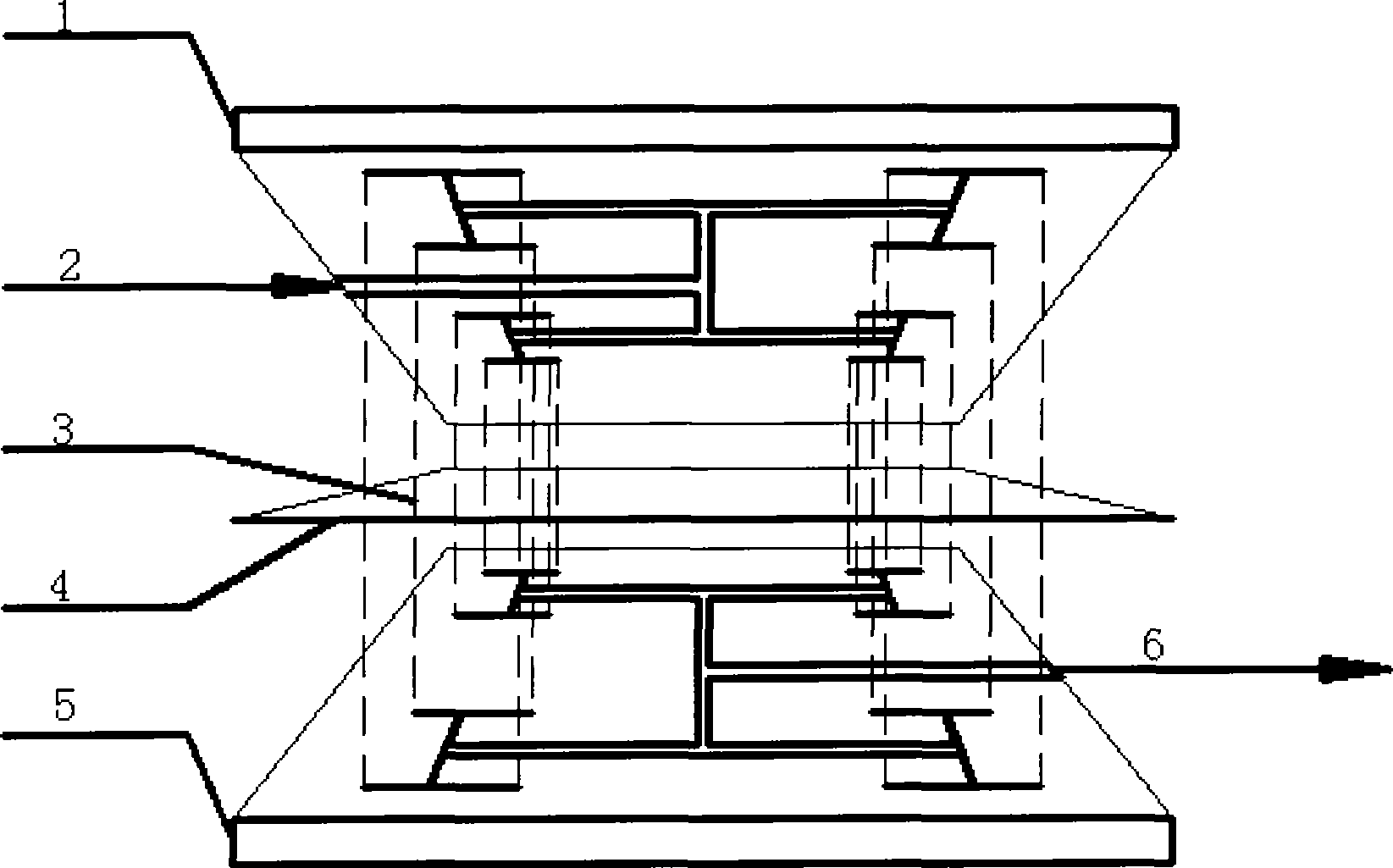

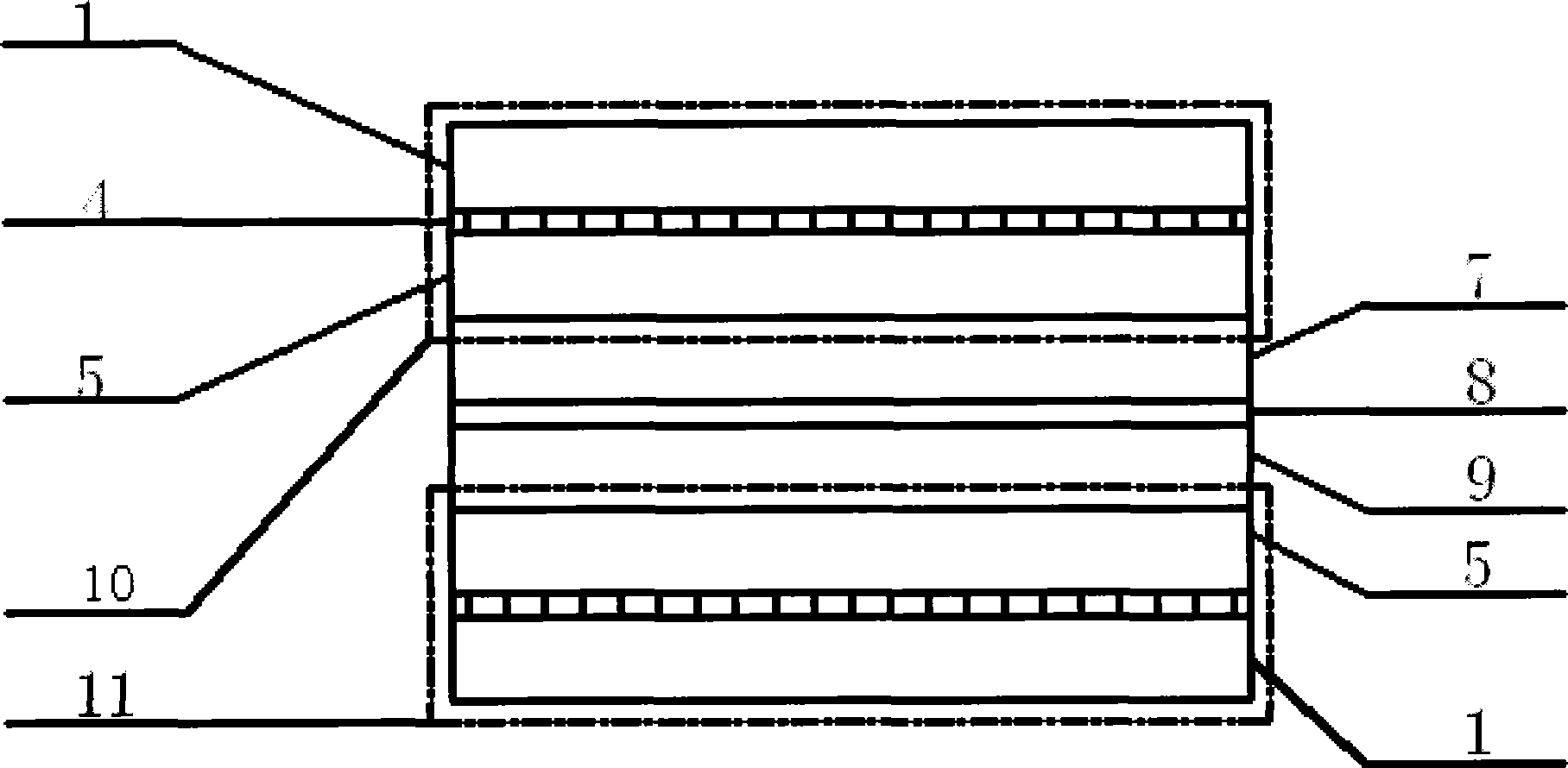

Fractal micro-channel bipolar plate used in proton exchange membrane fuel cell and processing method thereof

A proton exchange membrane and fuel cell technology, which is applied in fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of insufficient application of catalysts, unbalanced actual performance of membrane electrodes, and increased concentration polarization, etc. problems, to achieve the effect of facilitating the discharge of waste heat, improving fuel utilization, and reducing concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

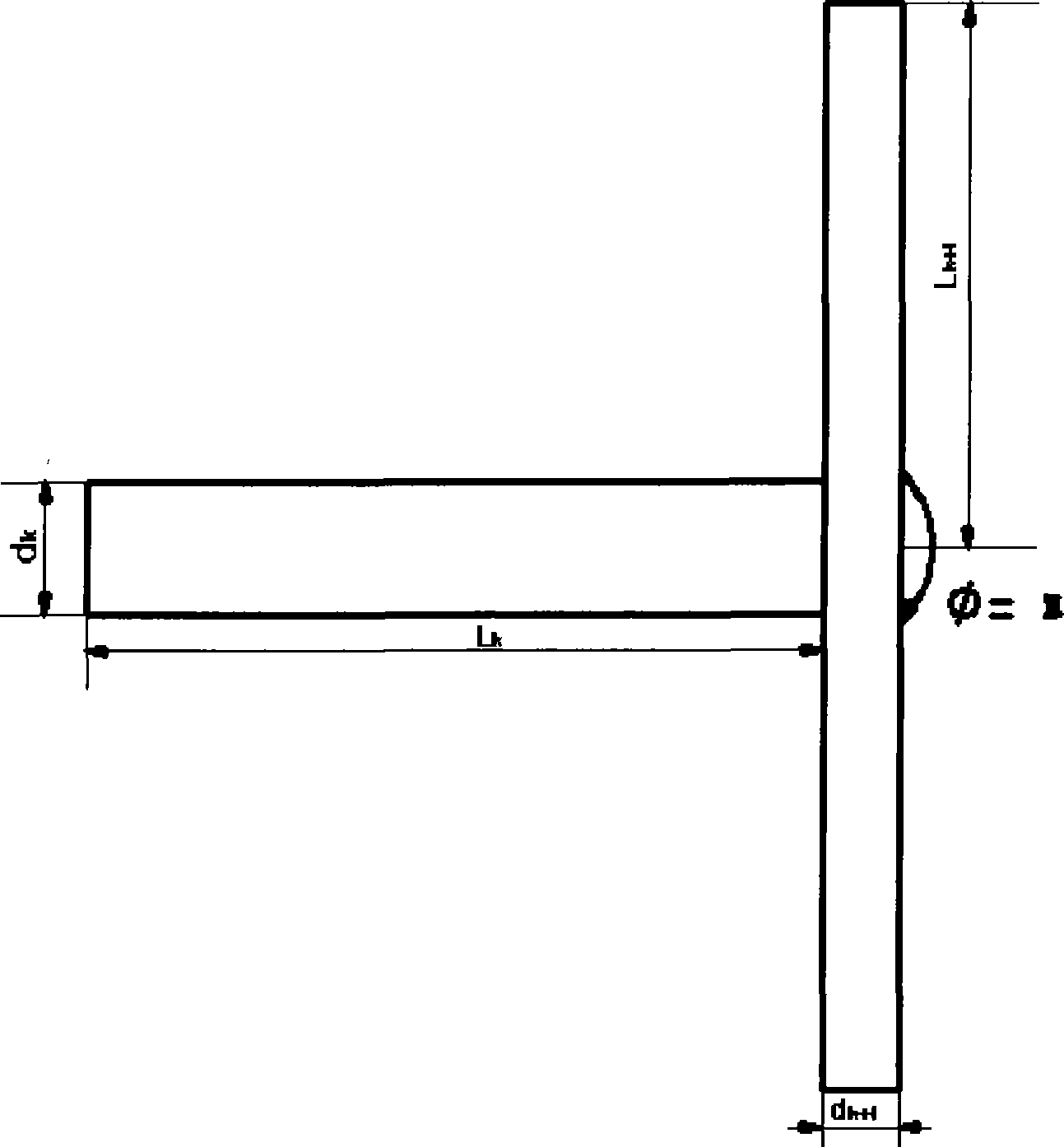

Embodiment 1

[0040] 316L stainless steel with a size of 50mm×50mm×0.2mm and a small resistivity is selected as the raw material of the upper and lower flow field plates. The surface is cleaned chemically or electrochemically, and the fractal microchannel structure protective layer is processed by photolithography technology. The size of the protective layer is the same as that of the flow field plate, and the initial hydraulic diameter d of the fractal microchannel structure 1 =200μm, initial length L 1 =50mm, the number of layers is n=20, and the hydraulic diameter of the nth layer is d n = d 1 N -n / 3 =200×2 -20 / 3 =1.97μm, channel length L n =L 1 N -n / 2 =50×2 -20 / 2 = 48.8 μm. The material of the protective layer is a material that cannot be damaged by the acidic corrosion solution. The protective layer processed with a fractal microchannel structure is firmly attached to the surface of the flow field plate, and etched at a temperature of 65°C with an etchant. The etchant formula i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com