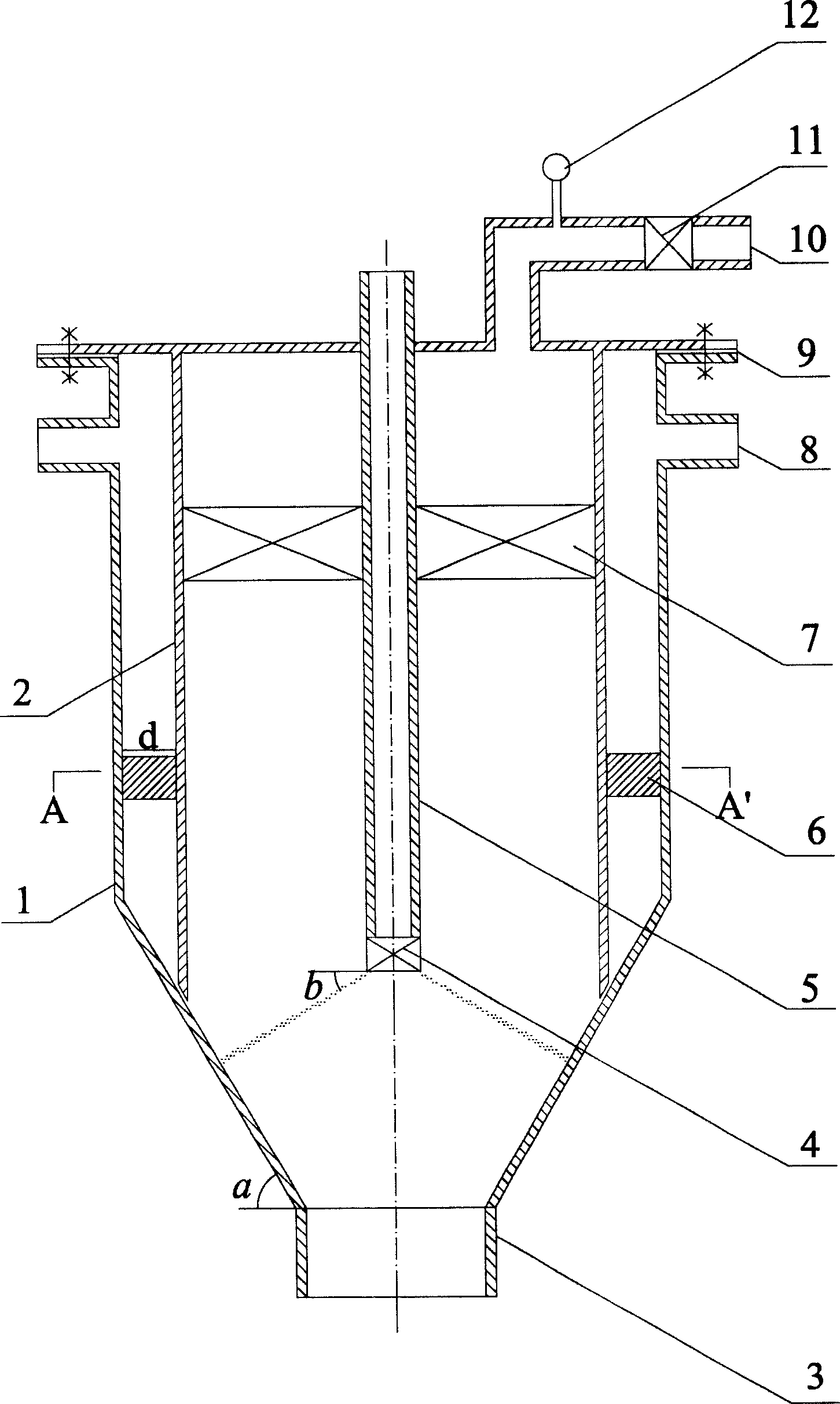

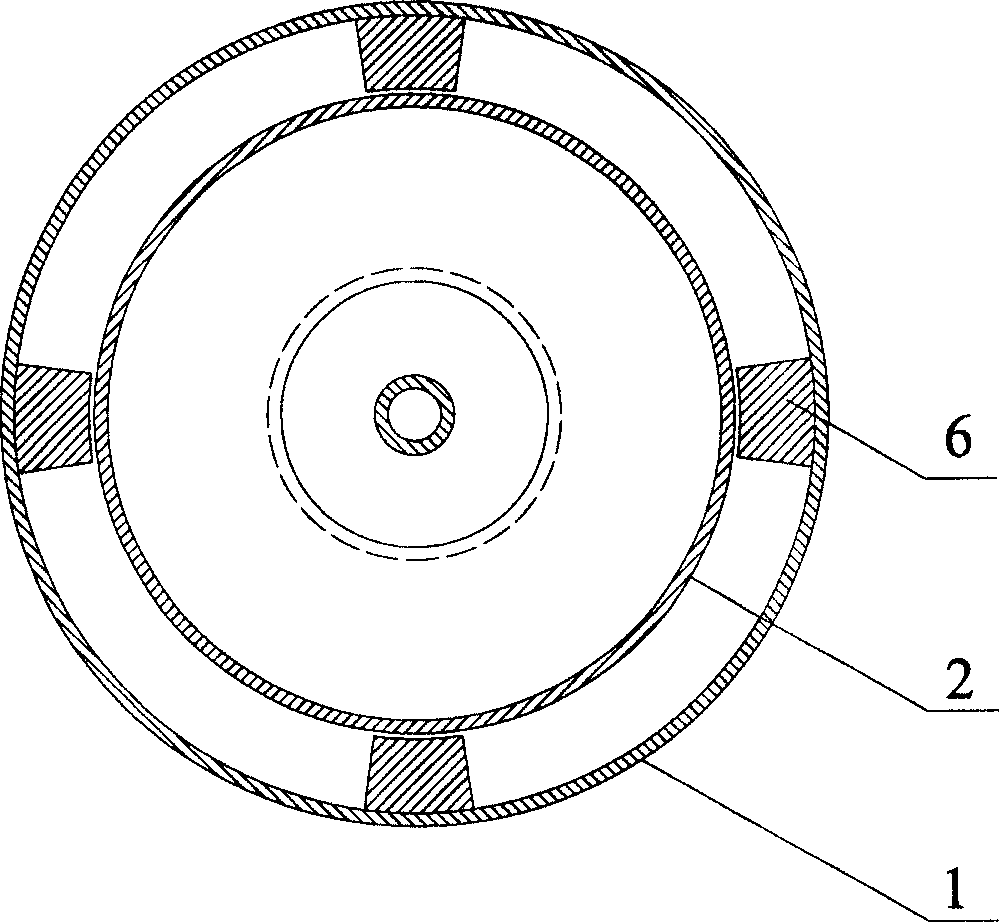

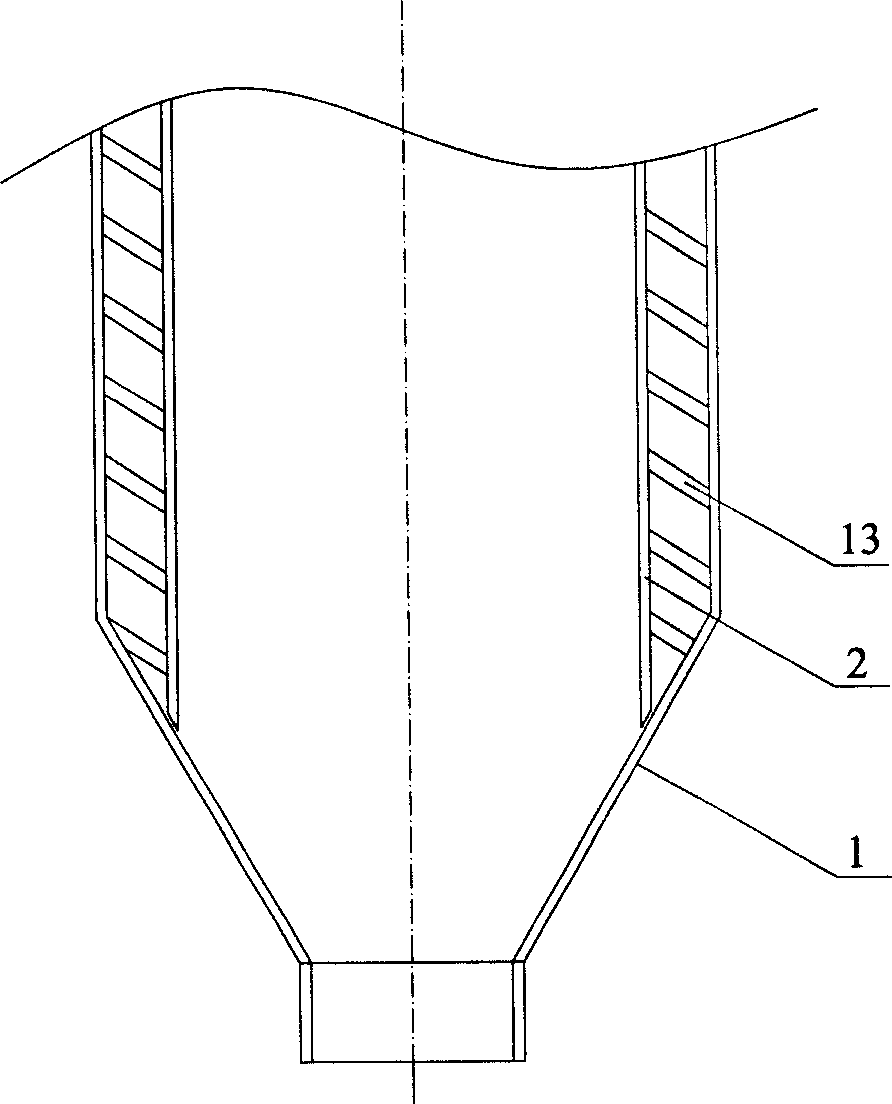

Liquid-liquid fast-mixing reactor

A mixed reactor and reactor technology, applied in the chemical method of reacting liquid with liquid, chemical/physical/physicochemical nozzle reactor, chemical instrument and method, etc., can solve the problems of small equipment operation flexibility, clogging, jetting, etc. Reactor structure is complex and other problems, to improve quality, reduce energy consumption, increase the effect of operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Laser-induced fluorescence technology is an advanced quantitative evaluation method for evaluating liquid-liquid mixing effects. Its main principle is to use some fluorescent substances (such as rhodamine B or rhodamine 6G) to generate visible light waves of a certain wavelength under laser-induced excitation. Then use a high-speed digital camera to continuously take pictures of the flow field. When the concentration of rhodamine in the solution is below a certain value, the concentration of the rhodamine solution has a linear relationship with the gray value of the corresponding picture pixel, so the flow field can be obtained by analyzing the pictures taken of the flow field. The concentration distribution of fluorescent substances in the field, and then analyze the mixing of liquid and liquid. Evaluate the mixing effect of the liquid-liquid fast mixing reactor of the present invention with this evaluation method, the model that laser adopts Dantec company to produce ...

Embodiment 2

[0039] In the chemical production process, it is often accompanied by complex liquid-liquid two-phase rapid parallel competition reactions or parallel-series competition reactions. The initial mixing effect of the liquid-liquid two-phase greatly affects the final product distribution, product yield and quality. . The common parallel competition reaction system is the competition reaction between acid-base-ester, the instantaneous chemical reaction between acid and base, and the fast hydrolysis reaction of ester under alkaline conditions, when the initial mixing of liquid-liquid two phases When the effect is high, the contact between the two phases is basically at the molecular level. At this time, the time scale of the reaction between the acid and the base is smaller than the time scale of the liquid-liquid mixing, and the acid-base neutralization reaction mainly occurs in the liquid phase. The hydrolysis reaction of the ester under basic conditions does not occur substantial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com