Pair-twist shielding instrument cable for flame-retardant fireproof boat and manufacturing method thereof

A flame-retardant and instrument cable technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, conductor/cable insulation, etc., can solve the problems of high tension in the wrapping tape, difficult to strip, easy to damage the insulating core, etc., to achieve Eliminates voids, enhances impregnation against moisture, and facilitates continuous delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

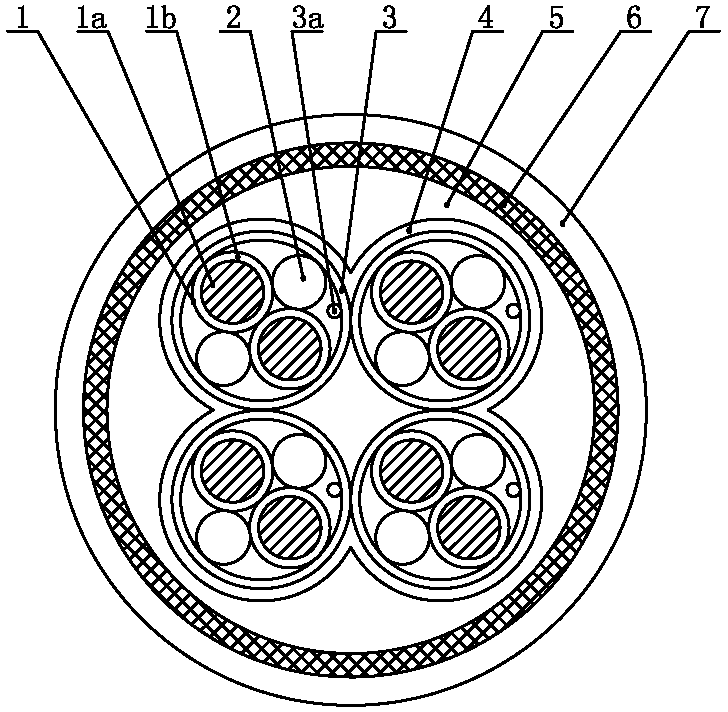

[0023] Such as figure 1 As shown, the flame-retardant and fire-resistant marine pair-twisted shielded instrument cable of the present invention includes the following steps in turn: the outer periphery of the twisted copper conductor 1a is extruded with a flame-retardant and fire-resistant ethylene-propylene rubber insulating layer 1b to form an insulating core 1, and the insulating core 1 is two by two. Twisted to form a pair of twisted wires, the gap of the pair of twisted wires is filled with a flame-retardant non-hygroscopic fiber core 2, and each pair of twisted wires adopts a different twisting pitch; The outer circumference is wrapped with copper foil polyester composite tape shielding layer 3 to form a twisted group; the copper foil of the copper foil polyester composite tape shielding layer 3 faces inward, and the inner side of the copper foil polyester composite tape shielding layer 3 is provided with tinned stranded copper Wire drainage wire 3a, tinned stranded copp...

Embodiment 2

[0028] Such as figure 1 As shown, the flame-retardant and fire-resistant marine pair-twisted shielded instrument cable of the present invention includes the following steps in turn: the outer periphery of the twisted copper conductor 1a is extruded with a flame-retardant and fire-resistant ethylene-propylene rubber insulating layer 1b to form an insulating core 1, and the insulating core 1 is two by two. Twisted to form a pair of twisted wires, the gap of the pair of twisted wires is filled with a flame-retardant non-hygroscopic fiber core 2, and each pair of twisted wires adopts a different twisting pitch; The outer circumference is wrapped with copper foil polyester composite tape shielding layer 3 to form a twisted group; the copper foil of the copper foil polyester composite tape shielding layer 3 faces inward, and the inner side of the copper foil polyester composite tape shielding layer 3 is provided with tinned stranded copper Wire drainage wire 3a, tinned stranded copp...

Embodiment 3

[0033] Such as figure 1 As shown, the flame-retardant and fire-resistant marine pair-twisted shielded instrument cable of the present invention includes the following steps in turn: the outer periphery of the twisted copper conductor 1a is extruded with a flame-retardant and fire-resistant ethylene-propylene rubber insulating layer 1b to form an insulating core 1, and the insulating core 1 is two by two. Twisted to form a pair of twisted wires, the gap of the pair of twisted wires is filled with a flame-retardant non-hygroscopic fiber core 2, and each pair of twisted wires adopts a different twisting pitch; The outer circumference is wrapped with copper foil polyester composite tape shielding layer 3 to form a twisted group; the copper foil of the copper foil polyester composite tape shielding layer 3 faces inward, and the inner side of the copper foil polyester composite tape shielding layer 3 is provided with tinned stranded copper Wire drainage wire 3a, tinned stranded copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com