Rotary type hollow fiber porous membrane foamless oxygen charging device and method

A rotary, microporous membrane technology, applied in the field of environmental engineering, can solve the problems of polluted air, low oxygen utilization rate, high energy consumption, and achieve the effects of low operating cost, reduced equipment cost and energy consumption, and large water treatment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

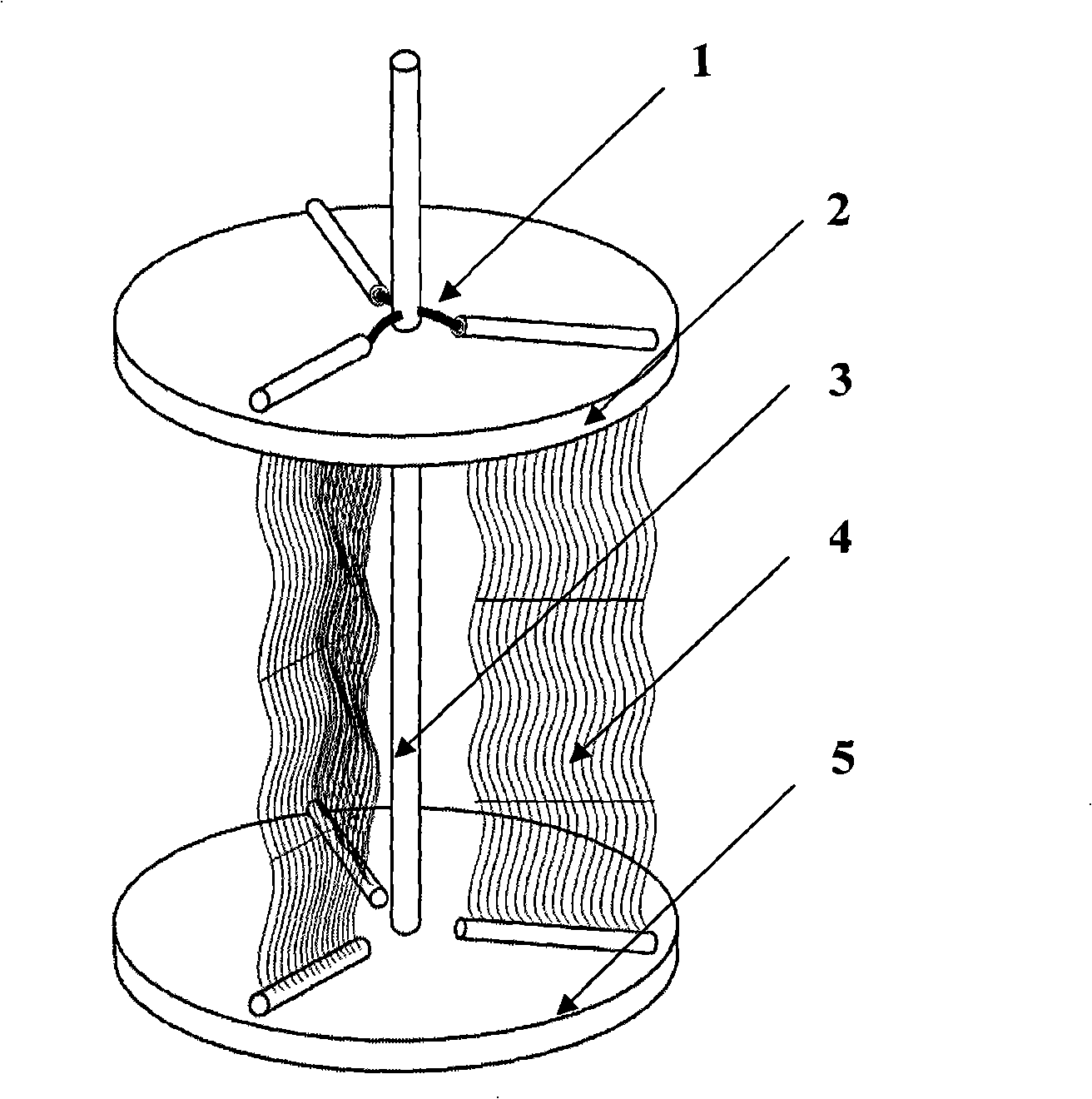

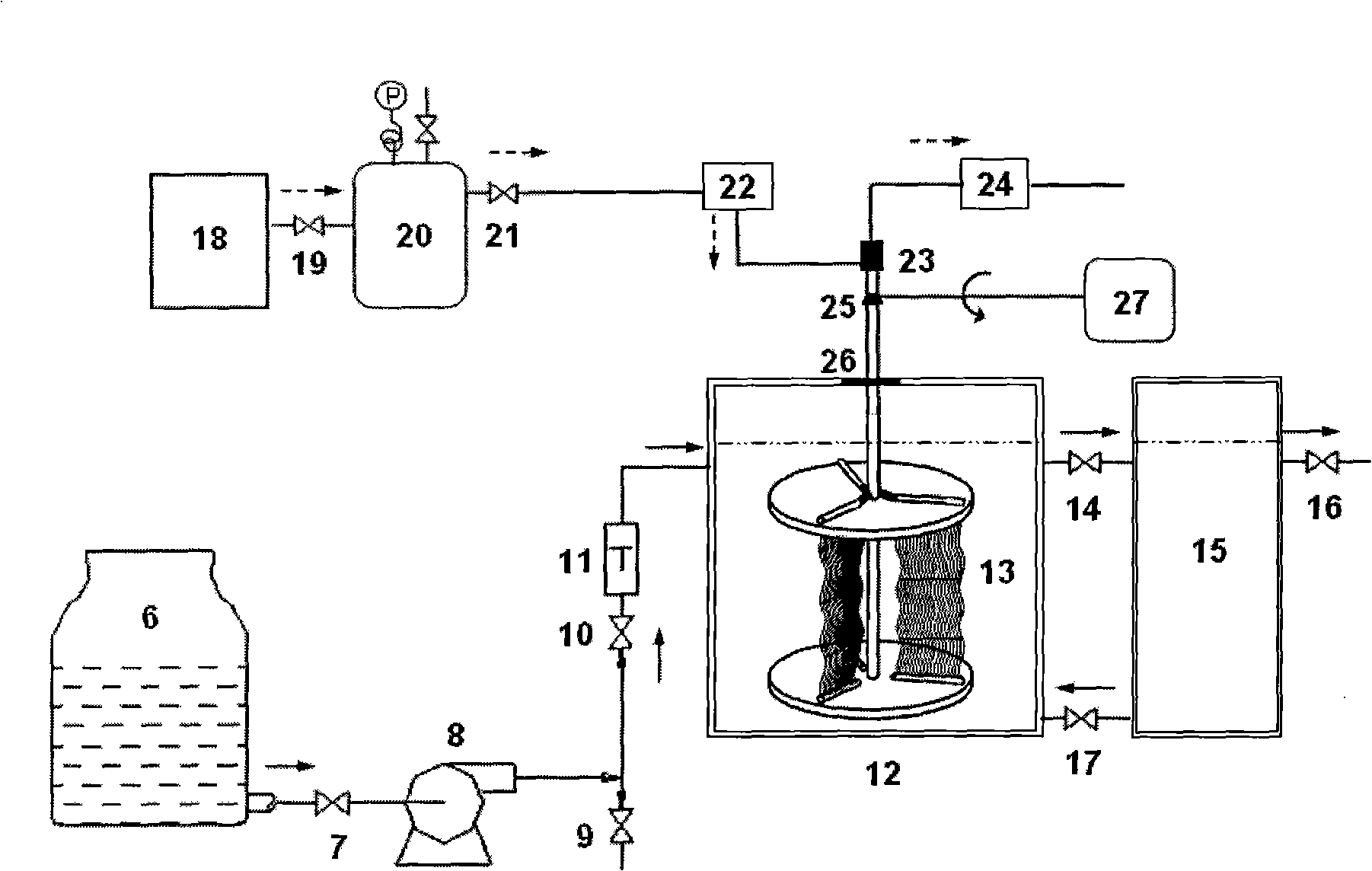

[0039] Three flat curtain hollow fiber membrane devices are used in the rotary bubble-free membrane oxygenation module 13, please refer to figure 1 , the hollow fiber membrane material is polypropylene, the outer diameter is 450 μm, the wall thickness is 40-50 μm, the membrane pore size is 0.1-0.2 μm; the porosity is 40-50%, the bubble point is greater than 0.5Mpa, and the gas flux is greater than 0.05cm 3 / cm 2 ·s·cmHg, the size of the planar curtain hollow fiber membrane module is 45×15cm, the effective length of the membrane filament is 40cm, and the effective area of the membrane is 3m 2 , intermittent exhaust every 1min for 5s, the speed is 20 rpm, the effective volume of the activated sludge aeration tank is 70L, the test water is deoxygenated water, the dissolved oxygen concentration is close to zero, and the air supply is air. The test conditions and results are as follows:

[0040]

Embodiment 2

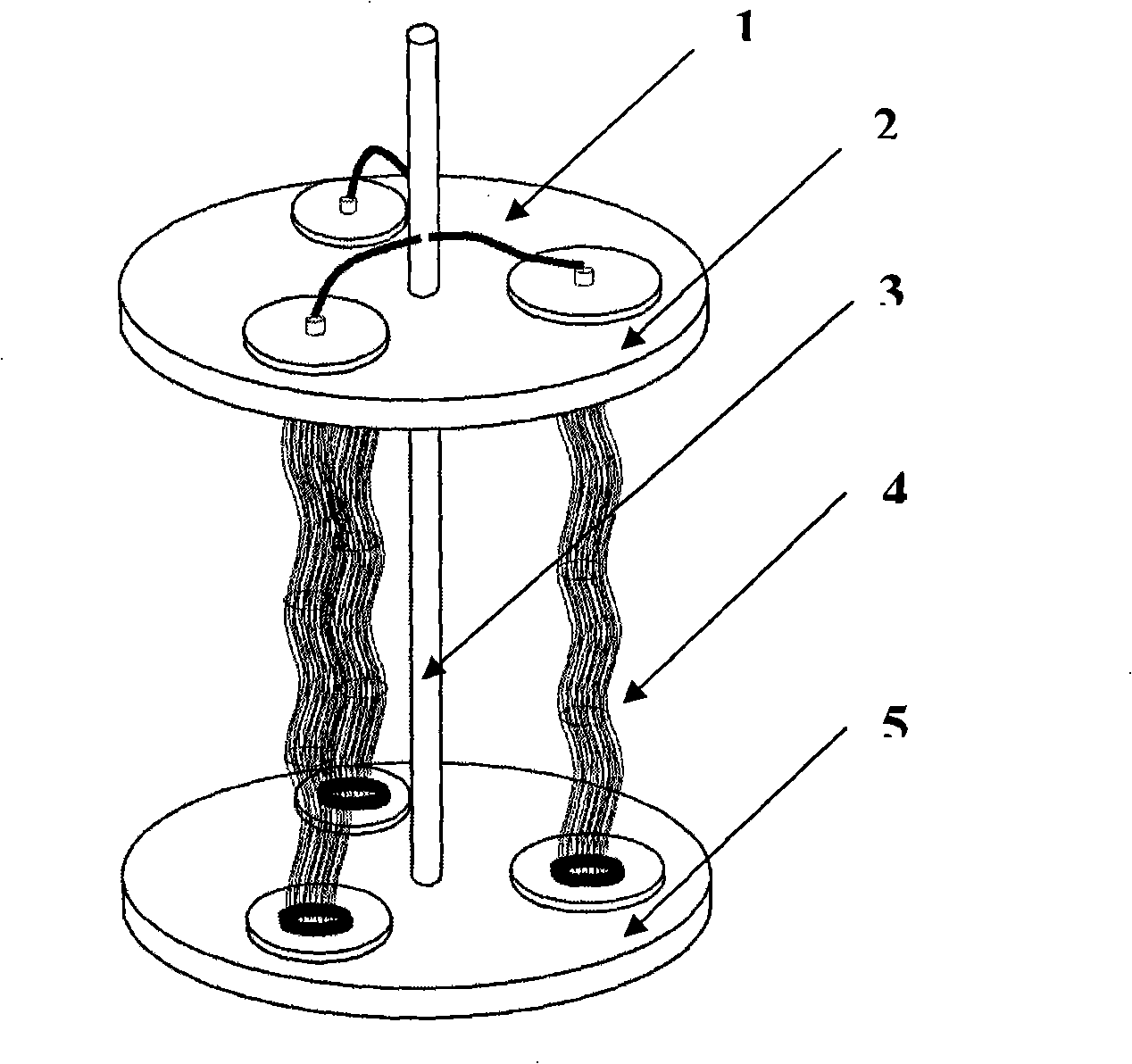

[0042] Three bundled hollow fiber membrane devices are used in the rotary bubble-free membrane oxygenation module 13, please refer to figure 2 , the hollow fiber membrane material is polypropylene, the outer diameter is 450 μm, the wall thickness is 40-50 μm, the membrane pore size is 0.1-0.2 μm; the porosity is 40-50%, the bubble point is greater than 0.5Mpa, and the gas flux is greater than 0.05cm 3 / cm 2 ·s·cmHg, the effective length of the membrane filament is 40cm, and the effective area of the membrane is 3m 2 , intermittent exhaust every 1min for 5s, the speed is 20 rpm, the effective volume of the activated sludge aeration tank is 70L, the test water is deoxygenated water, the dissolved oxygen concentration is close to zero, and the air supply is air. The test conditions and results are as follows:

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com