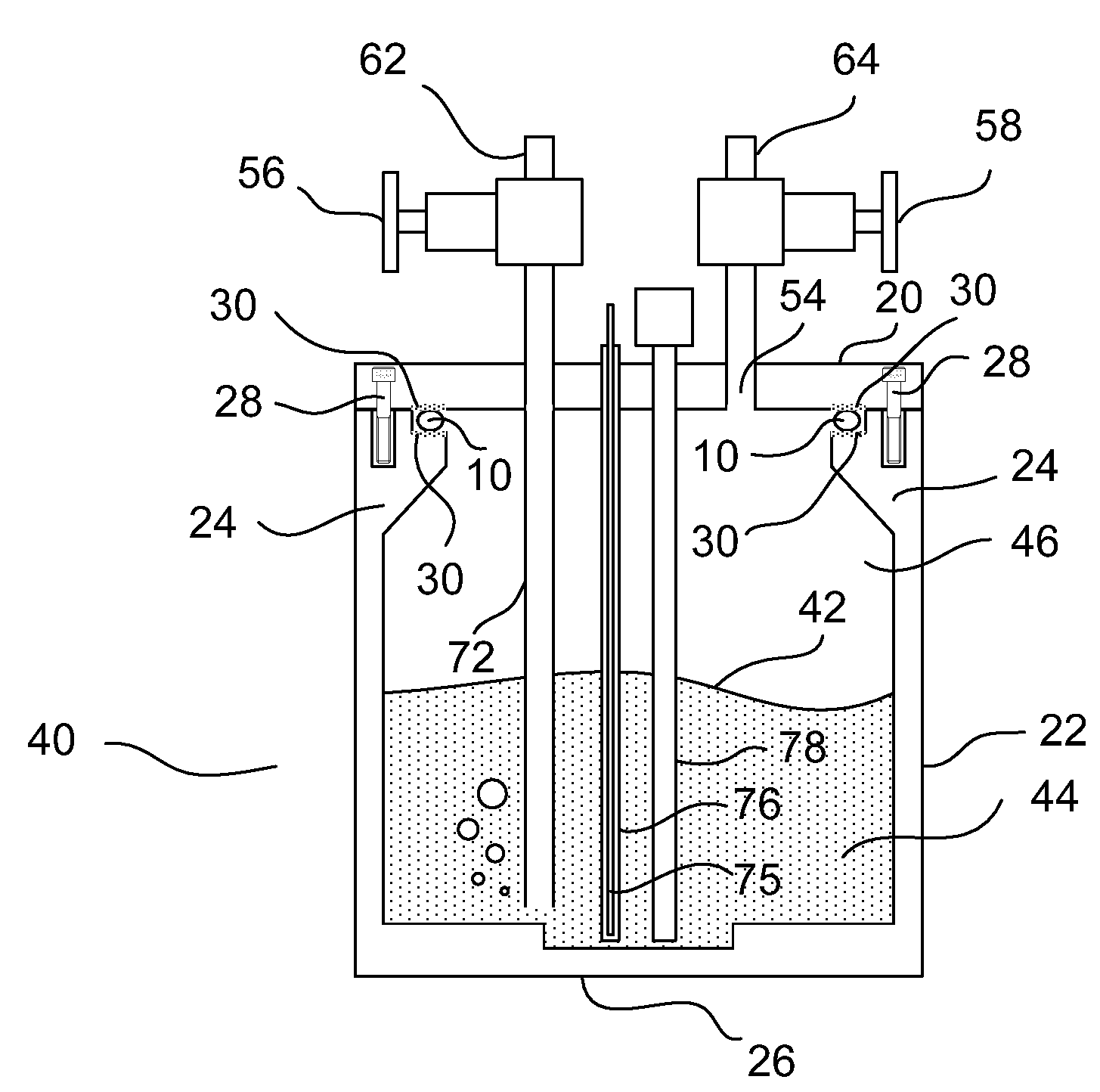

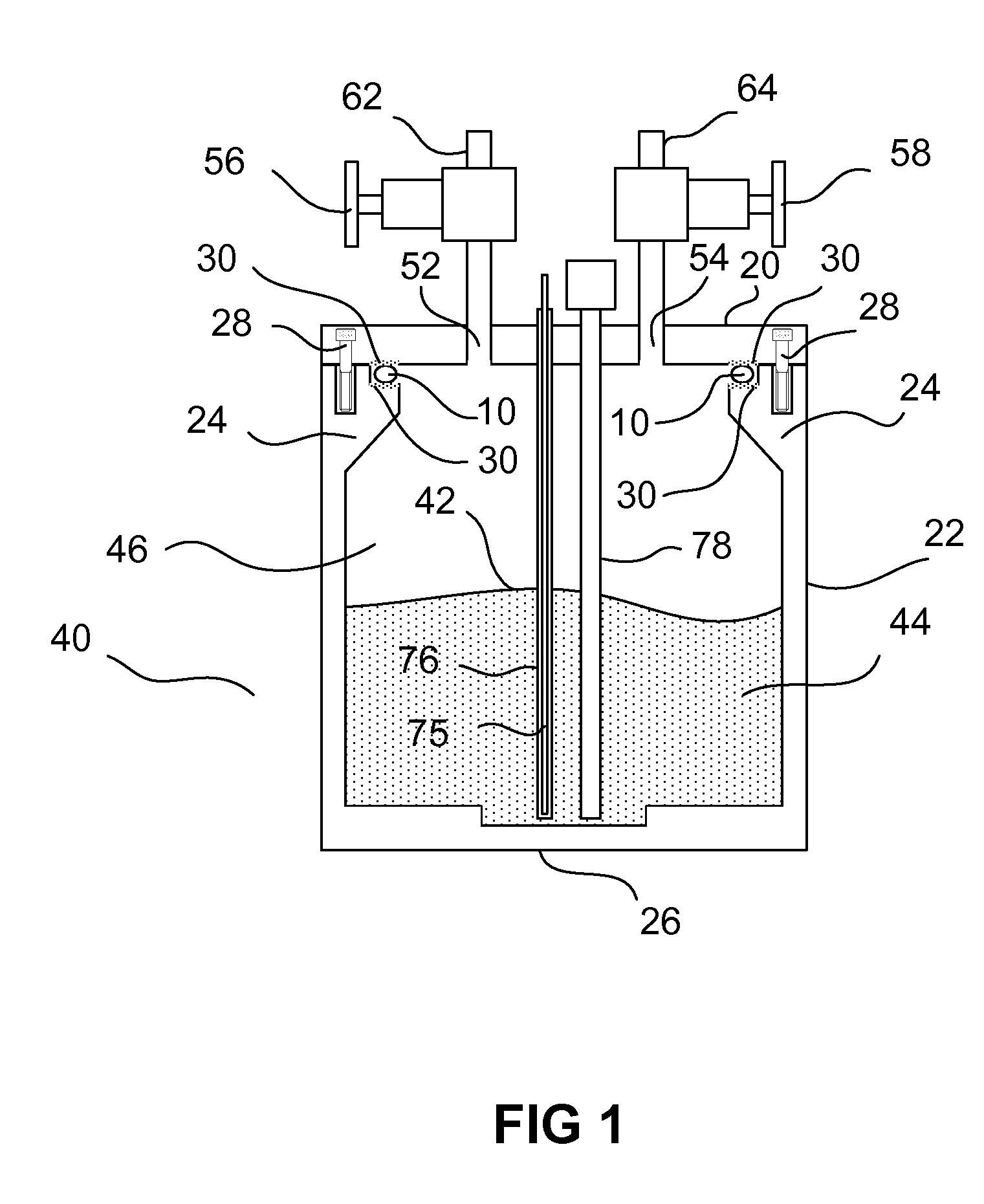

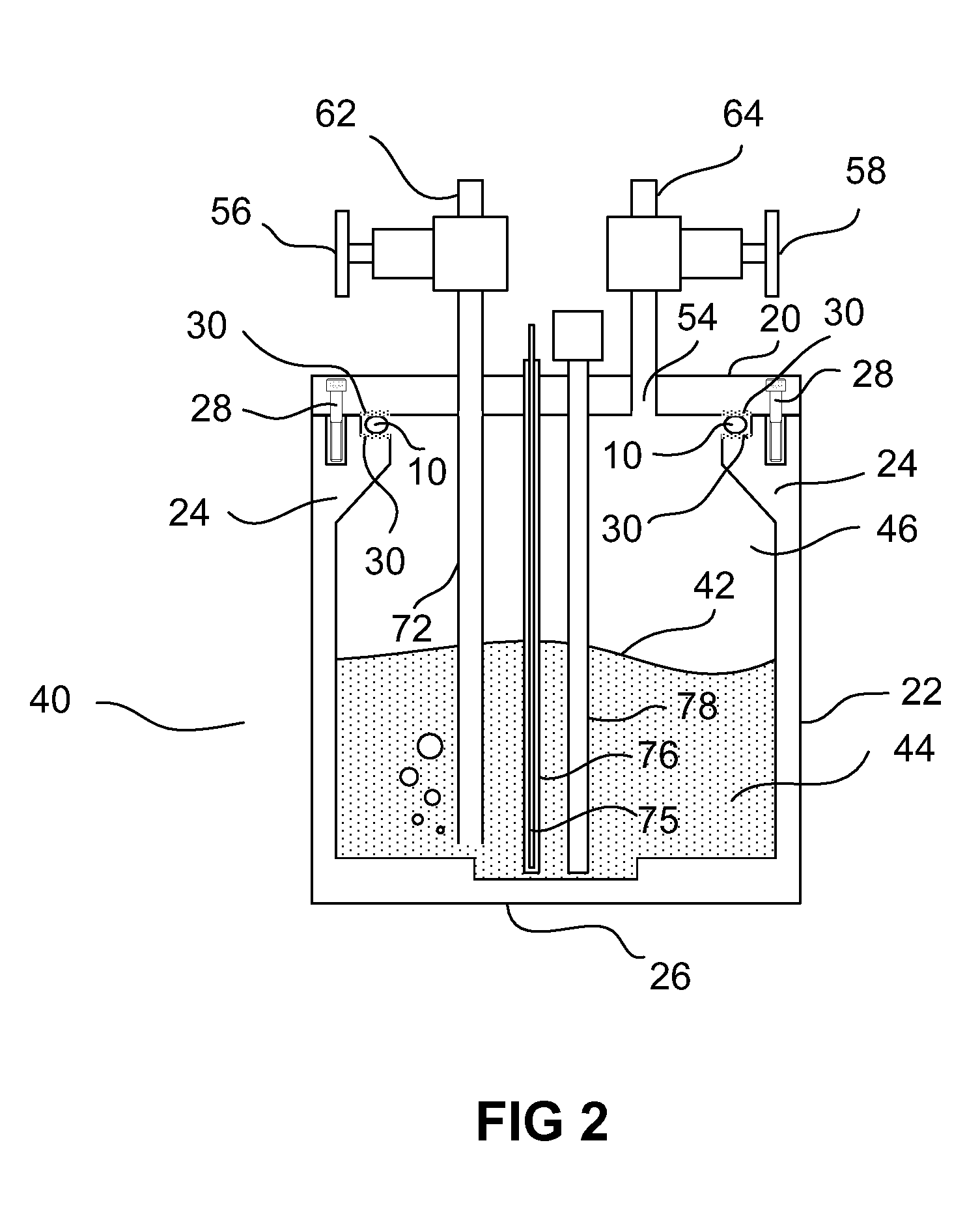

Method of Recovering Valuable Metal from Scrap Containing Conductive Oxide

ActiveUS20100101964A1Easy to getIncrease productivityElectrolysis componentsProcess efficiency improvementHydrogenElectrolysis

Proposed is a method of recovering valuable metal from scrap containing conductive oxide including the steps of using an insoluble electrode as either an anode or a cathode, using a scrap containing conductive oxide as the counter cathode or anode, performing electrolysis while periodically inverting the polarity, and recovering the scrap as hydroxide. With the foregoing method of recovering valuable metal from scrap containing conductive oxide, oxide system scrap is conductive oxide and a substance that can be reduced to metal or suboxide with hydrogen. This method enables the efficient recovery of valuable metal from sputtering target scrap containing conductive oxide or scrap such as mill ends of conductive oxide that arise during the production of such a sputtering target.

Owner:JX NIPPON MINING& METALS CORP

Method of Recovering Valuable Metal from Scrap Conductive Oxide

ActiveUS20100101963A1Easy to obtain hydroxideIncrease productivityPhotography auxillary processesElectrolysis componentsElectrolysisHydrogen

Proposed is a method of recovering valuable metal from scrap containing conductive oxide including the steps of using scrap containing conductive oxide and performing electrolysis while periodically inverting the polarity, and recovering the scrap as hydroxide. With the foregoing method of recovering valuable metal from scrap containing conductive oxide, oxide system scrap is conductive oxide and a substance that can be reduced to metal or suboxide with hydrogen. This method enables to efficiently recover valuable metal from sputtering target scrap containing conductive oxide or scrap such as mill ends of conductive oxide that arise during the production of such a sputtering target.

Owner:JX NIPPON MINING& METALS CORP

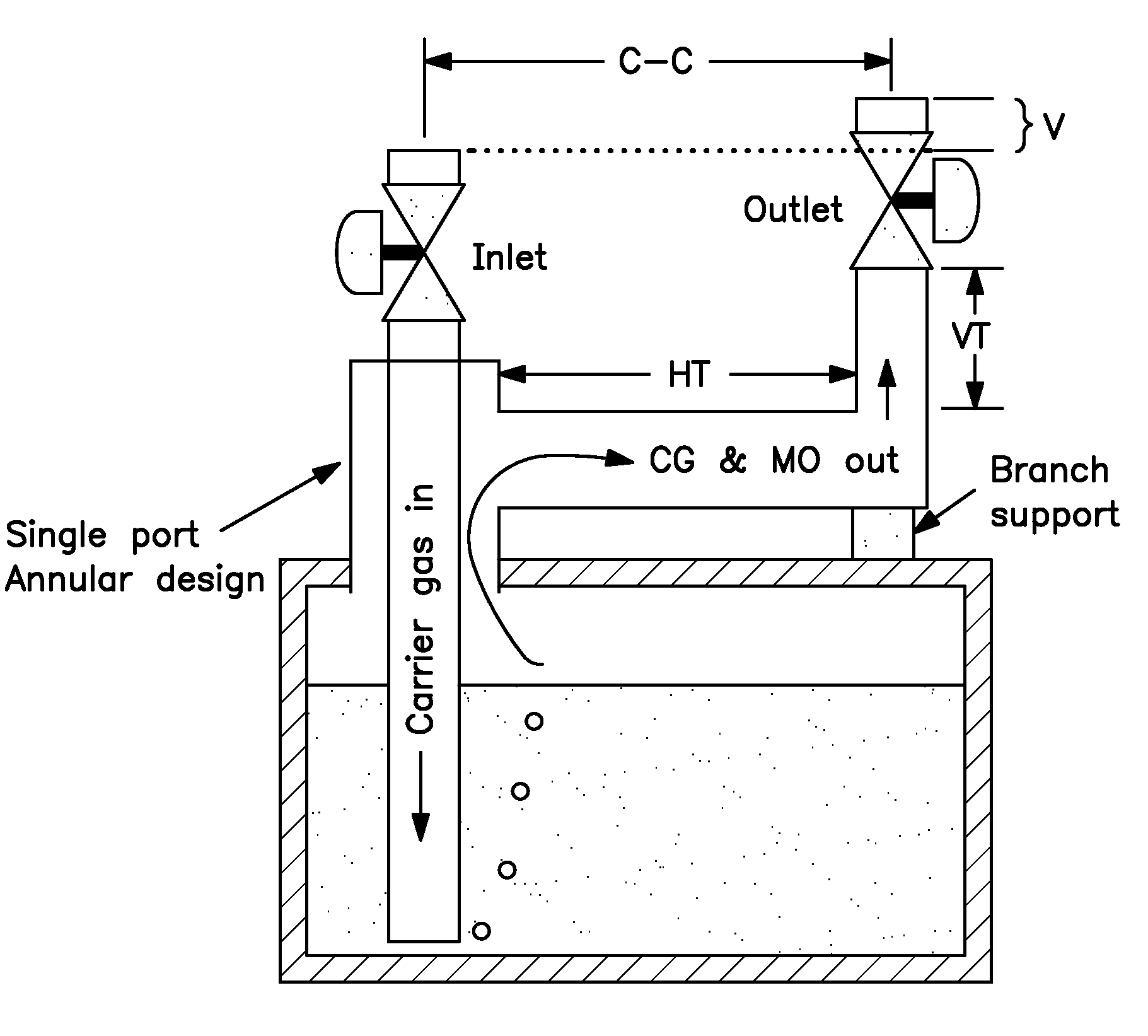

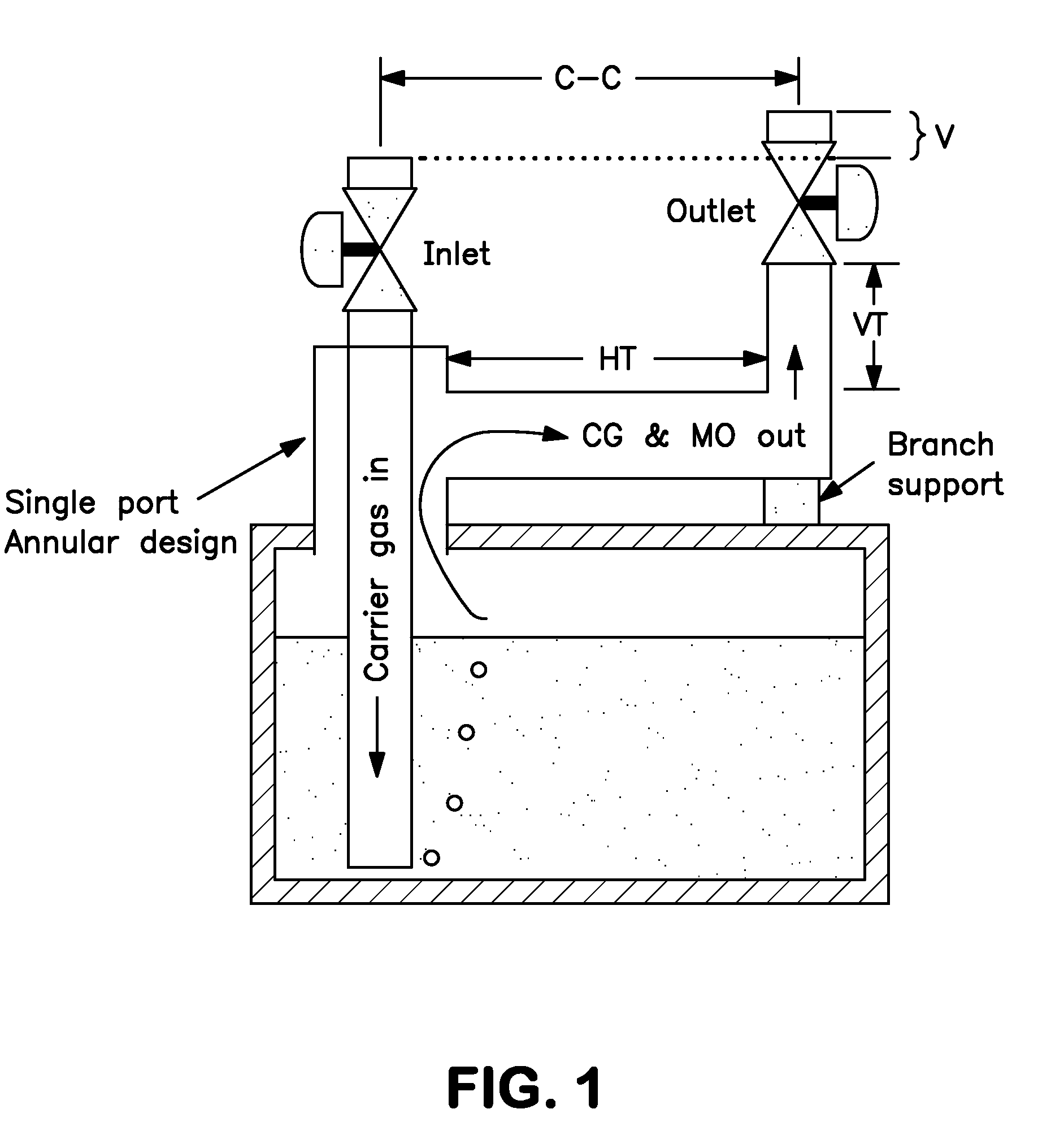

Reagent dispensing apparatuses and delivery methods

InactiveUS20100117246A1Easy to cleanIncrease usageCarburetting airMixing methodsSemiconductor materialsVapor phase

This invention relates to a vapor or liquid phase reagent dispensing apparatus that may be used for dispensing vapor or liquid phase reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices. The vapor phase reagent dispensing apparatus has a single port capable of receiving a carrier gas and dispensing a vapor phase reagent. The liquid phase reagent dispensing apparatus has a single port capable of receiving an inert gas and dispensing a liquid phase reagent.

Owner:PRAXAIR TECH INC

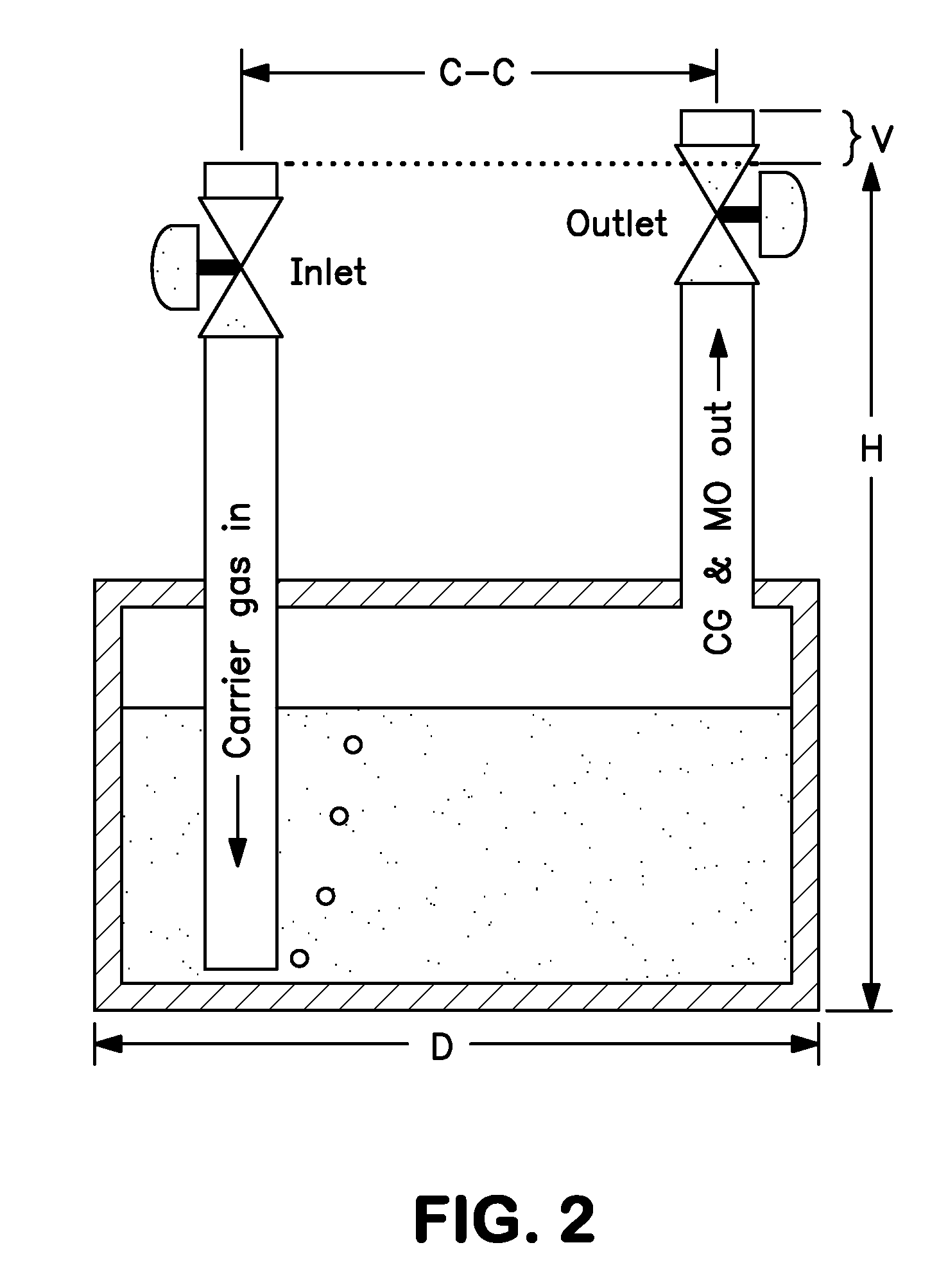

Bubbler apparatus and delivery method

InactiveUS20080182010A1Easy to cleanIncrease usageVacuum evaporation coatingSputtering coatingSemiconductor materialsGas phase

This invention relates to vapor phase reagent dispensing apparatus having a bubbler tube and also a metal seal aligned and in contact with the hardened opposing flat surfaces of a top wall member and a protuberance on a side wall member, wherein the hardened opposing flat surfaces of the top wall member and the protuberance have a hardness greater than the hardness of the metal seal. The dispensing apparatus may be used for dispensing of reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

Diptube apparatus and delivery method

InactiveUS20080182023A1Easy to cleanIncrease usageDoors/windowsContainer filling methodsSemiconductor materialsEngineering

This invention relates to a vapor or liquid phase reagent dispensing apparatus having a diptube and alsoa metal seal aligned and in contact with hardened opposing flat surfaces of a top wall member and a protuberance on a side wall member,wherein the hardened opposing flat surfaces of the top wall member and the protuberance have a hardness greater than the hardness of the metal seal. The dispensing apparatus may be used for dispensing of reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

Reagent dispensing apparatus and delivery method

InactiveUS20080213476A1Easy to cleanIncrease usageContainer filling methodsMaterial analysis by optical meansSemiconductor materialsEngineering

This invention relates to a vapor or liquid phase reagent dispensing apparatus comprising:a vessel which comprises a removable top wall member, a sidewall member and a bottom wall member configured to form an internal vessel compartment to hold a source chemical up to a fill level and to additionally define an inner gas volume above the fill level;said sidewall member having a protuberance that extends into the internal vessel compartment adjacent to the top wall member;said top wall member and said sidewall member having opposing flat surfaces, wherein the opposing flat surfaces are optionally in contact with one another;fastening means for securing said top wall member to said sidewall member through the opposing flat surfaces that are optionally in contact with one another;said top wall member and said protuberance having opposing flat surfaces, wherein the opposing flat surfaces are not in contact with one another and at least a portion of the opposing flat surfaces are hardened; anda metal seal aligned and in contact with the hardened opposing flat surfaces of said top wall member and said protuberance;wherein said hardened opposing flat surfaces of said top wall member and said protuberance have a hardness greater than the hardness of said metal seal. The dispensing apparatus may be used for dispensing of reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

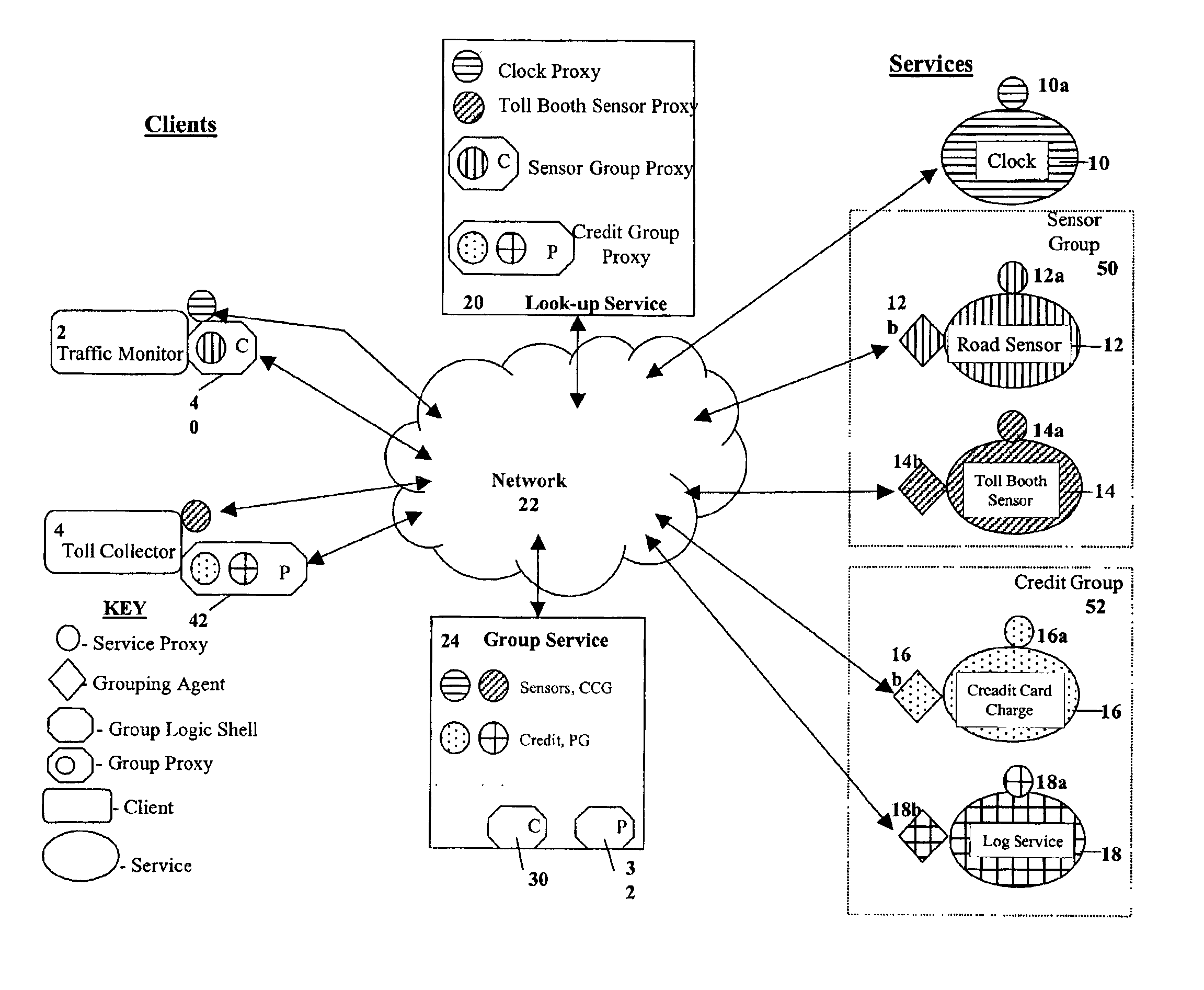

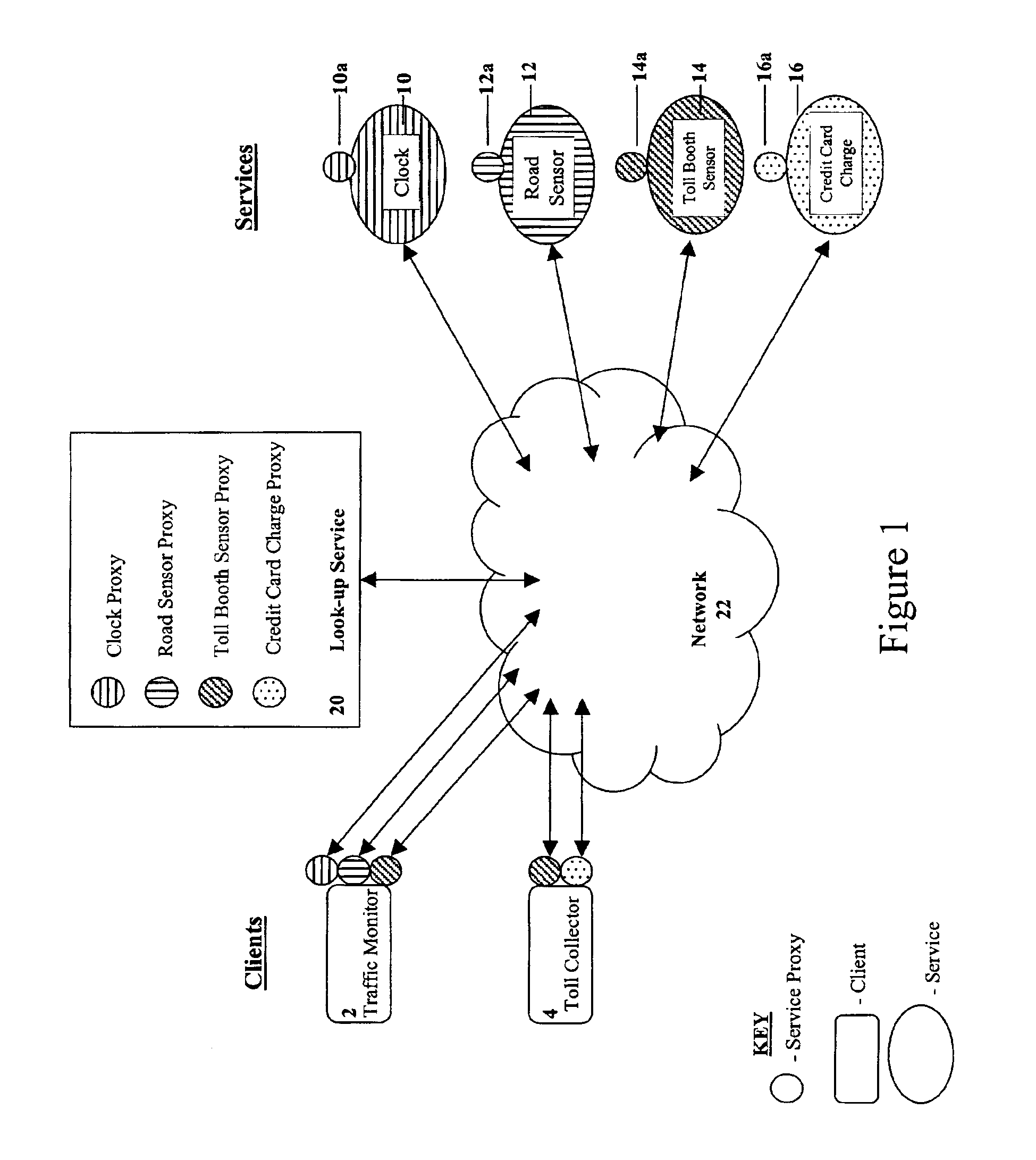

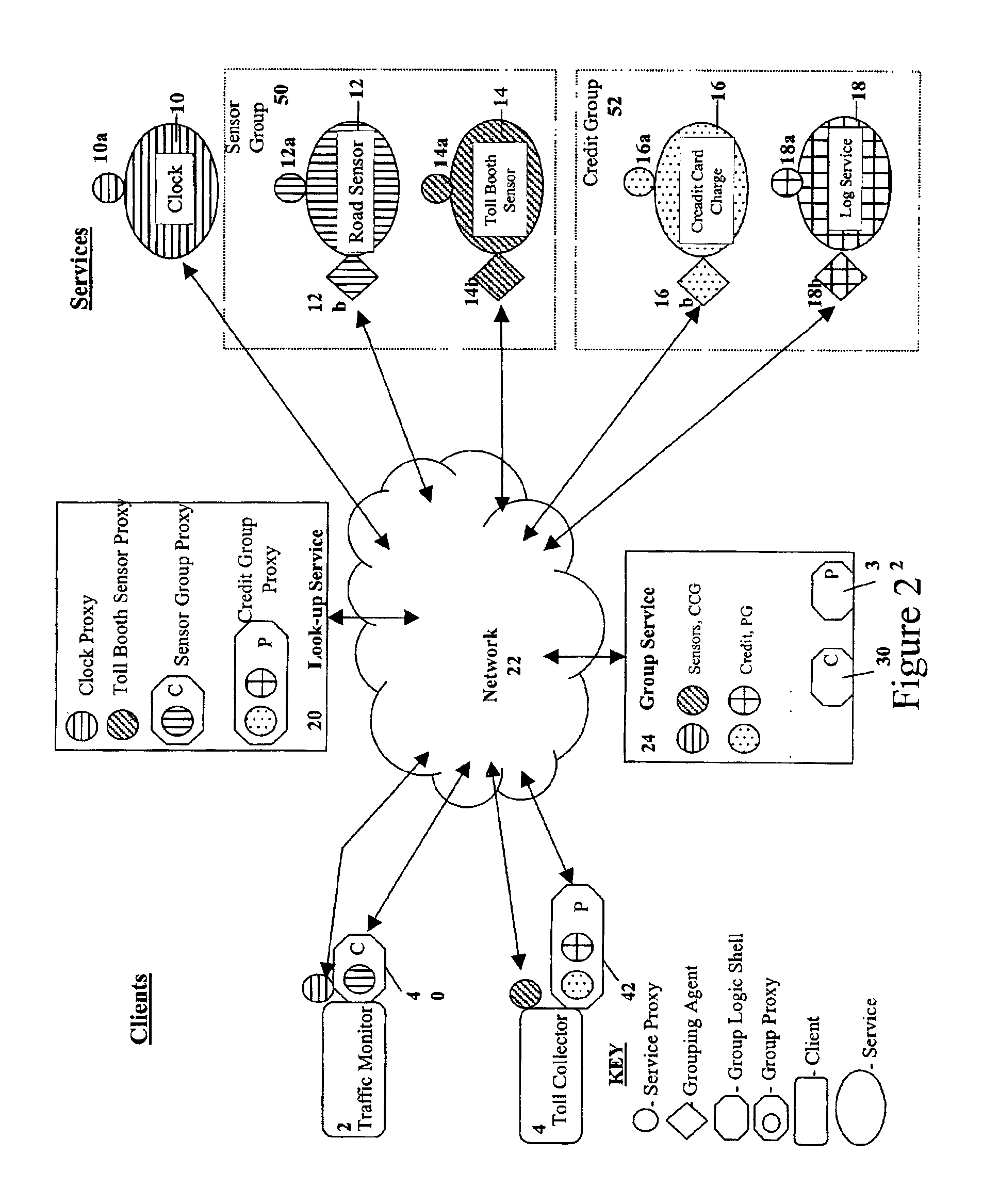

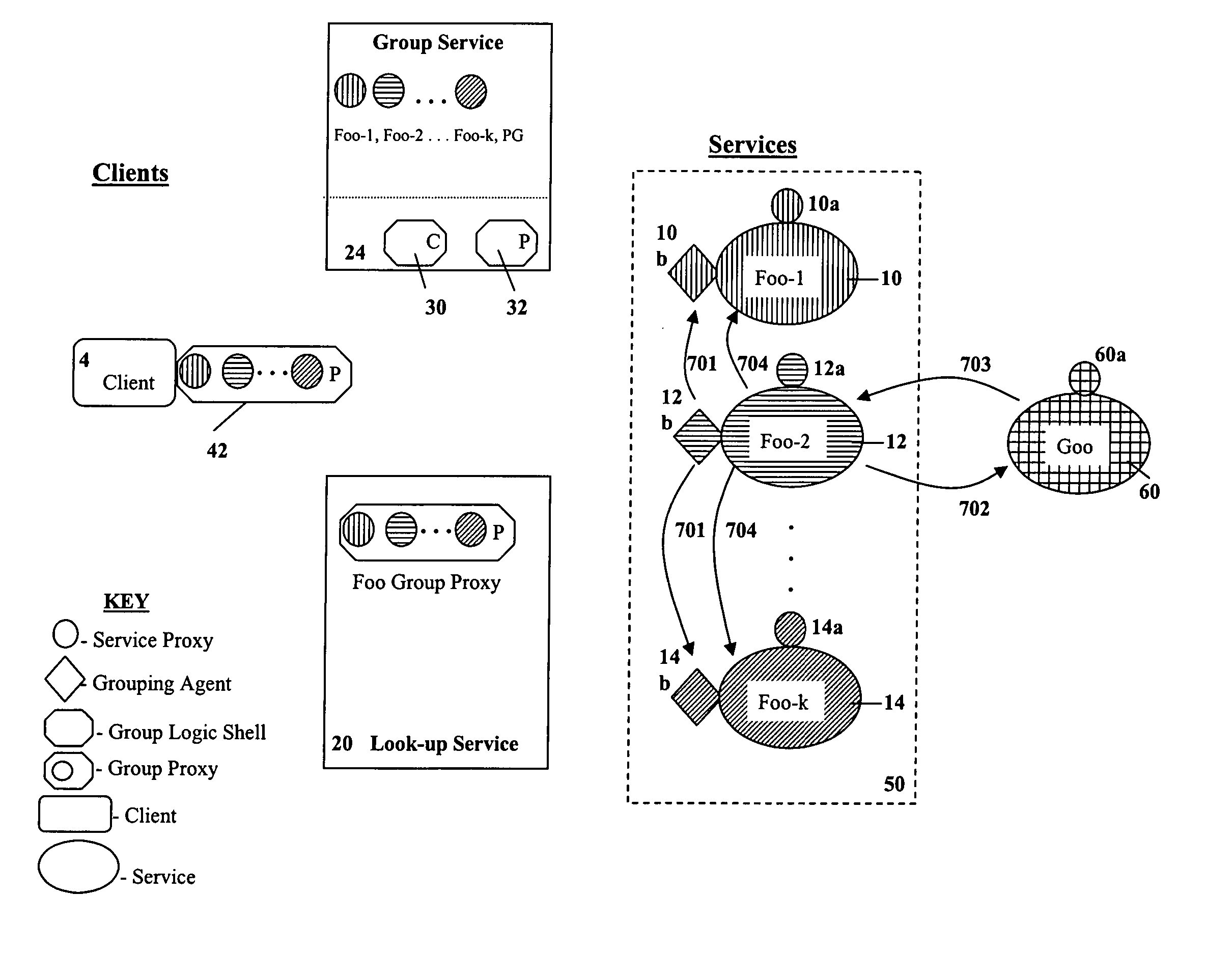

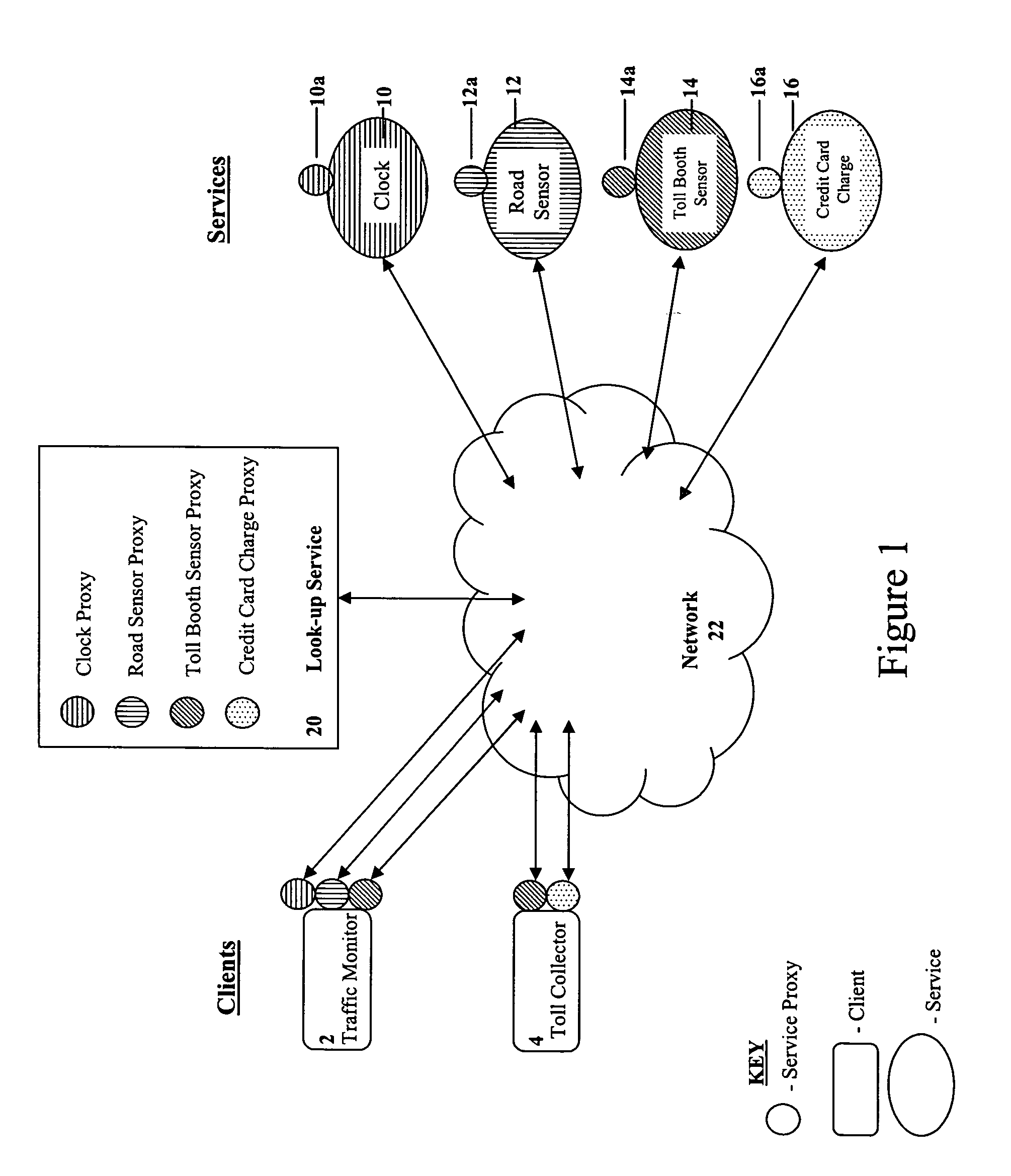

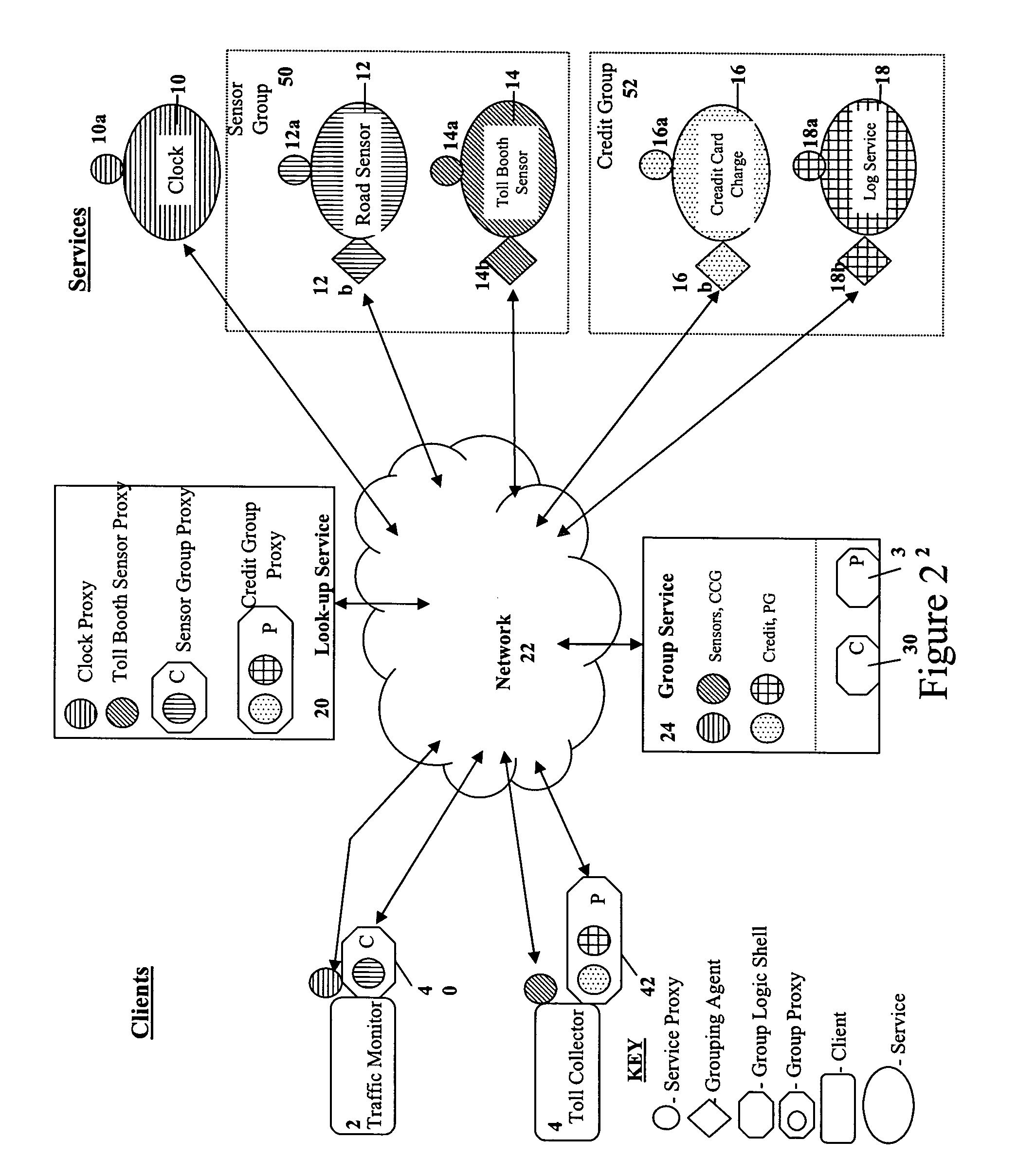

Method for handling transitions in grouped services in a distributed computing application

InactiveUS6951020B2RelievingMaintain purityResource allocationSecuring communicationClient-sideApplication software

The invention is a method of handling groups of services where the makeup of the groups can be determined and changed while the application is running. This is mainly accomplished through a group proxy, which is generated at run time, and which handles interactions with groups of services on behalf of one or more clients. The group proxy consists of a group logic shell which contains all the group-aware logic, and a service proxy for each service in the group which contains the necessary logic to interact with the particular service. The group proxy, which is given to a client for all of its interactions with the group of services, buffers calls from that client to its group when the group is unavailable because it is in transition. When the transition is complete the group proxy transmits the stored client commands to the group.

Owner:BLAZE ENTERTAINMENT

Apparatus and method for delivering vapor phase reagent to a deposition chamber

InactiveUS20080179767A1Easy to cleanIncrease usageLiquid degasificationMixing methodsSemiconductor materialsGas phase

This invention relates to a vapor or liquid phase reagent dispensing apparatus having a:metal seal aligned and in contact with hardened opposing flat surfaces of a top wall member and a protuberance on a side wall member, wherein the hardened opposing flat surfaces of the top wall member and the protuberance have a hardness greater than the hardness of the metal seal.The apparatus also has a temperature sensor and a source chemical level sensor extending through a centrally located portion of the top wall member and generally vertically downwardly to a sump cavity centrally located on a bottom wall member.The dispensing apparatus may be used for dispensing of reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

Method for switching group modes in a distributed computing application

InactiveUS20050229180A1RelievingMaintain purityResource allocationMemory systemsApplication softwareClient-side

Owner:BLAZE ENTERTAINMENT

Bubbler apparatus and method for delivering vapor phase reagent to a deposition chamber

InactiveUS20080182425A1Easy to cleanIncrease usageUsing liquid separation agentMixing methodsSemiconductor materialsGas phase

This invention relates to a vapor phase reagent dispensing apparatus having a bubbler tube and alsoa metal seal aligned and in contact with the hardened opposing flat surfaces of a top wall member and a protuberance on a side wall member, wherein the hardened opposing flat surfaces of the top wall member and the protuberance have a hardness greater than the hardness of the metal seal.The apparatus further has a temperature sensor and a source chemical level sensor extending through a centrally located portion of the top wall member and generally vertically downwardly to a sump cavity centrally located on a bottom wall member. The dispensing apparatus may be used for dispensing of reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

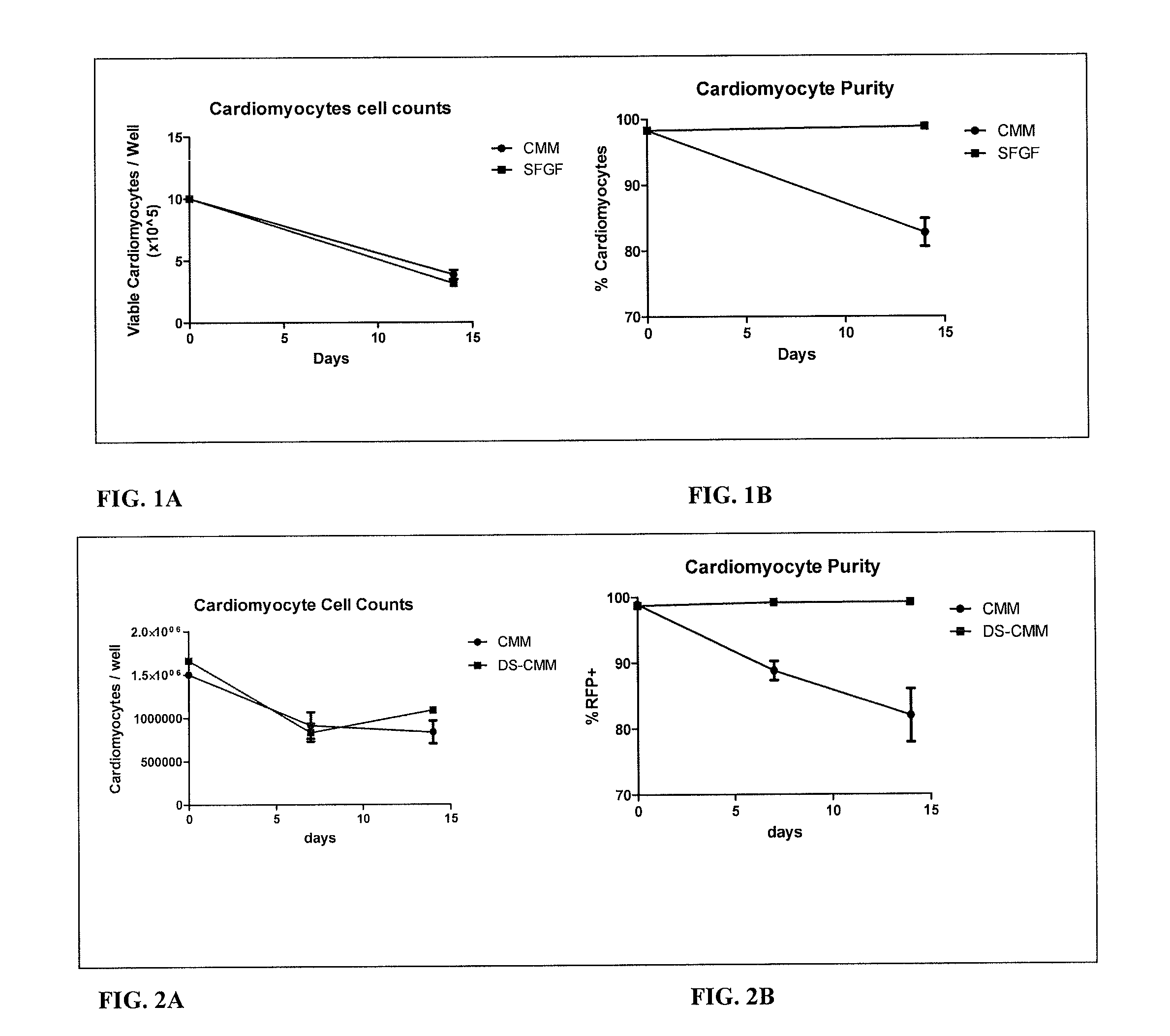

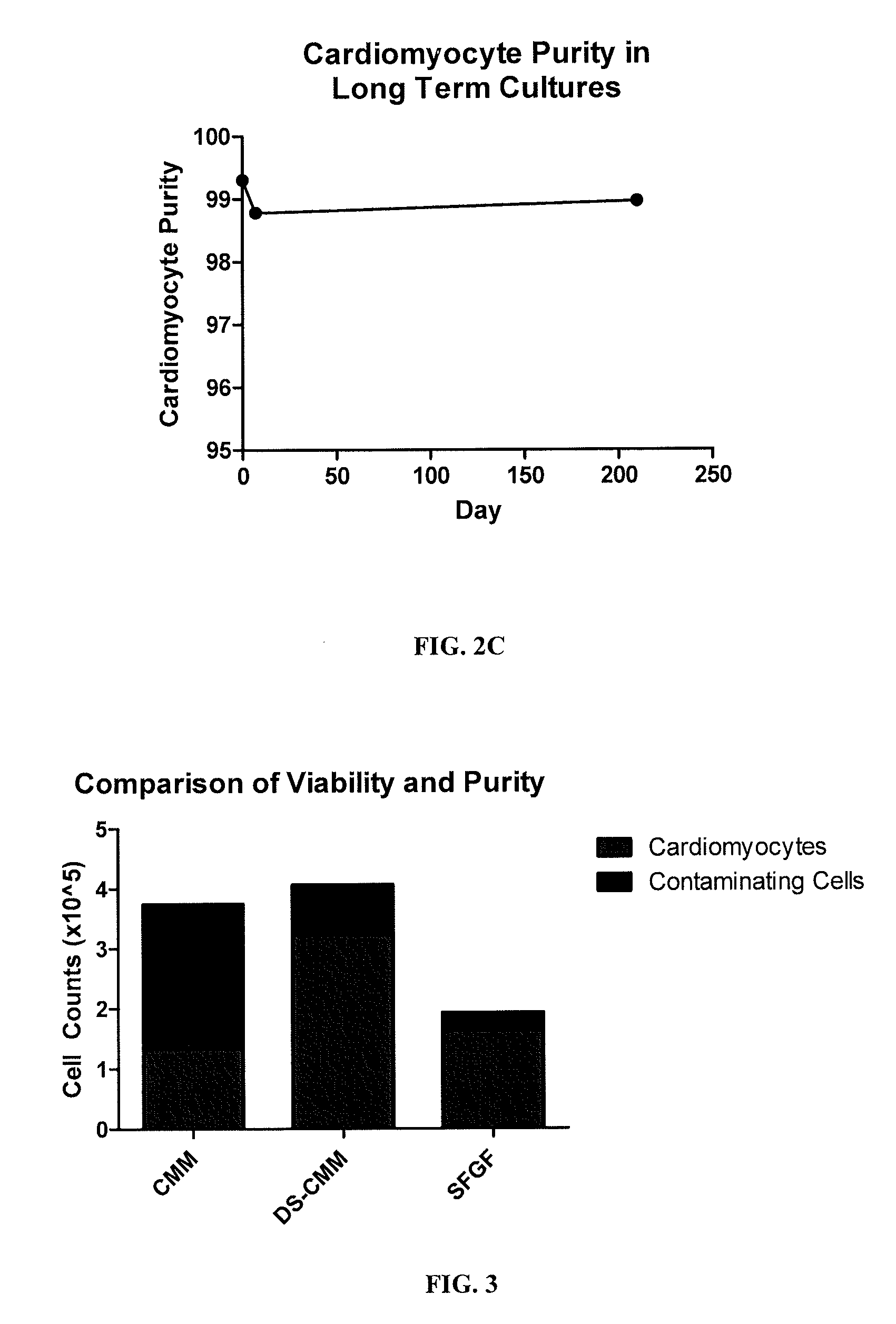

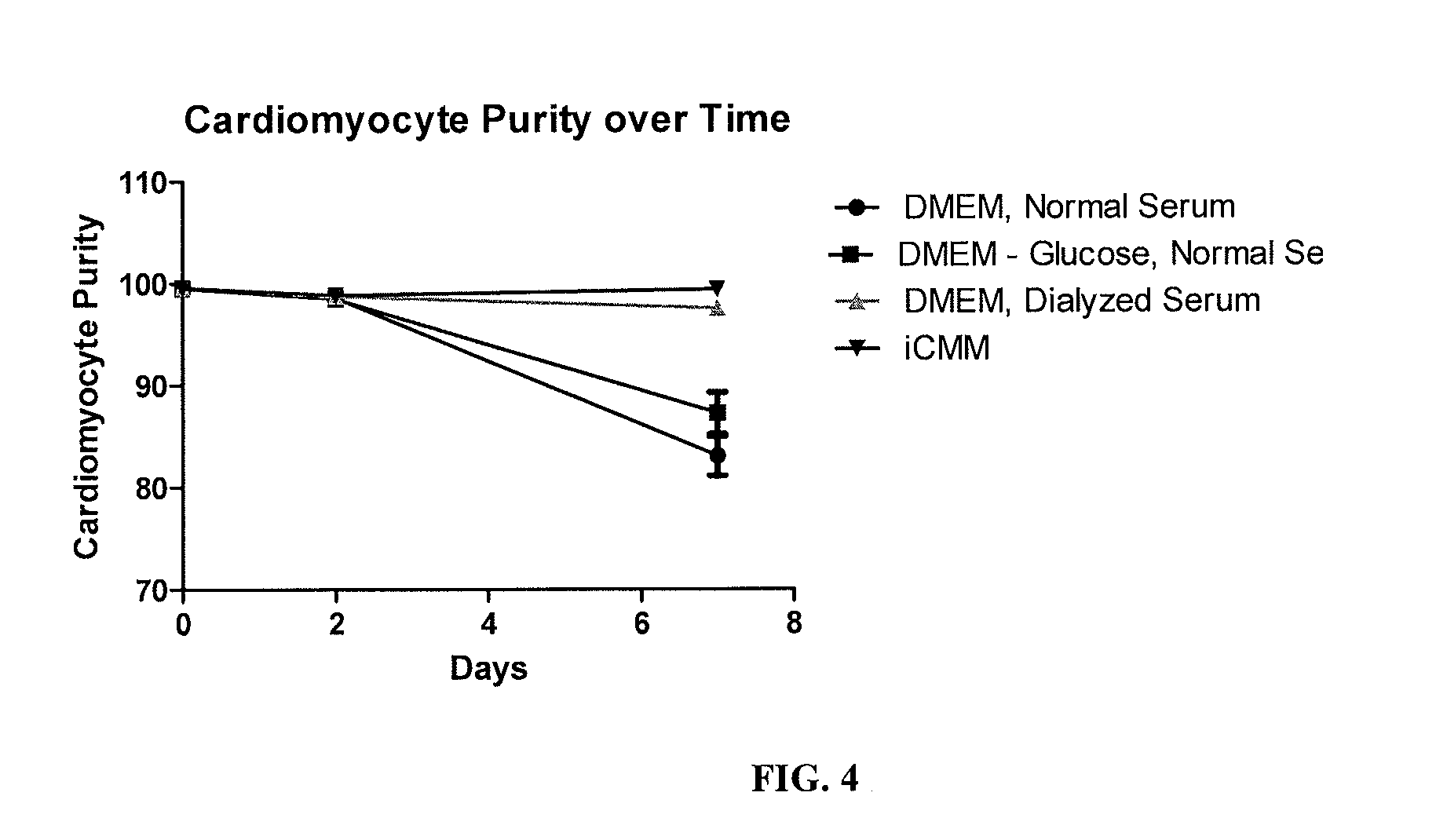

Cardiomyocyte medium with dialyzed serum

ActiveUS20110312090A1Improve stabilityMaintain purityCulture processArtificial cell constructsCardiac muscleBiology

Owner:FUJIFILM CELLULAR DYNAMICS INC

Adsorbents for pressure swing adsorption systems and methods of use therefor

InactiveUS20080148937A1Reduce frequencyMaintain purityGas treatmentIsotope separationPurification methodsSorbent

The present invention relates generally to adsorbents for use in pressure swing adsorption (PSA) prepurification processes. The invention more particularly relates to the design of adsorbent zones to be used in PSA prepurification processes that are expected to provide for extensions in PSA cycle time, thereby reducing blowdown loss and operating costs associated with the process. One particular embodiment of the present invention includes a first adsorption zone containing activated alumina and a second adsorption zone of an alumina-zeolite mixture or composite adsorbent in which the volume of the first zone does not exceed 50% of the total volume of the first and second zone.

Owner:PRAXAIR TECH INC

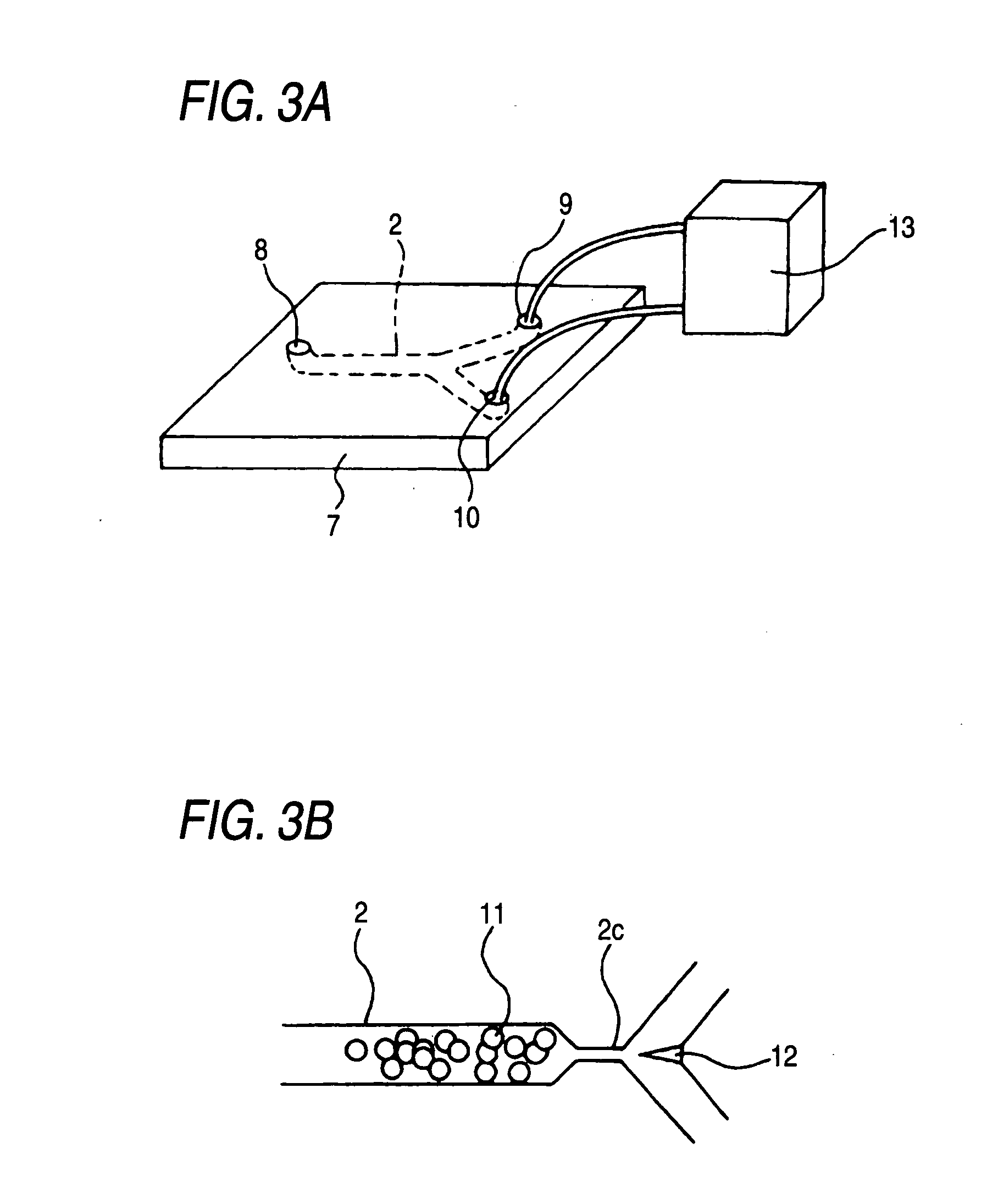

Microdevice for performing method of separating and purifying nucleic acid

InactiveUS20060068491A1Easily and swiftly separatingEasily and swiftly and purifyingBioreactor/fermenter combinationsBiological substance pretreatmentsMicro devicesNucleic acid

A microdevice for performing a method for separating and purifying a nucleic acid, the microdevice comprising: at least one opening; and at least one channel for passing a sample solution, wherein the method comprises: (A) a step of bringing a nucleic acid-containing sample solution into contact with a nucleic acid-adsorbing support having a function of adsorbing a nucleic acid; (B) a step of washing the nucleic acid-adsorbing support with a washing solution in a state of a nucleic acid being adsorbed to the support; and (C) a step of desorbing the nucleic acid from the nucleic acid-adsorbing support by a recovering solution, thereby purifying the nucleic acid; an apparatus for utilizing the microdevice; and a reagent kit for use in the microdevice.

Owner:FUJIFILM CORP

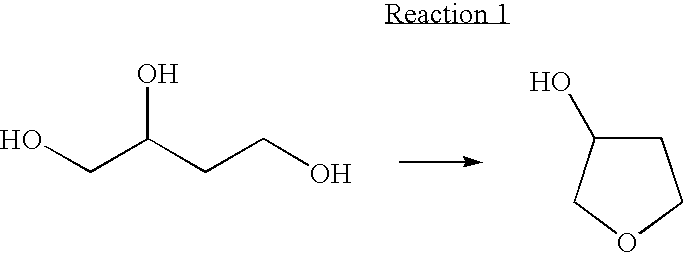

Method for Preparing 3-Hydroxytetrahydrofuran Using Cyclodehydration

ActiveUS20090005581A1High yieldHigh productivityOrganic chemistry3-HydroxytetrahydrofuranProduction rate

Disclosed is a method of preparing 3-hydroxytetrahydrofuran using cyclodehydration. More particularly, this invention relates to a method of preparing 3-hydroxytetrahydrofuran, including subjecting 1,2,4-butanetriol to cyclodehydration under reaction conditions of a reaction temperature of 30˜180° C. and reaction pressure of 5000 psig or less in the presence of a strong acid cation exchange resin catalyst having a sulfonic acid group as an exchange group. According to the method of this invention, 3-hydroxytetrahydrofuran can be economically prepared at higher yield and productivity than when using conventional methods.

Owner:SK BIOTEK

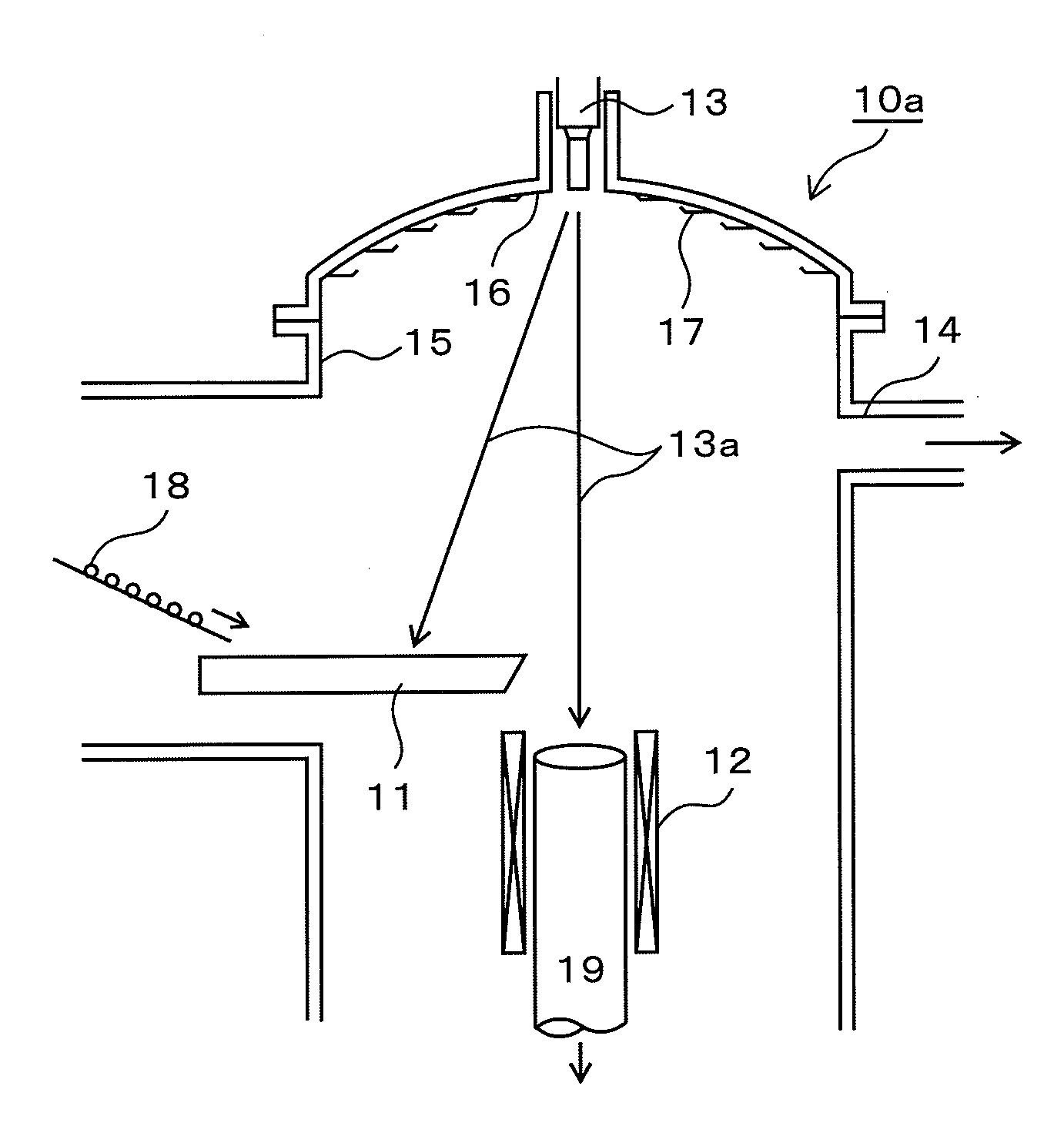

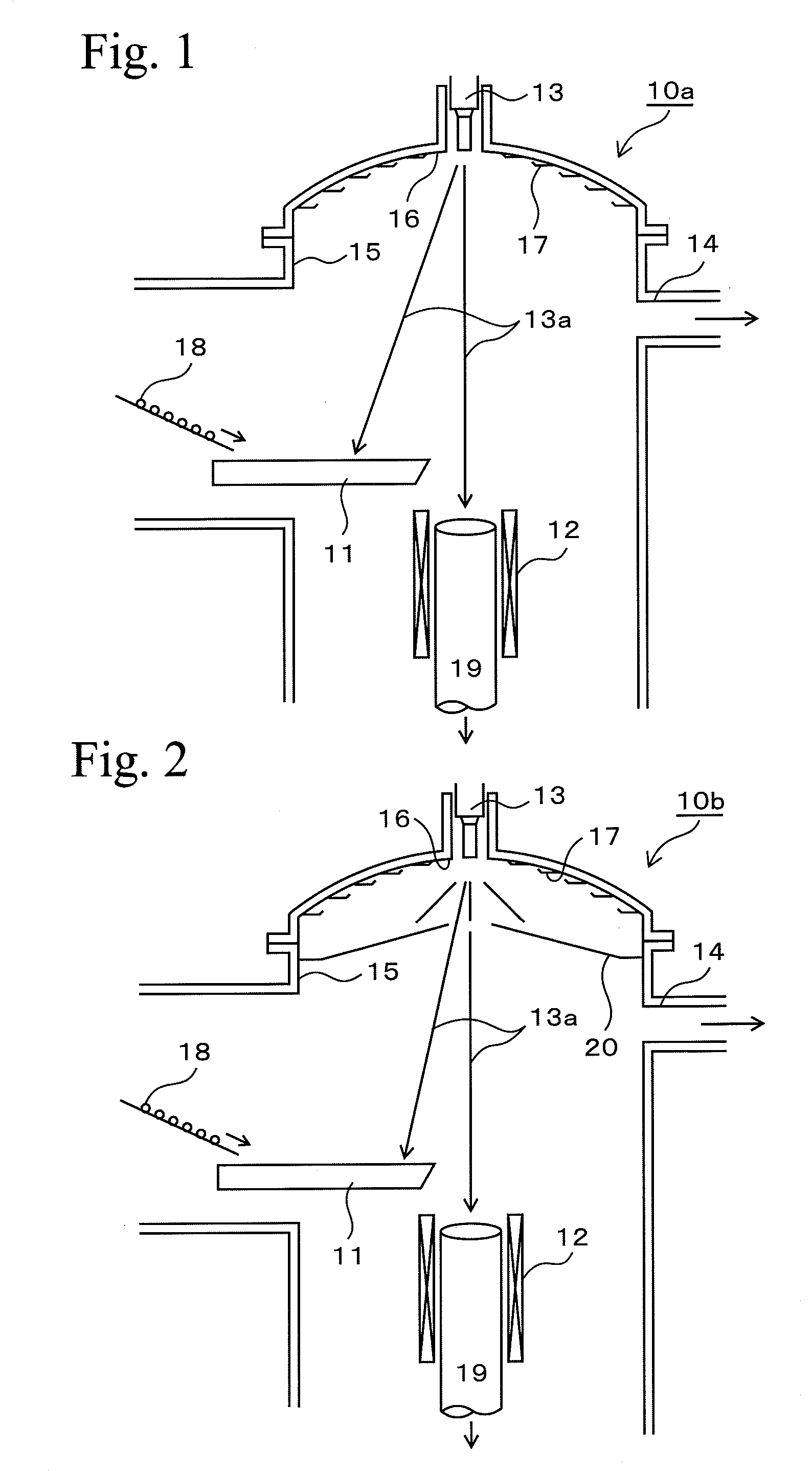

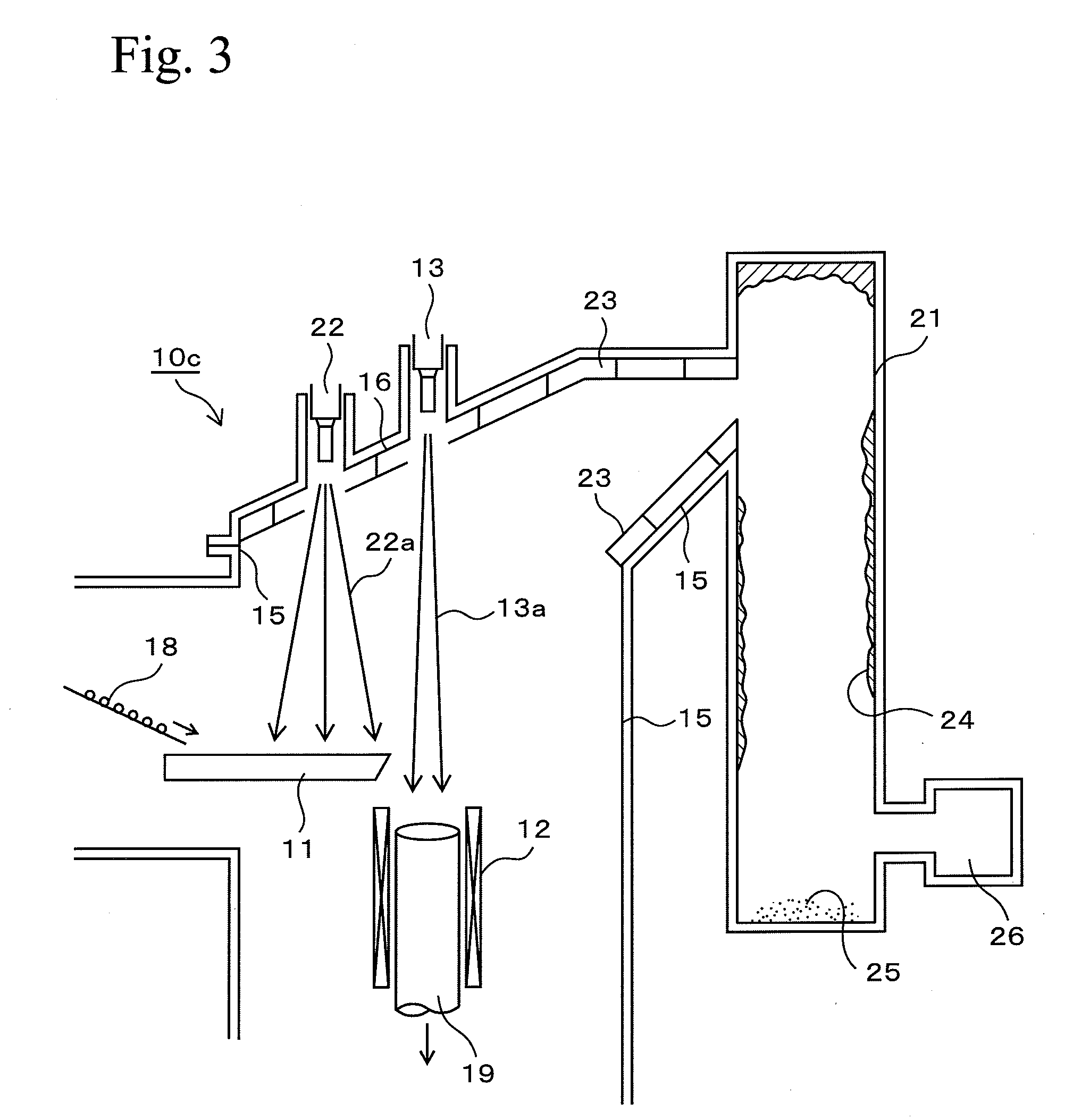

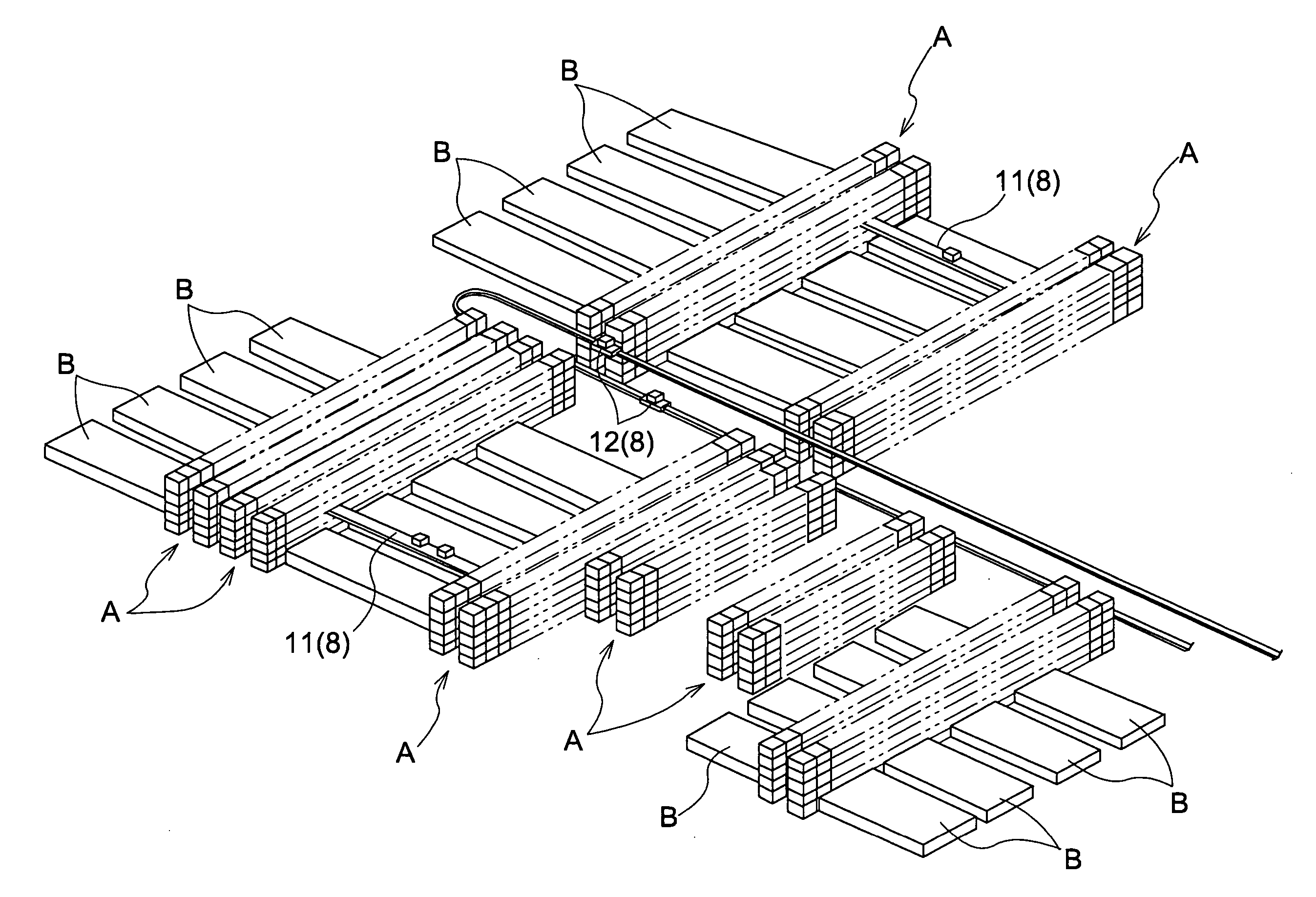

Apparatus For Melting Metal By Electron Beams And Process For Producing High-Melting Metal Ingot Using This Apparatus

ActiveUS20080105400A1Additional contamination of impurityReduce frequencyProcess efficiency improvementHearthElectron

The present invention provides an electron-beam furnace and a melting method that, in producing an ingot by melting a metal with an electron beam, can suppress the contamination of new impurities in the ingot production, are less likely to again result in inclusion of once evaporated impurities from a molten metal pool within a hearth or a mold, and can be improved in utilization rate. The electron-beam furnace for melting a refractory metal includes a feeder unit for raw materials, a melting unit for raw materials, which is connected to the feeder unit for raw materials and, at the same time, is defined by a furnace wall and a ceiling wall, and includes at least a hearth, a water-cooled mold, and an electron gun, and an evacuation unit for exhaust gas connected to the melting unit for raw materials. In this electron beam furnace, at least one of the furnace wall and the ceiling wall is lined with titanium or stainless steel, and in addition, plural fin-shaped members formed of titanium or stainless steel are provided at the ceiling wall. A lining, which can be attached and detached, is provided on the inner face of the electron beam furnace.

Owner:TOHO TITANIUM CO LTD

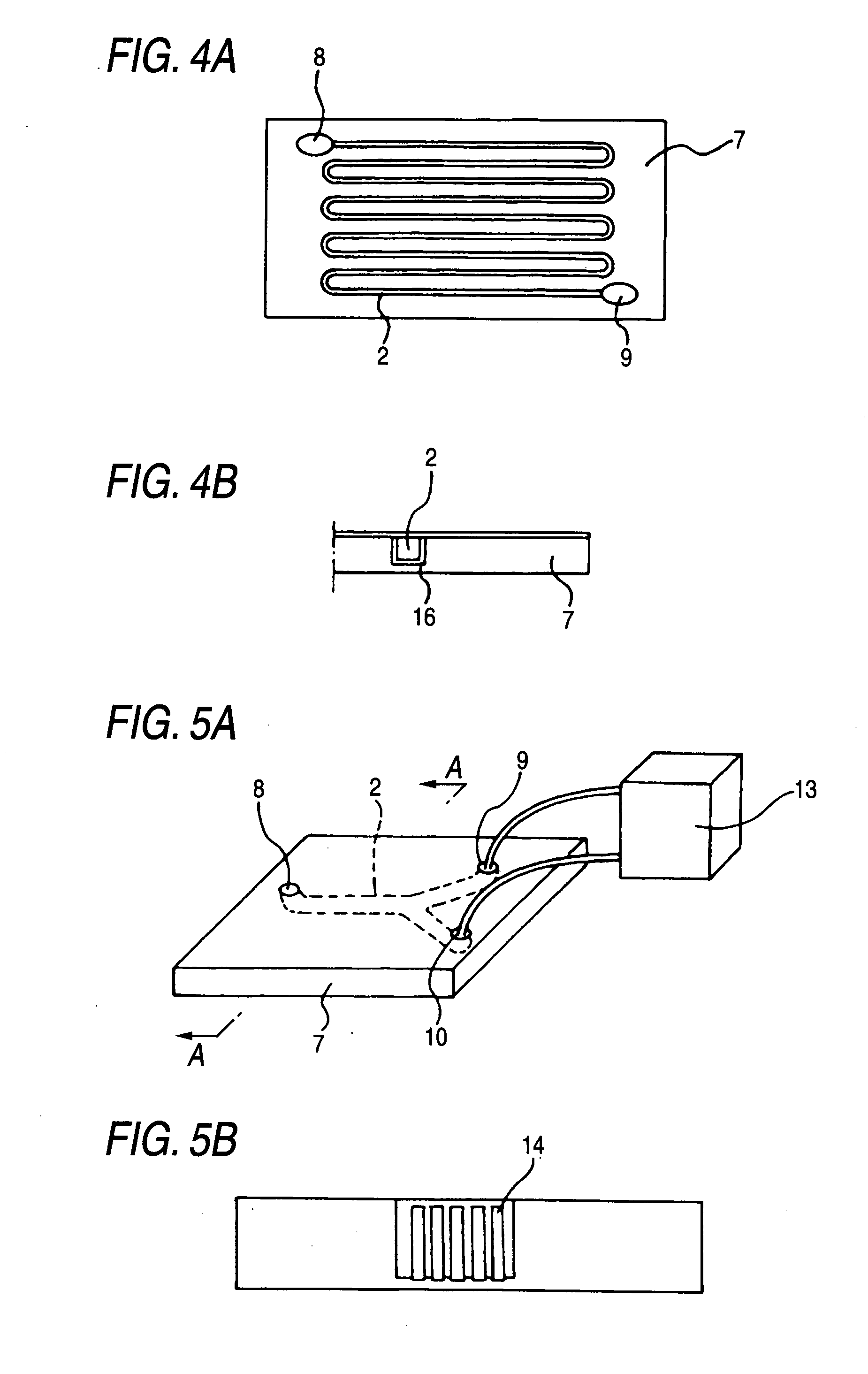

Container for storing substrate

ActiveUS20080067107A1Low running costMaintain purityCombination devicesConveyorsEngineeringClosed state

A container configured to hold a plurality of substrates lined up vertically with space therebetween, which includes a container main unit formed in a tube shape having a quadrangular cross section as a whole that includes a first opening provided on one end side and a second opening provided on the other end side of the container spaced apart in the horizontal direction from the first opening, the first opening serving as an entrance for loading and unloading the substrates, a fan filter unit that is provided in an area of the second opening and that causes movement of air from the second opening toward the first opening, and a lid configured to be attached in an area of the entrance of the container main unit, the lid having an open state and a closed state, and forming a ventilation opening that allows air to pass in the closed state.

Owner:DAIFUKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com