Organic-inorganic coupling phase change material without leakage at normal temperature

A technology of phase change materials and composite materials, applied in the field of organic-inorganic coupling phase change materials, can solve problems such as liquid leakage, poor packaging, and reduced heat transfer rate of materials, and achieve fast heat transfer rate, low cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (2) Preparation of organic-inorganic coupling phase change materials

[0040] Weigh a certain amount of acrylamide as a polymerizable monomer, N,N-methylenebisacrylamide as a crosslinking agent, and polyvinylpyrrolidone as a co-emulsifier, put the three into the same beaker, and add 5mL of distilled water to the beaker , dissolve acrylamide into the water phase under ultrasound for later use. Take out the beaker containing the acrylamide aqueous solution and put it into a water bath for stirring, add the oil-in-water emulsifier Tween 85 into the water phase, stir for 10 minutes, then slowly and evenly add the molten organic phase cetyl alcohol into the water phase phase, under the joint action of emulsifier and co-emulsifier, continue stirring to make cetyl alcohol-in-water emulsion. Then add the sodium sulfate decahydrate / diatomite composite material into the cetyl alcohol-in-water emulsion, and after stirring evenly, quickly mix ammonium persulfate (oxidant) and N,N,...

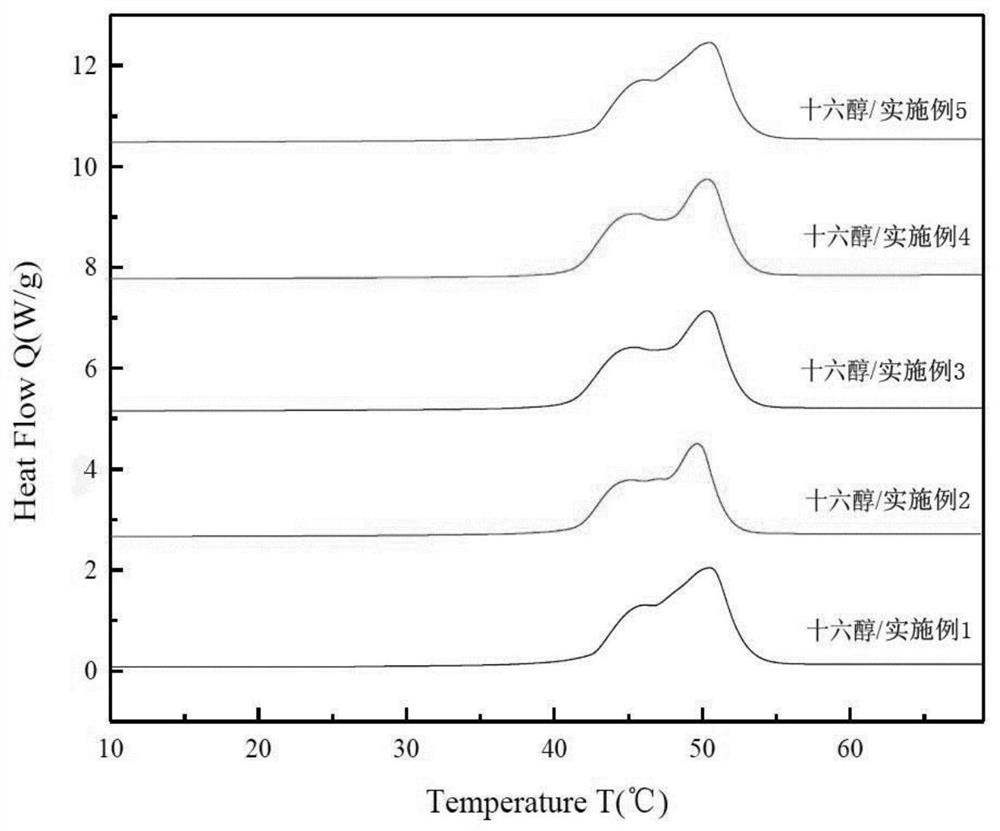

Embodiment 1

[0042] (1) Preparation of sodium sulfate decahydrate / diatomite composite material

[0043] According to the mass ratio of sodium sulfate decahydrate: diatomaceous earth = 4:1, weigh 4.00 grams of sodium sulfate decahydrate (SSD) and 1.00 grams of dried diatomaceous earth, mix them evenly and place them at 30 °C Dry it in a vacuum drying oven for 4 hours, and use vacuum impregnation and physical adsorption to adsorb the inorganic hydrated salt sodium sulfate decahydrate into diatomite with a porous structure. Put the prepared sodium sulfate decahydrate / diatomite composite phase change material into an oven at 30°C to dry for 6-8 hours, take it out after drying, grind and sieve, and make a sodium sulfate decahydrate / diatomite composite material as a spare .

[0044] (2) Preparation of organic-inorganic coupling phase change materials

[0045] Weigh 1.60 grams of acrylamide as a polymerization monomer, 0.40 grams of N,N-methylenebisacrylamide as a crosslinking agent, and 0.01 g...

Embodiment 2

[0047] The added quality of cetyl alcohol is 5 grams, and others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com