Coal and gas separation bin and method thereof

A technology for separating bins and gas, which is applied in the direction of gas discharge, earthwork drilling, safety devices, etc., and can solve the problems of life of underground operators, damage of well lanes and electromechanical equipment, uncontrollable and separation of outburst jet flow coal and gas, expansion Disaster scope and other issues, to achieve the effect of increasing coal and gas output in drilling outbursts, wide application, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

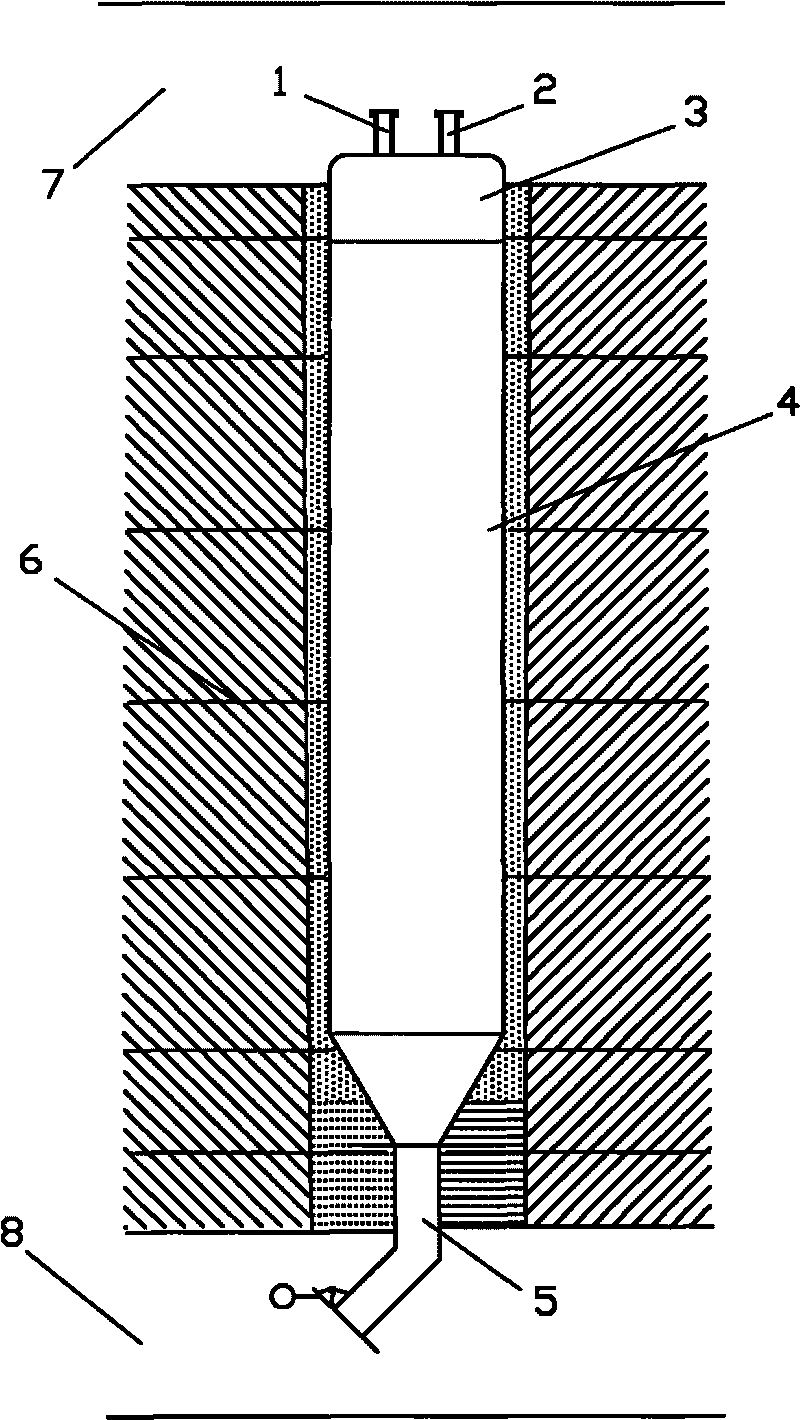

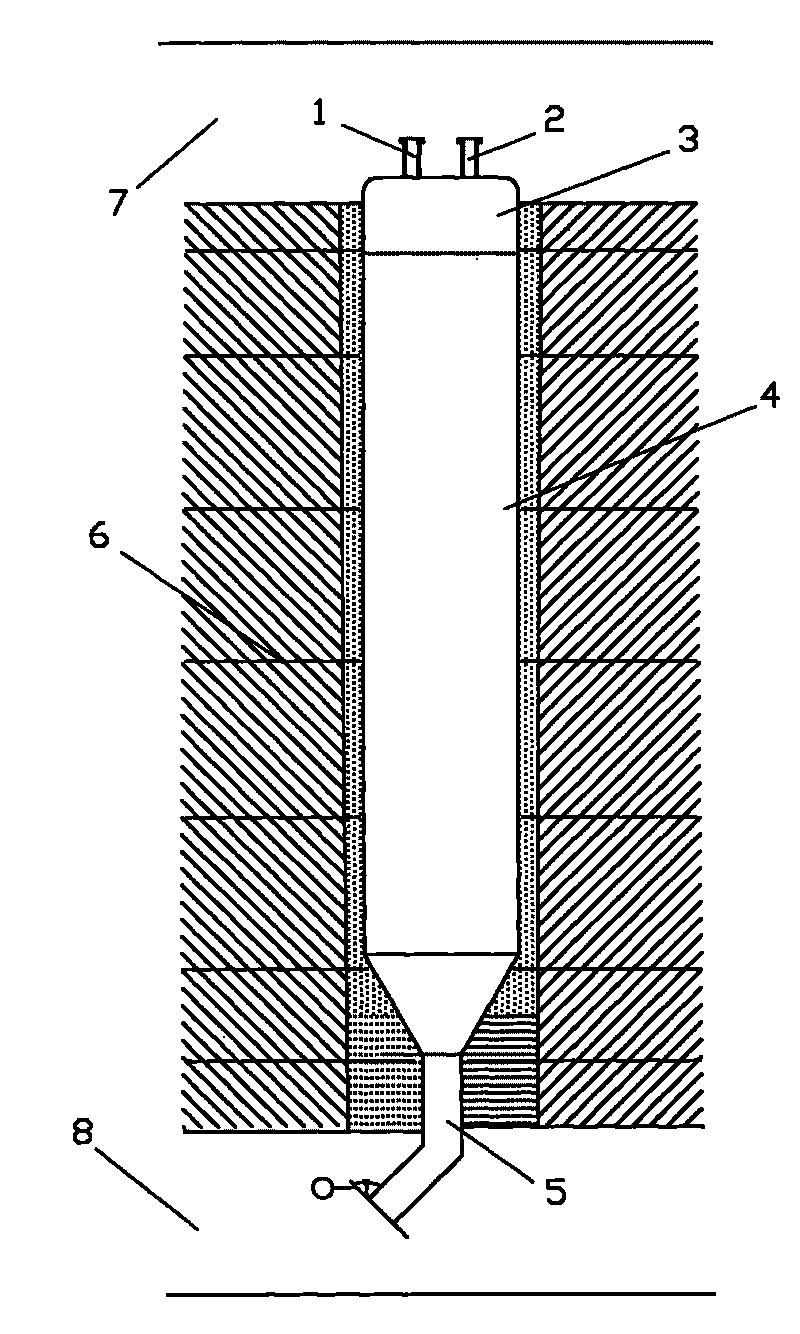

[0018] As shown in Figure 1, between the upper roadway 7 and the lower roadway 8, the lower part is poured into a funnel-shaped concrete separation bin body 4, and the bottom of the concrete separation bin body 4 is poured with a separation bin coal discharge pipe 5, and the separation bin coal discharge pipe 5 The coal outlet is provided with a counterweight door; the upper part of the concrete separation chamber body 4 is poured with a separation chamber cover 3, and the top of the separation chamber cover 3 is respectively provided with a jet pipe joint 1 and a discharge pipe joint 2 connected with the discharge pipe; The concrete separation bin body 4 is formed by pouring concrete, and its inner diameter is greater than 2 meters. The separation bin cover 3 and the separation bin coal discharge pipe 5 respectively arranged on the top and bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com