Patents

Literature

277results about How to "Mass transfer speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

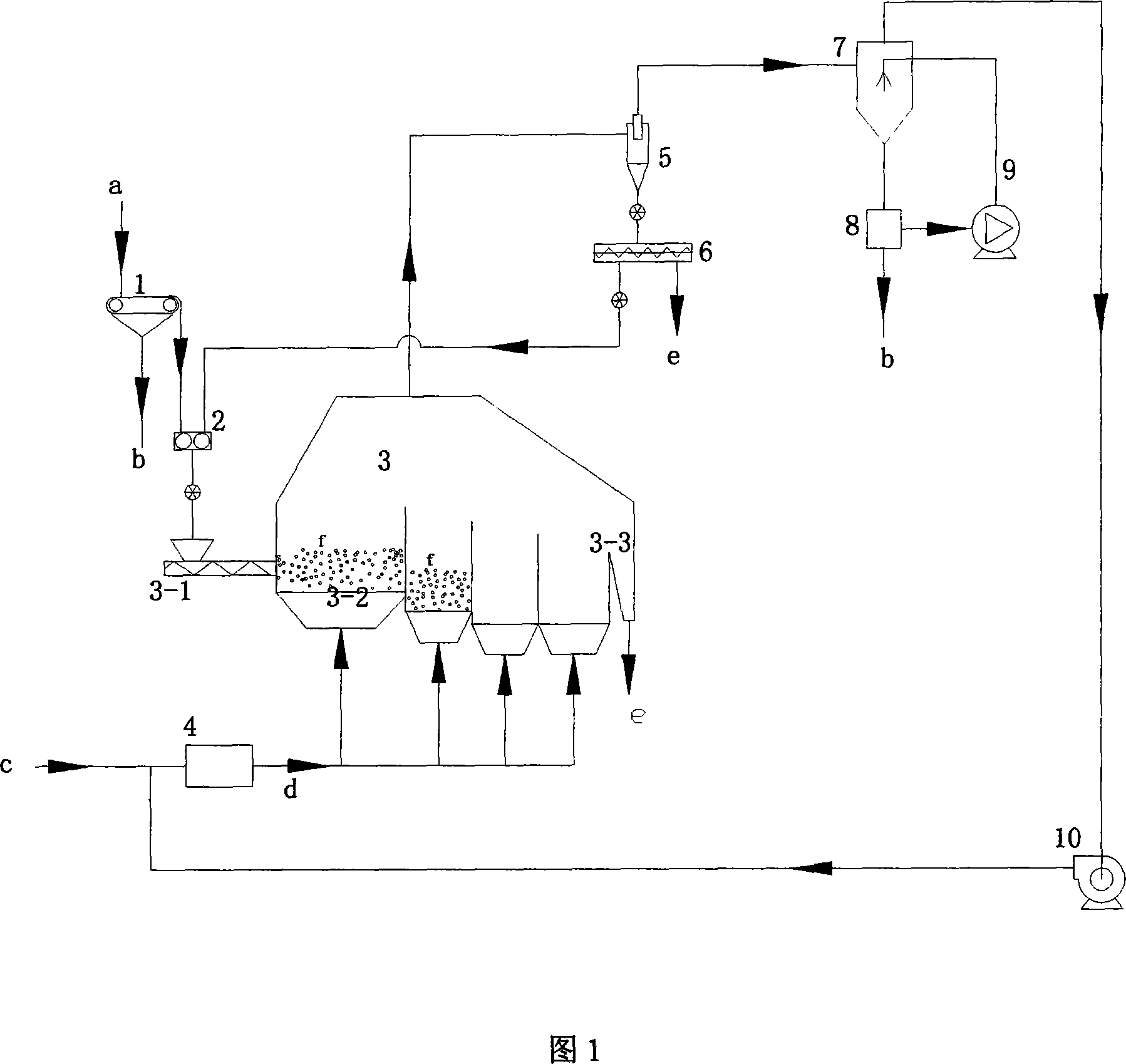

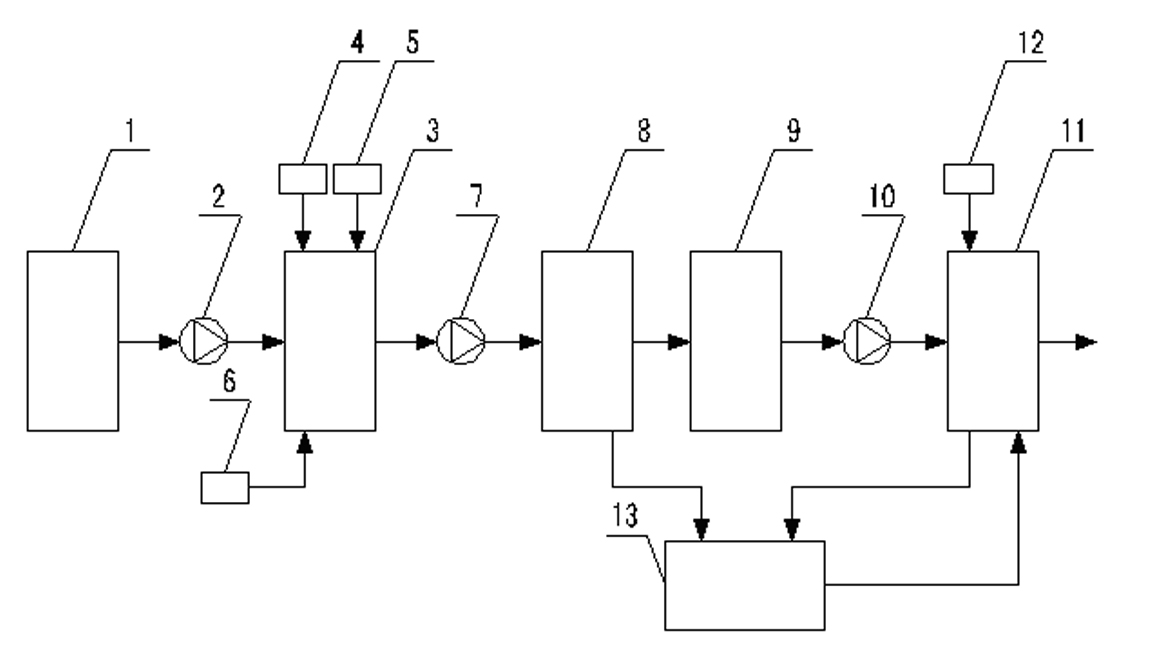

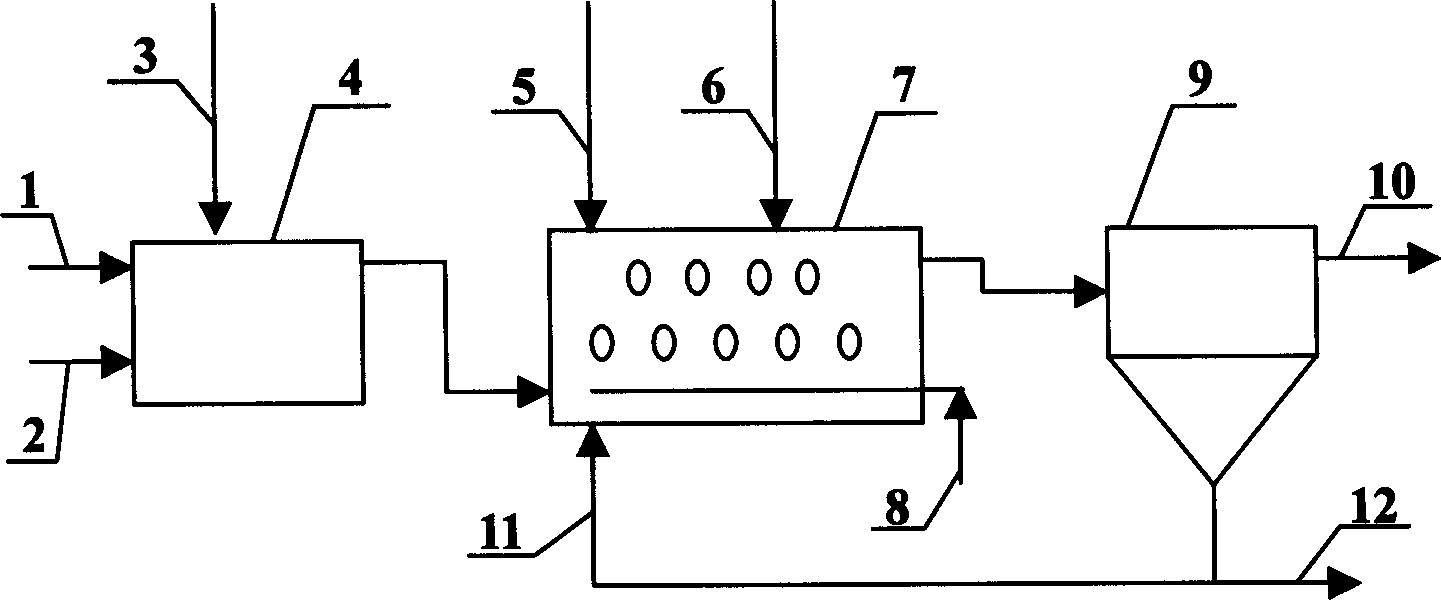

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

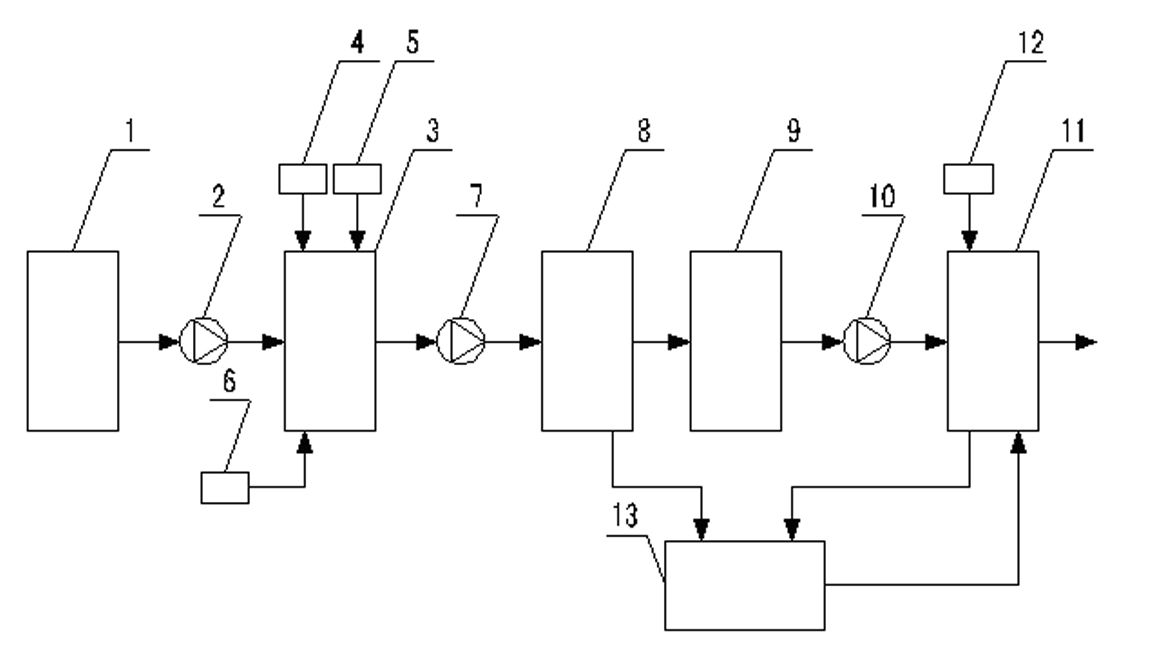

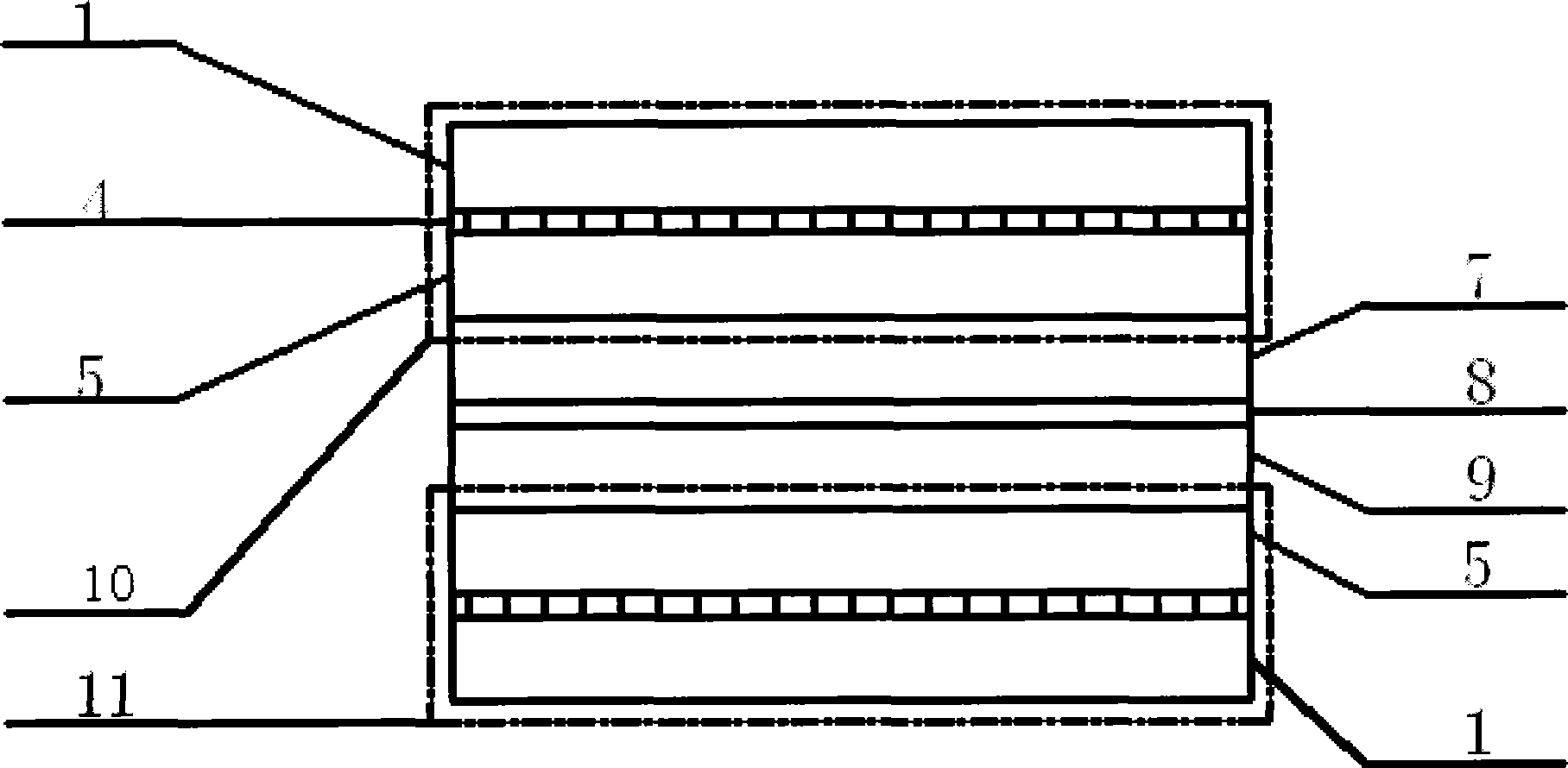

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

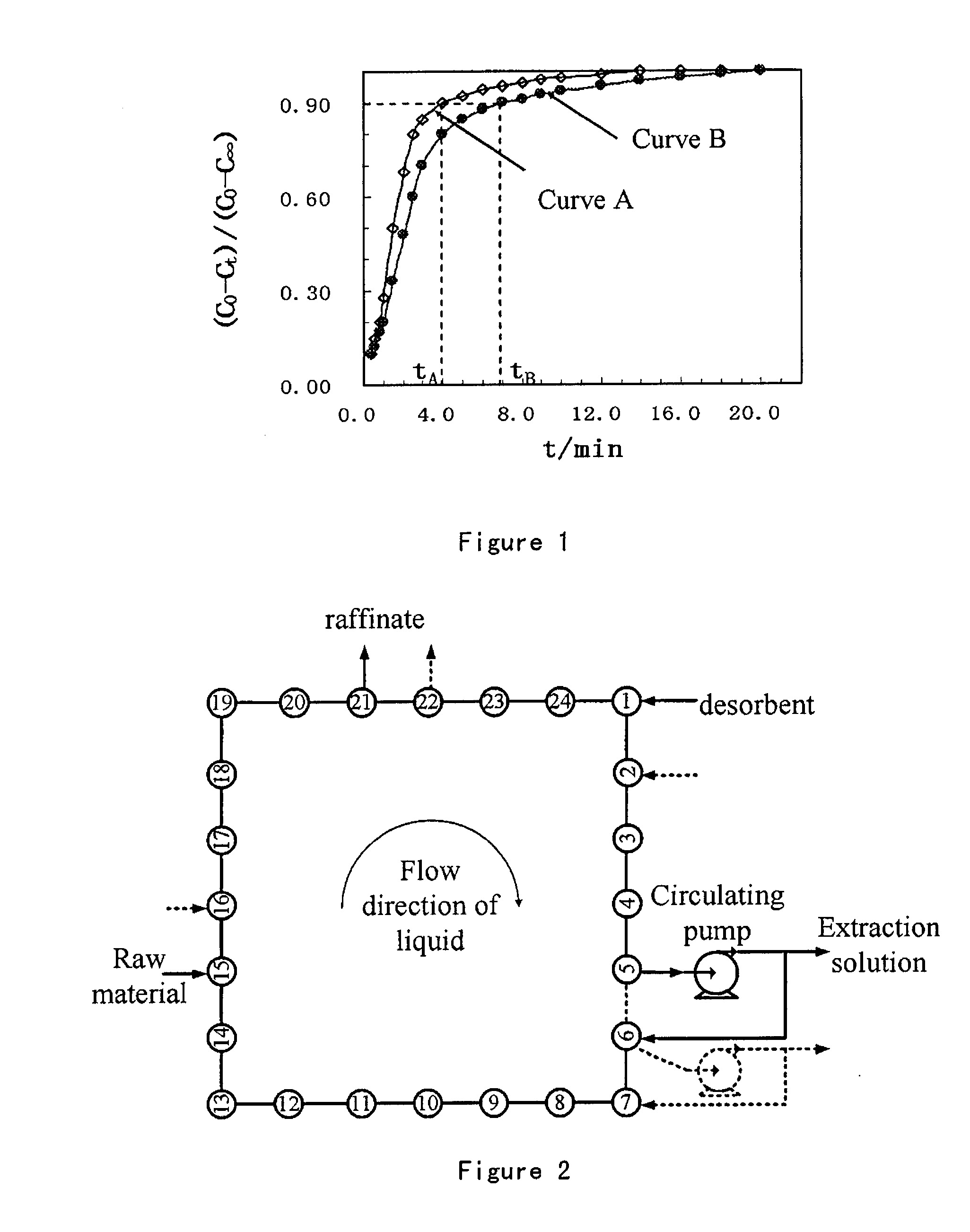

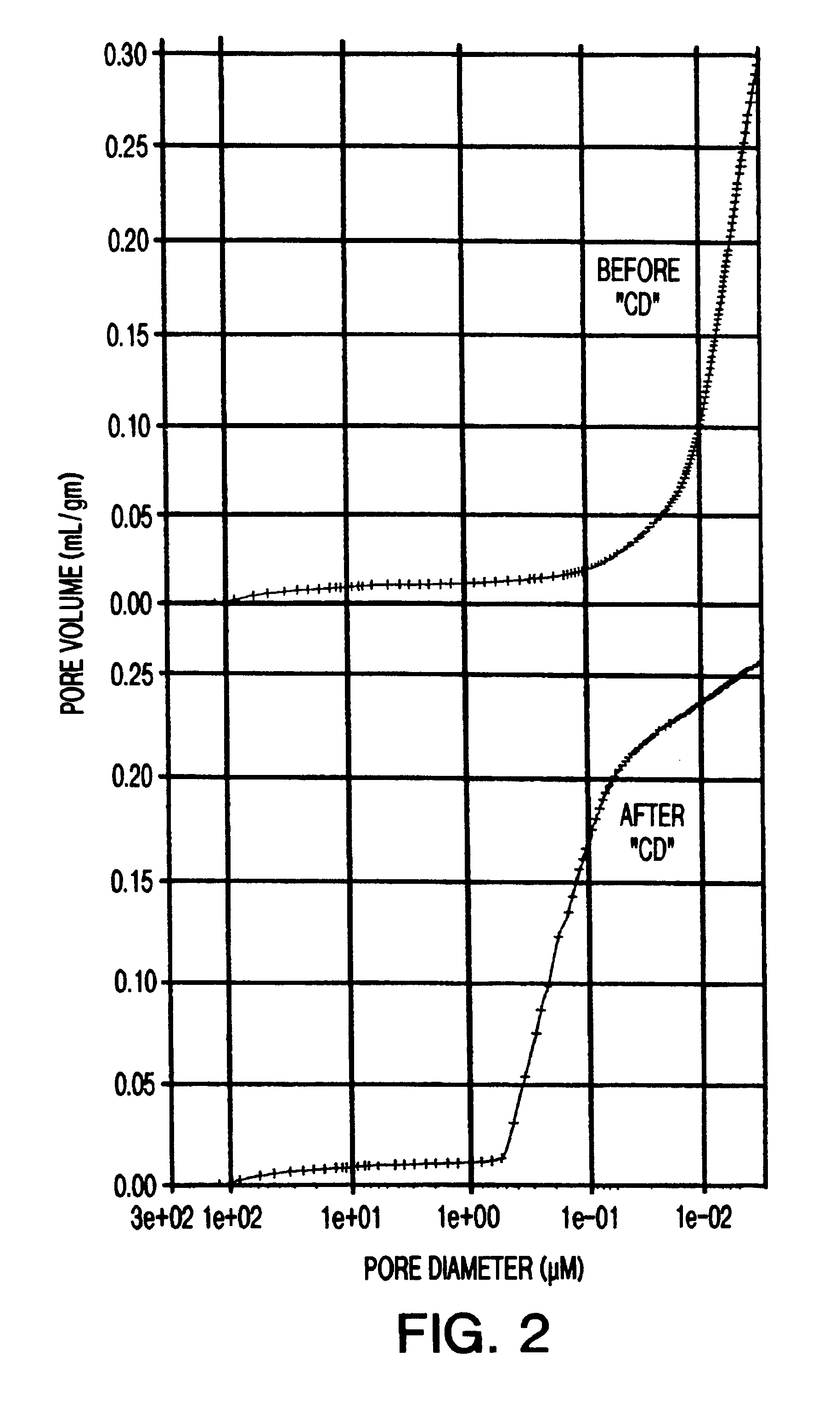

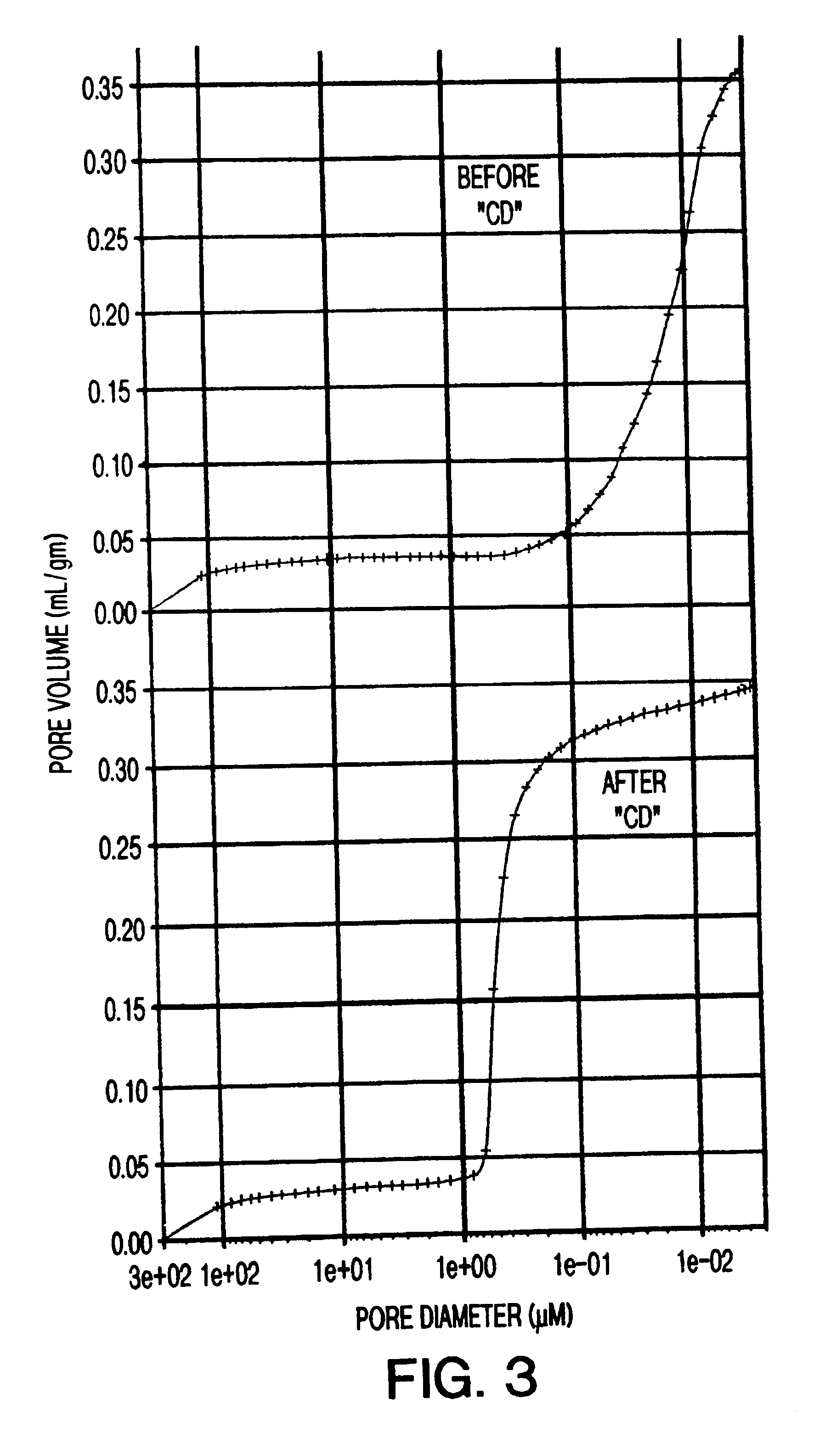

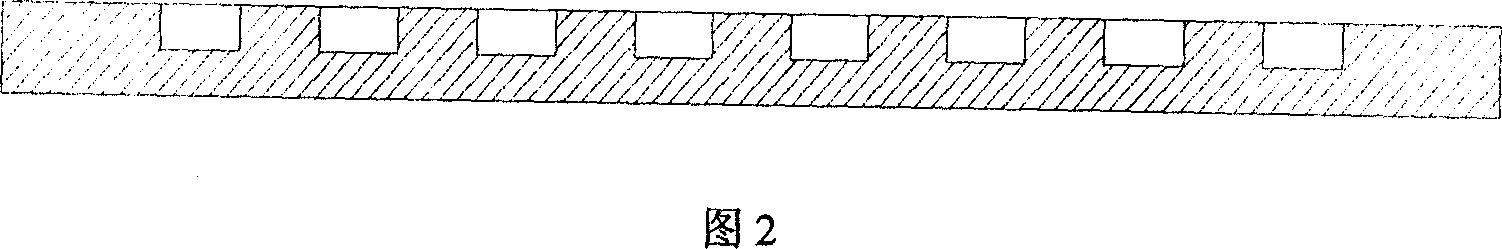

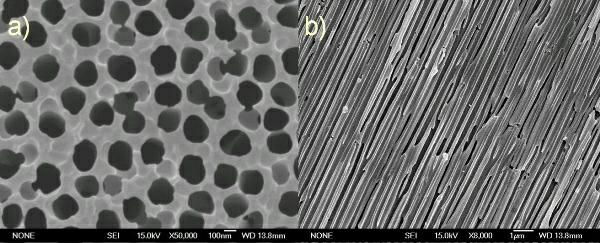

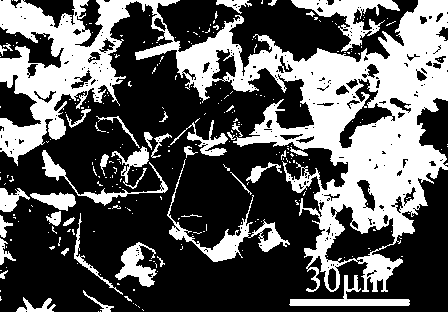

Agglomerated zeolite adsorbents and process for producing the same

ActiveUS20110105301A1Large hole volumeImprove mass transfer effectMolecular sieve catalystsOther chemical processesSorbentIon exchange

An agglomerated zeolite adsorbent which comprises 95-99.5 mass % of X zeolite and 0.5-5.0 mass % of binder, wherein the exchangeable cationic sites of said X zeolite are occupied by Group IIA metal and / or K, the total pore volume of said adsorbent is no less than 0.26 mL / g as measured by mercury porosimetry, the volume of pores with pore diameters from 100 to 500 nm is at least 60% based on the total pore volume. During shaping, a pore-forming agent is added to this adsorbent, and then the adsorbent is alkali treated for in-situ crystallization, followed by ion exchange. Said adsorbent has high adsorption capacity, fast mass transfer rate and good mechanical strength. Said adsorbent is suitable for liquid phase adsorptive separation of para-xylene from C8 aromatic hydrocarbons and is also suitable for adsorptive separation of other alkyl aromatic hydrocarbons isomers.

Owner:CHINA PETROCHEMICAL CORP +1

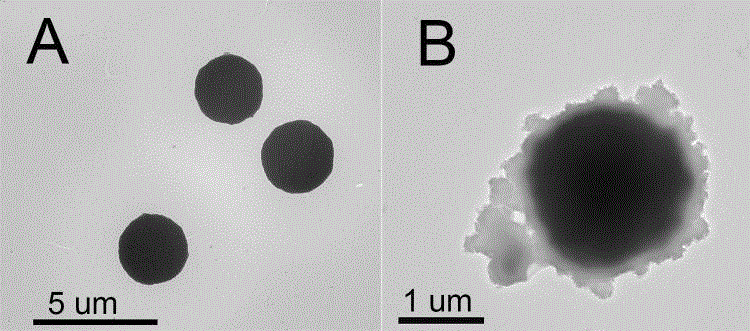

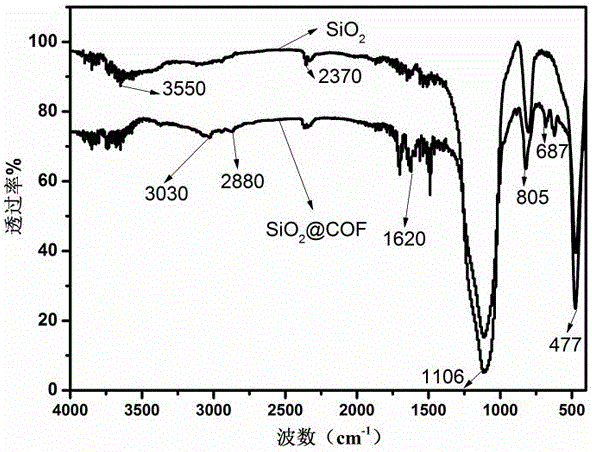

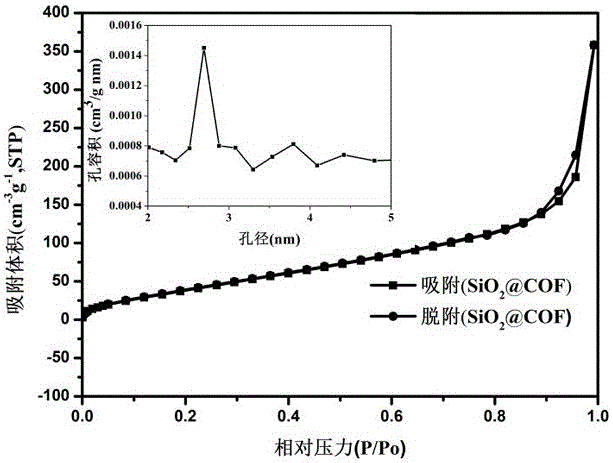

Preparation method of covalent organic framework composite microspheres with core-shell structures

InactiveCN107175053AMild preparation conditionsRaw materials are cheap and easy to getOther chemical processesDispersed particle separationMicrosphereSolid phase extraction

The invention relates to a preparation method of covalent organic framework composite microspheres with core-shell structures. The method comprises the following steps: dissolving silicon dioxide microspheres, a first construction element and a second construction element in an organic solvent; and after adding a catalyst, rapidly synthesizing into the composite microspheres with core-shell structures at a certain temperature. In a preparation process, reaction conditions are gentle, the method is simple, and the yield is high; the prepared covalent organic framework composite microspheres have the advantages of good core-shell morphology, high specific surface area, ordered pore structures, good mechanical stability, thermal stability, chemical stability and the like, if the microspheres are used as a chromatographic stationary phase, the chromatographic mass transfer resistance can be reduced effectively, the theoretical plate height is improved, and finally, column efficiency and degree of separation are improved; and if the microspheres are used as solid-phase extracting filler, the enrichment effect can be improved remarkably. The covalent organic framework composite microspheres with core-shell structures have good application prospects in the aspect of separation and enrichment of small organic molecules.

Owner:FUZHOU UNIV

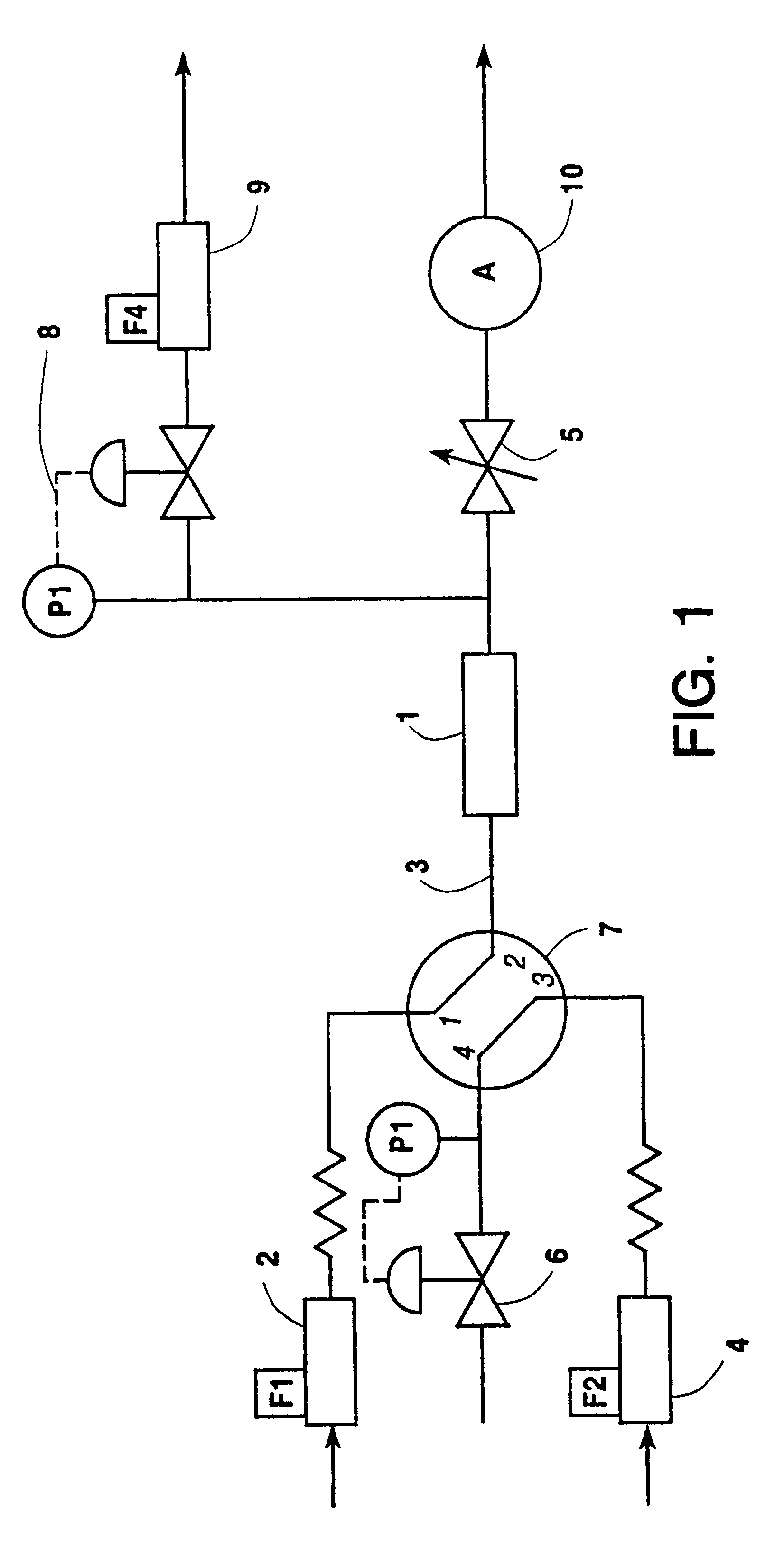

Advanced adsorbent for PSA

InactiveUS6425940B1Increase mass transfer rateMass transfer speedGas treatmentMolecular sieve catalystsSorbentOrganic chemistry

The invention relates to adsorbent materials having comparatively high intrinsic adsorption rates. Methods are disclosed whereby such rates can be achieved. In preferred embodiments, the adsorbent is a LiX zeolite material.

Owner:PRAXAIR TECH INC

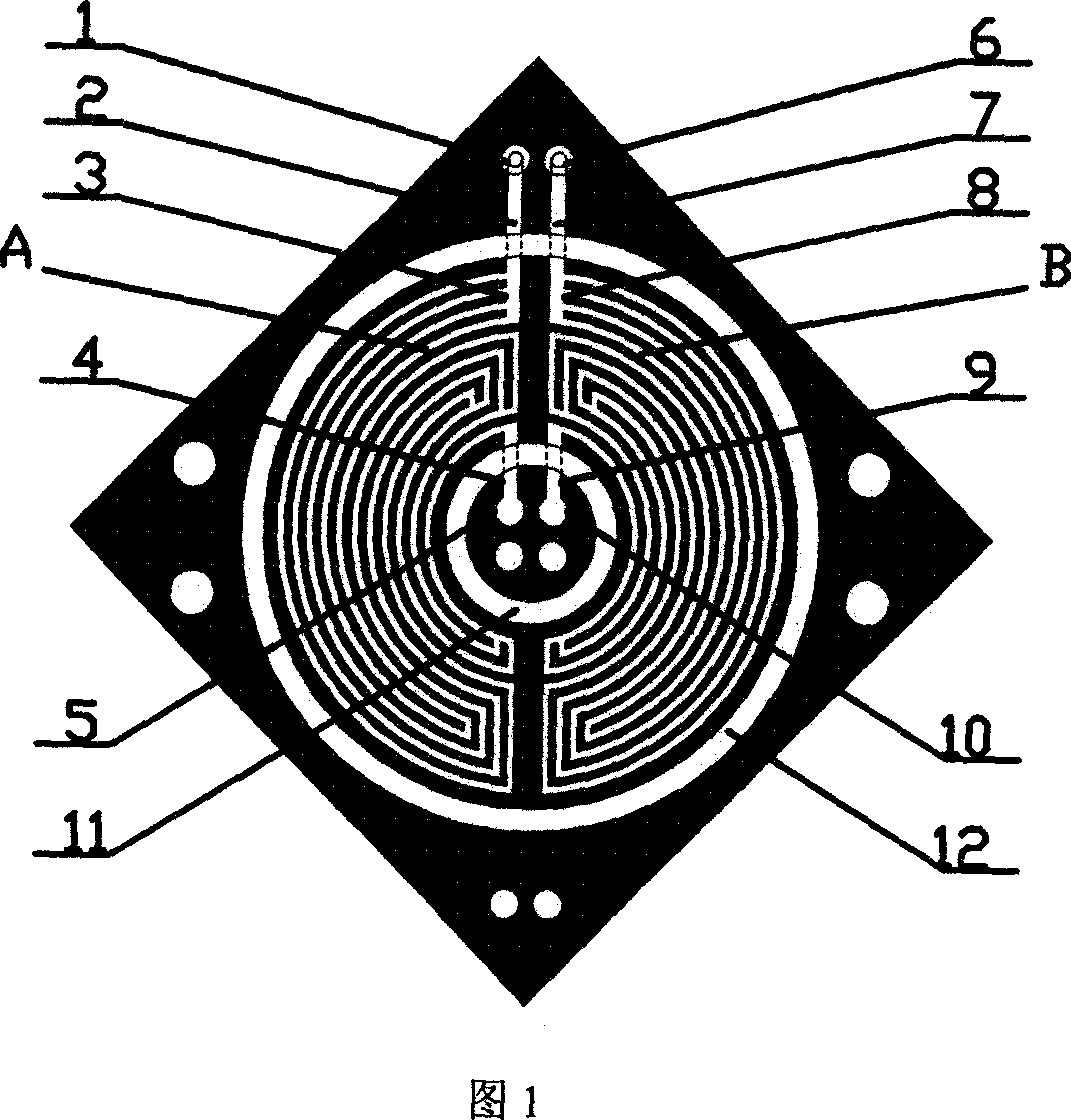

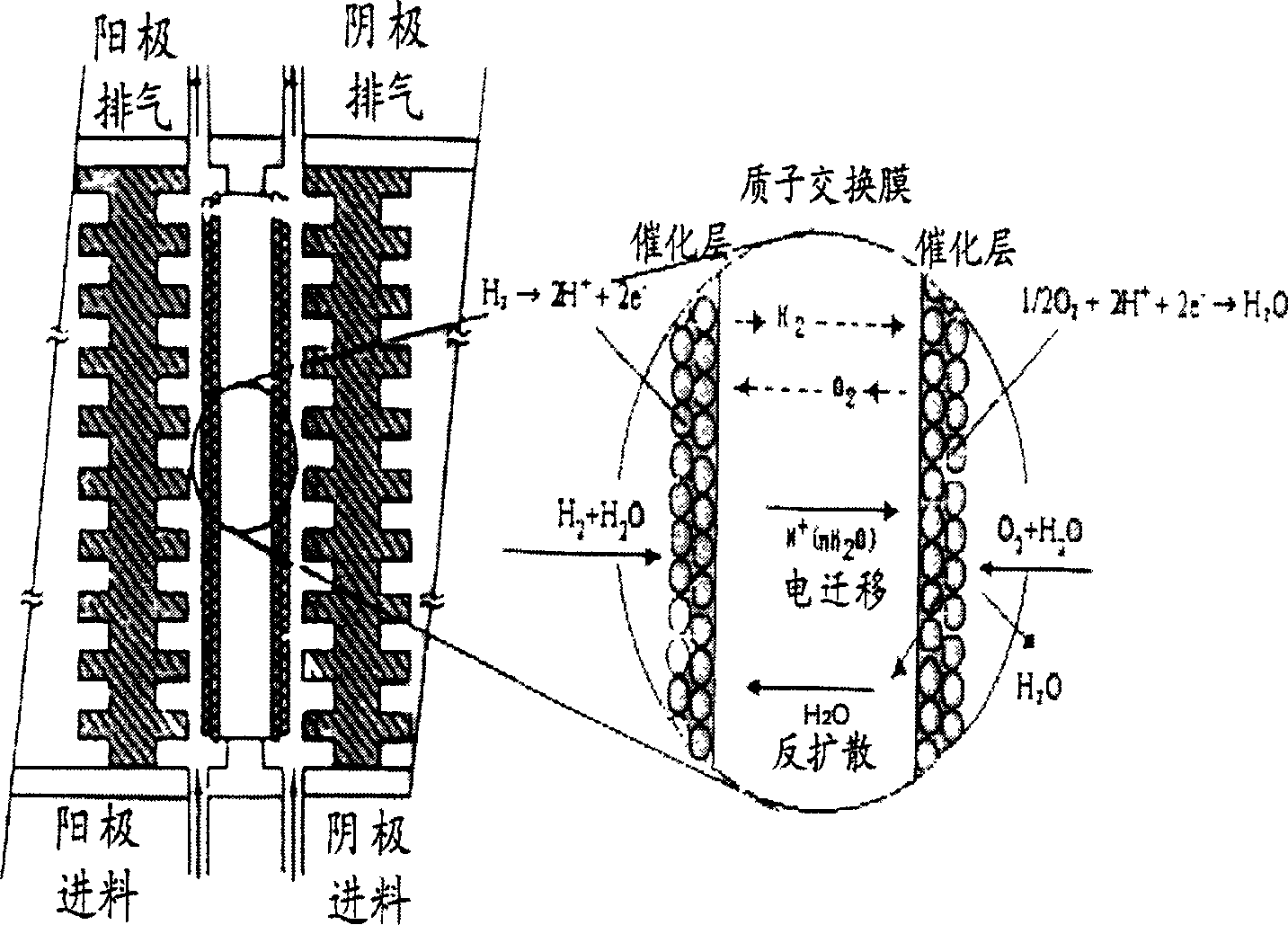

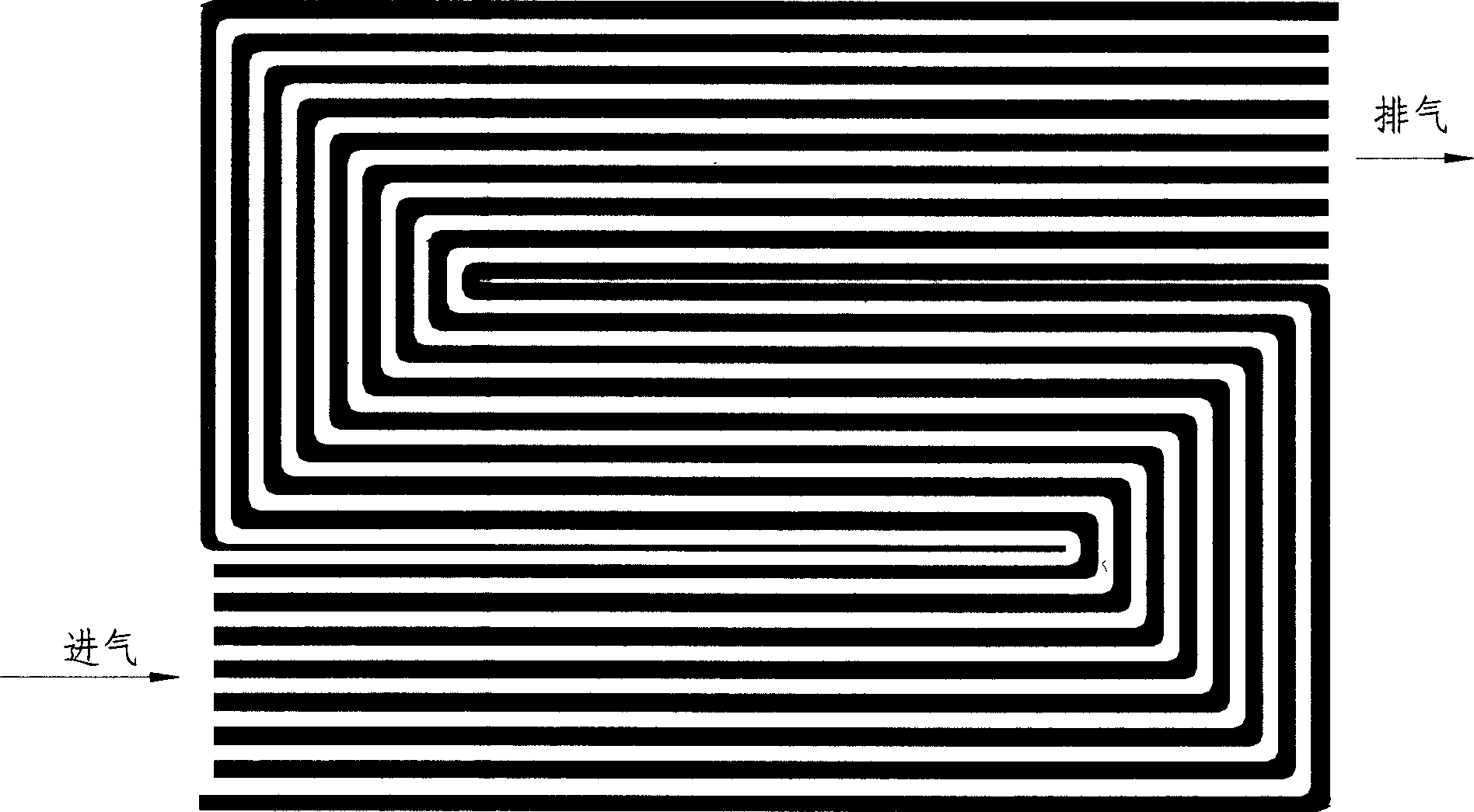

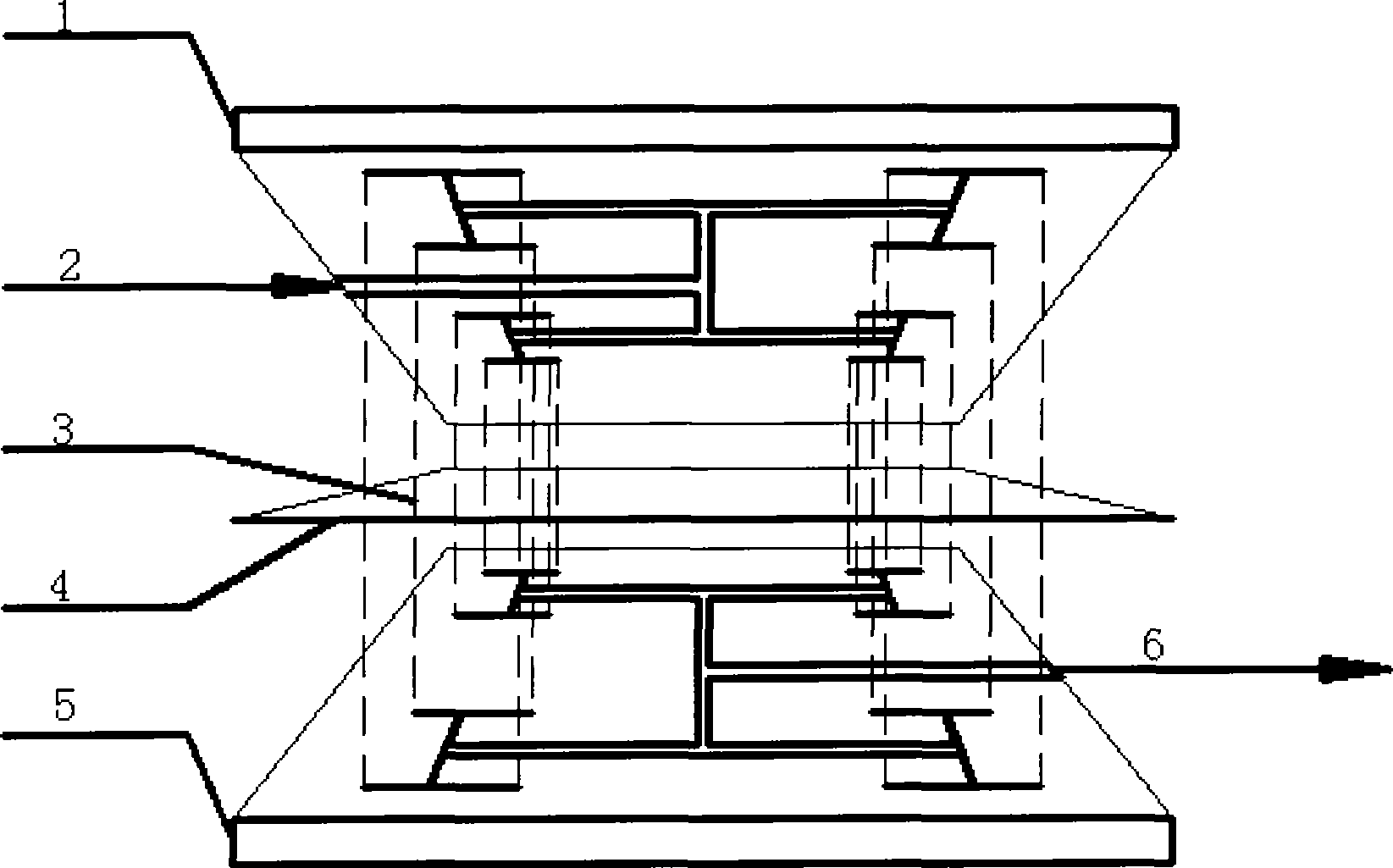

Mixed gradual conversion field of proton exchange membrane fuel cell

InactiveCN101047252AImprove unevennessEvenly distributedCell electrodesCollectors/separatorsMixed flowProton

A mixed and gradually varied flow field of proton exchange film fuel cell consists of slots at reaction region of mixed flow field, flow guiding slots at inlet and outlet, sealing slots and distribution slots for connecting flow guiding slots to slots at reaction region of mixed flow field. It is featured as setting slots at reaction region of mixed flow field to be multilayer grade slots in arc form and setting center of circle at sealing slots to be with the same central point as center of circle on slots at reaction region of mixed flow field.

Owner:UNIV OF SCI & TECH BEIJING

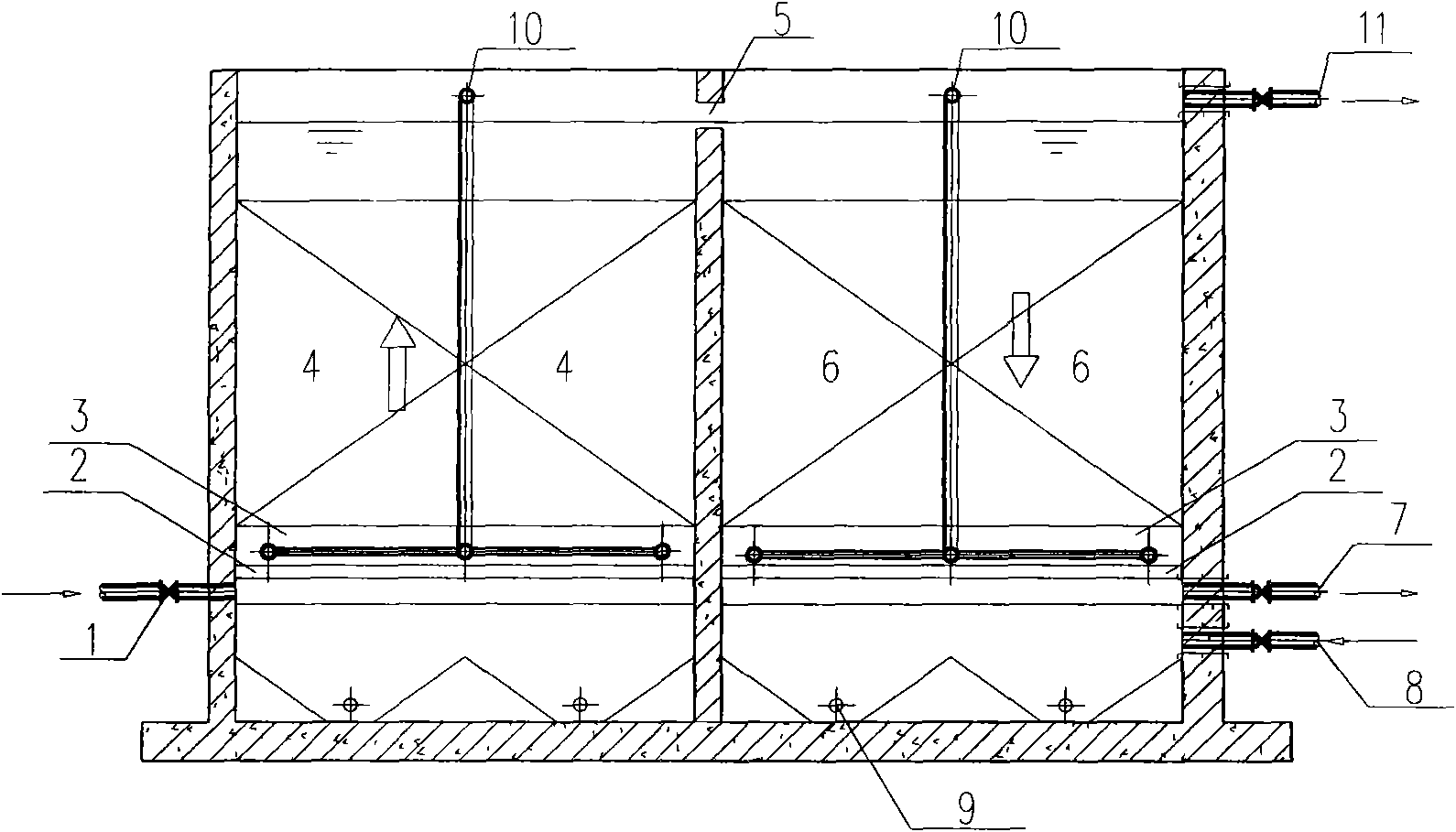

Biological aerated filter and process

ActiveCN101643269AAvoid easy cloggingMass transfer speedTreatment with aerobic and anaerobic processesSustainable biological treatmentScience and engineeringSewage treatment

The invention belongs to the technical field of environmental protection science and engineering, and in particular relates to a biological aerated filter for sewage treatment and a process. The biological aerated filter adopts a mode of two-stage series connection; a filter plate is arranged in the biological aerated filter; support layers are arranged on the filter plate; a first stage positioned above the support layers is provided with fillings; a second stage positioned above the support layers is provided with the fillings; an air pipe is arranged between the filter plate and the supportlayers; the upper part between the two stages of the biological aerated filter is provided with a water pore; the bottoms of the two stages of the biological aerated filter are provided with perforation spoil disposal pipes; a water inlet pipe is arranged at the lower part of the filter plate through the first-stage biological aerated filter; a back flush water inlet pipe and an outlet pipe are arranged at the lower part of the filter plate through the second-stage biological aerated filter, and a back flush outlet pipe is arranged at the upper part of the filter plate. The biological aeratedfilter has the process technology for sewage treatment with less land occupation, investment saving, low operating cost, high efficiency and convenient operation and management, and can be widely applied to the sewage treatment.

Owner:CISDI ENG CO LTD

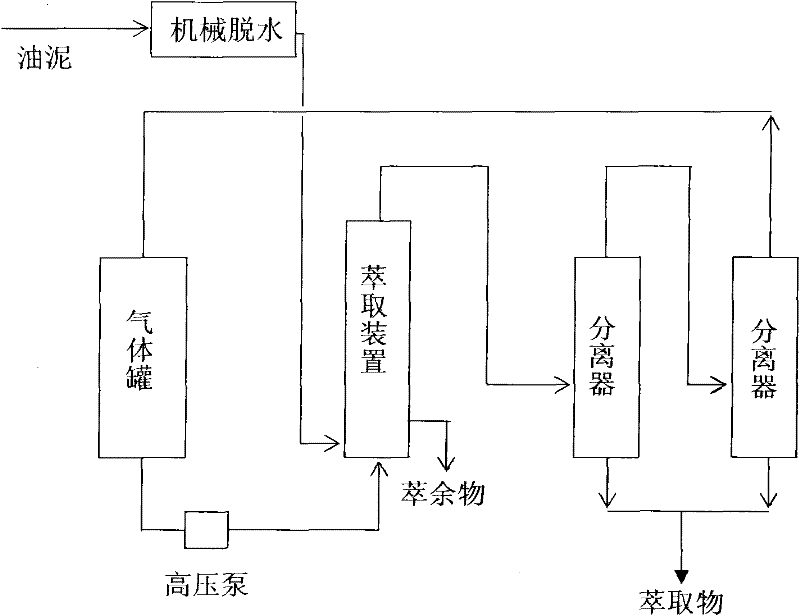

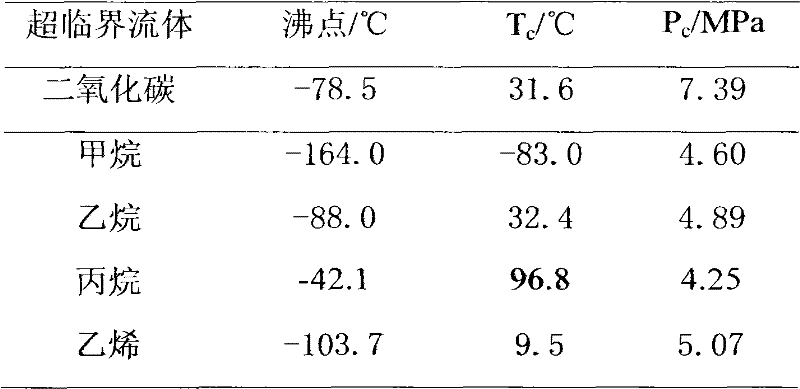

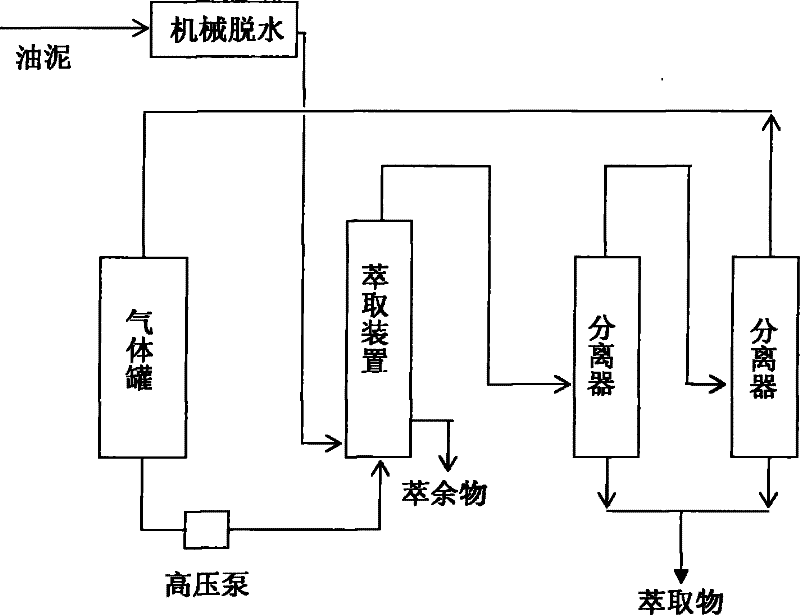

Method of ultrasound-enhanced supercritical extraction of oil sludge

ActiveCN102453494ARelieve pressureReduce the temperatureSludge treatmentTreatment with plural serial refining stagesUltrasound deviceOil sludge

The invention discloses a method of ultrasound-enhanced supercritical extraction of oil sludge. Oil sludge and extractants are added into a supercritical extraction device with an enhanced ultrasound device, and the supercritical extraction pressure and the supercritical extraction temperature are set for supercritical extraction. Compared with the prior art, the technology of the ultrasound-enhanced supercritical extraction is adopted in the method, so the extraction pressure and temperature are reduced, the extraction time is shortened, and finally the extraction efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

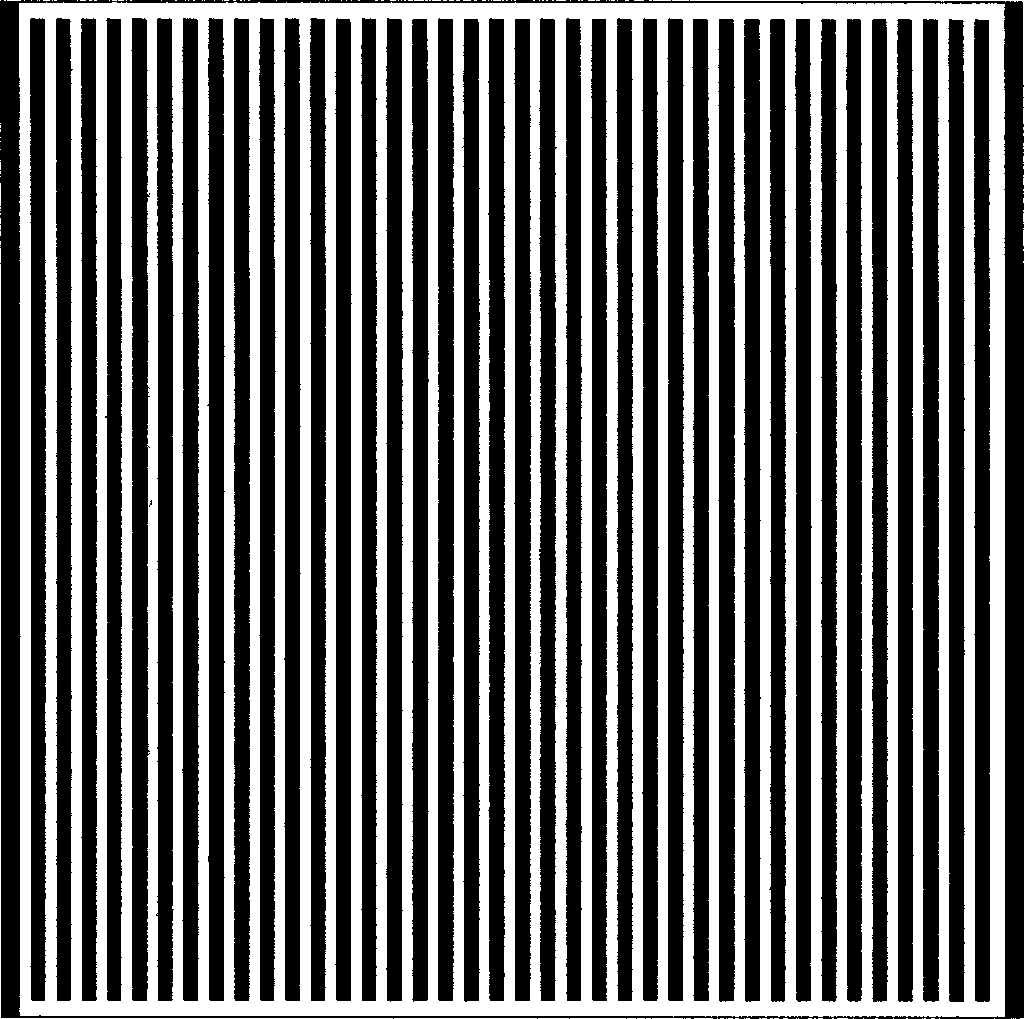

Proton exchange film fuel cell flow field structure

ActiveCN1622377AEasy to excludePromote accumulationCell electrodesSolid electrolyte fuel cellsProtonEngineering

The present invention relates to proton exchange membrane fuel cell. The flow field structure of proton exchange membrane fuel cell consists of netted flow field and deflecting stripes. The deflecting stripes are set inside the netted flow field and parallel to one group of sealing side walls, and have width equal to the height of the netted flow field. Each of the deflecting stripes has one end connected perpendicularly to the side wall and the other end constituting the gas channel. The gas channel has width not smaller than that of the gas inlet. The present invention has the advantages of high pole area utilization, being favorable to the exhaust of water produced in the electrochemical reaction and the elimination of inertial component, no dead arean of gas flow, and stable operation of the cell under low pressure and normal pressure.

Owner:SUNRISE POWER CO LTD

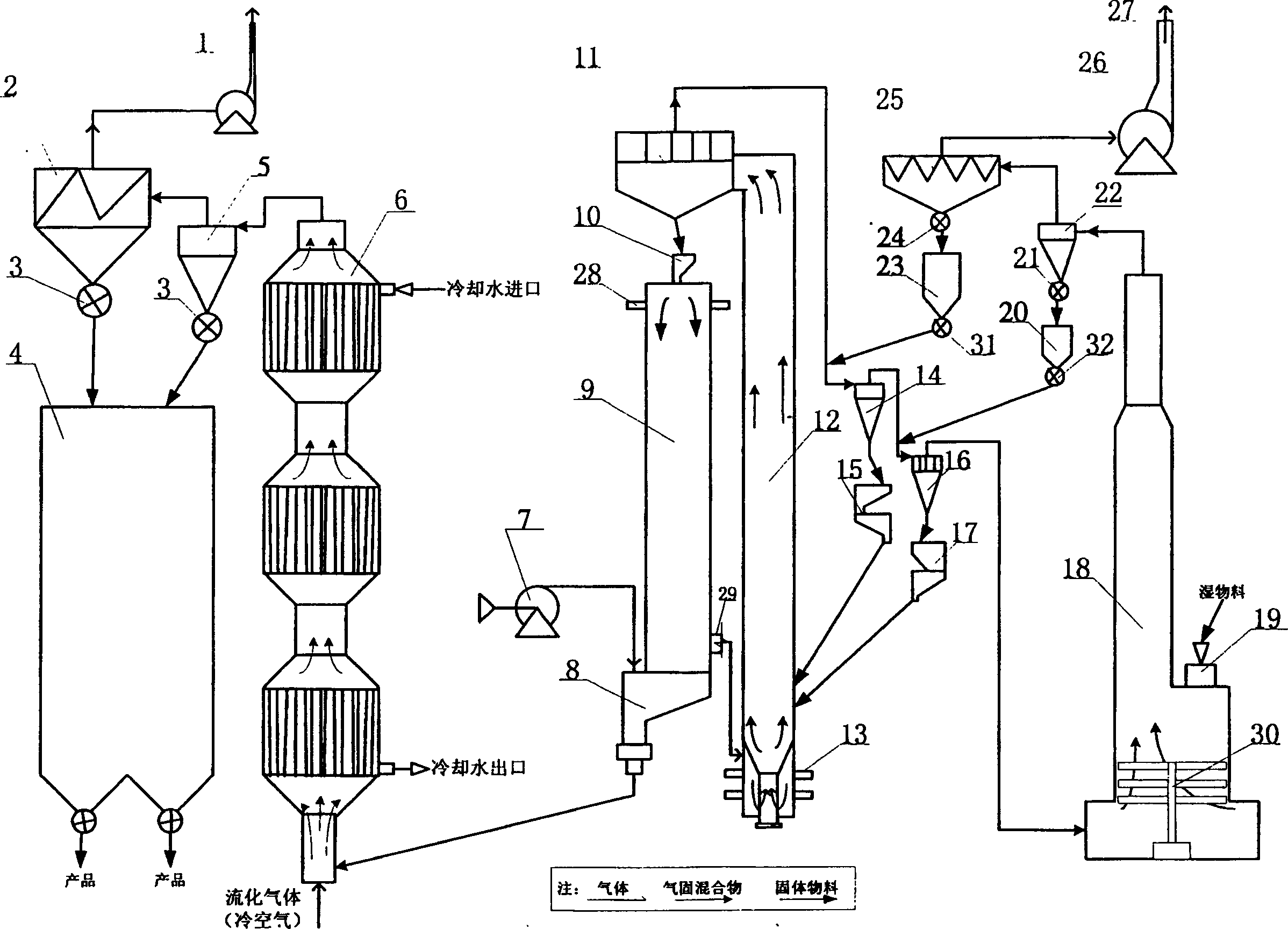

Fast fluidized calcining process

InactiveCN1632436AThe calcination reaction time is uniform and adjustableFast heat transfer rateFluidized bed combustionFluidised-bed furnacesMoving bedHigh-temperature corrosion

The invention is a new type of rapid fluidized calcination process, which effectively improves the conversion rate of the rapid fluidized calcination reaction of materials. It uses high-temperature flue gas to form gas-solid rapid fluidized mixing and heating of the material. Utilizing the characteristics of rapid fluidization, the material is quickly heated and mass transferred, and then the high-temperature material enters the moving bed calcination reactor through the high-temperature gas-solid separator; using the mobile The push flow of the material in the bed makes the calcination reaction time of the material uniform, the calcination reaction is sufficient, and the conversion rate is high; at the same time, the hot gas separated by the high-temperature gas-solid separator passes through the preheater to preheat the material and then enters rapid fluidization drying The wet material is dried in a dryer; the sensible heat of the calcined high-temperature material is recovered using a rapid fluidized cooler, and the material is cooled at the same time. The calcination process of the present invention has the characteristics of low energy consumption, large production capacity and easy amplification. The calcination temperature of the material can be adjusted from 500°C to 1300°C, and the calcination reaction time can be adjusted from a few minutes to a few hours.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

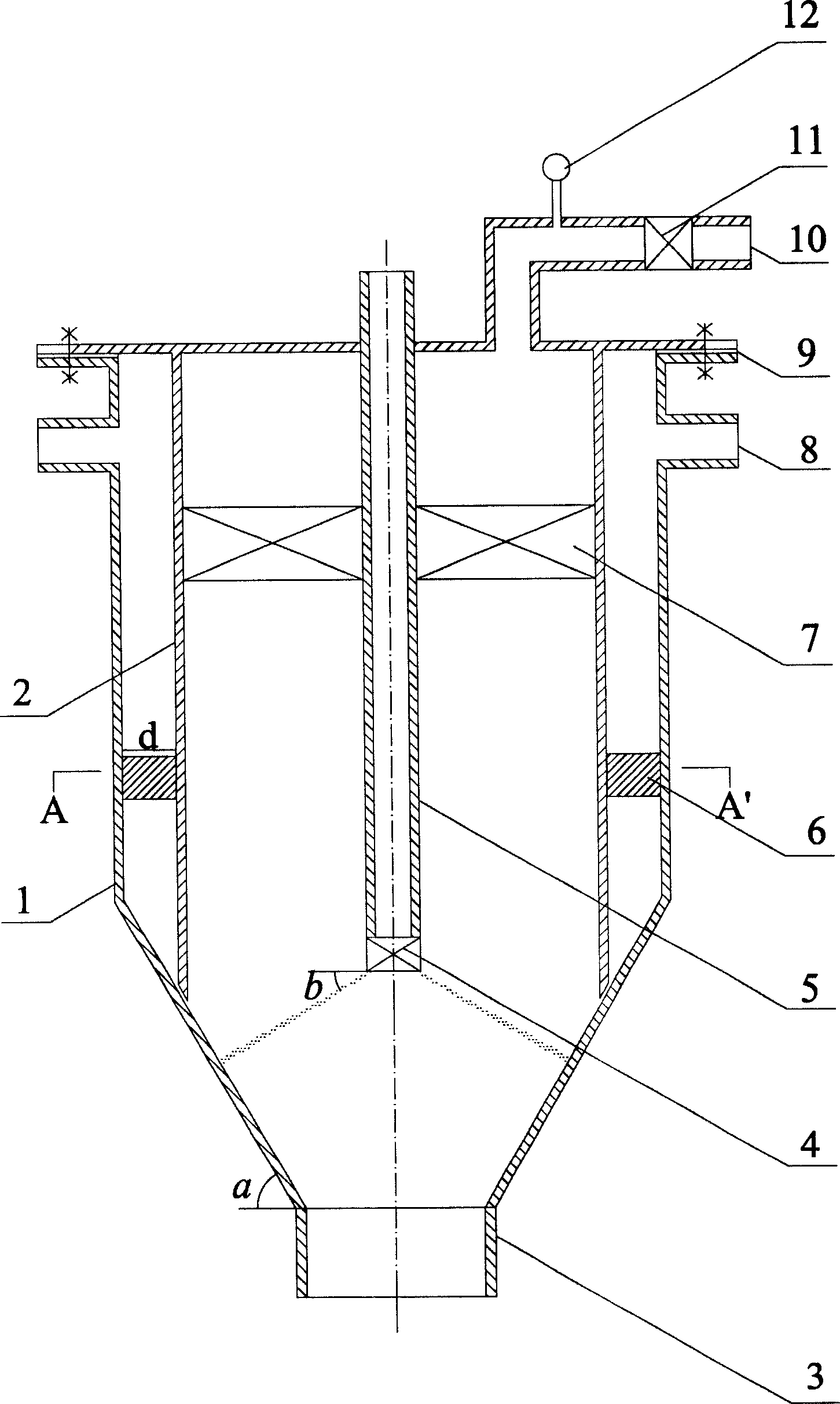

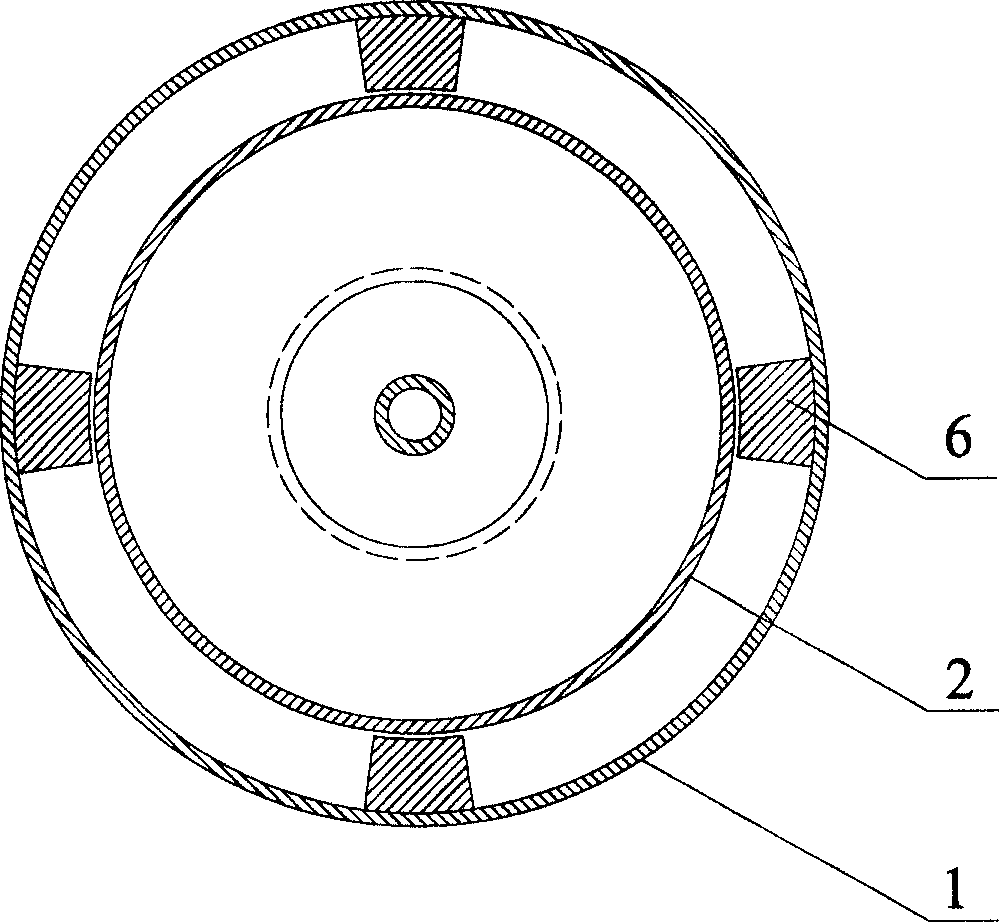

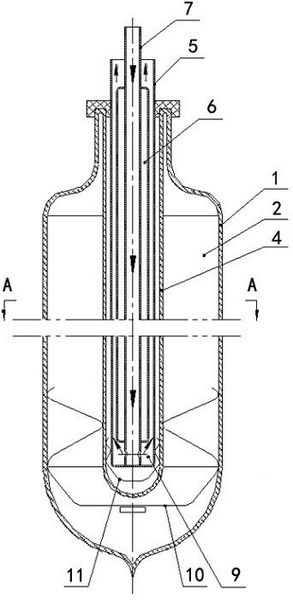

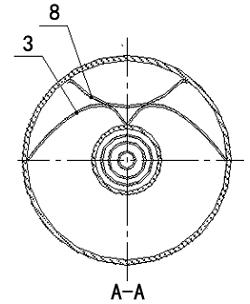

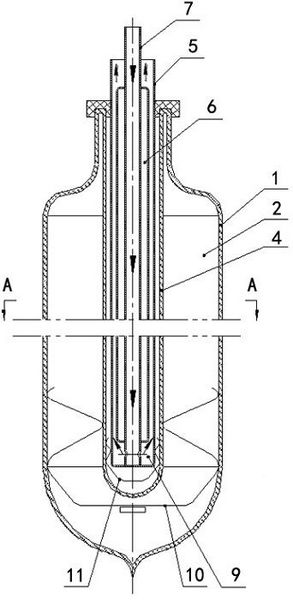

Liquid-liquid fast-mixing reactor

InactiveCN1669631AGuaranteed to proceed normallyEfficient mixingChemical/physical/physico-chemical nozzle-type rreactorsLiquid-liquid reaction processesCycloneSpray nozzle

The invention relates to a liquid-liquid fast-mixing reactor, which comprises a housing, an inner casing, a liquid conducting tube, an injector, a demister, a backing sheet, a pad, an adjusting valve, a manometer, wherein the housing (1) has a liquid feed inlet (8), the necked-in parts, and a liquid outlet (3); the inner casing (2) has the liquid conducting tube (5), the injector (4), the air outlet (10), the adjusting valve (11) and the manometer (12) inside. The space between the inwall of the housing (1) and the inner casing (2) forms a channel cyclone or non-cyclone through which a fold of liquid inlets, and another liquid passes the liquid conducting tube and the injector and forms the droplet distributed circlewise, the droplet connects with the film formed when the first fold of liquid passing the chine, and the two folds of liquid mix in the meeting point rapidly, then the product will be discharged from the liquid outlet (3).

Owner:TSINGHUA UNIV

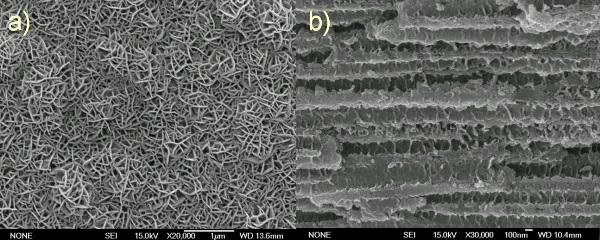

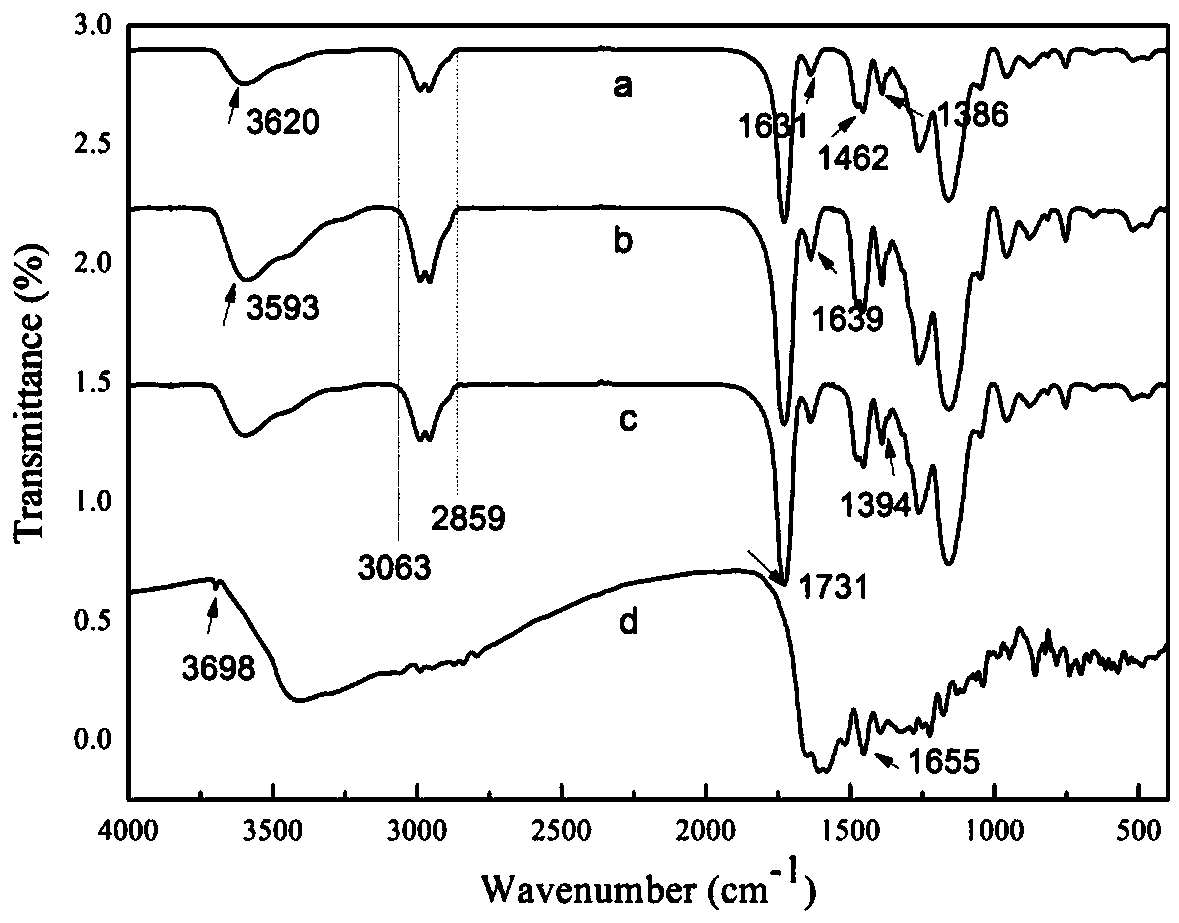

Preparation method of self-supporting molecularly imprinted polymer film

ActiveCN102432778ASolve the larger particlesSolve for uniformityOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceCyanoacetic acid

The invention relates to a preparation method of a self-supporting molecularly imprinted polymer film. The preparation method comprises the following steps of: firstly, reacting divalent metal ions with a porous alumina film to obtain a porous alumina-based layered double hydroxide; secondly, carrying out further reaction to obtain an SBC (Sulpho-Benzoyl Cyanoacetic Acid) intercalated porous alumina-based layered double hydroxide; and finally, mixing the SBC intercalated porous alumina-based layered double hydroxide with a polymerizable monomer, a polymerized cross-linking agent, a molecularly imprinted template agent and an organic solvent, dispersing by using ultrasound wave, adding a free base polymerization initiator for polymerizing, washing a product obtained by reacting and then drying to obtain the self-supporting molecularly imprinted polymer film. According to the self-supporting molecularly imprinted polymer film disclosed by the invention, the advantages of high strength, corrosion resistance, high temperature resistance and great specific area of an inorganic material as well as high load information quantity and adjustable performance of an organic polymer material can be fully exerted; the active free base polymerization is assisted in controlling; and the controllable synthesis of an ultrathin nano self-supporting structure of a molecularly imprinted material can be realized by using the controllability of the growth process of an active chain.

Owner:SHANGHAI UNIV

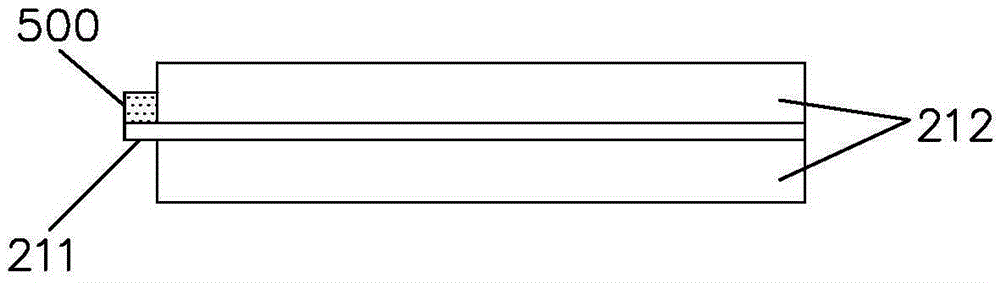

Medium and high temperature heat collecting tube for internal concentrated light and volume reduction solar energy and its manufacturing method

ActiveCN102278832AImprove heat collection efficiencyIncrease luminous energy densitySolar heat devicesSolar thermal energy generationVolume reductionSolar thermal collector

The invention relates to an internal-condensation capacity-reducing solar medium and high temperature heat collection pipe and a method for manufacturing the same. The heat collection pipe comprises a vacuum internal-condensation solar heat collector, wherein the vacuum internal-condensation solar heat collector consists of an outer cover tube which is made of a light-transmitting material, a heat absorption tube which is coaxial with the outer cover tube and a composite parabolic reflecting plate which is assembled between the outer cover tube and the heat absorption tube; a heat energy conductor is arranged in the vacuum internal-condensation solar heat collector; the heat energy conductor consists of a metal sleeve, a metal flow guide cavity tube which is assembled in the metal sleeve, and heat conduction media which are filled in the metal sleeve and the metal flow guide cavity tube; the metal sleeve is inserted into an internal cavity of the heat absorption tube and tightly contacted with the heat absorption tube; and a heat conduction heat medium transmission path is formed between the metal flow guide cavity tube and the metal sleeve. The preparation steps of the high temperature heat collection pipe are as following: manufacturing focus solar collector in vacuum, processing heat sensor, and then assembling and moulding. The internal-condensation capacity-reducing solar medium and high temperature heat collection pipe is high in heat collection efficiency, high in heat transfer speed and safe, and can convert solar energy into a medium and high temperature heat source for use.

Owner:河北光源太阳能有限公司

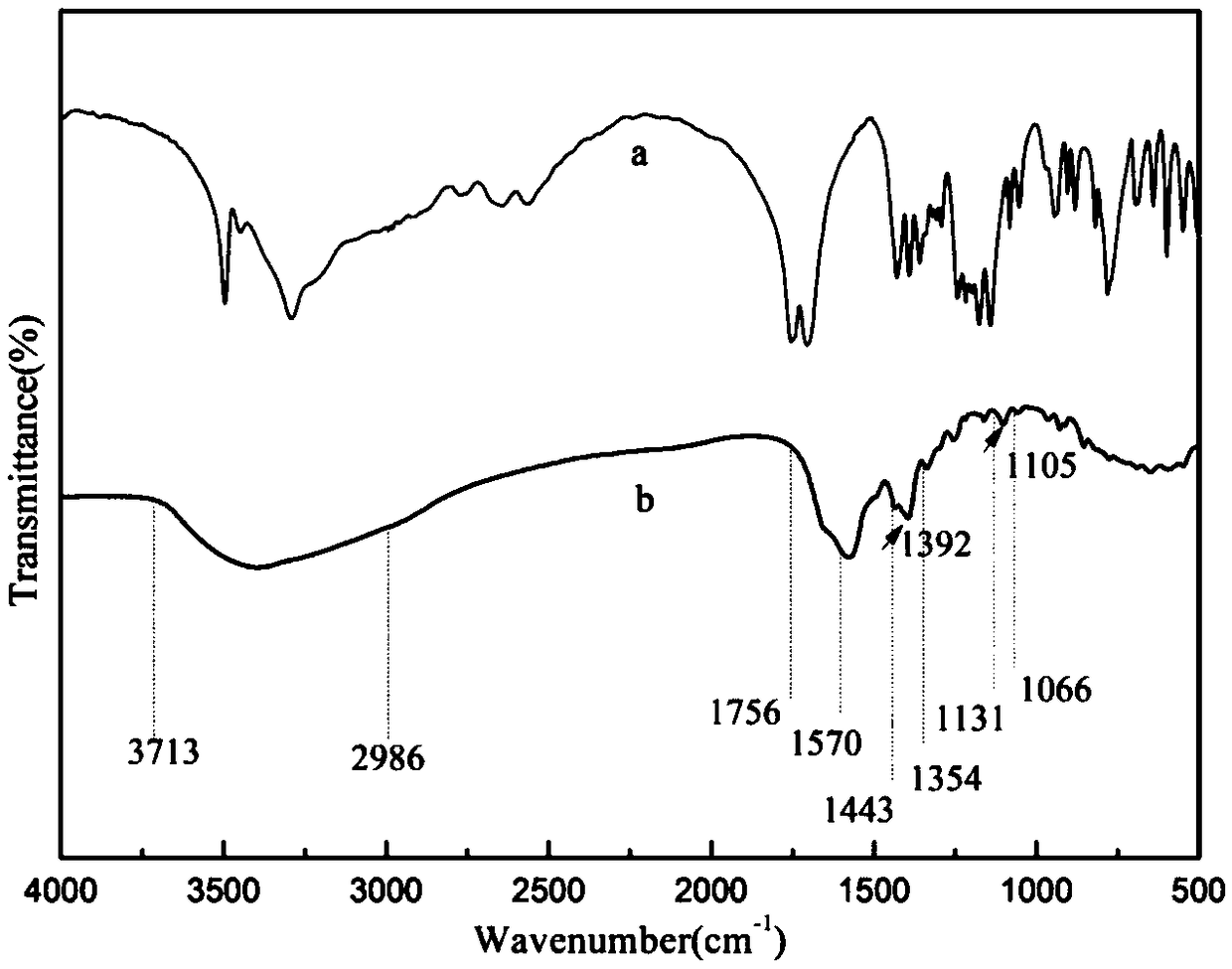

Method for electrochemical detection of acephate by aid of molecularly imprinted polymer film supported on surface of metal-organic framework material

InactiveCN106198701ALarge specific surface areaMass transfer speedMaterial electrochemical variablesMetal-organic frameworkDifferential pulse voltammetry

The invention relates to a method for electrochemical detection of acephate by the aid of a molecularly imprinted polymer film supported on the surface of a metal-organic framework material. The metal-organic framework material formed by cupric nitrate and 4,4'-biphenyldicarboxylic acid is taken as a support body, acephate is taken as a template molecule, methacrylic acid is taken as a function monomer, ethylene glycol dimethacrylate is taken as a crosslinking agent, azodiisobutyronitrile is taken as an initiator, the molecularly imprinted polymer film supported on the surface of the metal-organic framework material is synthesized and ultrasonically dispersed in a nafion solution for spin-coating of the surface of an electrode, and acephate is detected with a differential pulse voltammetry method. A molecularly imprinted polymer with large specific surface area and high mass transfer speed is obtained and is used for detecting acephate. The method has good stability and high sensitivity.

Owner:UNIV OF JINAN

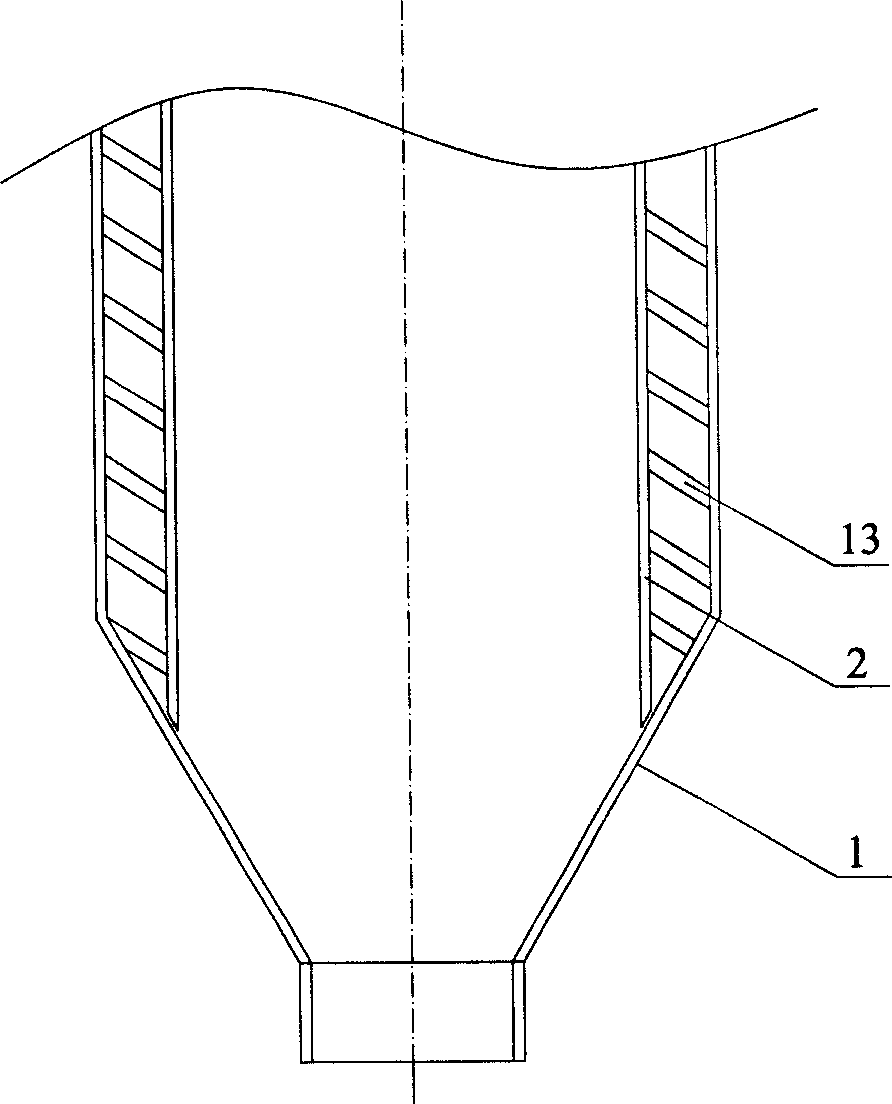

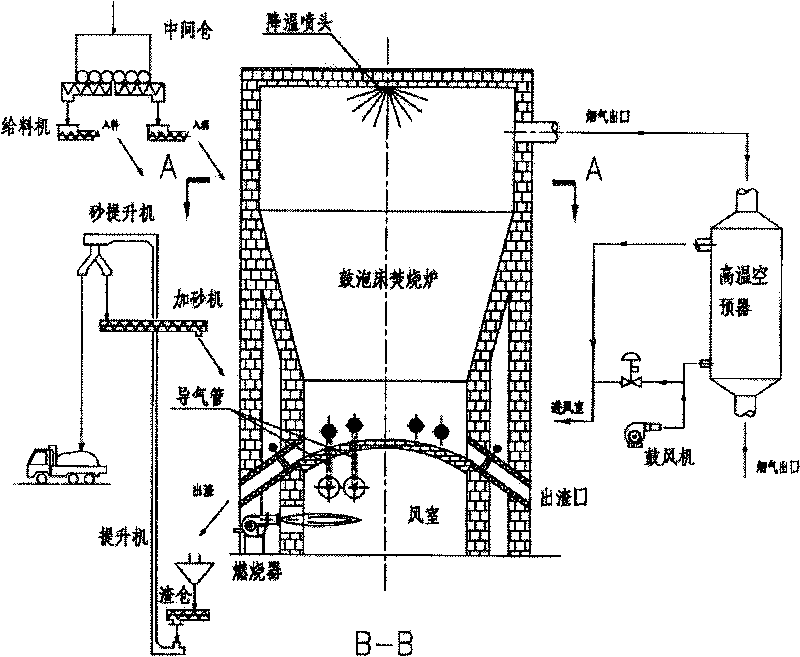

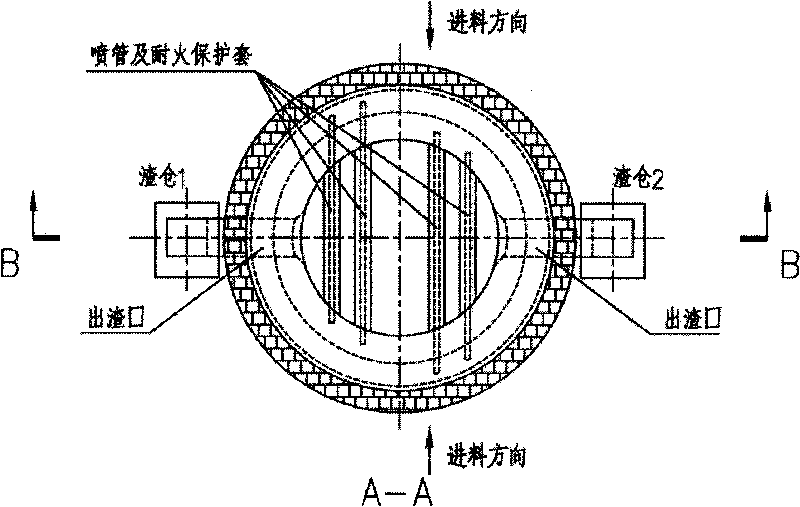

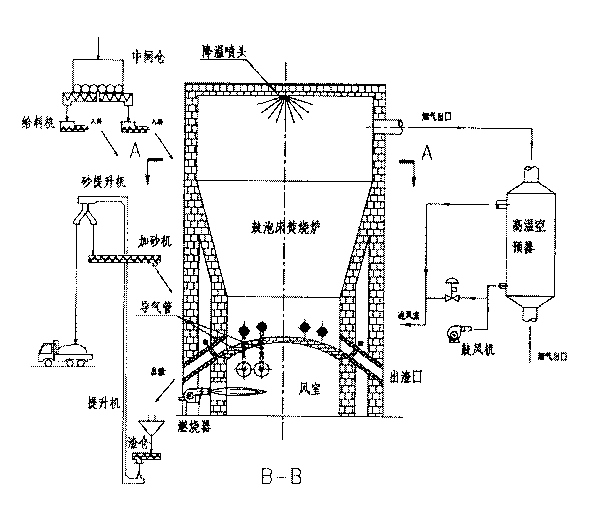

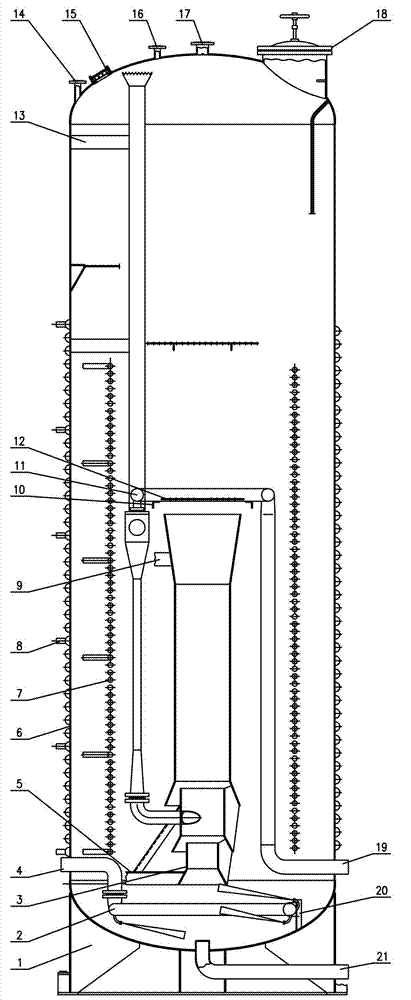

Sludge incinerator with no auxiliary fuel

InactiveCN101713543AIncineration stableMass transfer speedSludge treatment by oxidationByproduct vaporizationAir preheaterFailure rate

The invention relates to the field of environmental engineering, in particular to sludge incineration technology. The sludge incinerator with no auxiliary fuel overcomes the disadvantage that sludge incineration in the prior art requires the auxiliary fuel such as coal. The sludge incinerator with no auxiliary fuel mainly comprises a boiling section, a suspension chamber, a spray pipe, a gas-guide pipe, a support arch, a slag outlet, a cooling spray nozzle, a combustor, an air chamber and a high-temperature air pre-heater, a slag cabin, a sand hoisting machine, a sand feeder, a middle cabin and a feeding machine. The sludge incinerator with no auxiliary fuel has the following advantages that: the incinerator adopting the technology can realize stable incineration of the sludge under the condition of not adding the coal so as to achieve innocent treatment of the sludge; the sludge incinerator using the technology can store a large amount of heat inside, and a bed has a uniform reaction temperature, so that partial overheat phenomenon is prevented and the temperature in the bed is easy to be controlled; the sludge incinerator is also safe for treating sludge containing a lot of volatile substances (such as oil-containing sludge); a fluidized bed has a simple structure, a low failure rate and a low construction cost, and is provided with a mechanical transmission component; the sludge incinerator can lower the coefficient of excess air and can reduce power consumption; the sludge incinerator has wide fuel adaptability so as to realize controlling harmful gases, such as SO2, NOx and the like easily and to obtain higher combustion efficiency; and ash produced by sludge incineration has a plurality of applications.

Owner:刘沪滨

Method for removing heavy metals from sludge and special device thereof

InactiveCN101898859AMass transfer speedImprove utilizationSludge treatment by de-watering/drying/thickeningClimate change adaptationResource utilizationDigestion

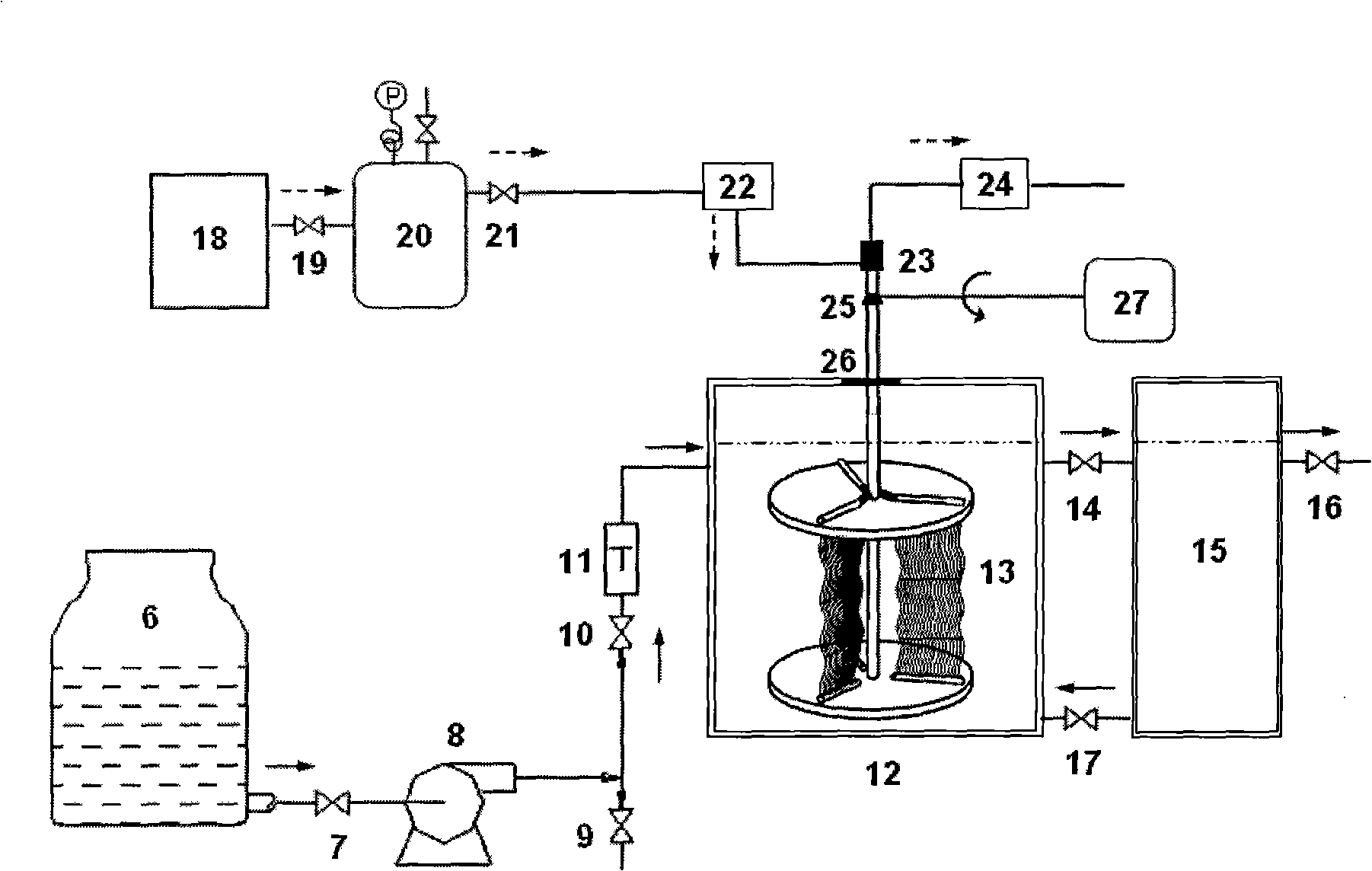

The invention discloses a technology for removing heavy metals from sludge and a device thereof. The technology comprises the following steps: a sludge pump is used to send the sludge of a sludge adjusting pool to a biological leaching tank, an ultrasonic generator with the low-frequency of 10kHz-60kHz and the amplitude of 20% is used to perform low-frequency ultrasonic wave strengthening pretreatment to the sludge in the biological leaching tank for 1-15min; then biological leaching treatment is performed; a settling pond is used for separation, wherein a sewage pump is used to pump the supernate with heavy metals to an electroflocculation machine and perform electroflocculation treatment according to the existing electroflocculation technology, sludge is dewatered with a sludge dewatering device, alkali is added to neutralize the dewatered sludge and the neutralized sludge can be used as fertilizer; and the filtrate generated by the sludge dewatering device is returned to the electroflocculation device for treatment. The technology of the invention utilizes the ultrasonic wave strengthening pretreatment to accelerate the mass transfer speed of the sludge system and facilitate acidophilic thiobacillus to utilize the substrate; the digestion period of microbes is reduced, the efficiency is increased; the electroflocculation device is used to treat the wastewater with heavy metals; and the secondary pollution problem is overcome, thus solving the heavy metal problem of sludge and realizing harmless resource utilization.

Owner:娄底市裕德科技有限公司

Method for rapidly and directly dipping nickel sulfide concentrate under action of ultrasonic wave

InactiveCN101717857AEnhanced mass transferReduced drag filmProcess efficiency improvementPotassium nitrateUltrasound - action

The invention discloses a method for rapidly and directly dipping nickel sulfide concentrate under the action of ultrasonic wave, belonging to the field of heavy non-ferrous metal hydrometallurgy. The method comprises the following steps of: crushing nickel ore (or directly using commercially-sold ore fines) and ensuring that the granularity of over 90 percent of ore is 0.15-0.08 mm; evenly mixing the nickel ore and water and placing the mixture into a stainless steel reactor, wherein the weight ratio of the water to the nickel ore is 5-30:1; adding an oxidant which can be sodium nitrate or potassium nitrate, wherein the weight ratio of concentrated sulfuric acid to the nickel ore is 0.5-1.1:1; finally keeping the ultrasonic frequency at 20.02kHz and the power at 50-150W under the action of ultrasonic wave; and directly dipping at normal pressure and normal temperature for 40-60 min. The invention has the characteristics of operation at normal pressure, high reaction speed, high leaching rate up to 97-99 percent for only 40-60 min and relative safety and low cost by taking solid nitrate as the oxidant.

Owner:JIANGSU UNIV

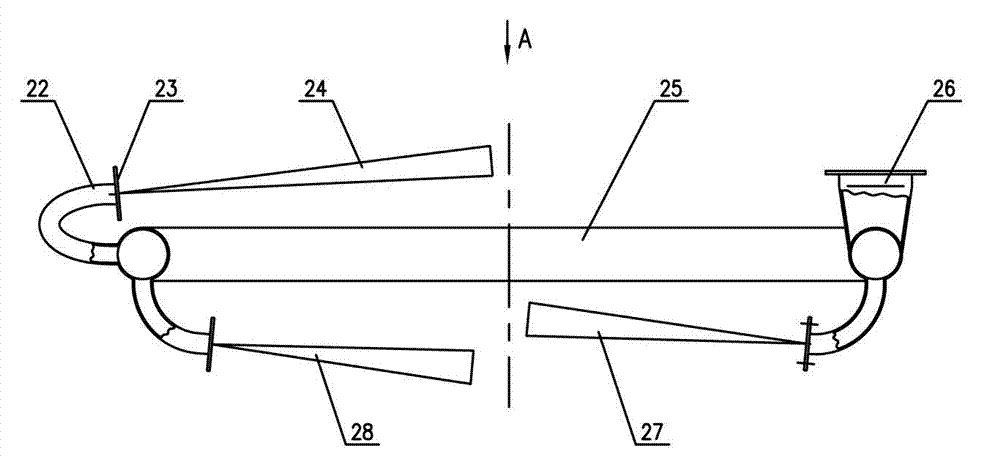

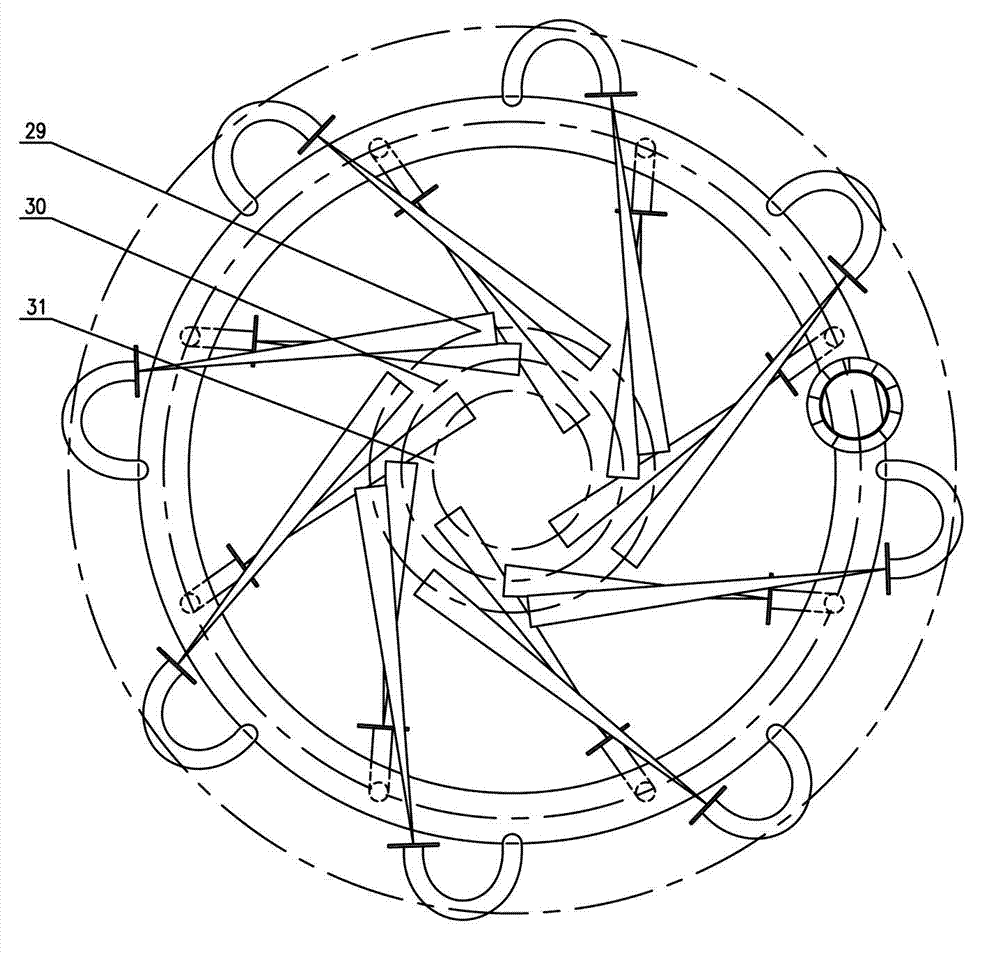

Rotary type hollow fiber porous membrane foamless oxygen charging device and method

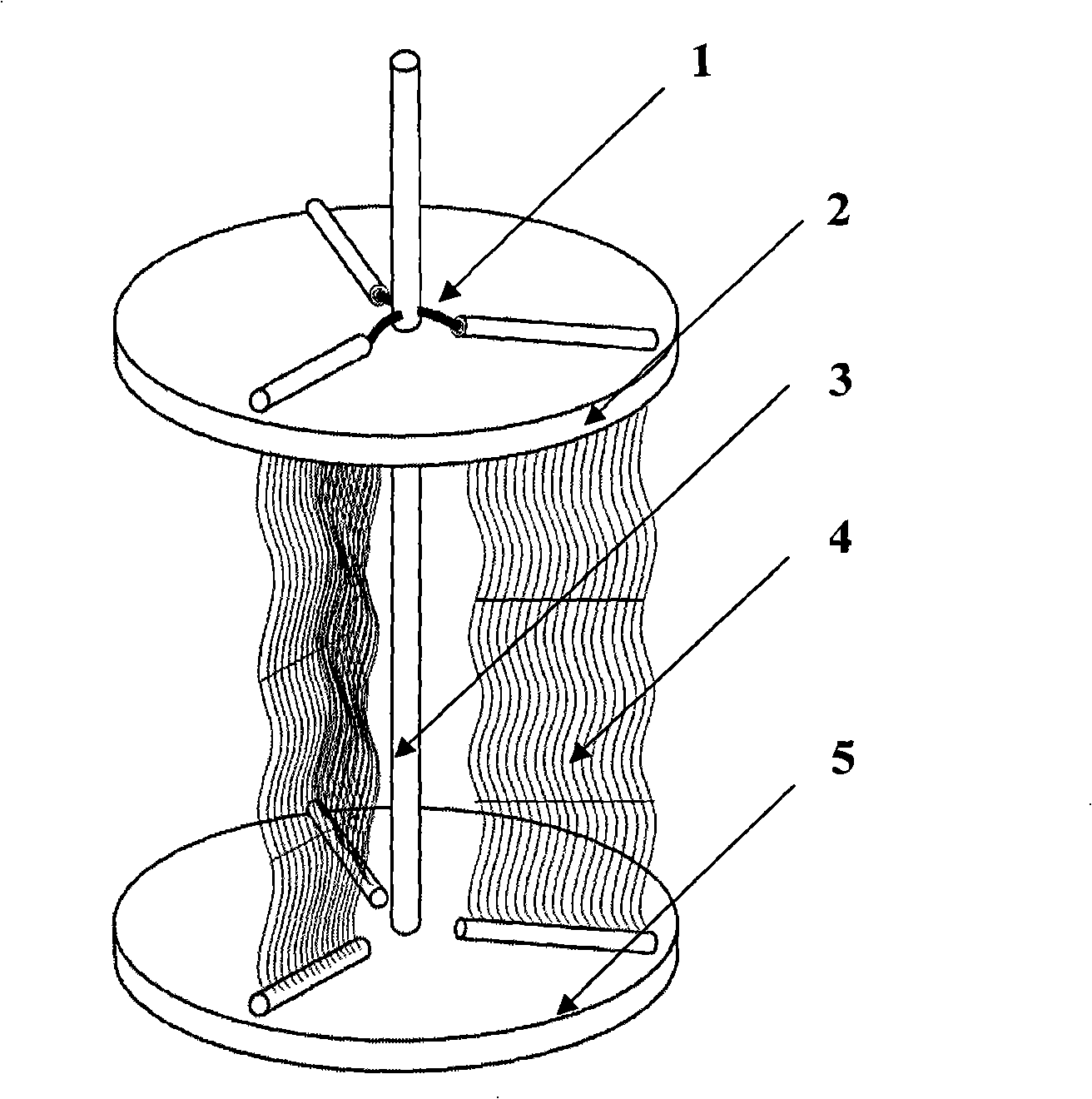

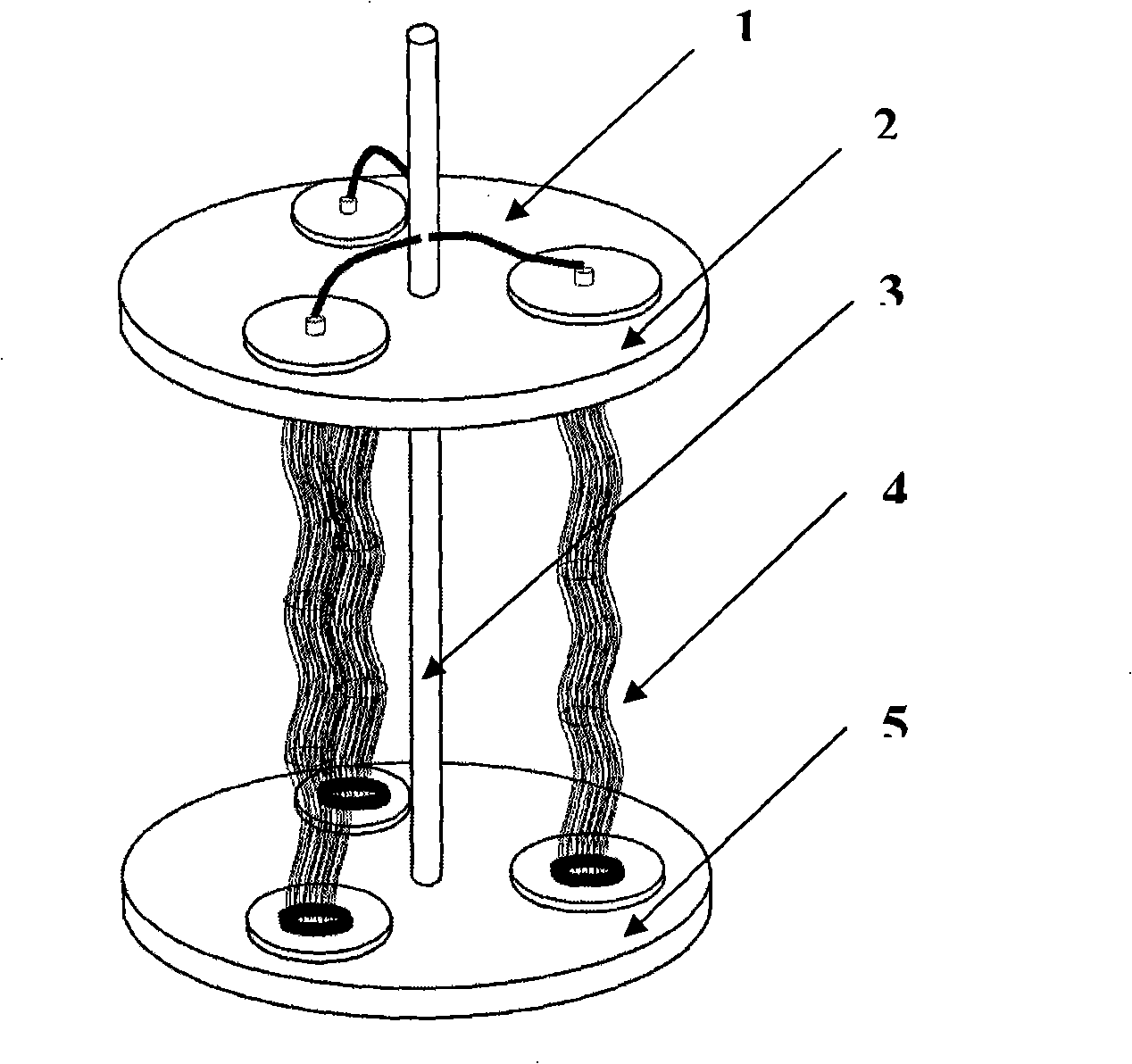

InactiveCN101514049AEasy to spreadIncrease line speedTreatment using aerobic processesSustainable biological treatmentFiberActivated sludge

The invention discloses a rotary type hollow fiber porous membrane foamless oxygen charging device and method. The device comprises a rotary foamless membrane type oxygen charging assemble, an air supplying and exhausting system, a water supplying and draining system and a motor and electrical control system. In the method, the raw water is added in an activated sludge aeration basin, the rotary foamless membrane type oxygen charging assemble rotates in the aeration basin at the speed of several to tens revolutions per minute, the oxygen charging adopts the intermittent air charging and discharging way, the air feeding pressure is controlled under the bubble point of the fiber membrane, the oxygen is dissolved rapidly on the membrane surface and is dispersed into the sludge water under the drive of the concentration difference and the pressure difference, the dissolved oxygen concentration is kept at 1 to 2.5 mg / l, the rotary oxygen charging assemble play the role of the mixing and activated sludge stirring. Compared with the traditional aeration method, the invention has high oxygen transmissibility, good oxygen charging effect, little oxygen charging amount, lower energy consumption, little membrane pollution, and convenient change and maintenance, and is very suitable for the upgrading and reforming of the activated sludge aeration basin in the sewage treatment technology.

Owner:ZHEJIANG UNIV

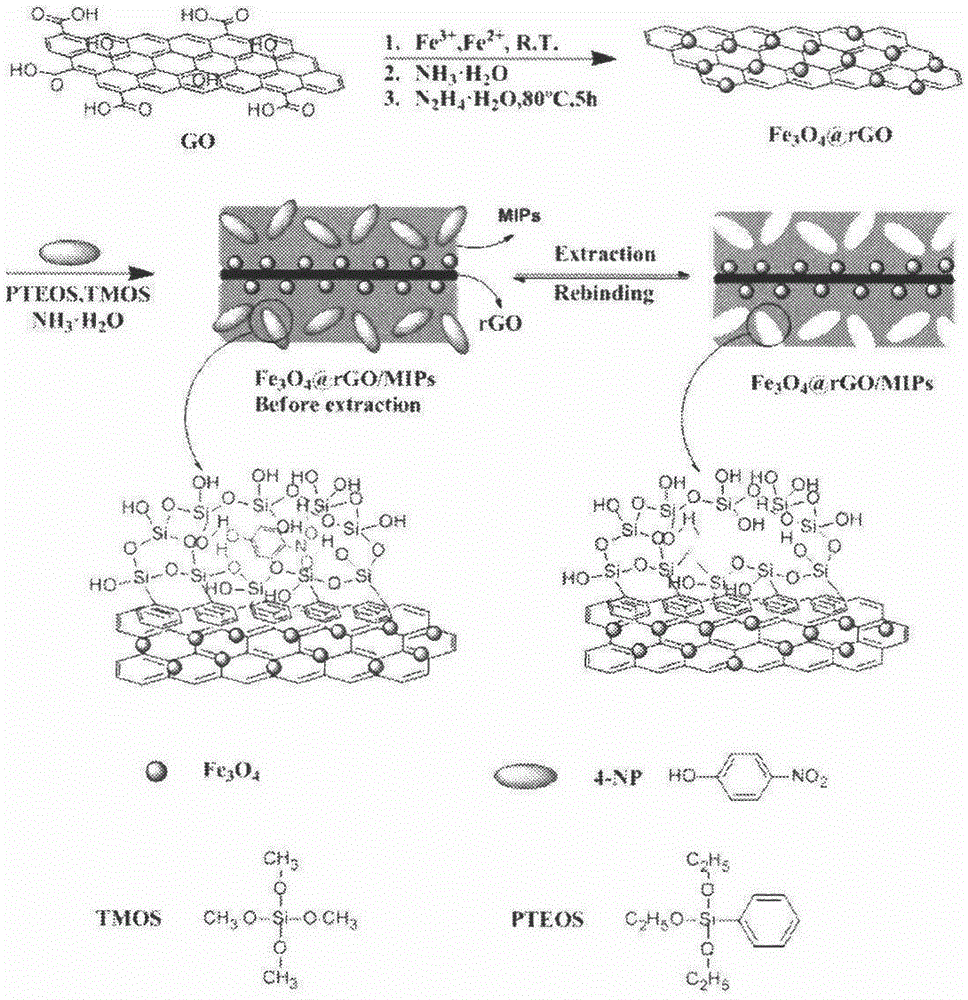

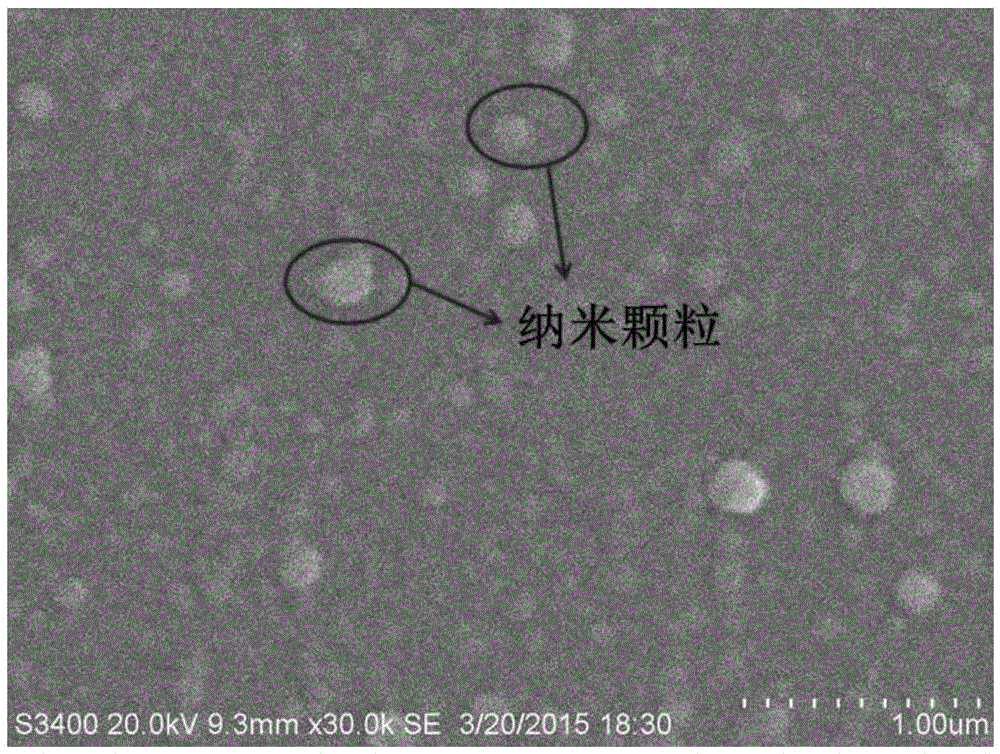

Preparation method for surface molecular imprinting nano-composite material of magnetic graphene

InactiveCN105148876ASuperparamagneticEasy to separateOther chemical processesAlkali metal oxides/hydroxidesFunctional monomerSolvent

The invention provides a preparation method for a surface molecular imprinting nano-composite material of magnetic graphene and belongs to the technical field of preparation of environmental protection functional materials. The method comprises the following steps: modifying a layer of Fe3O4 nano-particles on the surface of graphene; by using the obtained magnetic graphene as a carrier and using siloxane as a functional monomer and a cross-linking agent, preparing the surface molecular imprinting nano-composite material of the magnetic graphene in a water solution at normal temperature through a sol-gel method. The surface molecular imprinting nano-composite material of the magnetic graphene is applied to harmful substances or substances to be detected in a selective magnetic separation water body, so that target molecules can be quickly enriched and separated. The preparation method for the surface molecular imprinting nano-composite material of the magnetic graphene, provided by the invention, is simple, the carrier, template molecules, the functional monomer and a solvent are mixed in proportion, the cost is low, and energy conservation and environmental protection are achieved. A product has the advantages of specificity selection, high adsorption capacity, convenient magnetic separation, high speed and the like.

Owner:JIANGNAN UNIV

Method for extracting flavone compounds from granatum

The invention discloses a method for extracting flavone compounds from granatum by combining an enzymolysis method with ultrasonic microwave extraction, belongs to the technical field of comprehensive utilization of agricultural products, and relates to a functional food deep processing technology. The method mainly comprises the following steps of: performing vacuum drying or vacuum freeze-drying on the granatum which is taken as a raw material until the moisture content of the granatum is about 10 percent; crushing the dried granatum, wherein the particle size of granatum powder is 40 to 60 meshes; and extracting the flavone compounds from the granatum powder serving as a raw material by combining a biological enzymolysis method with an ultrasonic microwave extraction method, namely performing enzymolysis treatment by adopting compound enzyme, and further performing ultrasonic microwave extraction on a zymolyte to prepare the flavone compounds with high yield and purity.

Owner:JIANGNAN UNIV

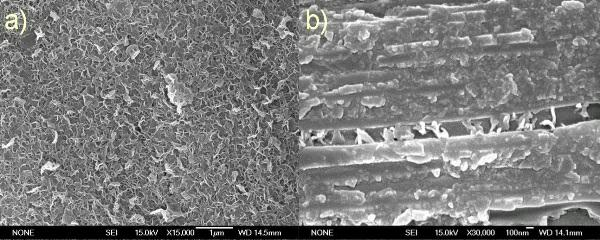

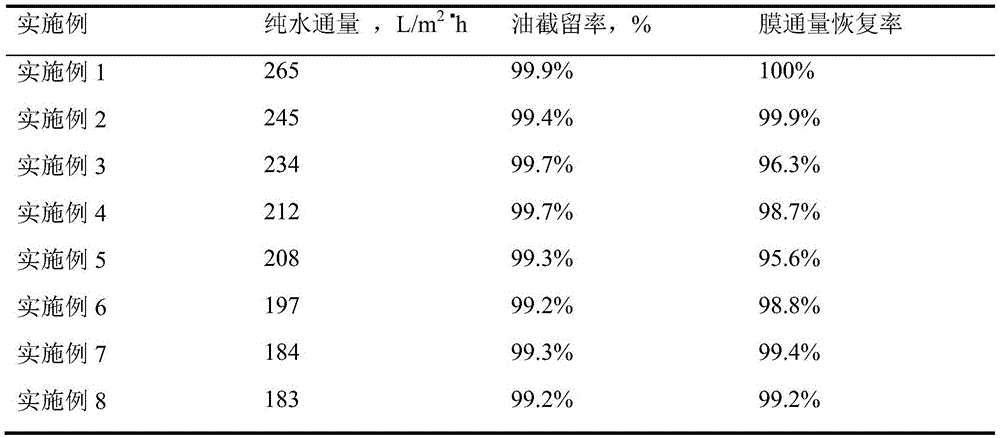

Preparation method of polymer-based nano composite ultrafiltration membrane

ActiveCN105536551AImprove adsorption capacityGood dispersionSemi-permeable membranesMembranesSynthesis methodsUltrafiltration

The invention discloses a preparation method of a polymer-based nano composite ultrafiltration membrane, and belongs to the field of membrane material preparation. The preparation method mainly comprises the steps: a hydrophobic polyvinylidene fluoride ultrafiltration membrane is prepared by a traditional phase transformation method, then the polyvinylidene fluoride ultrafiltration membrane is activated and modified by using potassium permanganate and sodium bisulfite, and the polyvinylidene fluoride ultrafiltration membrane is grafted with hydrophilic groups; and then a metal oxide precursor is introduced, the surface of the polyvinylidene fluoride ultrafiltration membrane is loaded with nano metal oxide by an in-situ deposition method, and thus the polymer-based nano composite ultrafiltration membrane is prepared. The synthesis method disclosed by the invention is simple in process, the problems that the utilization efficiency is low and nano materials are easy to agglomerate because the interior of a membrane piece is easily encapsulated with nanoparticles are solved, and the prepared polymer-based nano composite ultrafiltration membrane has the advantages of high utilization efficiency of nanomaterials, large membrane flux, strong anti-pollution ability, stable separation performance and the like.

Owner:NANJING UNIV

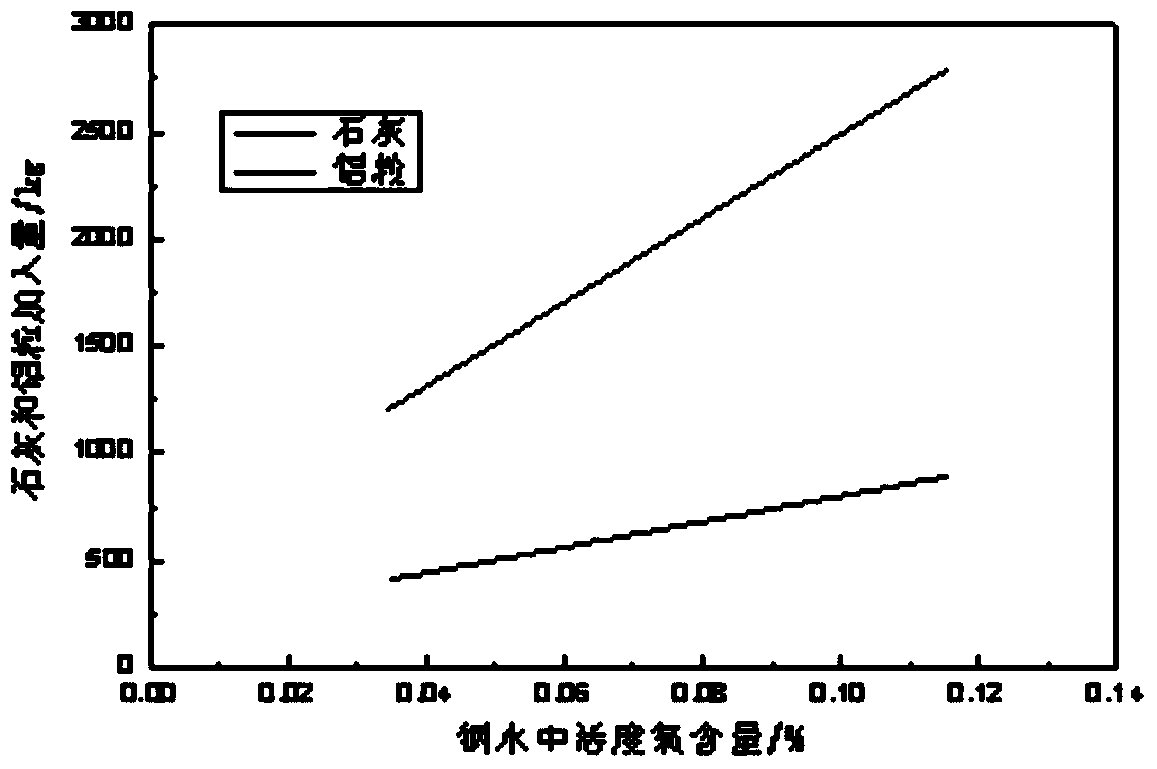

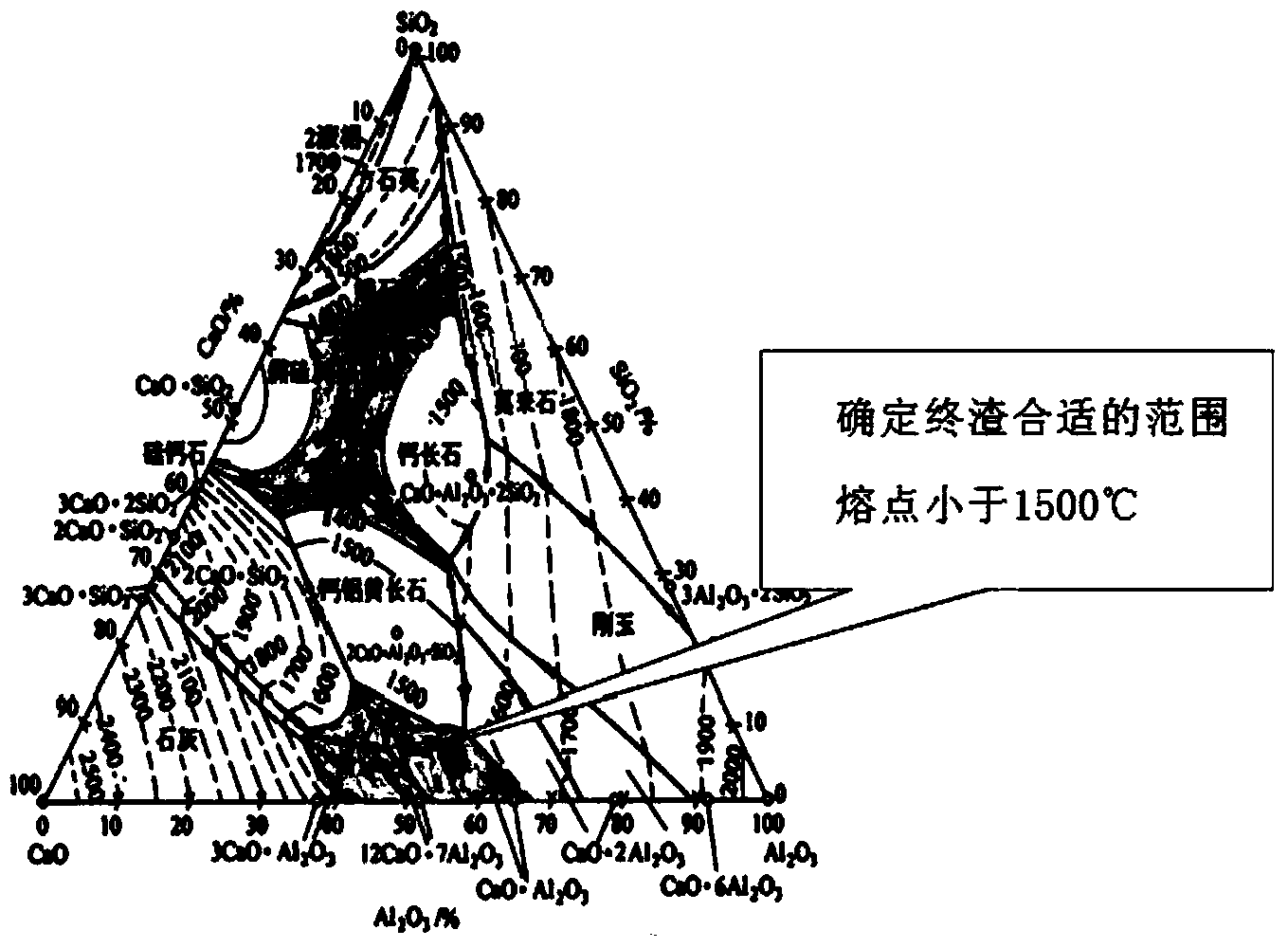

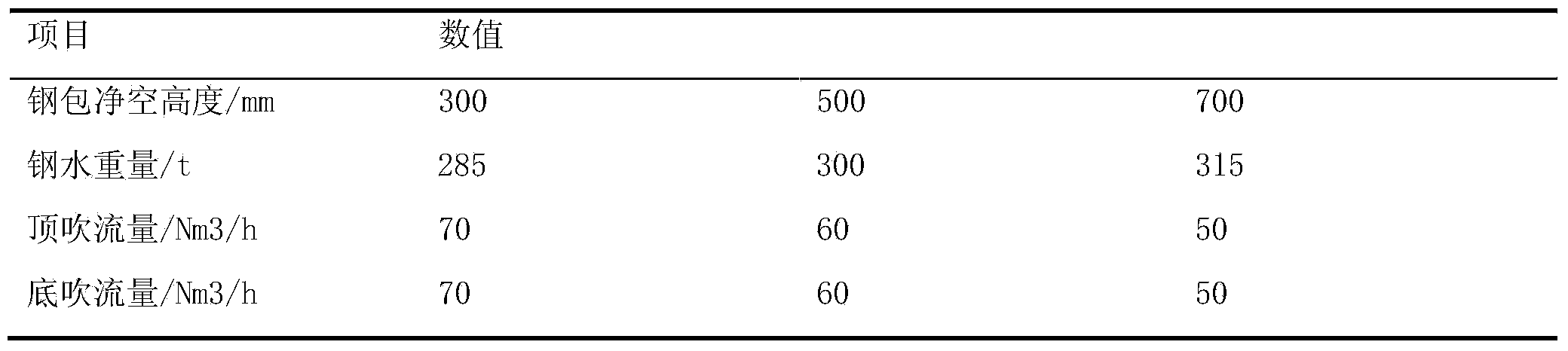

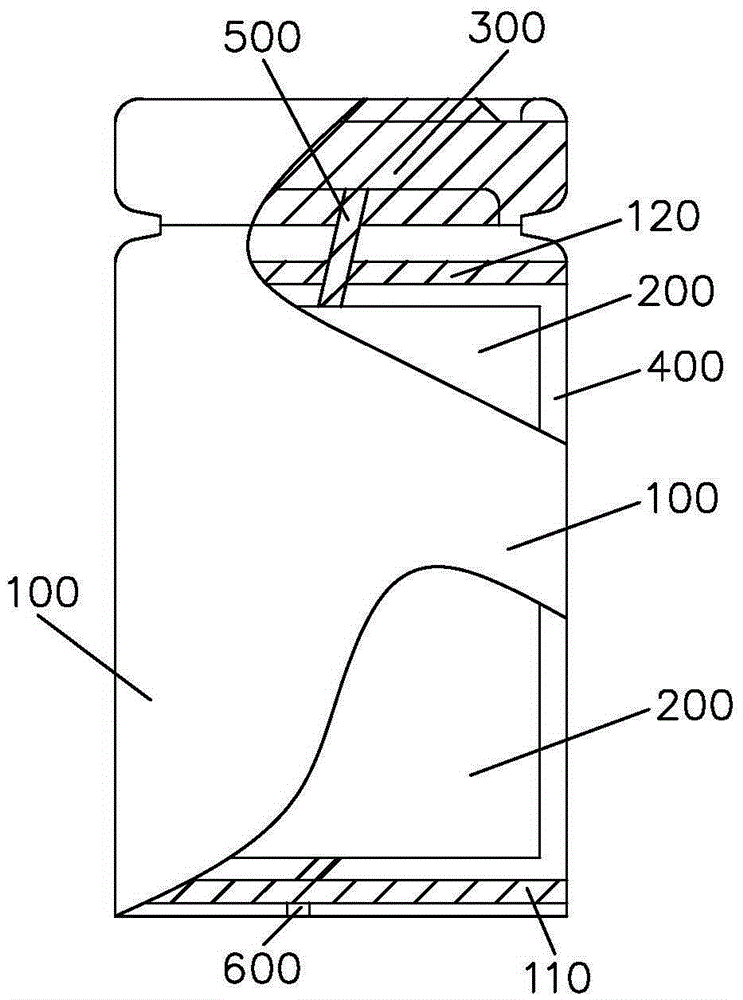

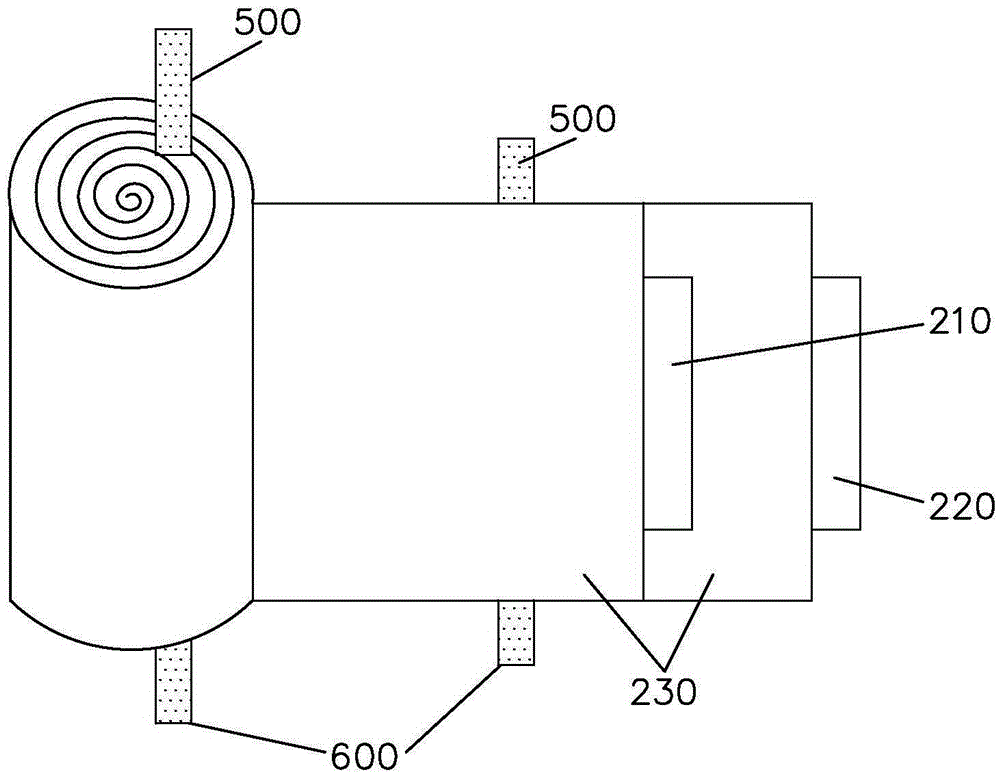

Desulfurization refining slag for steelmaking process and addition method thereof

InactiveCN103882183AIncrease the reaction interface areaHigh speedProcess efficiency improvementSteelmakingMetallurgy

The invention discloses a desulfurization refining slag for a steelmaking process. The refining slag comprises the following proportional components: 50%-60% of CaO, 7%-12% of SiO2, 28%-33% of Al2O3, and 4%-8% of MgO; the desulfurization rate of the LF (Ladle Furnace) refining slag is between 70.8%-92.0% and the content of sulfur at the finishing point ranges from 0.0004% to 0.0014%, so that excellent desulfurization is achieved and the requirements of the grade of steel for deep desulfurization can be completely met; the ratio of CaO to Al2O3 is controlled within the range of 1.7-1.9; the desulfurization refining slag has favorable adsorption and inclusion capacity.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Graphene ultralow-temperature power lithium battery

ActiveCN105390695AImprove conductivityChange smoothing structureMaterial nanotechnologyCell electrodesLithium iron phosphateNanoparticle

The invention discloses a graphene ultralow-temperature power lithium battery. The power lithium battery comprises a battery case, a negative electrode insulation sheet, a battery cell, a positive electrode insulation sheet and a cap. The battery cell comprises a positive electrode plate, a negative electrode plate and a diaphragm. The positive electrode plate comprises a positive electrode current collector, and positive electrode material coatings arranged on two side surfaces of the positive electrode current collector respectively; each positive electrode material coating is prepared by coating the surface of the positive electrode current collector with a positive electrode material mixture; and the positive electrode material mixture contains a nanoparticle positive electrode material, a positive electrode binder, a positive electrode mixed conductive agent and a positive electrode solvent, wherein the nanoparticle positive electrode material is a lithium iron phosphate nanoparticle, and the positive electrode mixed conductive agent contains, by weight, 97-99 parts of a positive electrode conductive agent base material, 0.2-0.4 parts of graphene, 0.2-0.4 parts of SP and 0.2-0.4 parts of KS-6.

Owner:王立军

Method for preparing (Y1-xEux)2(OH)5NO3.nH2O oversized rare-earth layered hydroxide compound particles

ActiveCN103011233ASimple technical solutionLarge particle sizeRare earth metal compoundsRare-earth elementAmmonium hydroxide

The invention belongs to the field of material science and particularly relates to a method for preparing (Y1-xEux)2(OH)5NO3.nH2O oversized rare-earth layered hydroxide compound particles. The method disclosed by the invention comprises the following steps of: mixing Eu(NO3)3.6H2O and Y(NO3)3.6H2O or a mixture of the Eu(NO3)3.6H2O and the Y(NO3)3.6H2O which are mixed in any proportion with ammonium nitrate, adding deionized water so as to prepare liquid with the rare earth ion concentration of 0.02-0.10 mol / L, adding ammonium hydroxide while stirring, adjusting the pH of the liquid to 6.5-7.0 so as to obtain a suspension, transferring the suspension into a reaction kettle, carrying out hydrothermal reaction for 24-168 hours at the temperature of 120-200 DEG C, and carrying out centrifugal separation, cleaning and drying on reaction products, thereby obtaining white powdered (Y1-xEux)2(OH)5NO3.nH2O particles, wherein x is greater than or equal to 0 and smaller than or equal to 1, and n is 1.5-1.8. The method disclosed by the invention is simple and feasible, and the obtained (Y1-xEux)2(OH)5NO3.nH2O particles are larger in size which is 10-300 microns, and are easily subjected to subsequent stripping processing.

Owner:NORTHEASTERN UNIV

Method for synthesizing adsorption functional material for number one Sudan red

InactiveCN101091911AImprove stabilityExtended service lifeOther chemical processesSynthesis methodsSorbent

The invention relates to a synthetic method of the sudan red I adsorption functional material, the major technique characteristic is that taking the sudan red I as the template member, the three-amino propyl orthoformate silicon alkyl which contains the double function group as the function monomer, the activation silicon ball as the carrier, using the technology of superficial member signature and the sol-gelatin method to synthesize the sudan red I adsorption functional material. The invention has the low cost, the simple experiment operation and the reaction condition is easy to control, the prepared sudan red I adsorption functional material as the absorbent can be used in the solid phase extract and liquid phase chromatograph association, and suitable to online adsorption examine the trace amount of the sudan red I in each kind of food and seasoning.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Emulsifying-type aerobic fermentation tank

InactiveCN102732417AExtended service lifeReduce dosageBioreactor/fermenter combinationsBiological substance pretreatmentsOxygen utilization rateBiochemical engineering

The present invention discloses an emulsifying-type aerobic fermentation tank. According to the aerobic fermentation tank in the prior art, increase of compressed air consumption and improvement of stirring motor power can not significantly increase specific yield, and can cause energy consumption increasing, product cost improving, equipment cost increasing and operating environment deterioration. The emulsifying-type aerobic fermentation tank of the present invention comprises a tank body and a gas-liquid mixing circulation apparatus, wherein the gas-liquid mixing circulation apparatus is located inside the tank body, and has at least two stages of gas-liquid mixers. The gas-liquid mixing circulation apparatus is arranged vertically. The tank body is provided with a tank body gas inlet pipe and a fermented liquid inlet pipe. The tank is characterized in that: a self-suction air ejection emulsifying supercharging device is arranged between the gas-liquid mixing circulation apparatus and the inner wall of the tank body. With the tank of the present invention, oxygen utilization rate, mass transfer rate, dissolved oxygen coefficient and specific yield are improved, energy is substantially saved, the equipment is simplified, the microbiological contamination rate is reduced, the equipment cost and the maintenance cost are reduced, and the service life of the fermentation tank isprolonged.

Owner:卢行娥

Method of treating coal gas effluent and coking effluent using diatomite and active sludge

InactiveCN1597565AEliminate or slow down inhibitionGood removal effectSustainable biological treatmentWater/sewage treatment by sorptionIndustrial effluentWater quality

A process for treating the gas waste water and coking waste water by diatomite and active sludge includes such steps as loading said waste water in bioreactor, adding diatomite and active sludge, aerating, flowing in depositing pool, depositing and mud-water separation.

Owner:HARBIN INST OF TECH

Method for extracting and separating anthocyanidin and polysaccharide from blueberry pomace

The invention relates to a method for extracting and separating anthocyanidin and polysaccharide from blueberry pomace. According to the method, blueberry pomace is used as raw material, enzyme-water solution is used as extraction solvent, and negative pressure cavitation strengthening extraction technology and macroporous resin enrichment and separation technology are applied to obtain anthocyanidin and polysaccharide from the blueberry pomace. Content of anthocyanidin in the obtained product is 26%-40%, and content of polysaccharide is 2.6%-13.8%. The method has the advantages that by-products of blueberries are utilized comprehensively, equipment is simple, economization and environmental protection. Further, the method fits with current trend of development and is suitable for industrialization.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Fractal micro-channel bipolar plate used in proton exchange membrane fuel cell and processing method thereof

InactiveCN101447572ADrop total pressureSmall total pressureCell electrodesFuel cell detailsElectrochemical responseLaser technology

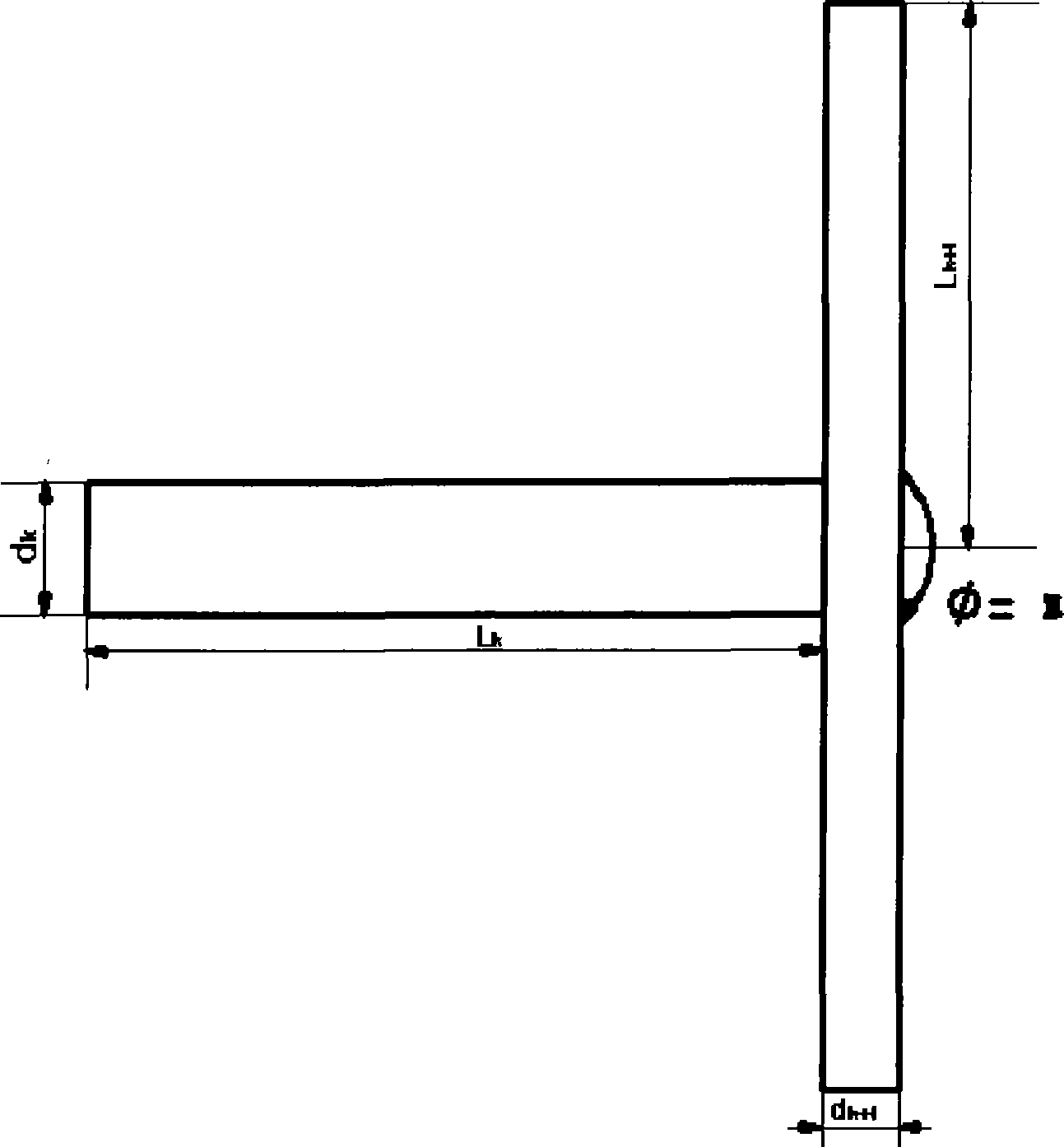

The invention discloses a fractal micro-channel bipolar plate used in a proton exchange membrane fuel cell and a processing method thereof. The fractal micro-channel bipolar plate comprises a cathode flow field plate (10), an anode flow field plate (11), a proton exchange membrane (8), a cathode diffusion layer (7) and an anode diffusion layer (9); an upper flow field plate (1) and a lower flow field plate (5) are equipped with fractal micro-channels each of which is provided with two branches in the next channel; bifurcation angle phi of single branch shape of the fractal micro-channel flow field structure equals pi. The fractal micro-channel structure is processed by an etching technology, and through holes on the separation membrane are processed by a laser technology. The fractal micro-channel bipolar plate used in the proton exchange membrane fuel cell can ensure that reaction gas is distributed to every part of an electrode, the fractal micro-channel structure can ensure uniform temperature distribution in the cell and small pressure drop, keep a certain linear velocity of the reaction gas in the flow field, effectively discharge the water which is generated by the electrochemical reaction, and enhance the efficiency of the fuel cell.

Owner:SOUTH CHINA UNIV OF TECH

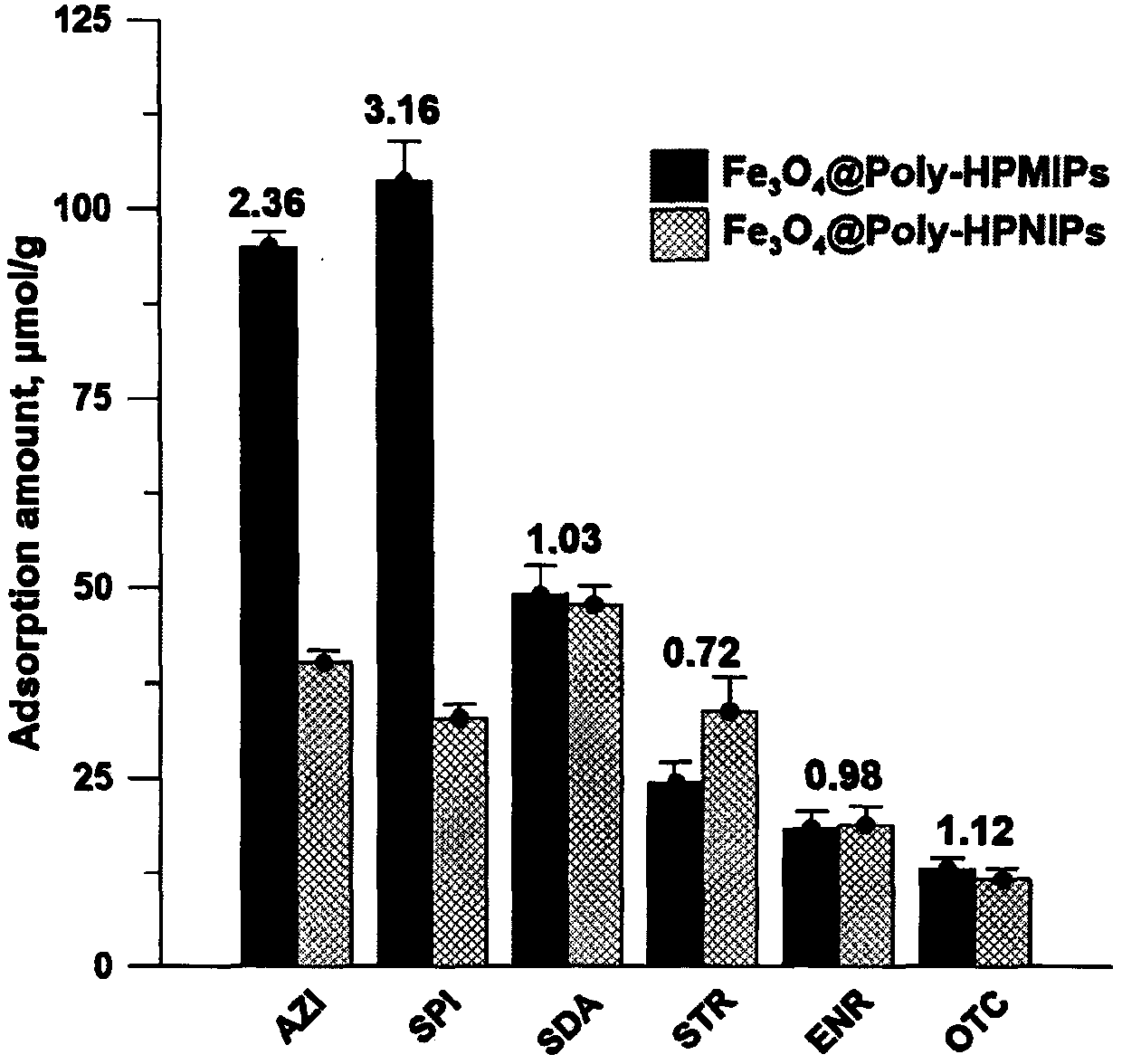

Preparation method and application of magnetic core-hollow porous molecular imprinting polymer satellite assembly for macrolide antibiotics

ActiveCN110204735AMass transfer speedLarge adsorption capacityComponent separationOther chemical processesMacrolide resistanceFunctional monomer

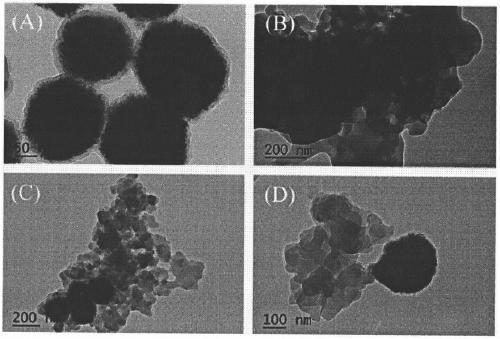

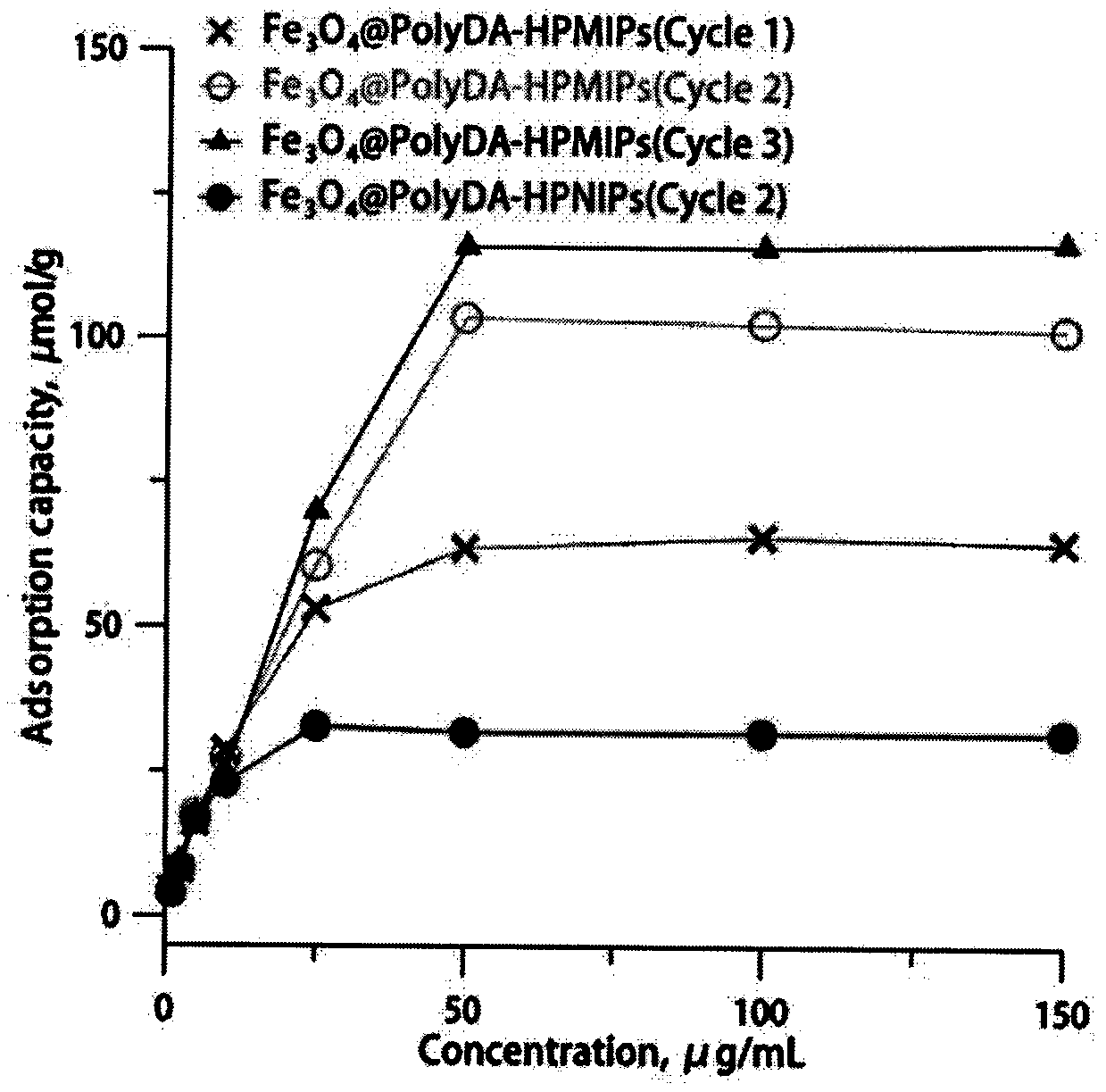

The invention discloses a high-selectivity magnetic core-hollow porous molecular imprinting polymer satellite assembly applied to determining the residual quantity of trace macrolide antibiotics in animal-derived foods and a preparation method of the assembly. With mesoporous silicon as a sacrificial support template, methacrylic acid as a functional monomer and spiromycin as a template molecule,hollow porous molecular imprinting polymers (HPMIPs) are prepared by means of a thermal initiation polymerization method; ferroferric oxide magnetic nanoparticles (Fe3O4NPs) are prepared by means of asolvothermal method. By utilizing the self-polymerization properties of dopamine, polydopamine-coated ferroferric oxide magnetic nanoparticles (Fe3O4@polyDA) are prepared, the HPMIPs are grafted on the surfaces of the polydopamine-coated ferroferric oxide magnetic nanoparticles (Fe3O4@polyDA), synthesized magnetic hollow porous molecular imprinting polymers (Fe3O4@polyDA-HPMIPs) are obtained andserve as a magnetic dispersion solid phase extraction adsorbent, macrolide drugs are selectively enriched and separated, and in combination with HPLC-MS / MS detection, the effect is ideal. The preparedmaterial has the advantages of high affinity, high adsorption capacity, a good magnetic response effect and the like and has broad application prospects in the field of food detection and the like.

Owner:CHINA PHARM UNIV

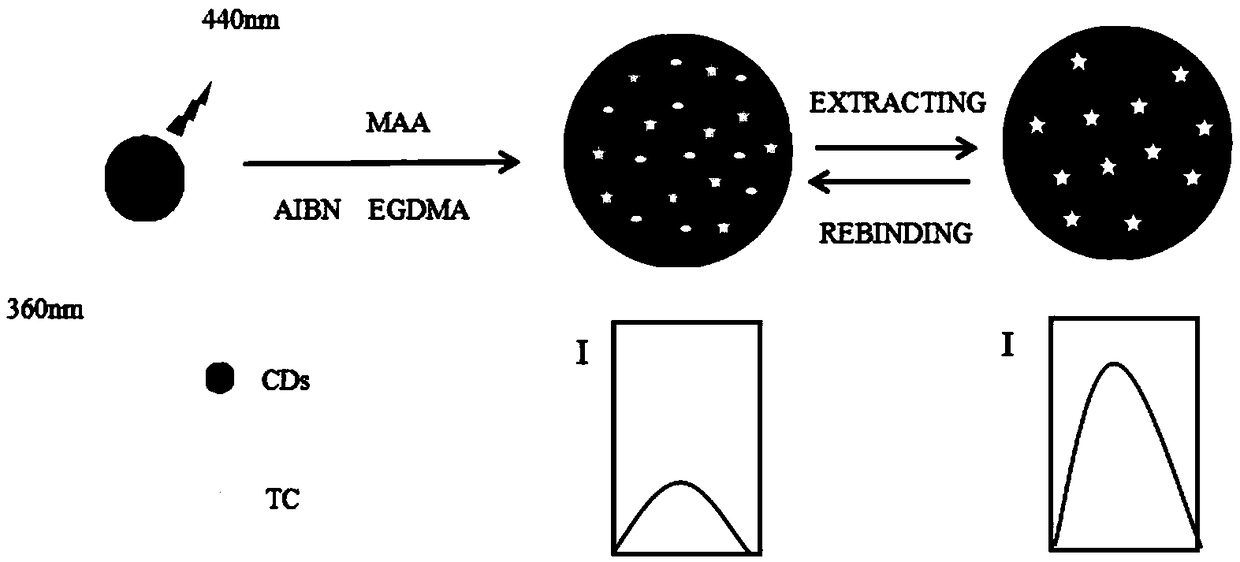

Preparation method of tetracycline carbon dot fluorescent molecular imprinting material

InactiveCN109160976AMass transfer speedGood stabilityOther chemical processesFluorescence/phosphorescenceSolventChemistry

The invention provides a preparation method of a tetracycline carbon dot fluorescent molecular imprinting material. The method comprises the following steps: adopting CDs as a carrier, adopting methanol / water as a solvent, and adding tetracycline, methacrylic acid, ethylene glycol dimethacrylate and azodiisobutyronitrile to form the tetracycline carbon dot fluorescent molecular imprinting material. The method has the advantages that green and stable carbon dots are taken as fluorescence detection signals, and are combined with the selectivity of a molecular imprinting technology, so that the fluorescent molecular imprinting composite material CDs@MIP with high selectivity on tetracycline is synthesized; the preparation technology is scientific, the cost is low, the method is simple to operate, and reaction conditions are easy to control; and the prepared tetracycline adsorption function material is applicable to adsorption detection on trace tetracycline in water environment, and has an excellent application prospect.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com