Cooling fan for traction converter of high-speed electric locomotive

A technology for traction converters and electric locomotives, which is applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of low temperature shock resistance and high-speed vibration and avoid losses , The effect of reducing separation loss and leakage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

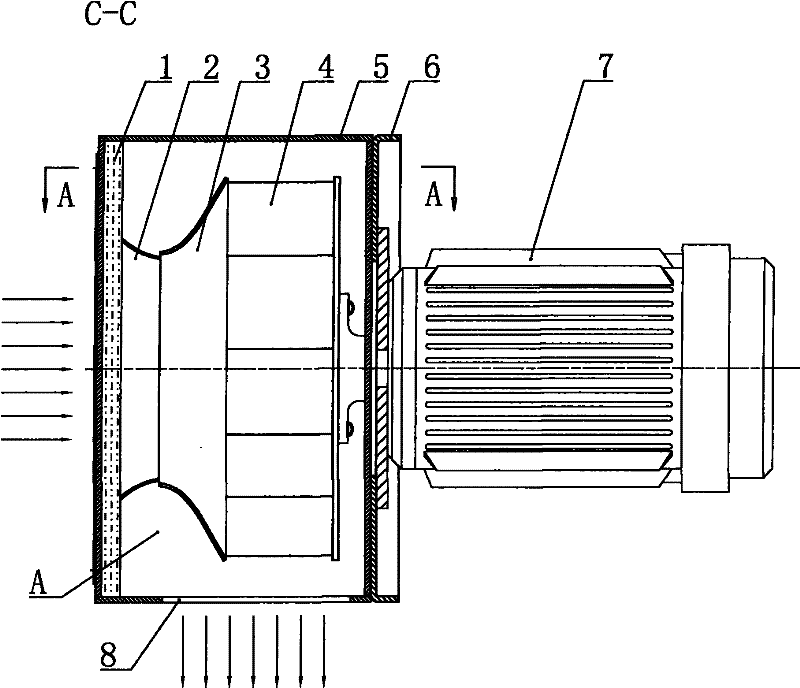

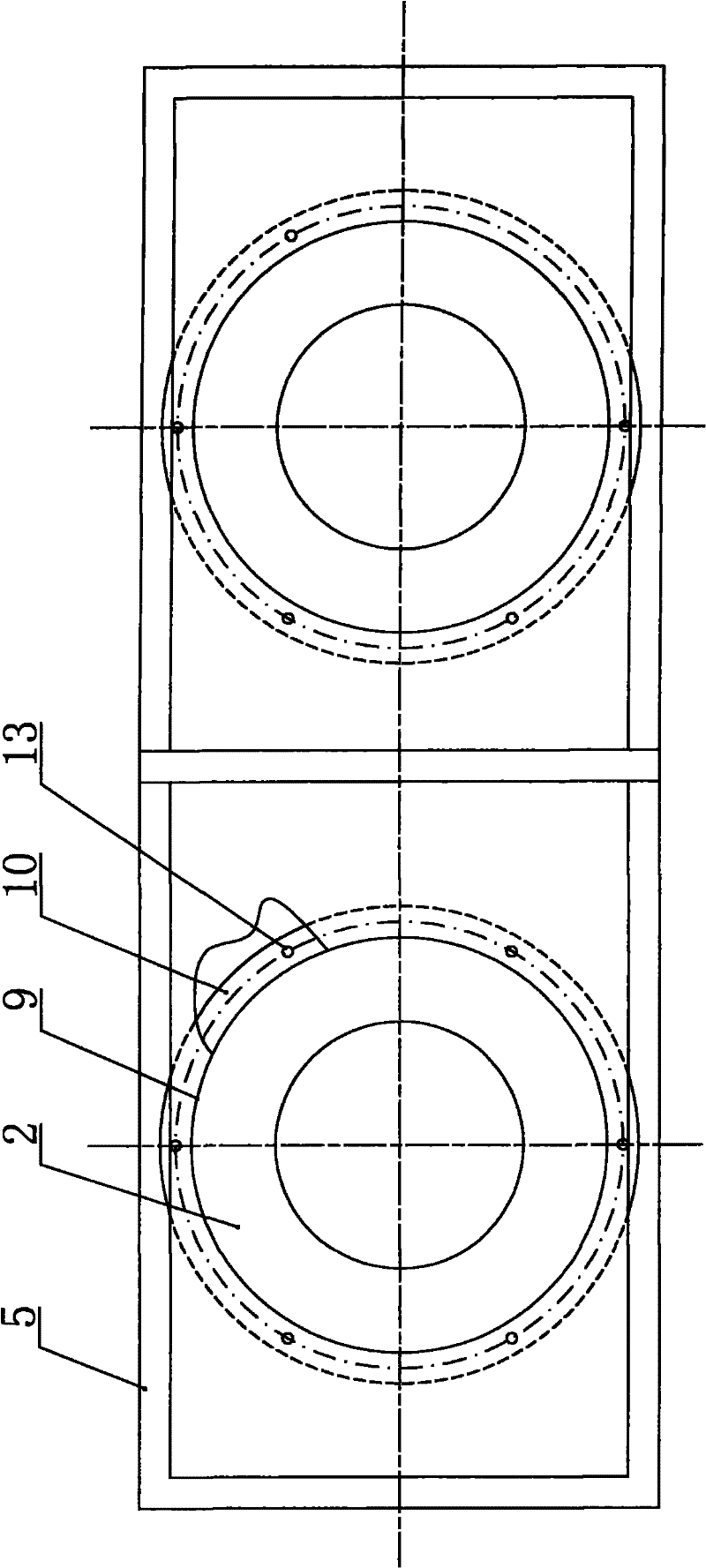

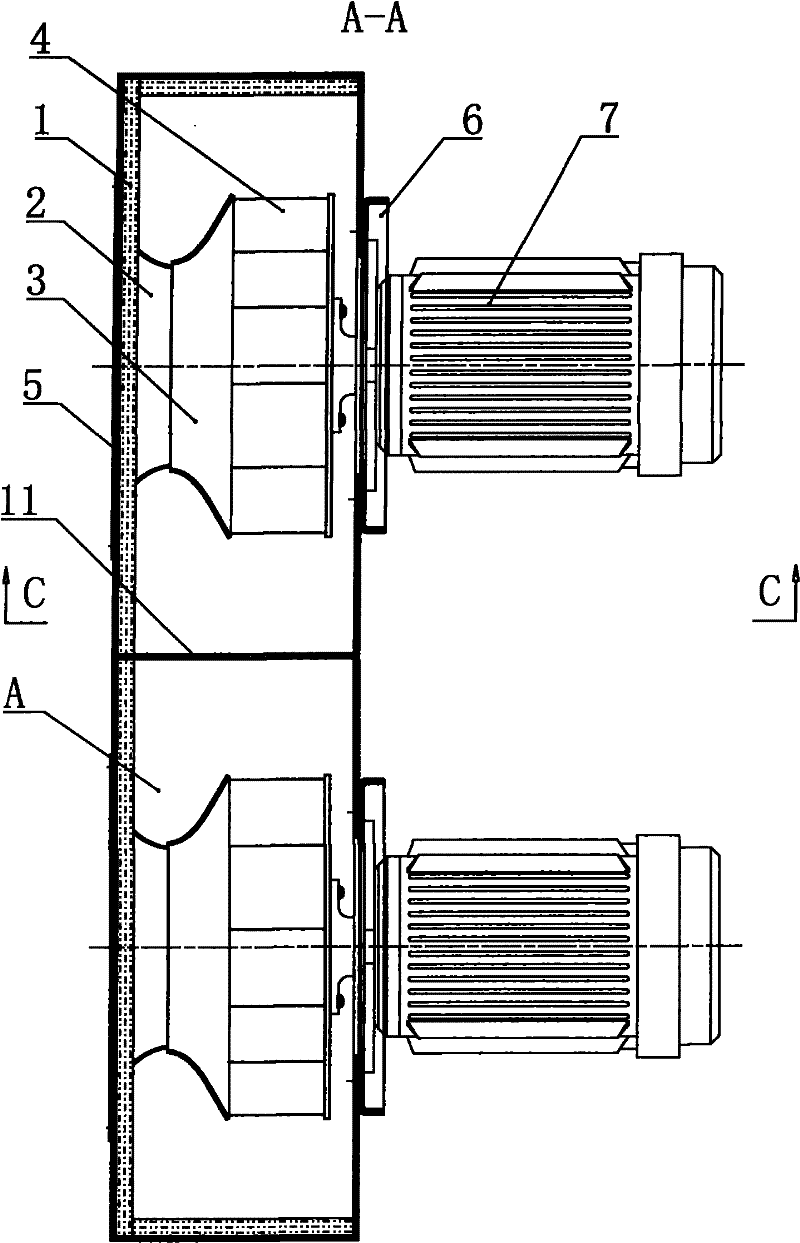

[0030] see Figure 1 to Figure 6 , a cooling fan for a high-speed electric locomotive traction converter of the present invention is combined with an impeller 4, a motor 7, and a motor mounting plate 6 on a rectangular box body 5 of an existing cooling system,

[0031] In the middle of this casing 5, divide into two independent cavities A with dividing plate 11, respectively house a motor 7 at the rear side of each this cavities A, at the front side and the lower side of each these cavities A The sides are respectively provided with an air inlet 9 and an air outlet 8. The rear side of each cavity A is respectively connected to the front end of a motor 7, and an impeller 4 is respectively arranged in each cavity A and is coaxially installed on the output shaft of the motor 7. When working, they all rotate counterclockwise (matched with the entire cooling system) without interfering with each other.

[0032] The impeller 4 is composed of a front disc 3, a rear disc 41 and a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com