Power battery heat management system based on flat plate heat pipes

A technology of thermal management system and plate heat pipe, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of large thermal resistance, neglect of battery heat generation characteristics, heat recycling, and heat dissipation capacity priority, etc., reaching a broad market Prospect, stable and reliable operation, high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

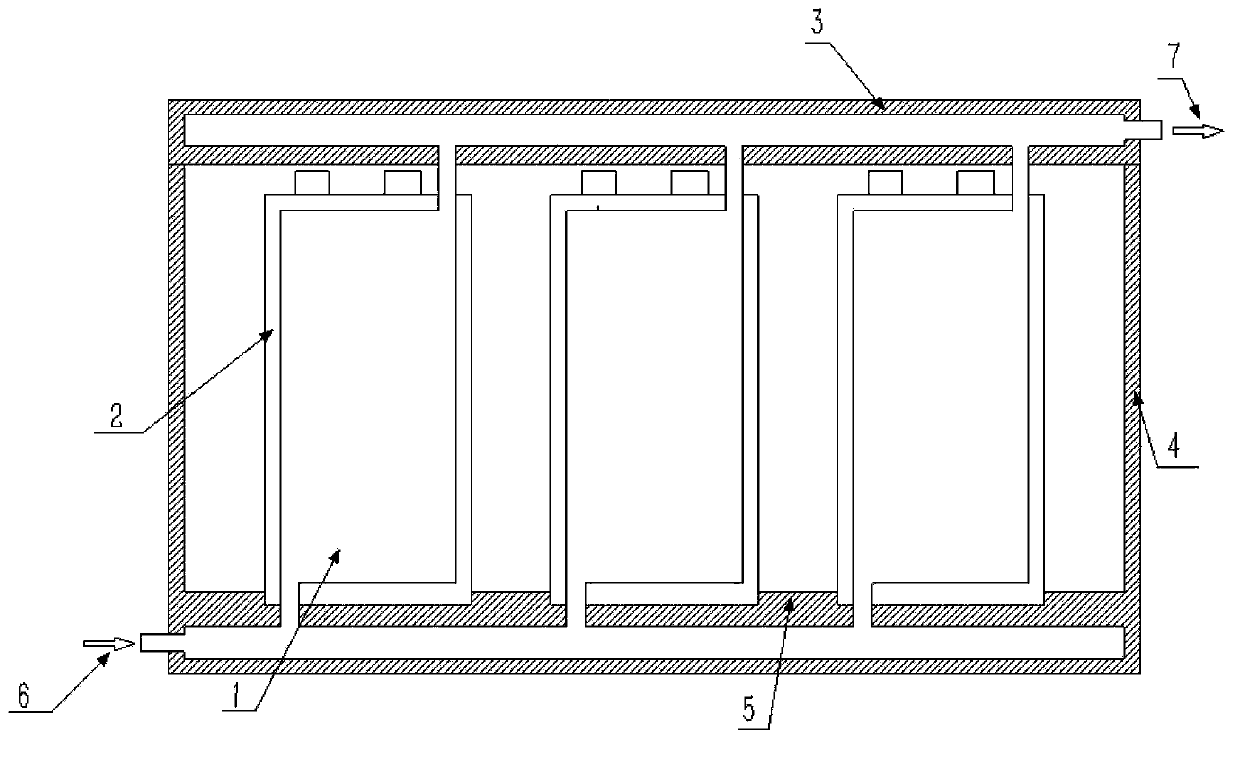

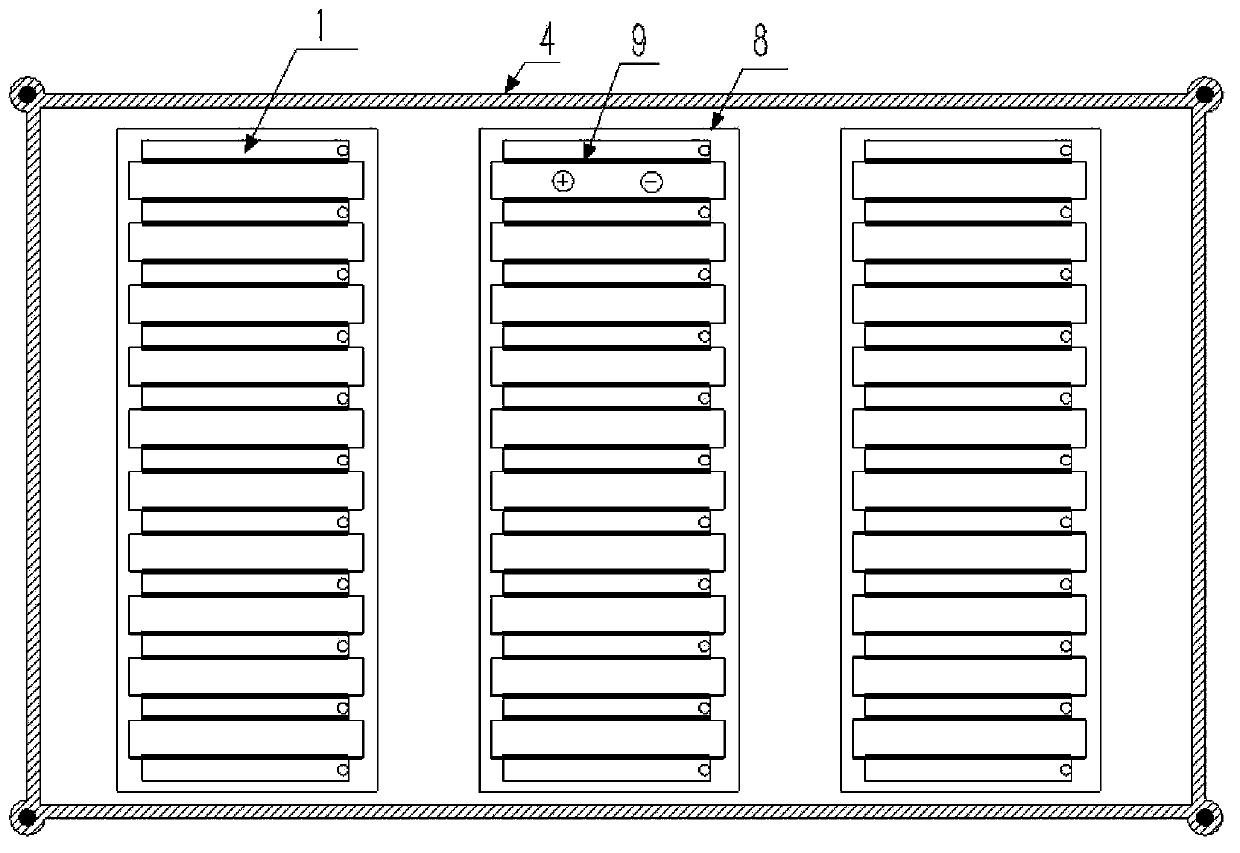

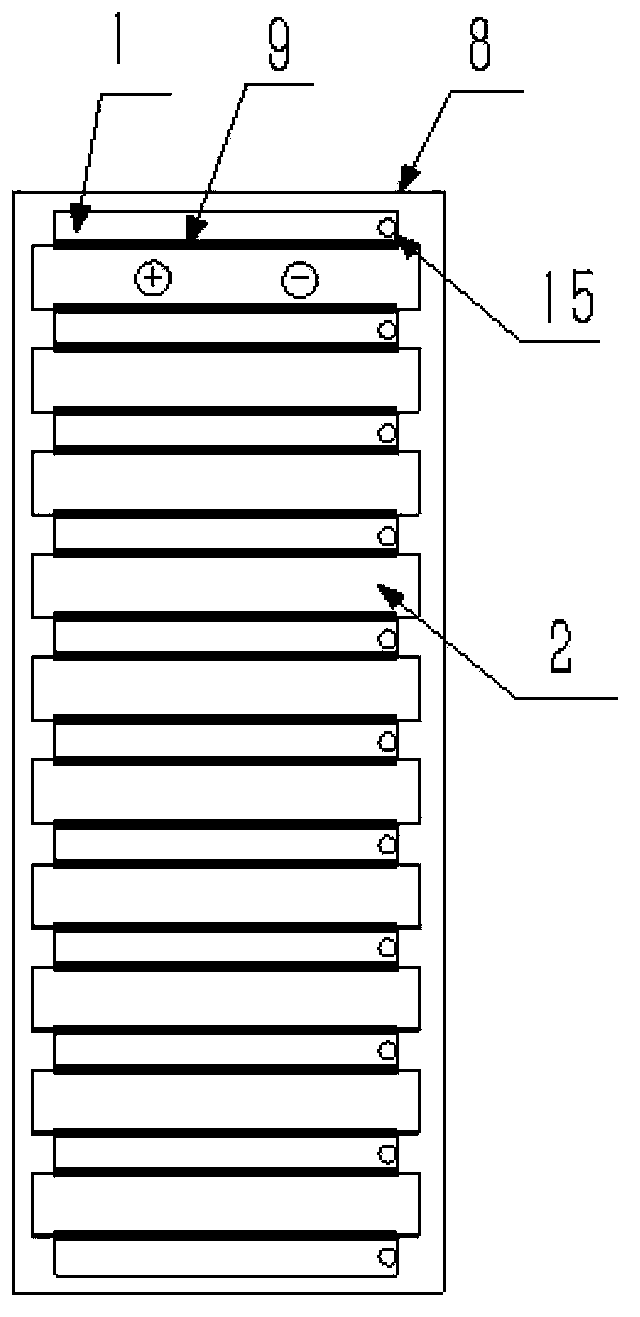

[0028] Such as figure 1 As shown, the system transfers the heat generated by the battery cells to the external environment of the battery module through the flat heat pipe 1, so as to efficiently manage the heat of the battery. The system includes a module box 4 and a box top cover 3 . A cooling water circulation cavity is provided at the bottom of the box body 4 and inside the top cover 3 , and communicates with the flat heat pipe 1 . The cooling water enters the bottom of the box from the water inlet 6, flows through the flat heat pipe 1, takes away the heat and enters the top cover 3 of the box, and finally discharges from the water outlet 7. At least two battery cell casings 8 are placed in the module box 4, and at least two battery module groups composed of battery cells 2 connected in series or in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com