Fast fluidized calcining process

A calcination process and fluidization technology, which is applied in the field of rapid fluidized calcination process, can solve the problems of material heat transfer, poor mass transfer, low production capacity of a single equipment, and reduced product conversion rate, etc., to achieve fast heat transfer rate, The effect of single line with large capacity and uniform reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

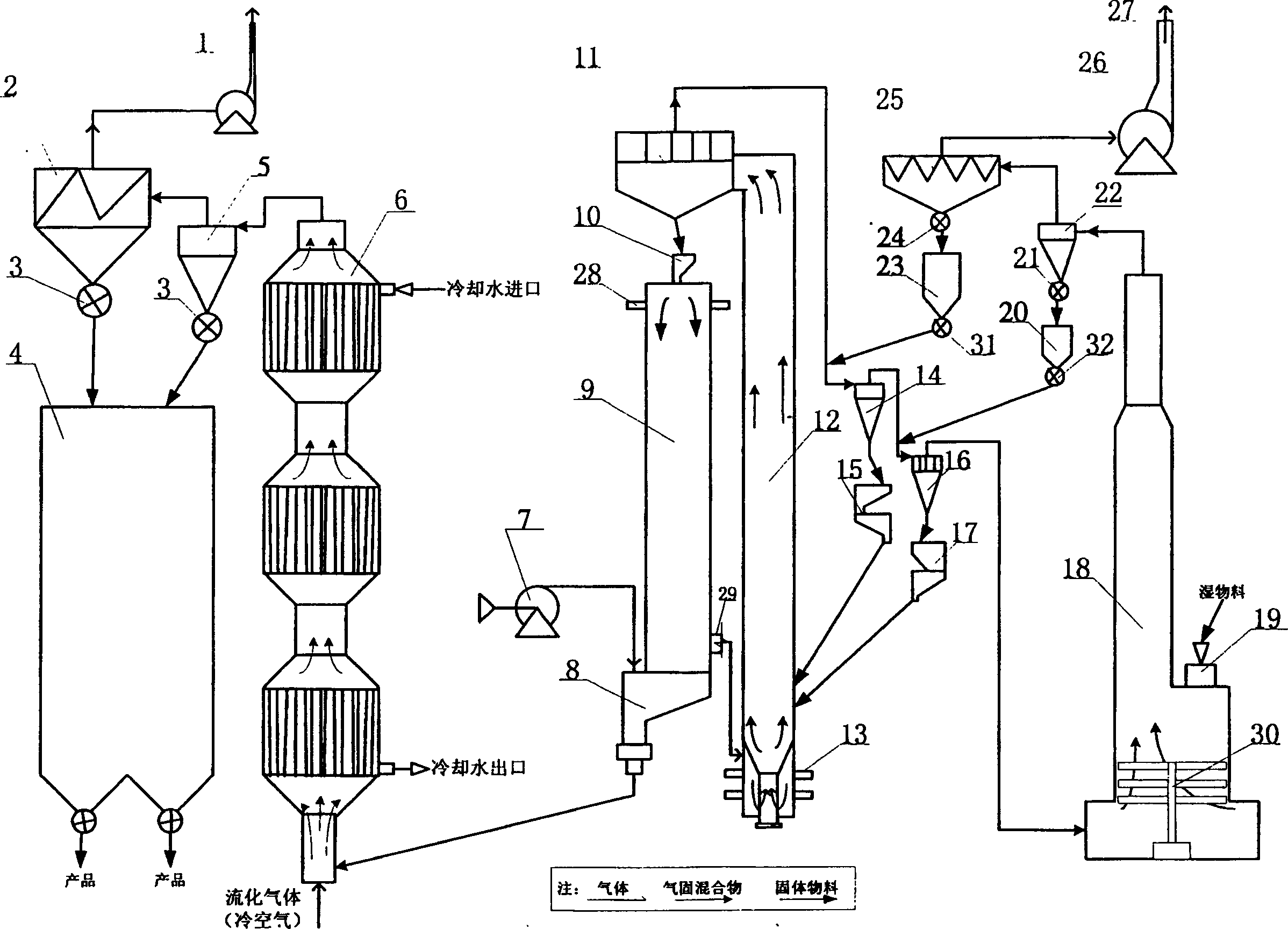

[0029] Such as figure 1 Shown, be the process flow diagram of rapid fluidized calcination process of the present invention, equipment wherein has: cooling induced draft fan 1, cooling bag dust collector 2, cooling feeder 3, product storehouse 4, cooling cyclone separator 5, Rapid fluidized cooler 6, cooling blower 7, cooling unloader 8, muffled moving bed calcination reactor 9, gas lock valve 10, high temperature gas-solid separator 11, rapid fluidized muffled calcined heating furnace 12, Burner burner 13, cyclone preheater 14, air lock valve 15, cyclone preheater 16, air lock valve 17, fast fluidized dryer 18, feeder 19, intermediate storage bin 20, feeder 21 , cyclone separator 22, intermediate storage bin 23, feeder 24, bag filter 25, drying induced draft fan 26, chimney 27, burner burner 28, flue gas outlet 29, stirring and crushing device 30, feeding Device 31, feeder 32; each part communicates with each other according to flow routine.

[0030] The muffled moving bed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com