Preparation method and application of magnetic core-hollow porous molecular imprinting polymer satellite assembly for macrolide antibiotics

A macrolide, molecular imprinting technology, applied in the field of analytical chemistry pretreatment, can solve the problems of laborious pretreatment procedures, reduced extraction efficiency, lack of selectivity, etc., and achieves fast mass transfer, large adsorption capacity, and adsorption The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1. A method for preparing a magnetic core-hollow porous molecularly imprinted polymer satellite assembly of macrolide antibiotics

[0030] (1) Step 1, Fe 3 O 4 Preparation of @polyDA particles: add 2~6g FeCl 3 ·6H 2 O and 0.5~3g sodium citrate dihydrate are dissolved in 50~100mL ethylene glycol, and then 3~6g sodium acetate are added and stirred. Then, the obtained mixture was sealed in a stainless steel autoclave and heated at 200°C for 10-20h to obtain Fe 3 O 4 NPs. Weigh 10~60mg Fe 3 O 4 NPs were dispersed in 10-20 mL of dopamine tris (Tris) solution (pH 6-9, 10mM Tris-HCl buffer), and stirred at room temperature for 6-15h. Separate the resulting product with a magnet, and then wash it several times to remove excess dopamine to obtain Fe 3 O 4 @polyDA particles.

[0031] (2) Step 2. Synthesis of hollow porous imprinting material: weigh 15-90 mL of acetonitrile and 2-30 mL of methanol to form a mixed solvent. Weigh 0.2-1.3 mmol of template molecules and dissolve ...

Embodiment 2

[0033] Example 2. For the analysis of Fe in macrolide antibiotics 3 O 4 @polyDA-HPMIPs adsorbent effect verification

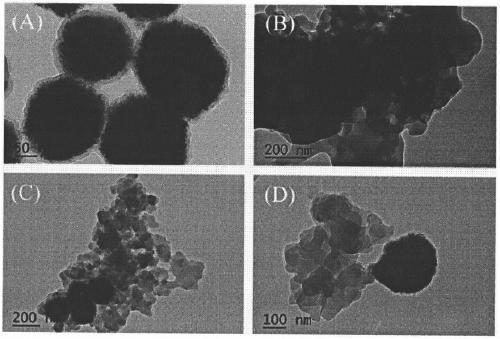

[0034] (1)Fe 3 O 4 @polyDA(A), HPMIPs(B) and Fe 3 O 4 The electron microscope picture of @polyDA-HPMIPs(C)(D) is as follows figure 1 What you see. figure 1 A nearly spherical Fe with an average size of about 210nm can be seen 3 O 4 Nanoparticles in Fe 3 O 4 The surface of the nanoparticles has a film with a thickness of about 12nm, indicating that the polyDA film was successfully deposited on Fe by oxidative polymerization. 3 O 4 Nanoparticle surface. figure 1 B shows that HPMIPs with a hollow mesoporous structure have been successfully synthesized. Because of their larger specific surface area and pore volume, they have higher adsorption capacity and adsorption rate. figure 1 C and figure 1 D shows Fe 3 O 4 The surface of @polyDA is connected with HPMIPs, indicating that HPMIPs are successfully grafted on Fe 3 O 4 On the surface of @polyDA, a magnetic core-hollow p...

Embodiment 3

[0037] Example 3. Fe 3 O 4 @polyDA-HPMIPs material testing commercially available honey

[0038] (1) Weigh 2~5g honey in a polypropylene centrifuge tube, add 5~10mL macrolide antibiotic buffer of different concentrations, and use 10~20mL K 2 HPO 4 The analytes were extracted with buffer (20mM, pH 8.0), vortexed and centrifuged, and the supernatant was further purified by Dispersive Solid Phase Extraction (DSPE) and spiked for analysis.

[0039] (2) Put the sample solution into a polypropylene centrifuge tube, add 10-20mg Fe 3 O 4 After @polyDA-HPMIPs, shake at constant temperature for 10-20min. Fast separation of Fe with macrolide antibiotics under strong magnetic field 3 O 4 @polyDA-HPMIPs, rinse with deionized water. Finally, use a methanol solution of 1 to 5% ammonia to treat Fe by ultrasound 3 O 4 @polyDA-HPMIPs to elute captured analytes. After desorption, pass the eluted fraction through N 2 The flow is evaporated to dryness, and then reconstituted with 200 μL of mobile phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com