Drip-imitating tube-type demister and demister device

A droplet-shaped, mist eliminator technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem of inability to effectively eliminate large mist droplets and uniformly distributed flue gas, tubular mist eliminator and mist eliminator The defogging efficiency and self-cleaning ability cannot meet the requirements, etc., to achieve the effect of increasing the area, reducing the flow resistance, and not easy to scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

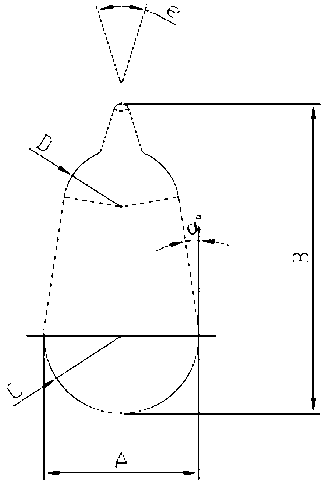

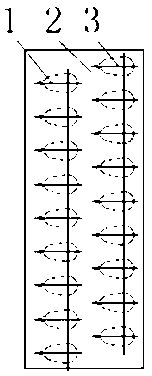

[0024] Such as figure 2 As shown, it is a structural schematic diagram of a two-layer tube-row imitation water-drop-shaped tube demister provided by the present invention, which includes two layers of parallel tube-rows 1, and the tube-row 1 is composed of evenly arranged cross-sections that are drop-shaped tubes 3 The two ends of the tube row 1 are respectively supported on the plate 2. The spacing between each tube row 1 is arbitrary.

[0025] Such as figure 1 As shown, the major axis B of the drop-shaped cross-section of the water-drop-shaped pipe 3 is twice the minor axis A of the drop-shaped cross-section, and the large circle C of the drop-shaped cross-section is 1.3 times the small circle D of the drop-shaped cross-section. The head of the small circle D of the drop-shaped section has a taper of 35°, and the inclination a of the pipe 3 is 9°.

Embodiment 2

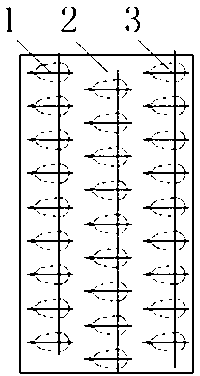

[0027] Such as image 3 As shown, it is a structural schematic diagram of a three-layer pipe row imitation water drop tube demister provided by the present invention. The difference between the imitation water drop tube demister of this embodiment and embodiment 1 is that There are three layers, and other structures are the same as in Embodiment 1.

Embodiment 3

[0029] Such as Figure 4A As shown, in order to use the demister device of the above-mentioned imitation water-drop-shaped pipe demister, the imitation water-drop-shaped pipe demister 5 is arranged at the upstream position of the flue gas desulfurization tower or the horizontal flue, and in the flue gas desulfurization tower or the horizontal flue A plate type mist eliminator 6 is arranged downstream of the channel.

[0030] Such as Figure 4B As shown, the flushing water pipes 10 of the water-drop-shaped tube demister 5 and the flat plate demister 6 are arranged upstream and downstream of the water-drop-shaped tube demister 5, while the downstream of the water-drop-shaped tube demister 5 It is necessary to arrange the flushing water pipe 10 to clean the blades of the flat plate mist eliminator 6 .

[0031] The water-drop-shaped tubular demister 5 is upstream at the inlet end of the flue gas, and downstream at the outlet end of the flue gas. The blades of the flat-plate mis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com