High-performance spray gun for molten iron injection pretreatment

A pretreatment and high-performance technology, applied in the field of high-performance spray guns, can solve the problems of insufficient attention to the contribution of desulfurization efficiency and constraints on desulfurization technical and economic indicators, so as to improve the penetration ratio of bubbles, increase the hysteresis effect, and extend the floating stroke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

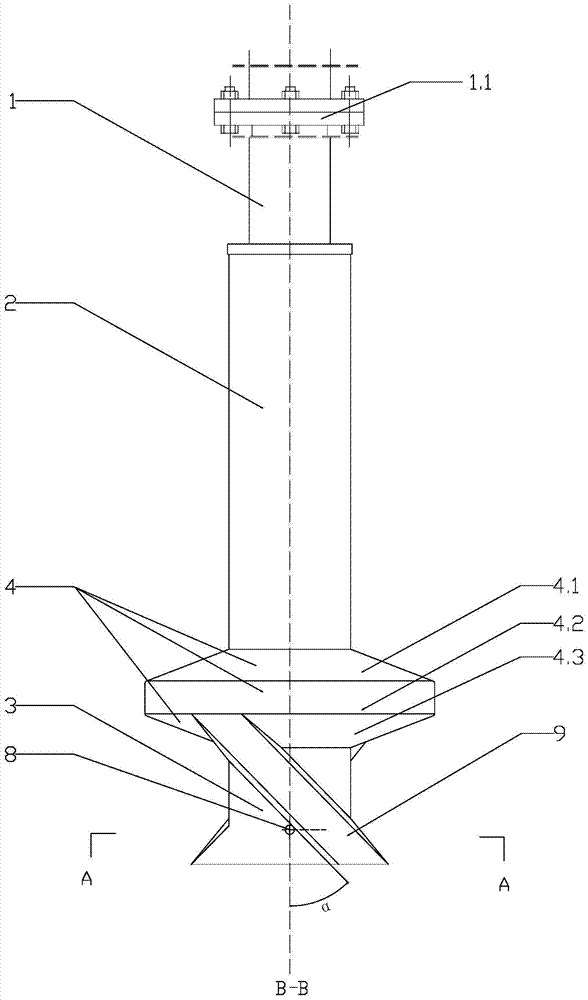

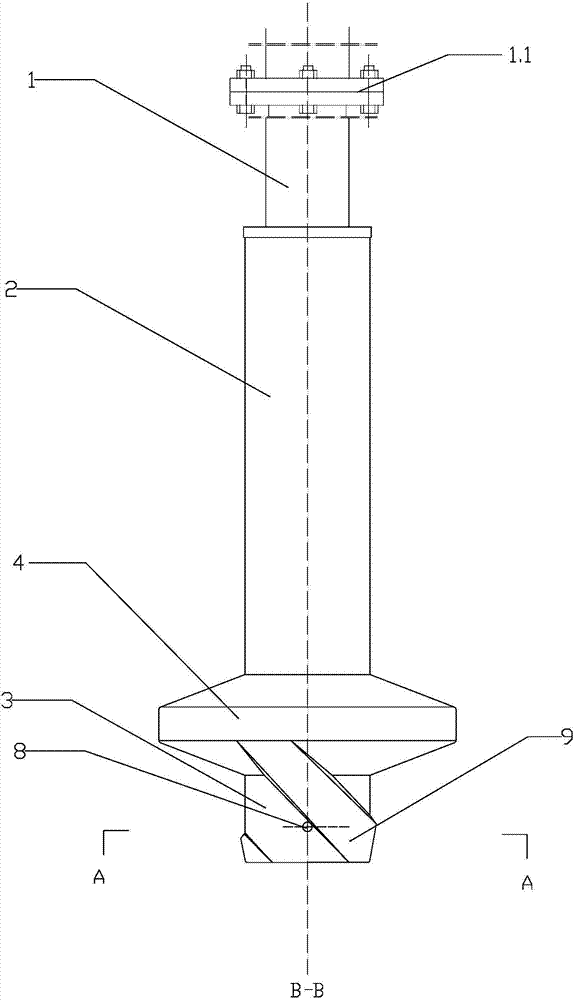

[0042] Such as figure 1 , 4 , 6 and 9, a high-performance spray gun used for molten iron injection pretreatment, including a connection section 1, a gun body section 2, and a spray section 3 connected in sequence, the connection section 1 includes a connecting flange 1.1, and the inside of the spray gun A spray gun main pipe 5 is provided, and the spray gun main pipe 5 is arranged between the connecting flange 1.1 and the bottom head 10 of the spray gun, and a swirl diffuser 4 is arranged between the gun body section 2 and the spray section 3, and the swirl diffuser 4 includes sequentially The upper circular platform body 4.1, the cylindrical body 4.2 and the lower rounded platform body 4.3 are connected, the upper round platform body 4.1 is connected with the gun body section 2, the lower inverted round platform body 4.3 is connected with the injection section 3, and the spray gun main pipe 5 and the head 10 are connected along the Two nozzles 8 are evenly opened in the circ...

Embodiment 2

[0048] Such as figure 1 , 4 , 6 and 10, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0049] The two nozzles 8 communicate with the main pipe 5 of the spray gun eccentrically, and the eccentric distance is e=XXXX~XXXX. 0≤e≤(D-d) / 2, wherein, D is the inner diameter of the main pipe 5 of the spray gun, and d is the inner diameter of the nozzle 8 .

Embodiment 3

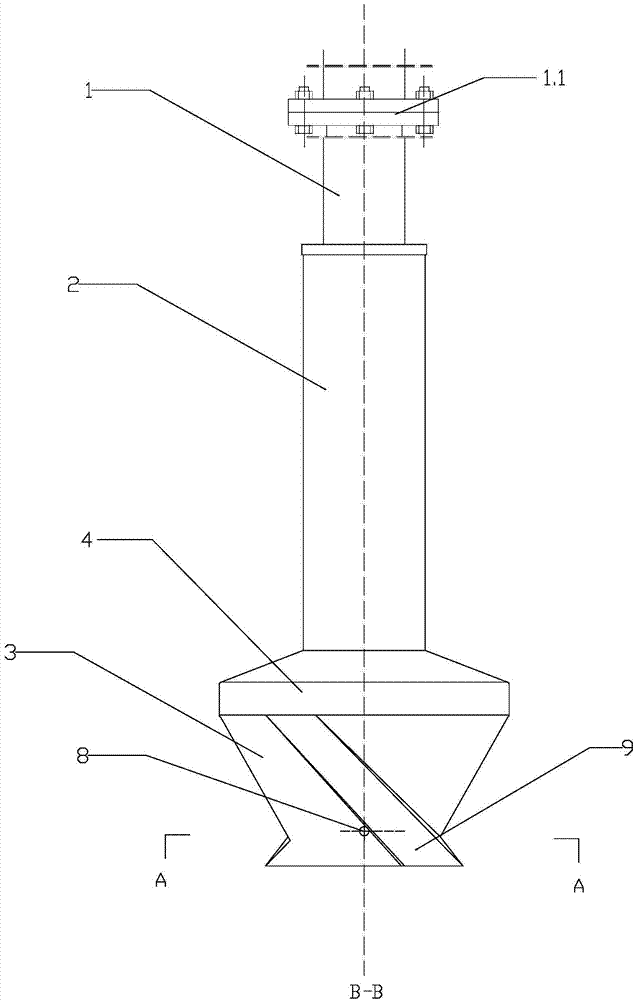

[0051] Such as figure 1 , 4 , 6, and 11, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0052] There are 3 nozzles 8, and the three nozzles 8 communicate with the center of the spray gun main pipe 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com