Method of ultrasound-enhanced supercritical extraction of oil sludge

An ultrasonic strengthening and supercritical technology, which is applied in chemical instruments and methods, petroleum industry, sludge treatment, etc., can solve the problems of high emulsification degree of oil sludge, low extraction efficiency, long extraction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

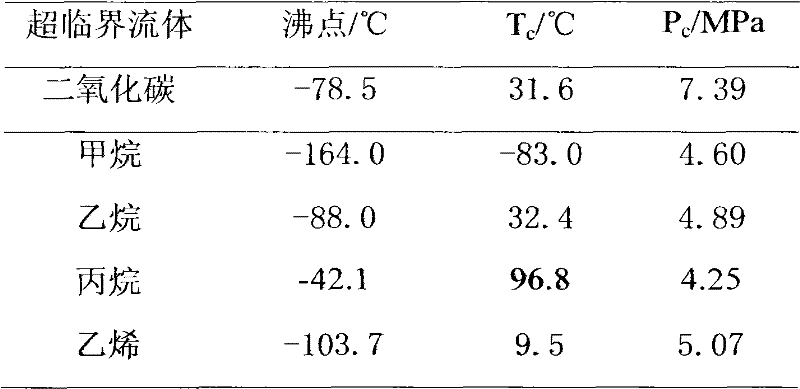

[0025] The specific embodiment of the present invention is described by taking oil sludge at the bottom of a refinery oil tank as an example. Oil sludge contains 65 wt% of oil, 18 wt% of water, and the rest is solid matter. Select CO 2 as a supercritical extractant. The ultrasonic power density is 100W / L, the frequency is 20kHz, and the irradiation mode is 6s / 6s (ultrasonic continuous irradiation time / ultrasonic intermittent time). The consumption of extractant and oil sludge is 30ml / g (oil sludge raw material).

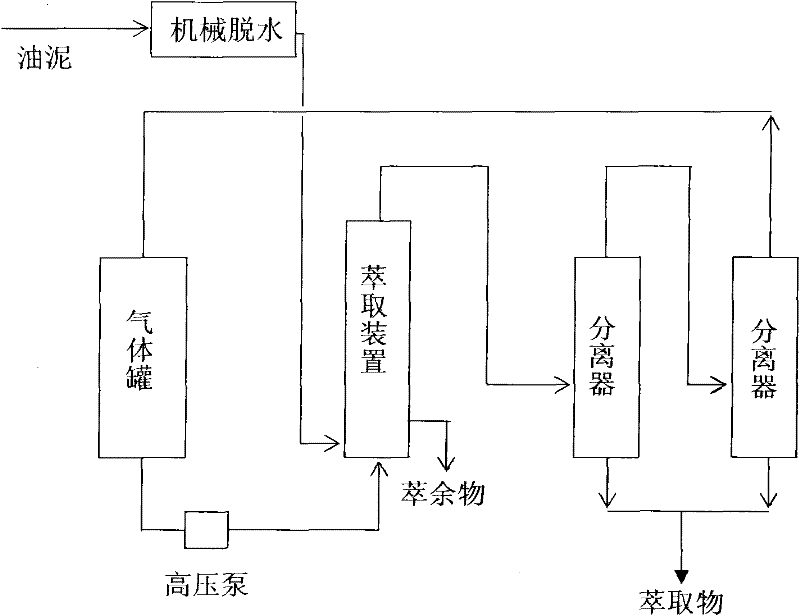

[0026] The oil sludge is dehydrated by mechanical stirring and then sent to the supercritical extraction kettle. The ultrasonic strengthening method adopts a built-in plug-in type. The ultrasonic transducer is directly placed in the extraction tank. The ultrasonic generator transmits the electric energy converted into ultrasonic frequency to the transducer, and then the transducer converts the electric energy into ultrasonic mechanical energy. From storage tank (...

specific Embodiment 2

[0027] The specific embodiment of the present invention is described by taking oil sludge at the bottom of a refinery oil tank as an example. Oil sludge contains 65% oil, 18% water, and the rest is solid matter. Ethane was chosen as the supercritical extractant. The extraction temperature is 30-100°C, the extraction pressure is 5-8MPa, the amount of extractant and sludge is 40ml / g (sludge raw material), and the extraction time is 2.5h. The ultrasonic power density is 80W / L, the frequency is 20kHz, and the irradiation mode is 6s / 6s (ultrasonic continuous irradiation time / ultrasonic intermittent time). The technical process is the same as in Example 1, and the extraction rate of oil sludge is 95%-99% (mass).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com