Method for preparing vinyl chloride by circulating fluidized bed reactor and device thereof

A circulating fluidized bed and reactor technology, which is used in hydrogen halide addition preparation, organic chemistry, etc., can solve the problems of less vinyl chloride catalyst, poor operation flexibility, low production intensity, etc., and achieve the effect of gas-solid contact Enhances, reduces backmixing, and reduces mercury loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

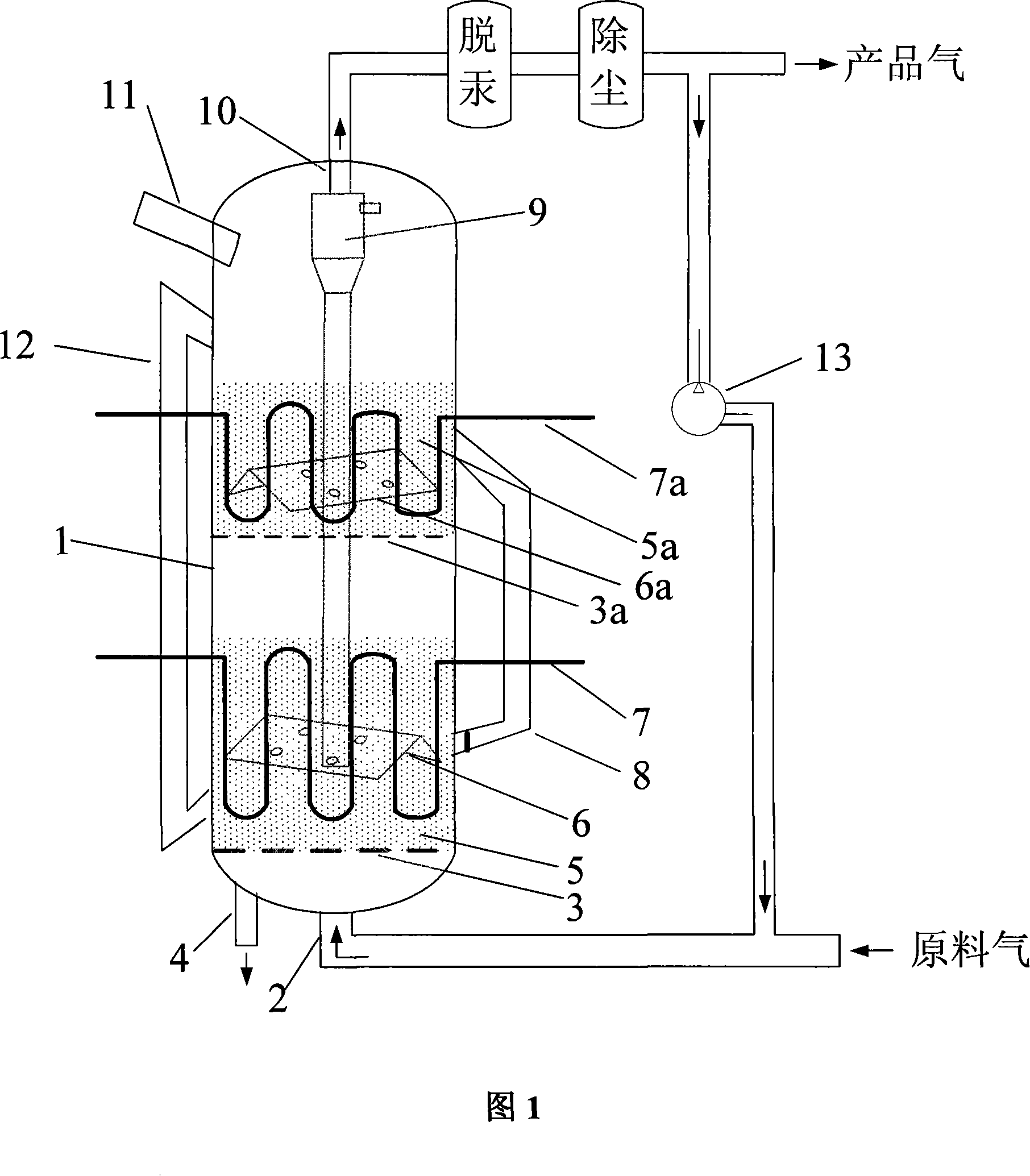

[0077] A circulating fluidized bed reactor with two catalyst dense phase zones was employed (Figure 1). Among them, the cyclone separator (one group) is built-in; the first gas distributor 3 adopts a tubular gas distributor whose pressure drop accounts for 20% of the total pressure drop of the catalyst in the first catalyst dense phase zone 5; 2 times, the total cross-sectional area is 5% of the cross-sectional area of the circulating fluidized bed reactor cylinder; 20% of the cylinder diameter of the fluidized bed reactor; the distance between the internal components of the same layer is 10% of the cylinder diameter of the circulating fluidized bed reactor; the distance between the first gas distributor 3 and the second gas distributor 3a is 10 times the diameter of the cylinder of the circulating fluidized bed reactor; the distance from the upper end of the external overflow pipe 8 connecting the first and second catalyst dense-phase regions to the second gas distributor 3...

Embodiment 2

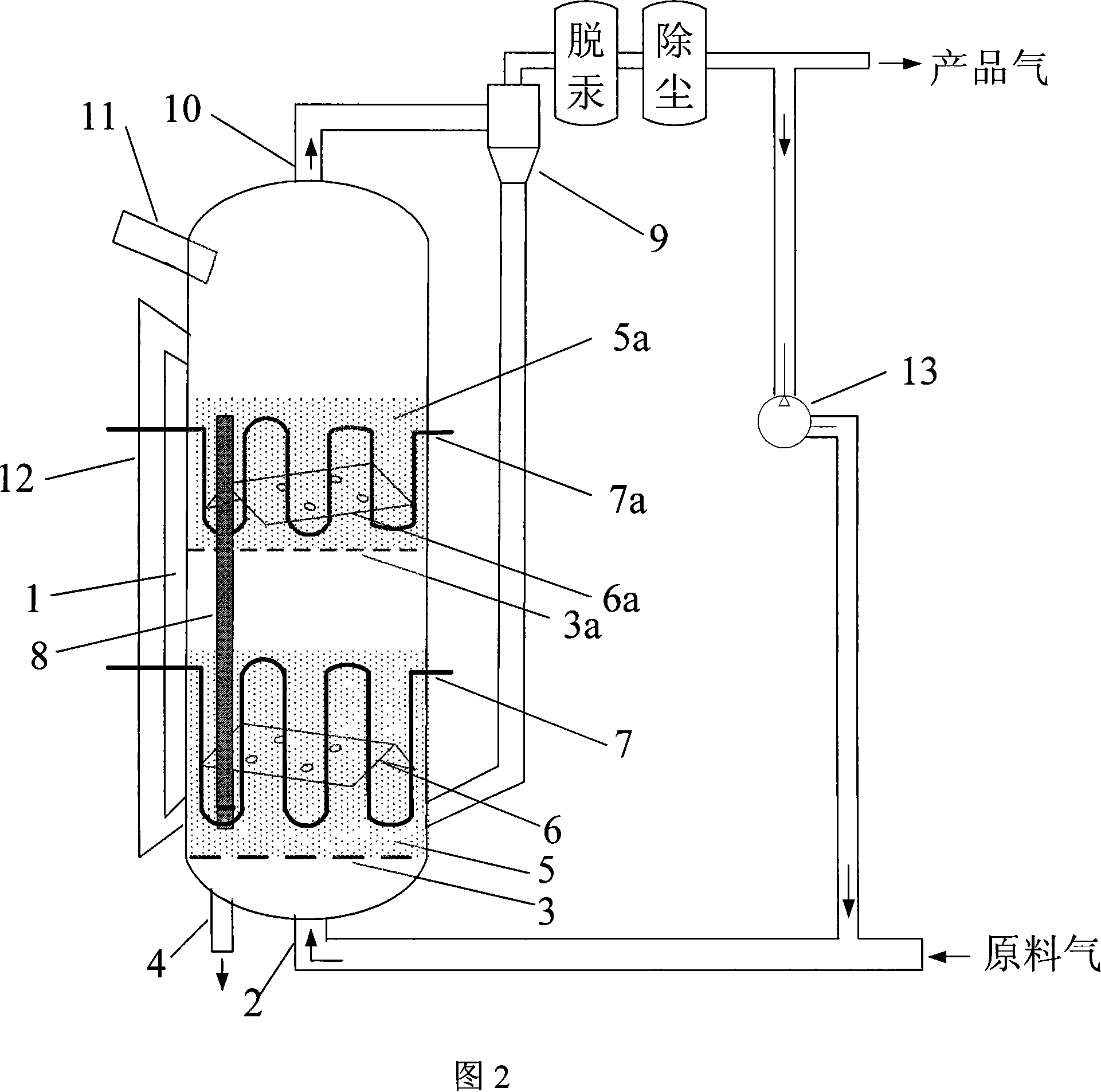

[0082] A circulating fluidized bed reactor with two catalyst dense phase zones was employed (Figure 2). Among them, the cyclone separator (two groups) is external; the first gas distributor 3 adopts a plate gas distributor whose pressure drop accounts for 35% of the total pressure drop of the catalyst in the first catalyst dense phase zone 5; 1 times, the heat exchange tube with a total cross-sectional area of 30% of the cross-sectional area of the cylinder of the circulating fluidized bed reactor; the void ratio of the internal member is 50%; the intersection angle of two adjacent layers of internal members is 45°, and the distance is 20% of the cylinder diameter of the fluidized bed reactor; the distance between the internal components of the same layer is 1% of the cylinder diameter of the circulating fluidized bed reactor; the distance between the first gas distributor 3 and the second gas distributor 3a is 8 times of the cylinder diameter of the circulating fluidized ...

Embodiment 3

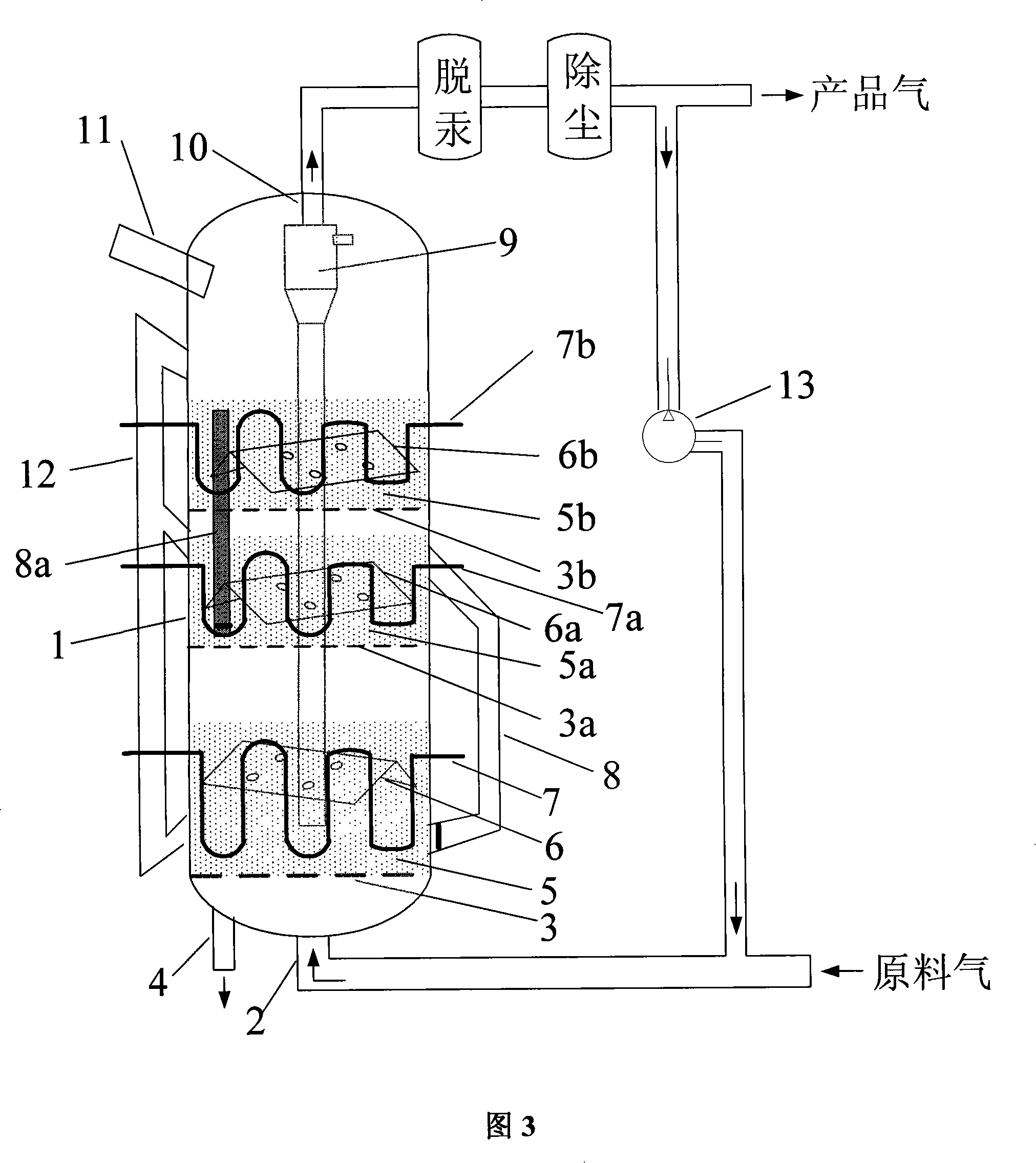

[0087] A circulating fluidized bed reactor with three catalyst dense phase zones was employed (Figure 3). Among them, the cyclone separator (two groups) is built-in; the first gas distributor 3 adopts a float valve type gas distributor whose pressure drop accounts for 30% of the total pressure drop of the catalyst in the first catalyst dense phase zone 5; the height used is the height of the catalyst dense phase 1.5 times of the heat exchange tube with a total cross-sectional area of 15% of the cross-sectional area of the cylinder of the circulating fluidized bed reactor; the void ratio of the inner member is 70%, the intersection angle of two adjacent inner members is 90°, and the distance is cyclic 80% of the cylinder diameter of the fluidized bed reactor; the distance between internal components of the same layer is 10% of the cylinder diameter of the circulating fluidized bed reactor; the distance between the first gas distributor 3 and the second gas distributor 3a It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com