Method for pre-sintering copper-containing active magnesium diboride superconducting block

A technology of magnesium diboride and superconducting block, which is applied in the field of superconducting, and achieves the effects of strong controllability, stable structure and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Adding mass fraction of 3wt.% copper and MgB 2 The powder is fully mixed in an agate mortar, and then it is pressed into small pieces under a pressure of 5MPa, and the pressed sample is put into a thermogravimetric differential thermal analyzer (Mettler Toledo TGA / DSC1 / ), and passed into Argon gas is used for low-temperature sintering, and the setting program is as follows: after heating up to 900°C at a heating rate of 20°C / min, heat preservation and sintering at this temperature for 10 minutes, and then cool down to 650°C at a cooling rate of 40°C / min, and heat preservation for one Hours, and finally down to room temperature at a cooling rate of 40°C / min.

Embodiment 2

[0022] Adding copper and MgB with a mass fraction of 1wt.% 2 The powder is fully mixed in an agate mortar, and then pressed into small pieces under a pressure of 2MPa, and the pressed sample is put into a thermogravimetric differential thermal analyzer (Mettler Toledo TGA / DSC1 / ), and passed into Argon gas is used for low-temperature sintering, and the setting program is: after heating up to 1000°C at a heating rate of 10°C / min, heat preservation and sintering at this temperature for 0 minutes, and then cool down to 600°C at a cooling rate of 50°C / min, and heat preservation for 0 Hours, and finally cooled down to room temperature at a cooling rate of 50°C / min.

Embodiment 3

[0024] Adding mass fraction of 5wt.% copper and MgB 2 The powders were fully mixed in an agate mortar, and then pressed into small pieces under a pressure of 8 MPa, and the pressed samples were put into a thermogravimetric differential thermal analyzer (Mettler Toledo TGA / DSC1 / ), and passed into Argon gas is used for low-temperature sintering, and the setting program is as follows: after heating up to 800°C at a heating rate of 10°C / min, heat preservation and sintering at this temperature for 20 minutes, and then cool down to 700°C at a cooling rate of 10°C / min, and then hold heat for 3 hours, and finally cooled down to room temperature at a cooling rate of 10°C / min.

[0025] The first sintering method is selected to obtain more superconducting phases. By adding copper, not only can the oxidation rate be effectively reduced, but also a certain effective pinning center can be introduced on this basis to obtain a better superconducting phase. .

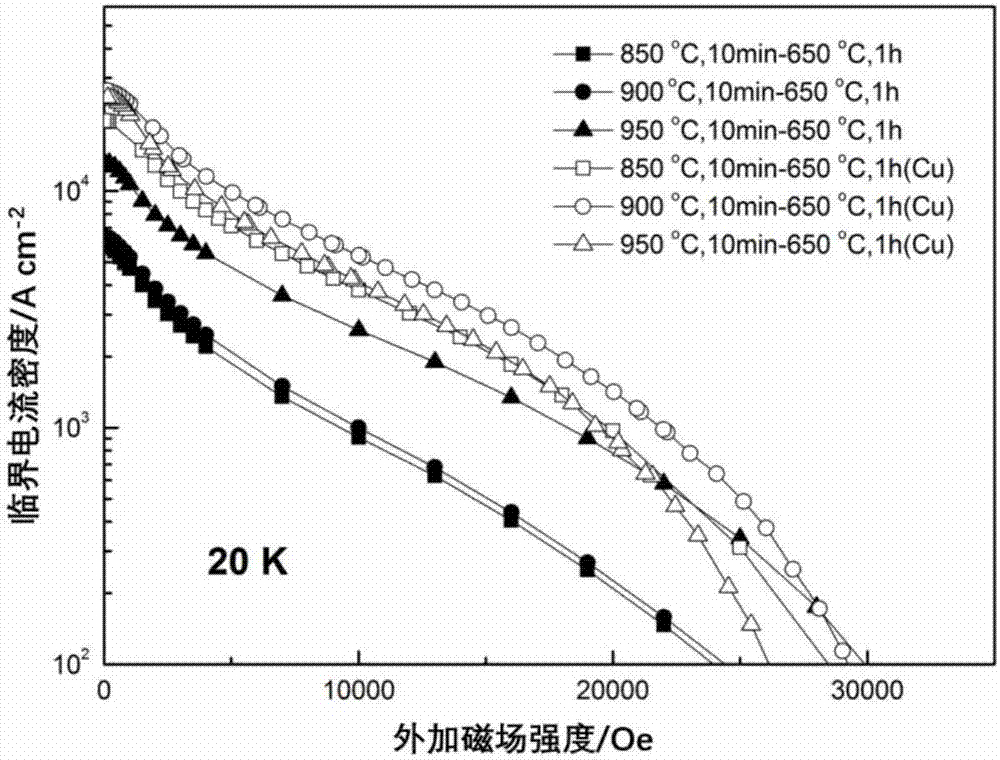

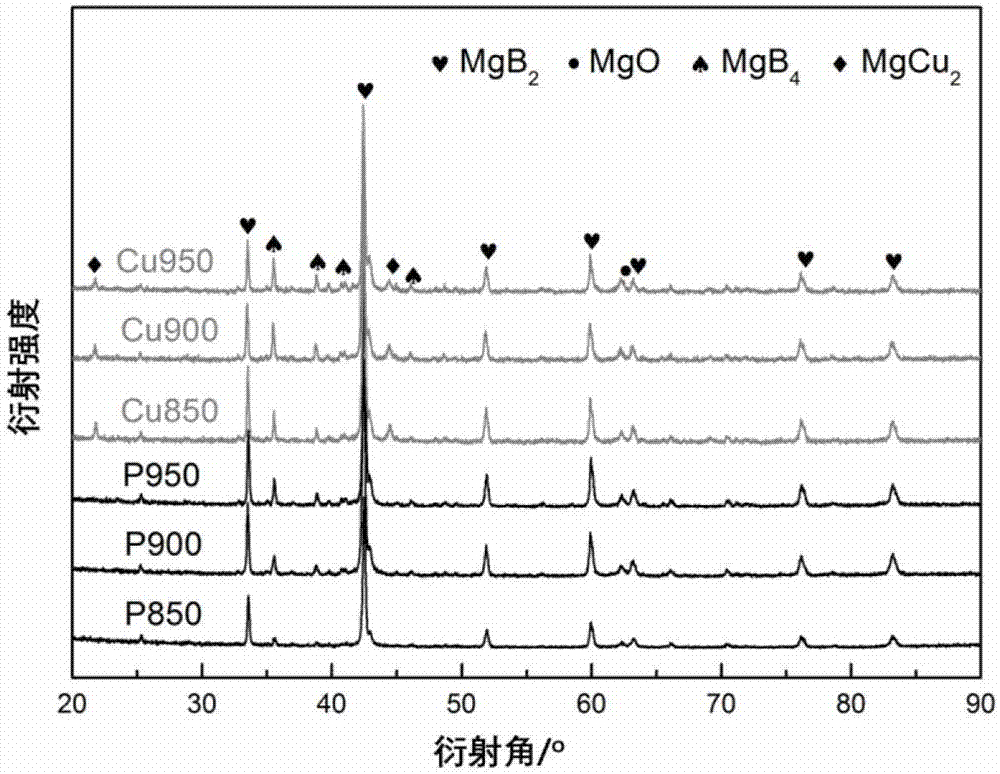

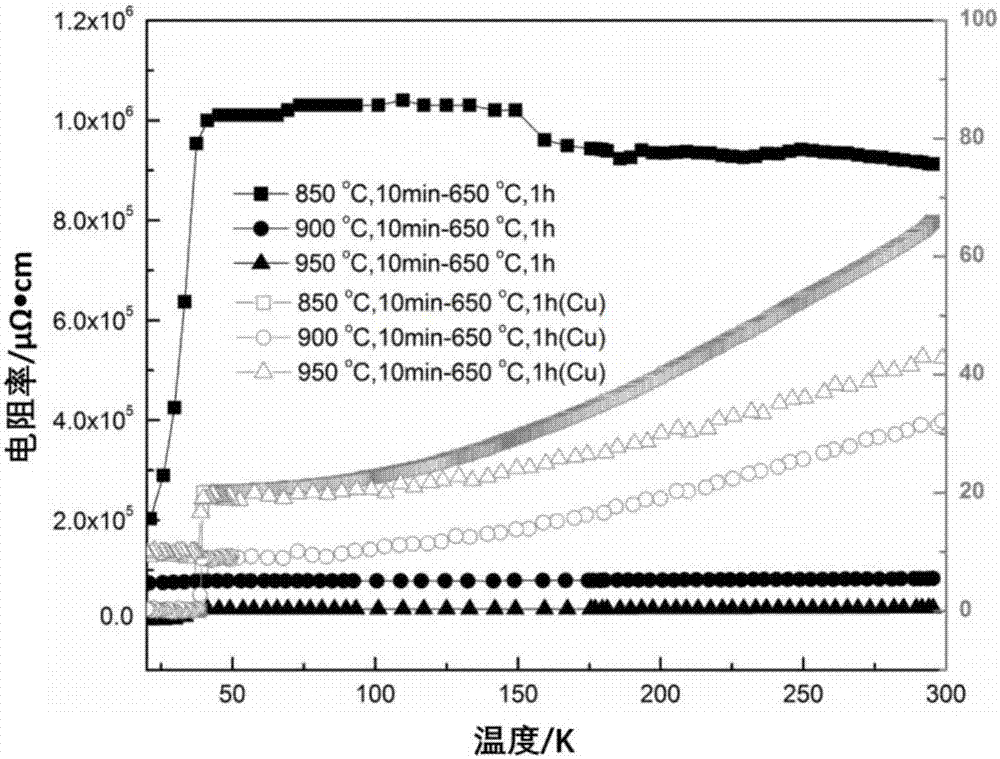

[0026] From figure 2 It can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com