Flat belt lateral swelling combined vacuum pre-pressing foundation processing device and method

A foundation treatment and sling technology, which is applied in the direction of foundation structure engineering, soil protection, construction, etc., can solve the problems of no further improvement, slow clay consolidation rate, high electricity costs, etc., to shorten the vertical drainage distance and improve The effect of foundation bearing capacity and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

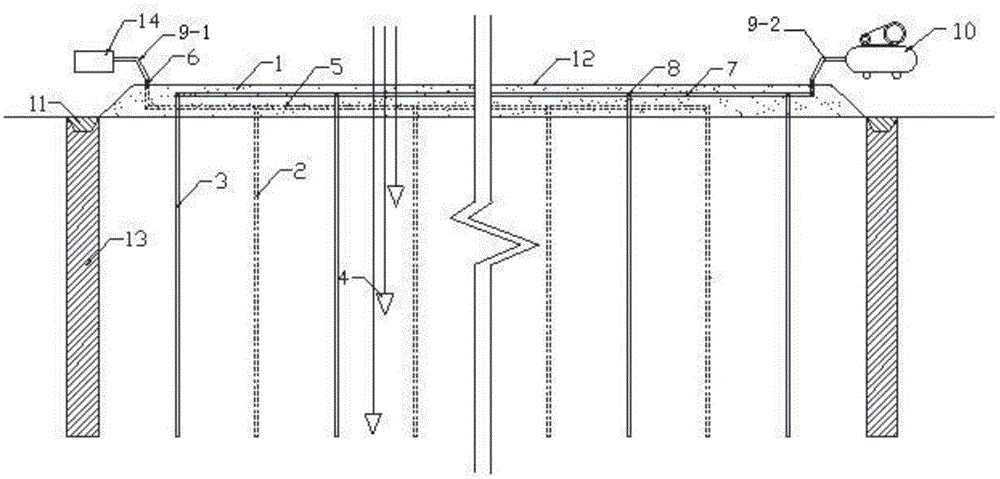

[0028] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0029] Taking an area of 10,000 square meters with a length and width of 100m×100m as an example, the site is leveled and a sand cushion is laid on the surface. The sand cushion is set with medium-coarse sand, the thickness can be 40-50cm, and the permeability coefficient is greater than 1×10 -2 cm / s.

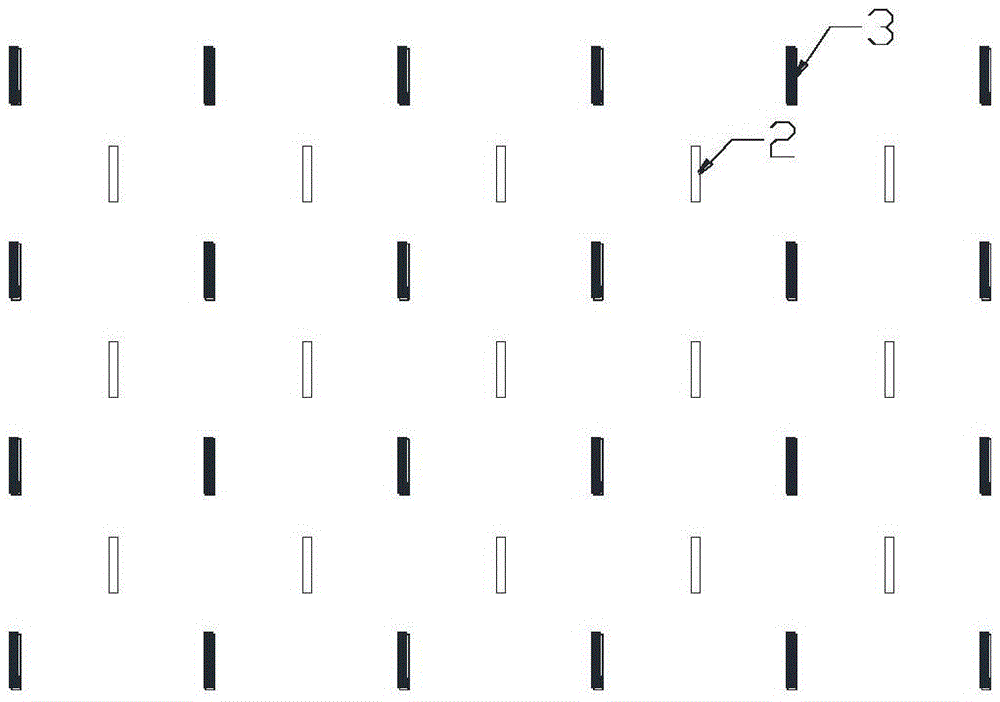

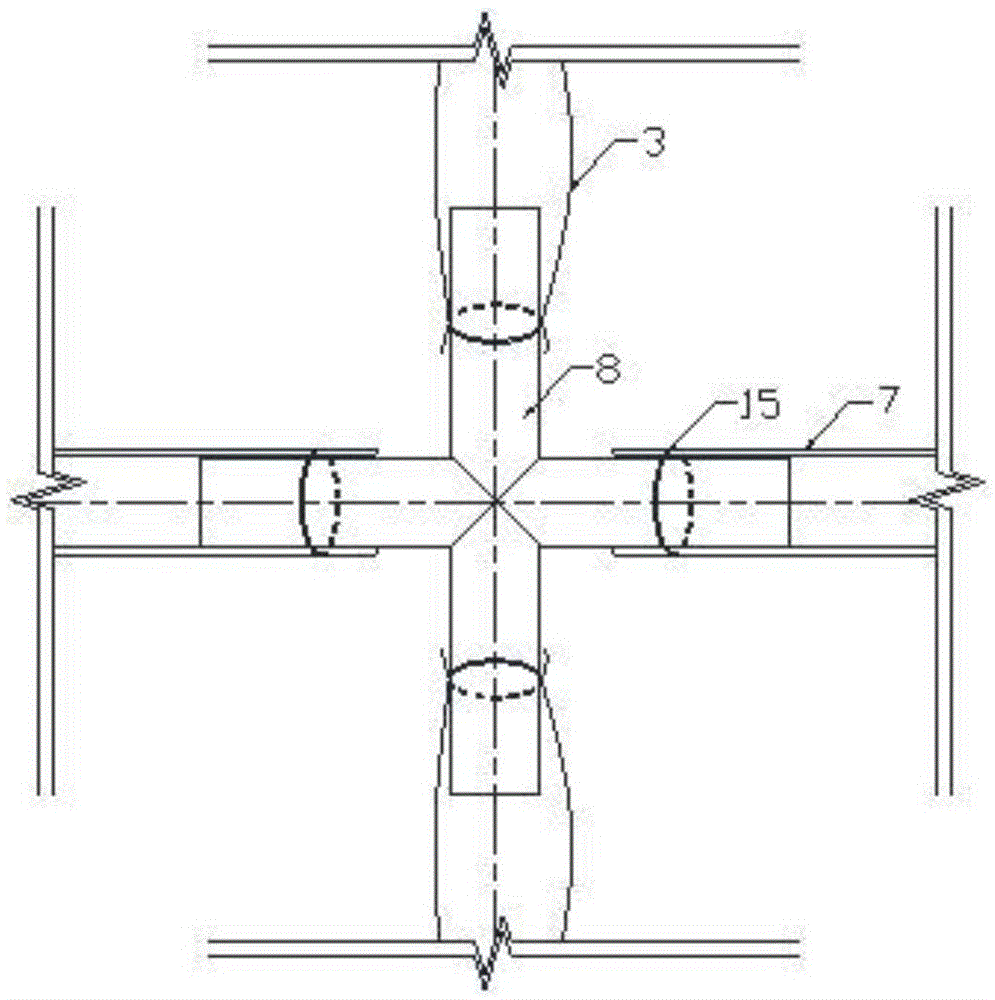

[0030] Set up plastic drainage boards and plastic slings in an area of 10,000 square meters: arrange according to the plane spacing of plastic drainage boards, use a plugging machine to drill plastic drainage boards to the design depth, and use B-type plastic drainage boards for plastic drainage boards , to avoid pollution of the head of the plastic drainage board during the laying process; according to the planar spacing of the plastic flat belt, use the plugging machine to set the plastic flat belt to the design depth, and the plastic flat be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com