Emulsifying-type aerobic fermentation tank

A technology of aerobic fermentation and emulsifier, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc. Cost increase and other issues, to achieve the effect of reducing equipment cost and maintenance costs, saving energy and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

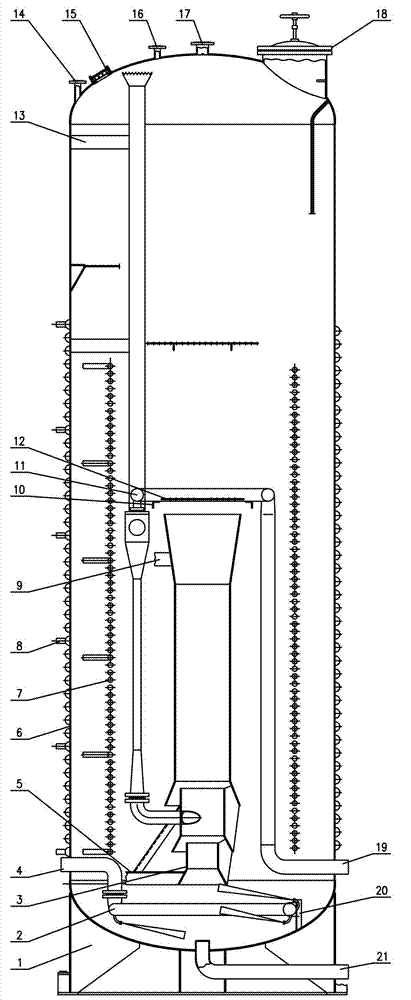

[0027] Such as figure 1 In the emulsified aerobic fermentation tank shown, the tank body 6 is a long cylindrical vertical airtight container, the tank body 6 and the skirt 1 are fixedly connected into one body, and the top of the tank body 6 has a feed inlet 14, a sight glass 15, Strain nutrient solution inlet 16, exhaust port 17, manhole 18 and other interfaces, the bottom of the tank body 6 has a fermentation liquid outlet pipe 21 extending outside the tank, and the outer wall of the tank body 6 is fixedly connected with a special-shaped pipe band (or jacket) for replacement Heater 8, tank body 6 has tank body inlet pipe 4 and fermentation liquid inlet pipe 19, and inner coil heat exchanger 7 is arranged in tank body 6.

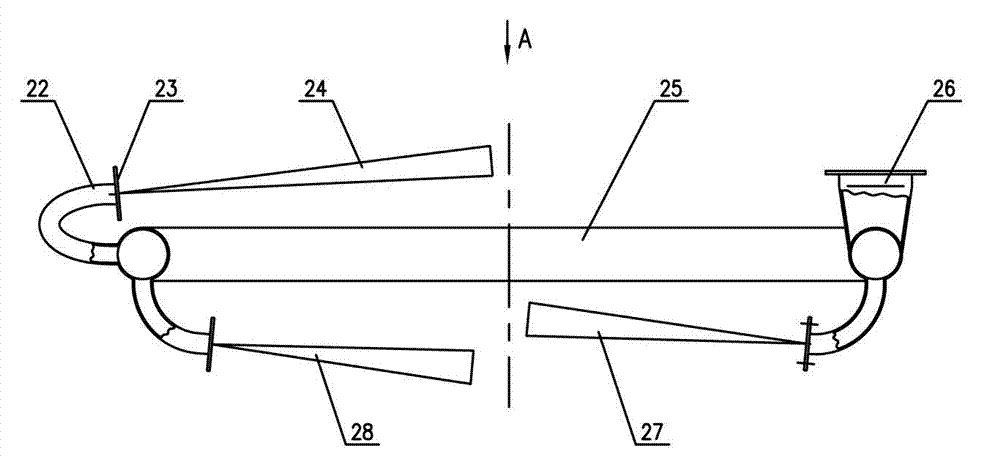

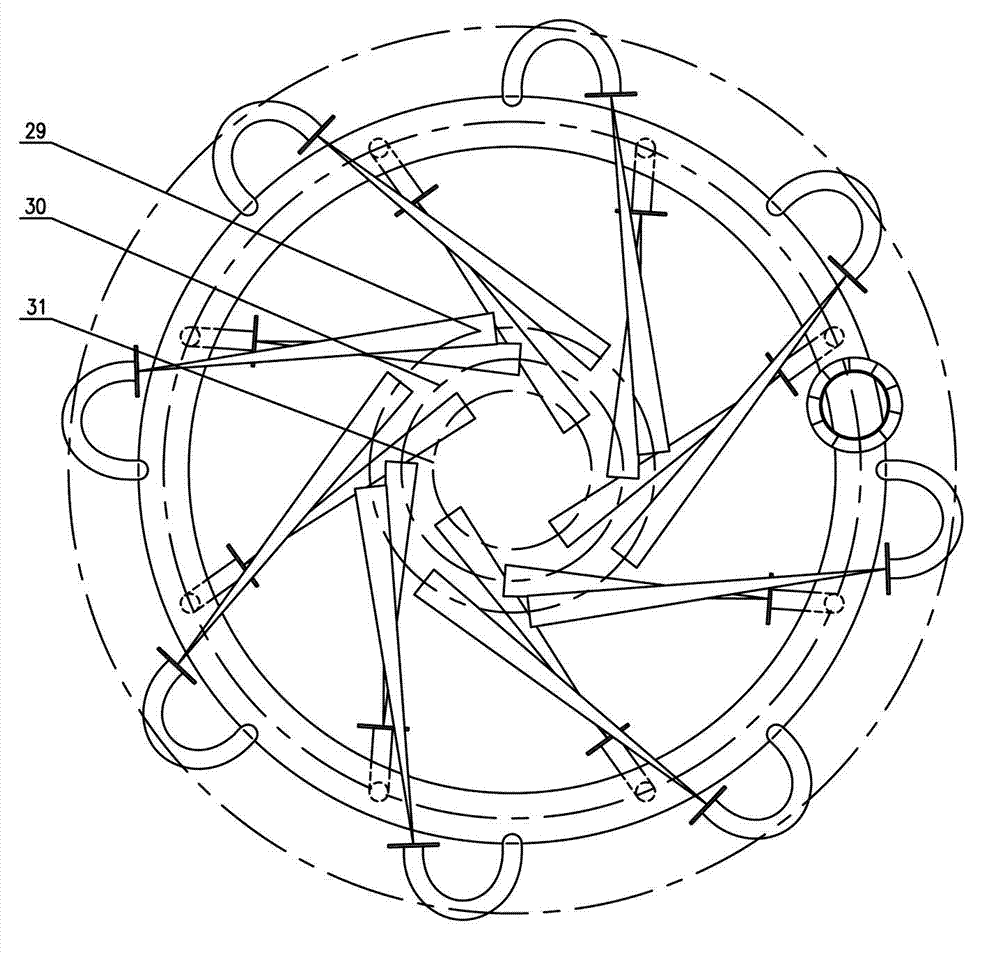

[0028] Such as Figure 2-3 As shown, there is a gas-liquid jet emulsification device 2 at the bottom of the tank body 6, and the gas-liquid jet emulsification device 2 consists of a plurality of elbows 22, a plurality of flanges 23, a ring pipe 25, an air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com