Vulcanization startup method of hydrocracking device

A technology of hydrocracking and hydrogen sulfide, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problem that the heat of reaction is not fully utilized, so as to reduce the duration of sulfidation, reduce energy consumption, and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

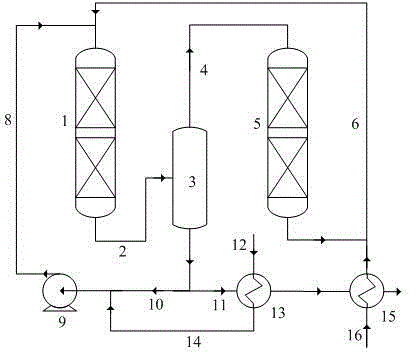

[0038] use figure 1 In the process flow shown, the catalysts used are FF-46 hydrocracking pre-refining catalyst and FC-32 hydrocracking catalyst developed by Fushun Petrochemical Research Institute. Catalyst properties are listed in Table 1. After the airtightness is completed, the system pressure is adjusted to 12.0MPa, and the circulating hydrogen compressor is started. The hydrogen circulation route is the first reverse (refining reactor)-high fractionation-second reverse (cracking reactor)-first reverse. When the inlet temperature of the first reverse bed rises to 120°C, the process oil starts to enter. The properties of the process oil are shown in Table 2. The start-up oil circulation circuit is one reverse-high score-one reverse. Volumetric space velocity 1.0h -1 , Hydrogen oil ratio 700:1. After the catalyst is fully wetted, raise the bed inlet temperature to 150°C and start injecting C 2 S. Slowly raise the temperature of the first and second reactor beds, and a...

Embodiment 2

[0041] use figure 1 Shown technological process, catalyzer is with embodiment 1. After the airtightness is completed, the system pressure is adjusted to 12.0MPa, and the circulating hydrogen compressor is started. The hydrogen circulation route is the first reverse (refining reactor)-high fractionation-second reverse (cracking reactor)-first reverse. When the inlet temperature of the first reverse bed rises to 120°C, the process oil starts to enter. The properties of the process oil are shown in Table 2. The start-up oil circulation circuit is one reverse-high score-one reverse. Volumetric space velocity 1.0h -1 , Hydrogen oil ratio 700:1. After the catalyst is fully wetted, raise the bed inlet temperature to 150°C and start injecting C 2 S. Raise the temperature of the first and second reaction beds slowly. After the hydrogen sulfide penetrates the entire bed, raise the inlet temperature of the first reaction bed to 230°C, and keep the constant temperature vulcanization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com