Method for manufacturing phase-change heat absorption swelling fire-retardant wood and swelling fire-retardant wood

A technology of intumescent flame retardant and manufacturing method, applied in the direction of wood processing, impregnating wood, manufacturing tools, etc., can solve the problems of rapid temperature rise, low fire efficiency, etc., to increase the time for fire rescue and escape, reduce fire losses, The effect of thermal insulation and oxygen insulation on wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

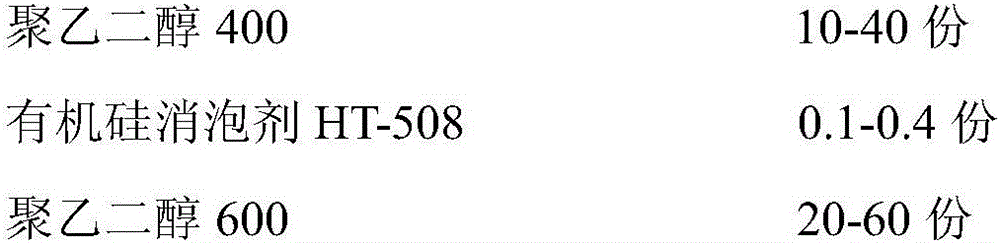

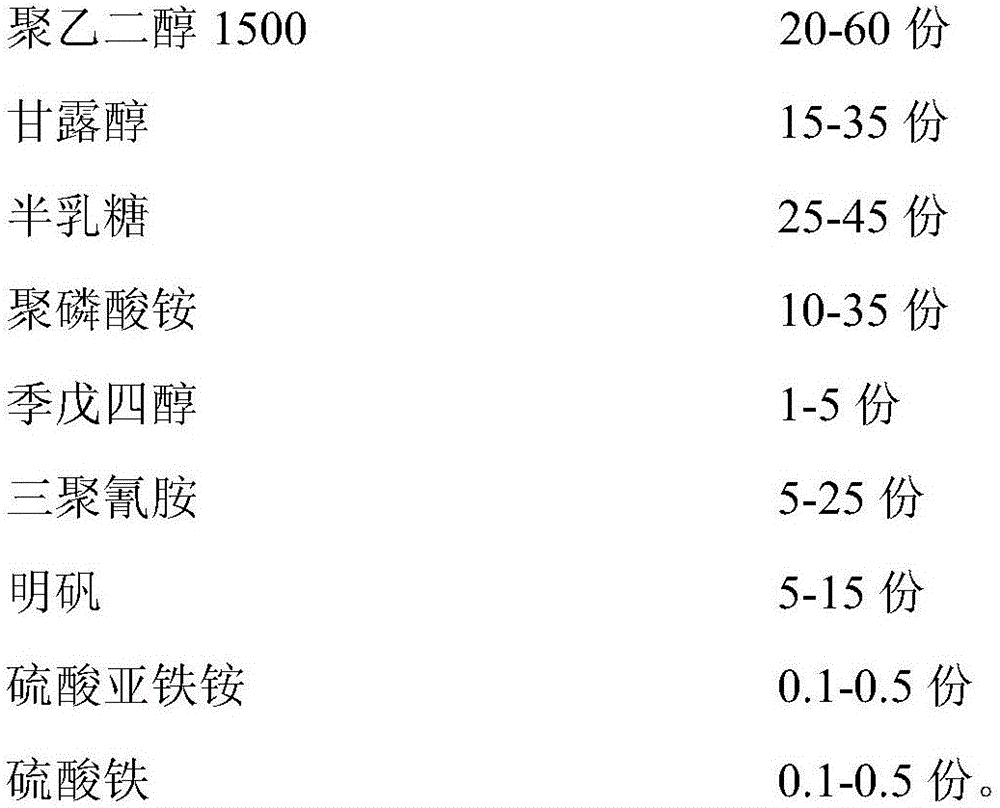

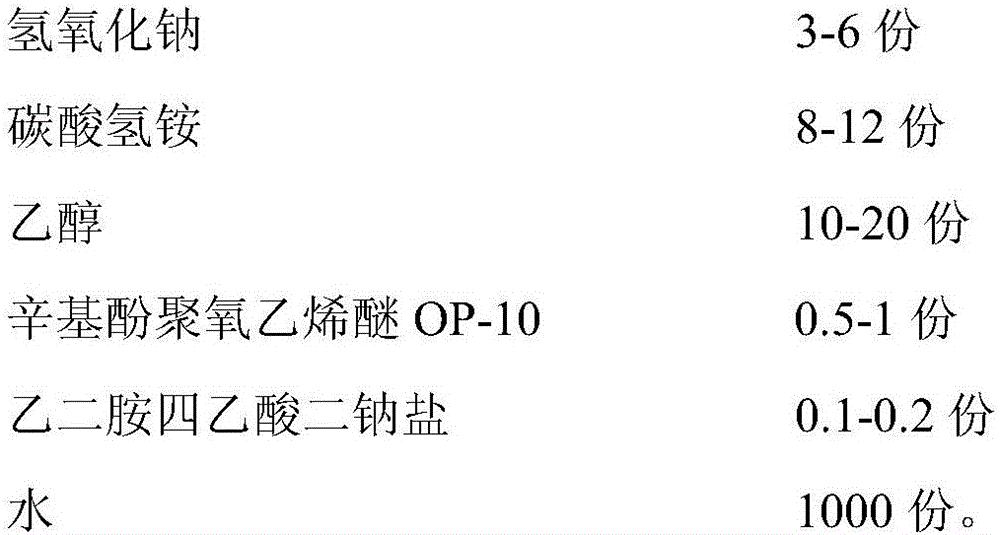

Embodiment 1

[0051] The invention discloses a method for manufacturing phase-change heat-absorbing expanded flame-retardant wood and an embodiment of the expanded flame-retardant wood. The phase-change heat-absorbing expansion flame-retardant wood is obtained by immersing solid wood components in a phase-change heat absorption expansion flame-retardant impregnating solution, drying, and then sanding and shaping and surface sealing protection treatment. The phase-change heat-absorbing intumescent flame-retardant wood can be used to make fire doors, vehicle and ship cabinets, furniture, floors, etc., and can effectively reduce fire occurrence and fire losses.

[0052] Its concrete manufacturing method comprises the following steps:

[0053] (1) Select poplar wood without rot, moth, stuttering, cracking and other defects as raw material, sawn and planed into a poplar board square of 450mm×60mm×16mm.

[0054] (2) the poplar board side prepared by step (1) is packed into the pretreatment tank,...

Embodiment 2

[0058] The invention discloses a method for manufacturing phase-change heat-absorbing expanded flame-retardant wood and an embodiment of the expanded flame-retardant wood. The phase-change heat-absorbing expansion flame-retardant wood is obtained by immersing solid wood components in a phase-change heat absorption expansion flame-retardant impregnating solution, drying, and then sanding and shaping and surface sealing protection treatment. The phase-change heat-absorbing intumescent flame-retardant wood can be used to make fire doors, vehicle and ship cabinets, furniture, floors, etc., and can effectively reduce fire occurrence and fire losses.

[0059] Its concrete manufacturing method comprises the following steps:

[0060] (1) Select poplar wood without rot, moth, stuttering, cracking and other defects as raw material, sawn and planed into a poplar board square of 450mm×60mm×16mm.

[0061] (2) Put the poplar board square prepared in step (1) into the pretreatment tank, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com