Inclined hole type treatment casing and gas compressor

A technology for dealing with casings and compressors, applied to machines/engines, mechanical equipment, non-variable pumps, etc., can solve problems such as compressor surge, reduce impact, improve utilization rate, and reduce negative impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] When the existing processing casing is applied to the compressor, it does not help much to improve the compressor surge phenomenon and the stability margin of the compressor. With the development of time, the gas turbine requires the compressor to have a high pressure ratio and a high load. How to improve the stability margin of the compressor has always been a difficult problem restricting the performance improvement of the gas turbine. Therefore, a solution different from existing processing casings is urgently needed.

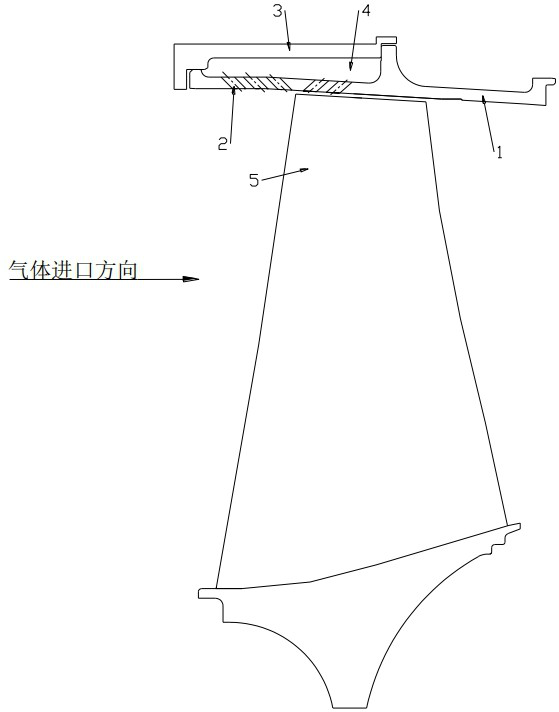

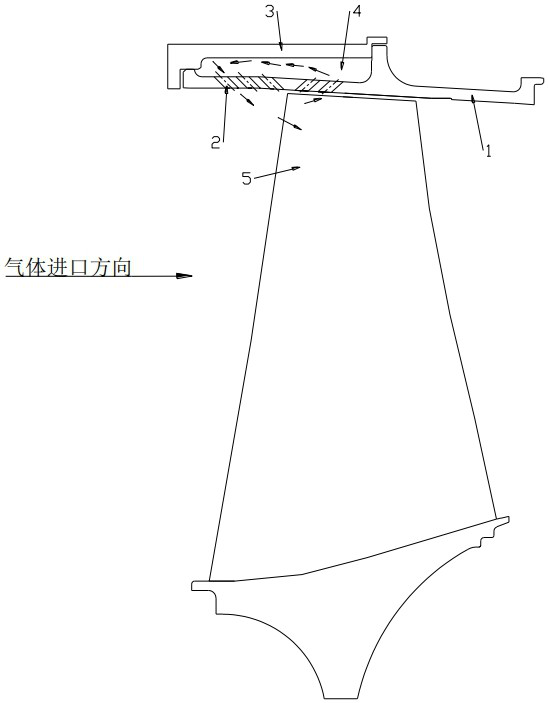

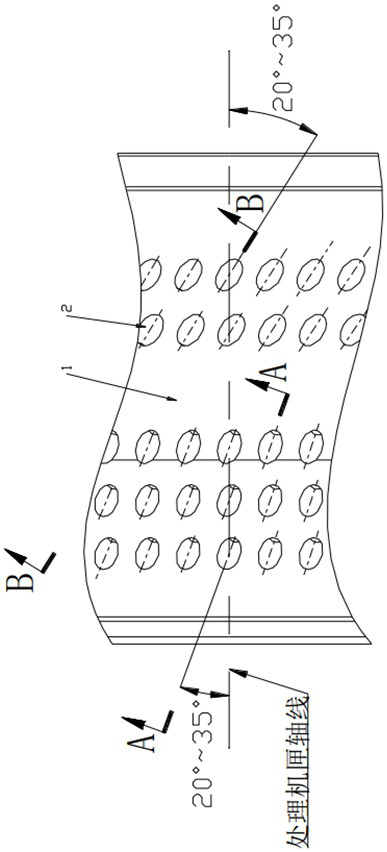

[0034] like Figure 1-Figure 5 As shown, a slanted hole type processing casing includes a casing body 1 and several air holes 2 arranged on the casing body 1, that is, the present invention provides a slanted hole type processing casing, which uses the air holes 2 to guide The blocked gas on the flow channel of the compressor pushes the blocked gas below to flow to the rear of the flow channel, reducing the influence of the blocked gas on the flow fi...

Embodiment 2

[0056] In this embodiment, on the basis of embodiment 1, the use of the oblique-hole processing casing described in embodiment 1 is described: a compressor includes the above-mentioned oblique-hole processing casing.

[0057] Through the oblique hole processing casing with simple structure and good workmanship, the gas above the compressor flow channel is sucked into the additional chamber 4, and then sprayed out to push the stagnant gas under the flow channel to replenish the active flow and improve the entire flow. The blockage of the channel makes the gas flow in the channel more smooth. In this way, it not only reduces the influence of stagnant gas on the stability of the flow channel, but also improves the utilization rate of the gas, reduces the negative impact of the compressor due to the change of the rotational speed, and can greatly improve the performance of the compressor. Stability margin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com