Method of treating coal gas effluent and coking effluent using diatomite and active sludge

A technology for activated sludge and coking wastewater, applied in water/sludge/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0006] Embodiment 1: This embodiment consists of the following processes: (1) inject waste water into the bioreactor, then add activated sludge and diatomaceous earth for aeration; (2) pass the waste water mixture through the secondary Sedimentation tank for mud-water separation, diatomaceous earth together with activated sludge in the secondary sedimentation tank for mud-water separation, together with the sludge back to the diatomite-activated sludge reactor. The dosage of diatomite is 300-3000mg / L, and the dosage of diatomite is preferably 2000mg / L; the diatomite is natural diatomite, artificially purified diatomite or surface modified diatomite , wherein the surface modification includes inorganic salt impregnation modification and medium-high temperature (100-800°C) sintering modification; the diatomaceous earth is added to the bioreactor in the form of wet solution addition or direct addition using dry injection equipment Add; the COD value of the waste water when it ent...

specific Embodiment approach 2

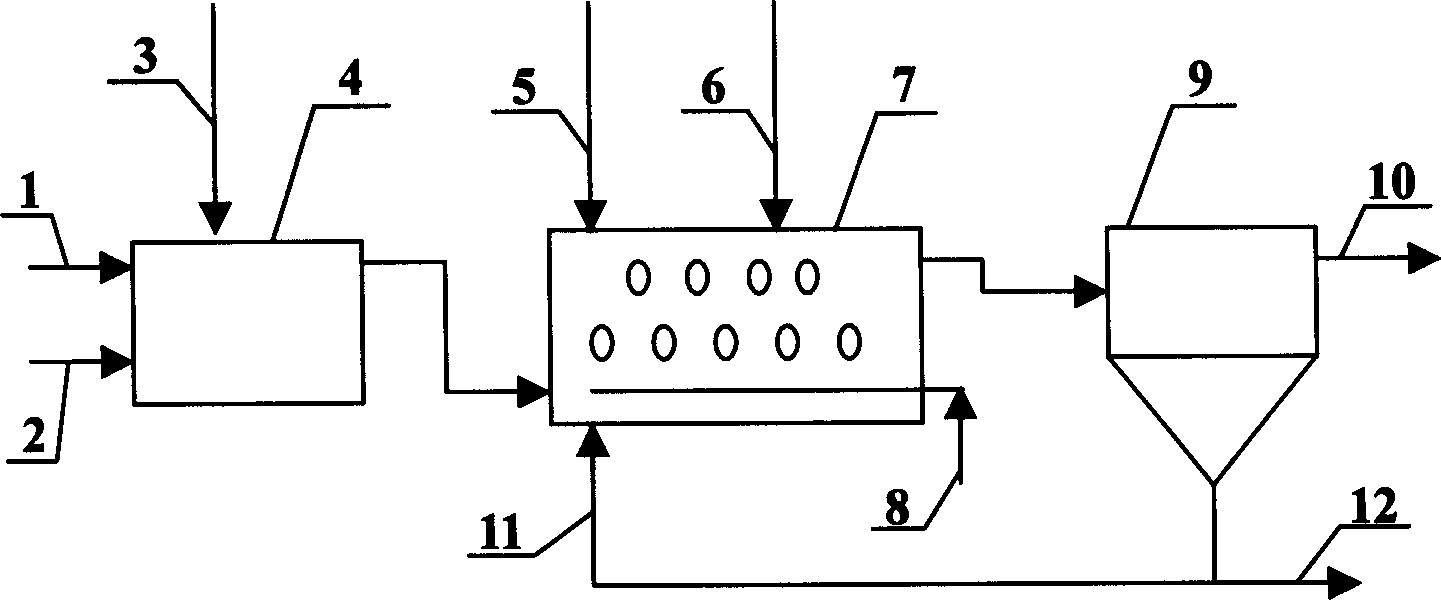

[0007] Specific implementation mode two: the following combination figure 1 The present embodiment is described in detail. This embodiment is achieved in the following way: a. Inject gas or coking waste water (generally waste water after ammonia steaming and dephenolization pretreatment) into the regulating tank with a certain flow rate, and then inject dilution water in a certain proportion (dilution water can use coarsely filtered river water, domestic sewage, etc.), so that the COD concentration of the wastewater in the adjustment tank is 800-3600mg / L, and the preferred range is 1800-2600mg / L; b, due to the high concentration of ammonia in the wastewater , the pH of the mixed water in the adjustment tank is relatively high, and a small amount of sulfuric acid, phosphoric acid and other acid agents need to be added to control the pH between 6.5 and 7.5; Oxygen aeration to form an aerobic biochemical environment, then add a certain amount of phosphorus, calcium, magnesium and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com