Preparation method of polymer-based nano composite ultrafiltration membrane

A nanocomposite and ultrafiltration membrane technology, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of low utilization rate of nanomaterials, easy agglomeration of inorganic nanomaterials, etc., and achieve fast oil-water mass transfer and anti-pollution. Powerful, even-textured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

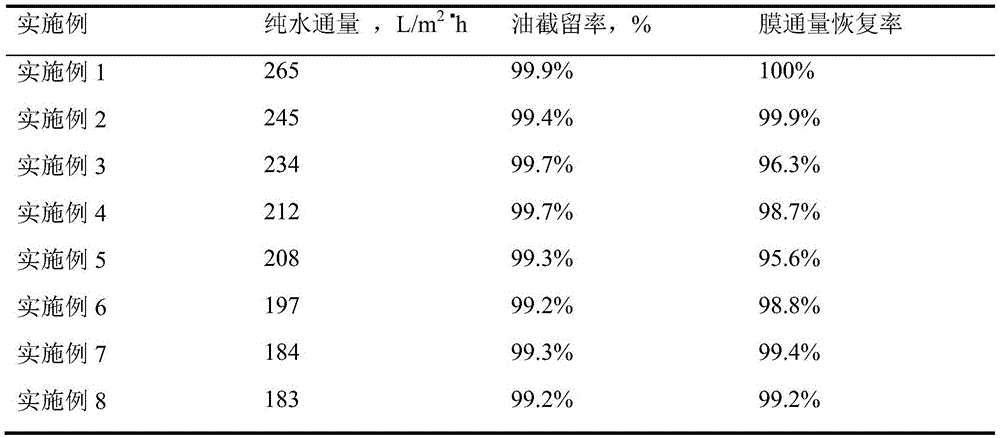

Embodiment 1

[0034] (1) Based on 100 parts of casting solution, take 20 parts of polyvinylidene fluoride powder and dissolve in 70 parts of dimethylacetamide solvent, add 10 parts of polyvinylpyrrolidone porogen, stir evenly, and defoam and mature Finally, the traditional phase transformation method is used to allow the casting solution to stand, gel, and scrape the membrane to synthesize polyvinylidene fluoride ultrafiltration membranes;

[0035] (2) The polyvinylidene fluoride ultrafiltration membrane that step (1) obtains is added to the KMnO containing the NaOH of mass fraction 10% and mass fraction 5%. 4 The activation reaction is carried out in the mixed solution, and the activation reaction time is 48h;

[0036] (3) the activated polyvinylidene fluoride ultrafiltration membrane obtained in step (2) is placed in a mass fraction of 30% NaHSO 3 Soak in the solution for 6 hours, and then wash with deionized water until the effluent is clear to obtain a modified polyvinylidene fluoride ...

Embodiment 2

[0040] Other conditions of this instance are the same as embodiment 1, and the difference is:

[0041] In step (1), the polyvinylidene fluoride is 35 parts, the solvent is 60 parts of dimethylformamide, and the porogen is 5 parts of polyethylene glycol;

[0042] In step (2), the mass fraction of NaOH in the mixed solution is 30%, KMnO 4 The mass fraction is 20%, and the activation reaction time is 29h;

[0043] The bisulfite solution adopted in the step (3) is that the mass fraction is 10% NaHSO 3 solution, soaking time is 1h;

[0044] The metal oxide precursor solution adopted in step (4) is a zirconium oxychloride solution with a mass fraction of 2%;

[0045] In step (5), the mass fraction of NaOH solution is 5%, and the polymer-based nanocomposite ultrafiltration membrane is prepared after in-situ deposition, washing and drying.

Embodiment 3

[0047] Other conditions of this instance are the same as embodiment 1, and the difference is:

[0048] In step (1), the polyvinylidene fluoride is 35 parts, the solvent is 40 parts of dimethyl sulfoxide, and the porogen is 25 parts of polyvinyl alcohol;

[0049] In step (2), the mass fraction of NaOH in the mixed solution is 5%, KMnO 4 The mass fraction of is 10%, and the activation reaction time is 6h;

[0050] The bisulfite solution that adopts in step (3) is the KHSO of 15% that massfraction is 3 Solution, soaking time is 3h;

[0051] The metal oxide precursor solution adopted in step (4) is a manganese nitrate solution with a mass fraction of 40%;

[0052] In step (5), the mass fraction of NaOH solution is 5%, and the polymer-based nanocomposite ultrafiltration membrane is prepared after in-situ deposition, washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com