All-solid-state lithium battery, garnet solid-state electrolyte and preparation method thereof

A solid electrolyte, garnet technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of large interface contact resistance, achieve good interface contact, increase effective contact area, and reduce contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

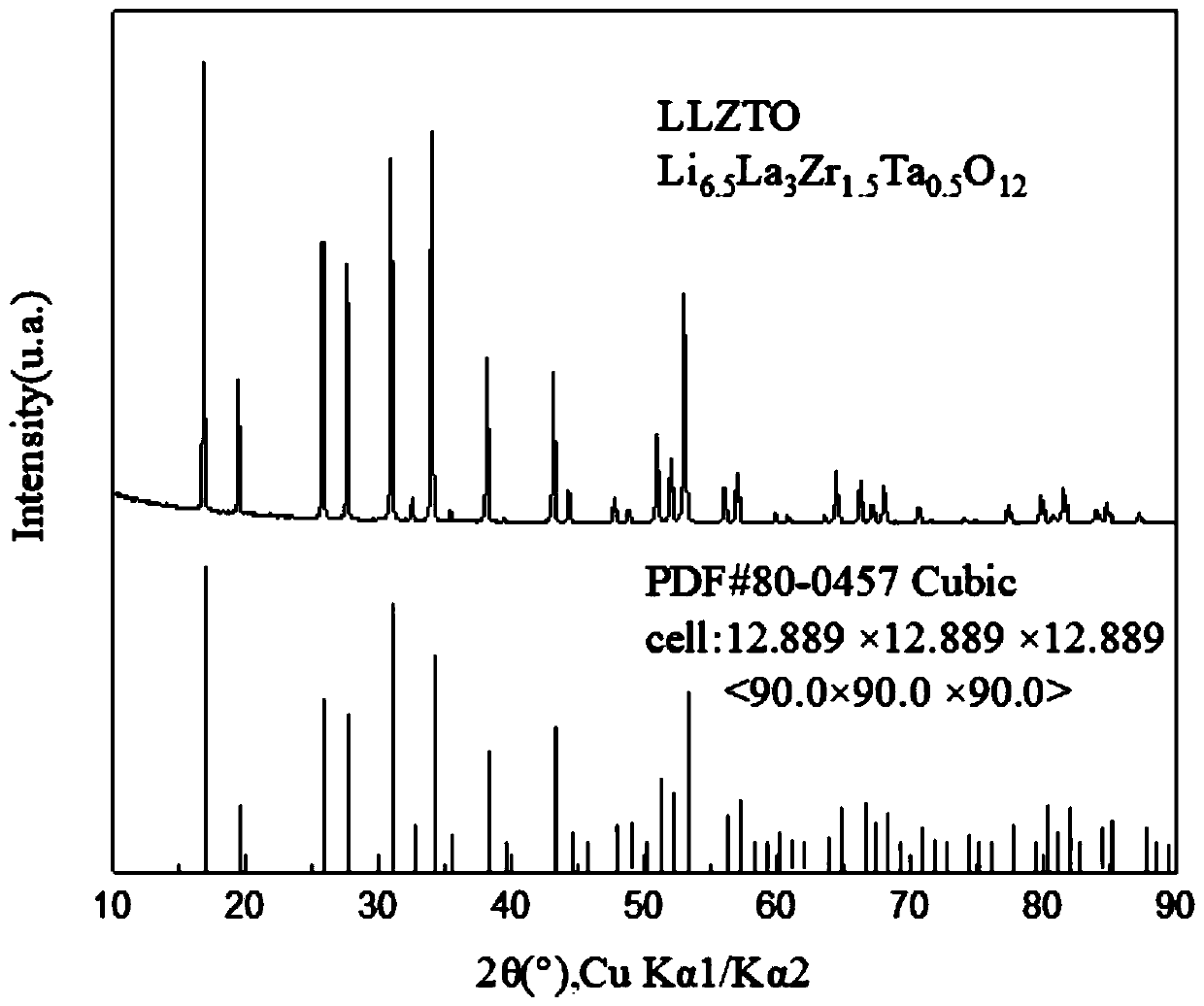

[0031] (1) Preparation of garnet solid electrolyte (Li 6.5 La 3 Zr 1.5 Ta 0.5 o 12 ) matrix

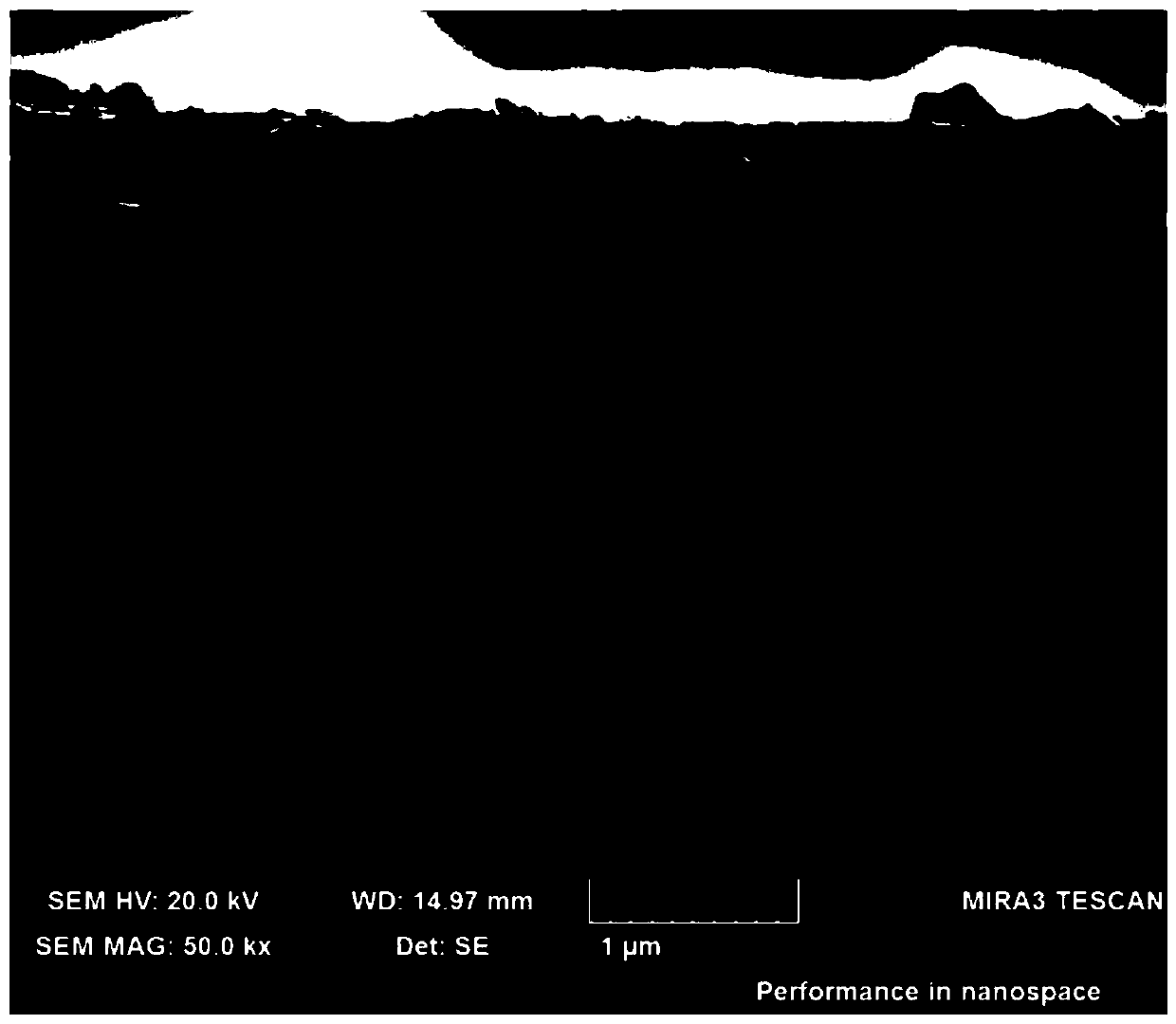

[0032]First, the raw materials lithium hydroxide monohydrate, lanthanum oxide, zirconium oxide, and tantalum oxide were placed in a ball mill tank containing isopropanol according to the stoichiometric ratio at a speed of 400 rpm for 6 hours, and the excess lithium was 15% to supplement the high-temperature sintering of the solid electrolyte. Lithium evaporates during the process. After ball milling, the raw materials were dried in vacuum and then placed in a muffle furnace for sintering at 950° C. for 6 h to obtain the precursor powder. Then, the precursor powder was placed in a ball mill jar and ball milled at a speed of 400 rpm for 12 hours to obtain an active fine powder precursor. After the fine powder precursor was compressed by a tablet press at 200 rpm, it was placed in a muffle furnace for sintering at 1250°C for 50 minutes to obtain a solid electrolyte matrix. The obt...

Embodiment 2

[0040] (1) Preparation of garnet solid electrolyte (Li 6.6 La 3 Zr 1.6 Ta 0.4 o 12 ) matrix

[0041] The Li 6.5 La 3 Zr 1.6 Ta 0.4 o 12 The electrolyte matrix was also synthesized by a solid-phase method. The preparation method is the same as in Example 1.

[0042] (2) Form an interface modification layer on the surface of the substrate

[0043] Place the above solid electrolyte matrix on a clean platform, weigh 0.006g of NbS with a particle size of 38um 2 Place on the surface of the solid electrolyte matrix and grind for 5 minutes, so that a layer of 3um NbS is formed on the surface of the solid electrolyte matrix 2 interface layer to obtain a solid electrolyte (S3) after interface modification.

[0044] (3) Preparation of all-solid lithium pair batteries

[0045] The interface-modified solid electrolyte (S3) prepared above was cold-pressed with two lithium sheets to obtain an all-solid lithium pair battery. The results show that compared with the unmodified al...

Embodiment 3

[0049] (1) Preparation of garnet solid electrolyte (Li 6.7 La 3 Zr 1.7 Nb 0.3 o 12 ) matrix

[0050] The Li 6.7 La 3 Zr 1.7 Nb 0.3 o 12 The electrolyte matrix was also synthesized by a solid-phase method. The preparation method is the same as in Example 1.

[0051] (2) Form an interface modification layer on the surface of the substrate

[0052] Place the above solid electrolyte matrix on a clean platform and weigh 0.008g of MoSe with a particle size of 5um 2 Place on the surface of the solid electrolyte matrix and grind for 3 minutes, so that a layer of 2um MoSe is formed on the surface of the solid electrolyte matrix 2 interface layer to obtain a solid electrolyte (S4) after interface modification.

[0053] (3) Preparation of all-solid lithium pair batteries

[0054] The interface-modified solid electrolyte (S4) prepared above was cold-pressed with two lithium sheets to obtain an all-solid lithium pair battery. After the lithium pair battery test, compared wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com