Salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and manufacturing method of telecommunication cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

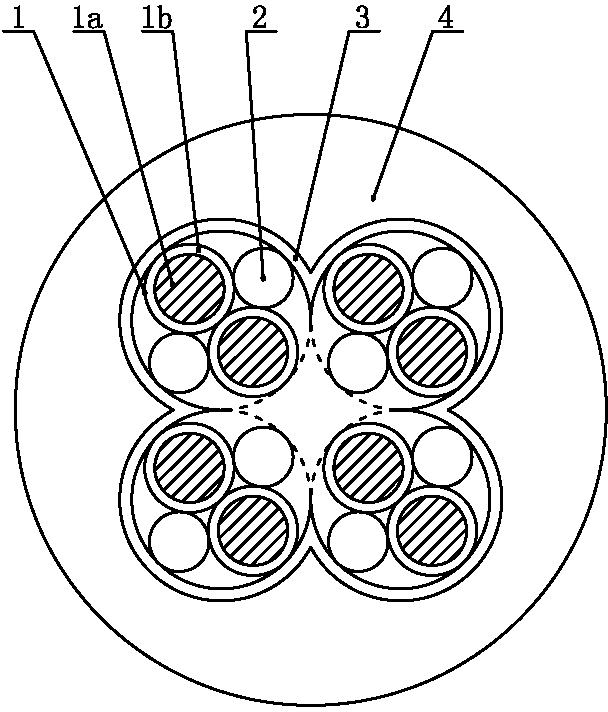

[0023] Such as figure 1 As shown, the salt-corrosion-resistant and torsion-resistant communication cable for marine wind power of the present invention includes the following steps in turn: the outer periphery of the stranded copper conductor 1a is evenly extruded with a salt-rot-resistant and torsion-resistant rubber insulating layer 1b to form an insulating core 1, and the insulating core 1 Two pairs of twisted wires are twisted to form a pair of twisted wires. The gaps of the pair of twisted wires are filled with flame-retardant non-hygroscopic fiber filler 2. Each pair of twisted wires adopts different twisting pitches. Multiple pairs of twisted wires are twisted Synthesize the cable core, then wrap the low-strength non-woven longitudinal cladding 3 on the outer periphery of the cable core, and finally extrude the sheath 4 on the outer periphery of the low-strength non-woven longitudinal cladding 3, and the sheath 4 wraps the low-strength non-woven fabric The longitudinal ...

Embodiment 2

[0028] Such as figure 1As shown, the salt-corrosion-resistant and torsion-resistant communication cable for marine wind power of the present invention includes the following steps in turn: the outer periphery of the stranded copper conductor 1a is evenly extruded with a salt-rot-resistant and torsion-resistant rubber insulating layer 1b to form an insulating core 1, and the insulating core 1 Two pairs of twisted wires are twisted to form a pair of twisted wires. The gaps of the pair of twisted wires are filled with flame-retardant non-hygroscopic fiber filler 2. Each pair of twisted wires adopts different twisting pitches. Multiple pairs of twisted wires are twisted Synthesize the cable core, then wrap the low-strength non-woven longitudinal cladding 3 on the outer periphery of the cable core, and finally extrude the sheath 4 on the outer periphery of the low-strength non-woven longitudinal cladding 3, and the sheath 4 wraps the low-strength non-woven fabric The longitudinal c...

Embodiment 3

[0033] Such as figure 1 As shown, the salt-corrosion-resistant and torsion-resistant communication cable for marine wind power of the present invention includes the following steps in turn: the outer periphery of the stranded copper conductor 1a is evenly extruded with a salt-rot-resistant and torsion-resistant rubber insulating layer 1b to form an insulating core 1, and the insulating core 1 Two pairs of twisted wires are twisted to form a pair of twisted wires. The gaps of the pair of twisted wires are filled with flame-retardant non-hygroscopic fiber filler 2. Each pair of twisted wires adopts different twisting pitches. Multiple pairs of twisted wires are twisted Synthesize the cable core, then wrap the low-strength non-woven longitudinal cladding 3 on the outer periphery of the cable core, and finally extrude the sheath 4 on the outer periphery of the low-strength non-woven longitudinal cladding 3, and the sheath 4 wraps the low-strength non-woven fabric The longitudinal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Insulation resistance constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com