Composite cable for flame-retardant fireproof boat and manufacturing method thereof

A flame-retardant and fire-resistant composite cable technology, which is used in the manufacture of cables/conductors, insulating cables, insulating conductors/cables, etc. Enhances impregnation against moisture, eliminates voids, and facilitates stretch transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

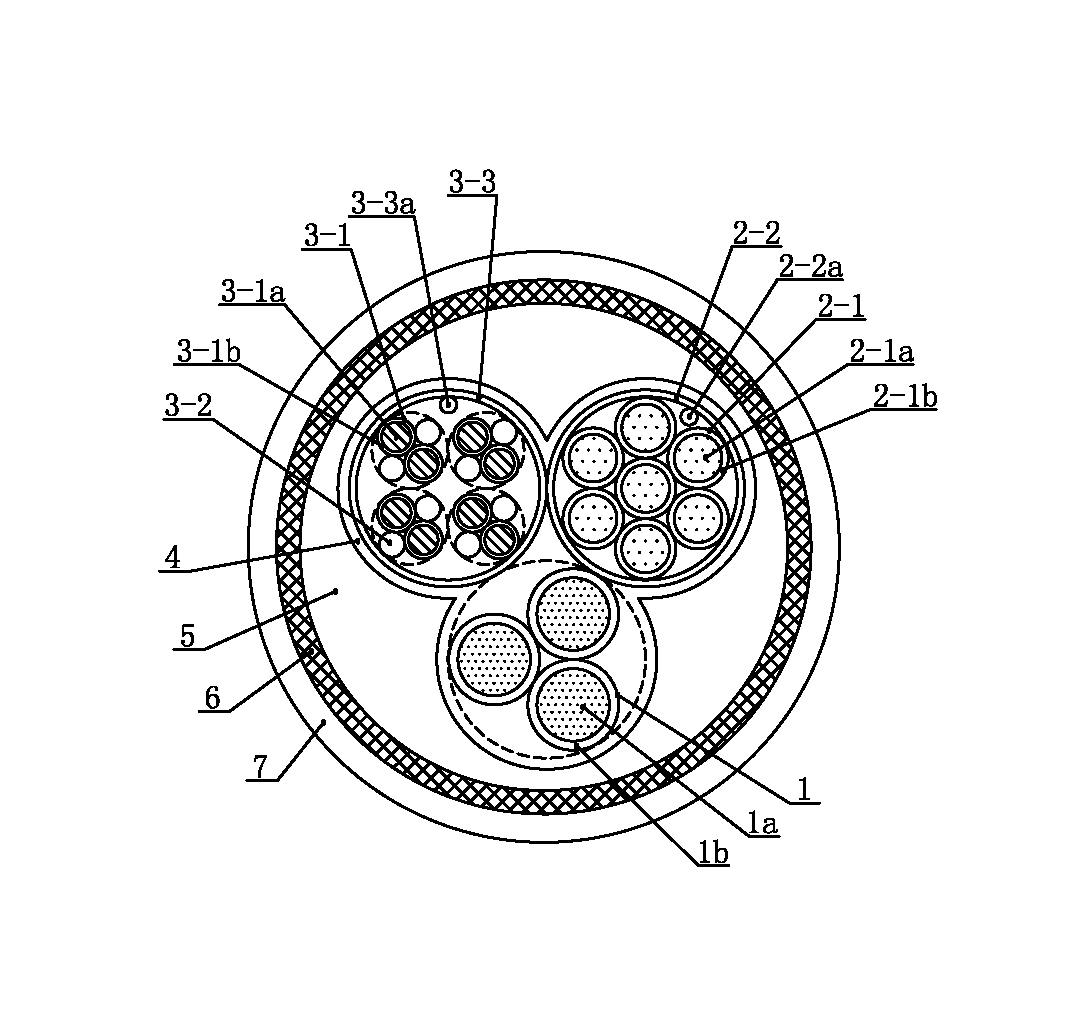

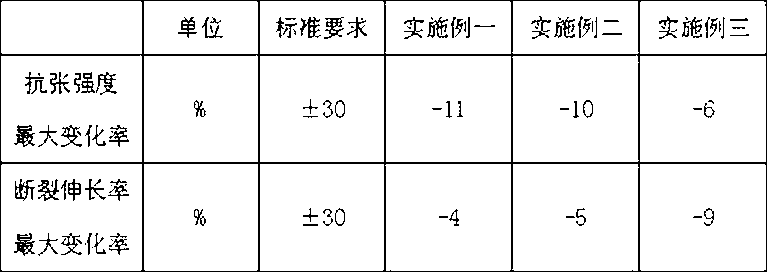

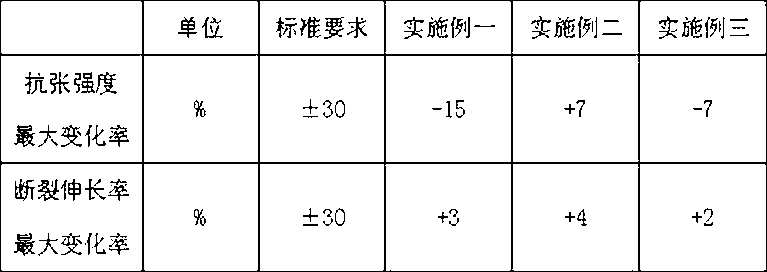

[0023] Such as figure 1As shown, the flame-retardant and fire-resistant marine composite cable of the present invention includes the following steps: (1) the power cable insulation layer 1b is extruded around the power cable stranded copper conductor 1a to form a power cable insulation core 1, and a plurality of power cable insulation cores 1 Mutually twisted to form the core of the power cable; (2) Control cable stranded copper conductor 2-1a outer peripheral extruded control cable insulation layer 2-1b constitutes the control cable insulation core 2-1, multiple control cable insulation core 2 -1 twisted with each other to form the control cable core, the outer periphery of the control cable core is wrapped with the control cable copper foil shielding layer 2-2, the copper foil of the control cable copper foil shielding layer 2-2 faces inward and the inner side is provided with control cable drainage Line 2-2a, control cable drain line 2-2a runs through the entire length of t...

Embodiment 2

[0028] Such as figure 1 As shown, the flame-retardant and fire-resistant marine composite cable of the present invention includes the following steps: (1) the power cable insulation layer 1b is extruded around the power cable stranded copper conductor 1a to form a power cable insulation core 1, and a plurality of power cable insulation cores 1 Mutually twisted to form the core of the power cable; (2) Control cable stranded copper conductor 2-1a outer peripheral extruded control cable insulation layer 2-1b constitutes the control cable insulation core 2-1, multiple control cable insulation core 2 -1 twisted with each other to form the control cable core, the outer periphery of the control cable core is wrapped with the control cable copper foil shielding layer 2-2, the copper foil of the control cable copper foil shielding layer 2-2 faces inward and the inner side is provided with control cable drainage Line 2-2a, control cable drain line 2-2a runs through the entire length of ...

Embodiment 3

[0033] Such as figure 1 As shown, the flame-retardant and fire-resistant marine composite cable of the present invention includes the following steps: (1) the power cable insulation layer 1b is extruded around the power cable stranded copper conductor 1a to form a power cable insulation core 1, and a plurality of power cable insulation cores 1 Mutually twisted to form the core of the power cable; (2) Control cable stranded copper conductor 2-1a outer peripheral extruded control cable insulation layer 2-1b constitutes the control cable insulation core 2-1, multiple control cable insulation core 2 -1 twisted with each other to form the control cable core, the outer periphery of the control cable core is wrapped with the control cable copper foil shielding layer 2-2, the copper foil of the control cable copper foil shielding layer 2-2 faces inward and the inner side is provided with control cable drainage Line 2-2a, control cable drain line 2-2a runs through the entire length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com