Patents

Literature

51results about How to "Smoke suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of coated halogen-free flame-retardant foamable polystyrene

InactiveCN102977402AAvoid fireWith flame retardant functionNon-macromolecular adhesive additivesMacromolecular adhesive additivesBenzoyl peroxideThermal insulation

The invention belongs to the field of expandable polystyrene heat insulating materials, and particularly relates to a preparation method of coated halogen-free flame-retardant foamable polystyrene. The method comprises the following steps: adding polyvinyl alcohol and tricalcium phosphate into deionized water, and evenly mixing to obtain a mixed solution A; adding ammonium polyphosphate, melamine polyphosphate or PNP intumescent flame retardant into styrene, and adding benzoyl peroxide to obtain a mixed solution B; adding the mixed solution B into the mixed solution A to react, and adding a foaming agent to react to obtain halogen-free flame-retardant foamable polystyrene granules; and adding the prepared granules into a phenol formaldehyde resin or melamine resin binding agent containing small amounts of alkali silicate water solution and smoke inhibitor to carry out coating, thereby finally obtaining the coated halogen-free flame-retardant foamable polystyrene granules. The coated halogen-free flame-retardant foamable polystyrene has the advantages of excellent thermal insulation and heat shielding properties, and outstanding flame retardancy and smoke inhibition property, and can be used a flame-retardant architectural thermal insulation material.

Owner:LIAONING TECHNICAL UNIVERSITY

Multi-functional microencapsulated additives for polymeric compositions

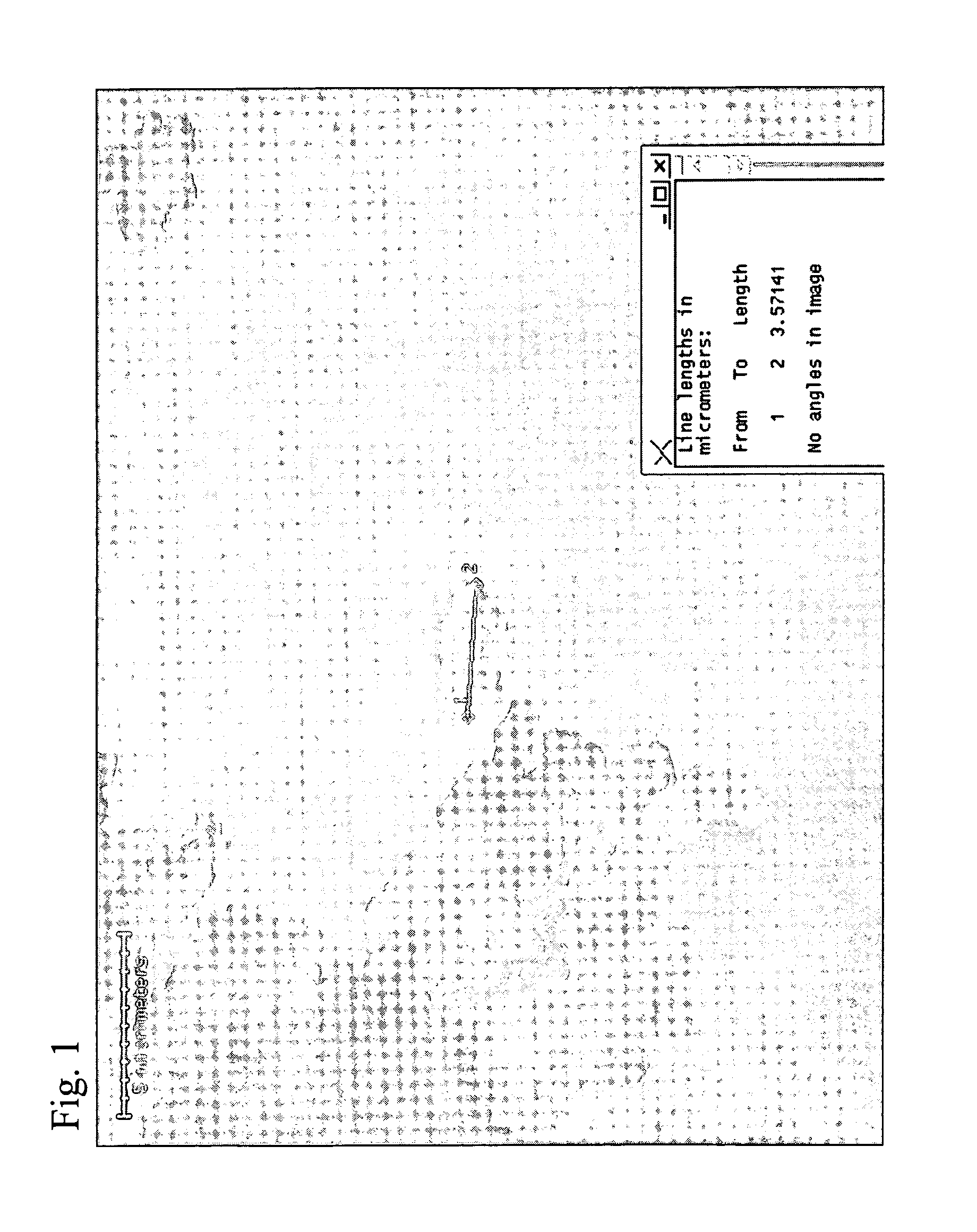

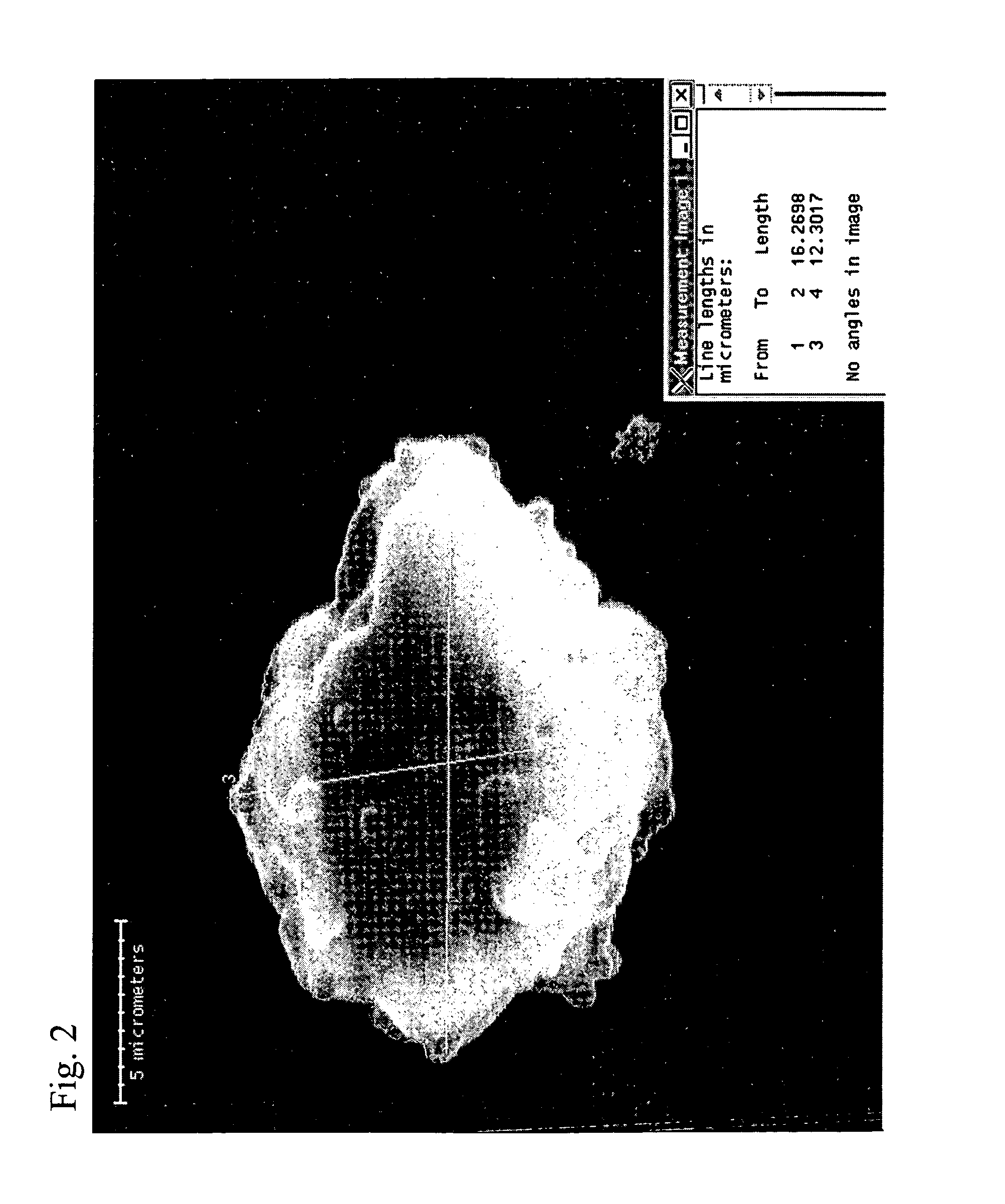

InactiveUS7005457B2Low thermal conductivitySmoke suppressionPharmaceutical product form changeCapsule deliveryMaterials sciencePolymer

Owner:OC FOAMULAR BOARD CO LTD +1

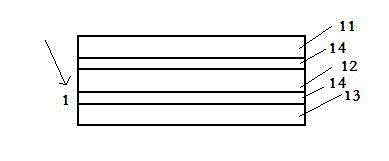

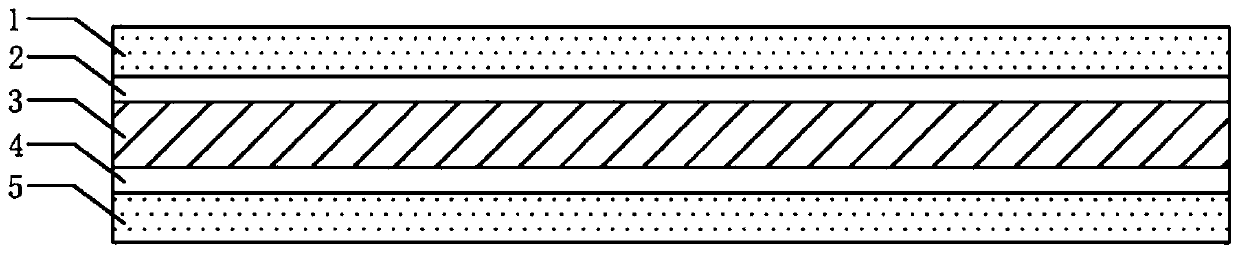

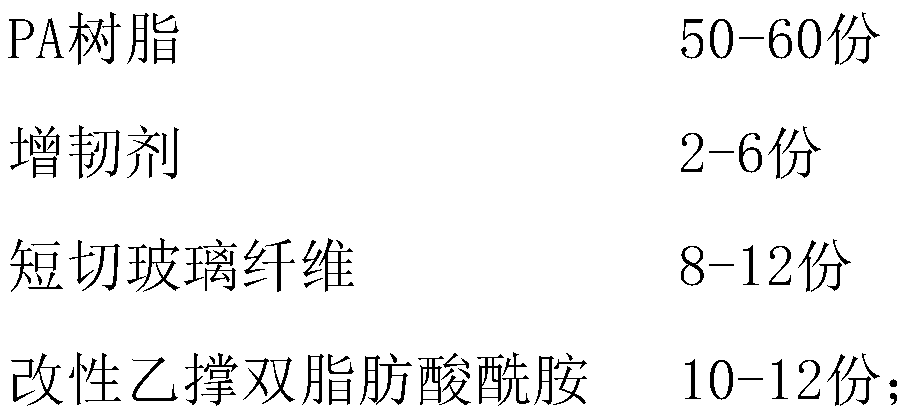

Formaldehyde purification inflaming retarding oriented strand board and manufacturing method thereof

The invention relates to a paint-free decorative overlay fitment board, in particular to a formaldehyde purification inflaming retarding oriented strand board and a manufacturing method thereof, and belongs to the wood processing industry. The formaldehyde purification inflaming retarding oriented strand board comprises a base material layer, an upper surface layer decorative film adhesive layer and a lower surface layer decorative film adhesive layer. The upper surface layer decorative film adhesive layer and / or the lower surface layer decorative film adhesive layer are immersed with an amino resin adhesive solution and a formaldehyde decomposition adhesive solution, the base material layer is an oriented strand board layer, the oriented strand board layer comprises an upper surface layer, a lower surface layer and a core layer shaving layer, wherein the glue mixing wood shavings on the upper and lower surface layers are longitudinally arranged in the fiber direction, the glue mixing wood shavings on the core layer shaving layer are transversely arranged in the fiber direction, an inflaming retarding layer is arranged between the lower surface shaving layer and the core layer shaving layer, and an inflaming retarding layer is arranged between the upper surface shaving layer and the core layer shaving layer. The manufacturing method of the paint-free decorative overlay fitment board comprises the steps of base material sanding, formaldehyde decomposition adhesive solution preparation, decorative film adhesive manufacturing, assembling and pressing and sticking. The formaldehyde purification inflaming retarding oriented strand board is realistic in effect, low in cost and good in formaldehyde purification effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

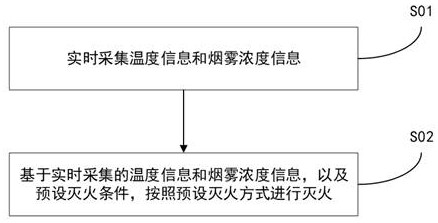

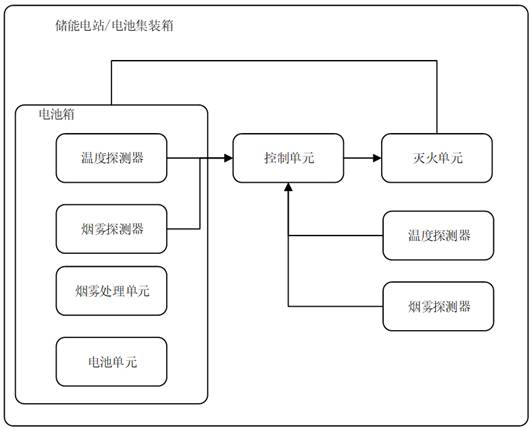

Fire extinguishing system and method for energy storage power station or battery container

InactiveCN112717306AInhibition of re-ignitionHigh decomposition temperatureFire rescueLithium-ion batteryFalse alarm

The invention discloses a fire extinguishing system and method for an energy storage power station or a battery container, and aims to improve a fire extinguishing system for a lithium ion battery fire in the energy storage power station and the container based on the thermal runaway combustion characteristic of a lithium ion battery and aiming at the condition that after open fire of the lithium ion battery is extinguished, re-combustion and thermal runaway spreading are generated, the detection of the thermal runaway and fire of the battery is optimized, and a liquid reburning inhibitor is introduced. Fire extinguishing can be conducted by considering the whole system and the fire of an ignition point, meanwhile, the possibility of false alarm can be effectively avoided, and high accuracy is achieved. Secondly, the liquid reburning inhibitor is introduced while a gas extinguishing agent is used in the fire extinguishing system, the gas extinguishing agent can effectively extinguish open fire generated by thermal runaway of the battery, the liquid reburning inhibitor can effectively inhibit reburning and smoke generation of the battery and thermal runaway spreading, and the safety coefficient is higher.

Owner:CHINA ELECTRIC POWER RES INST

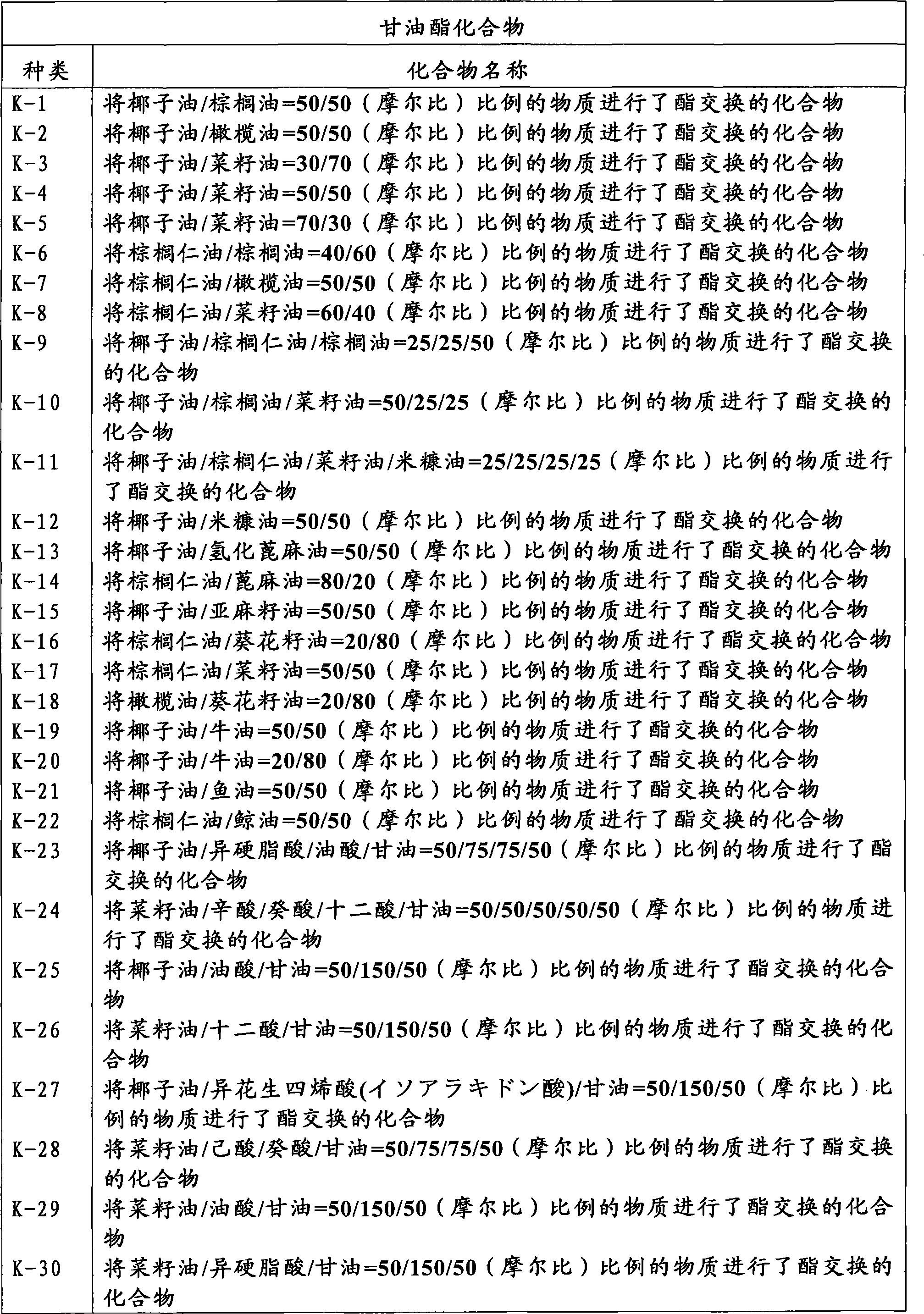

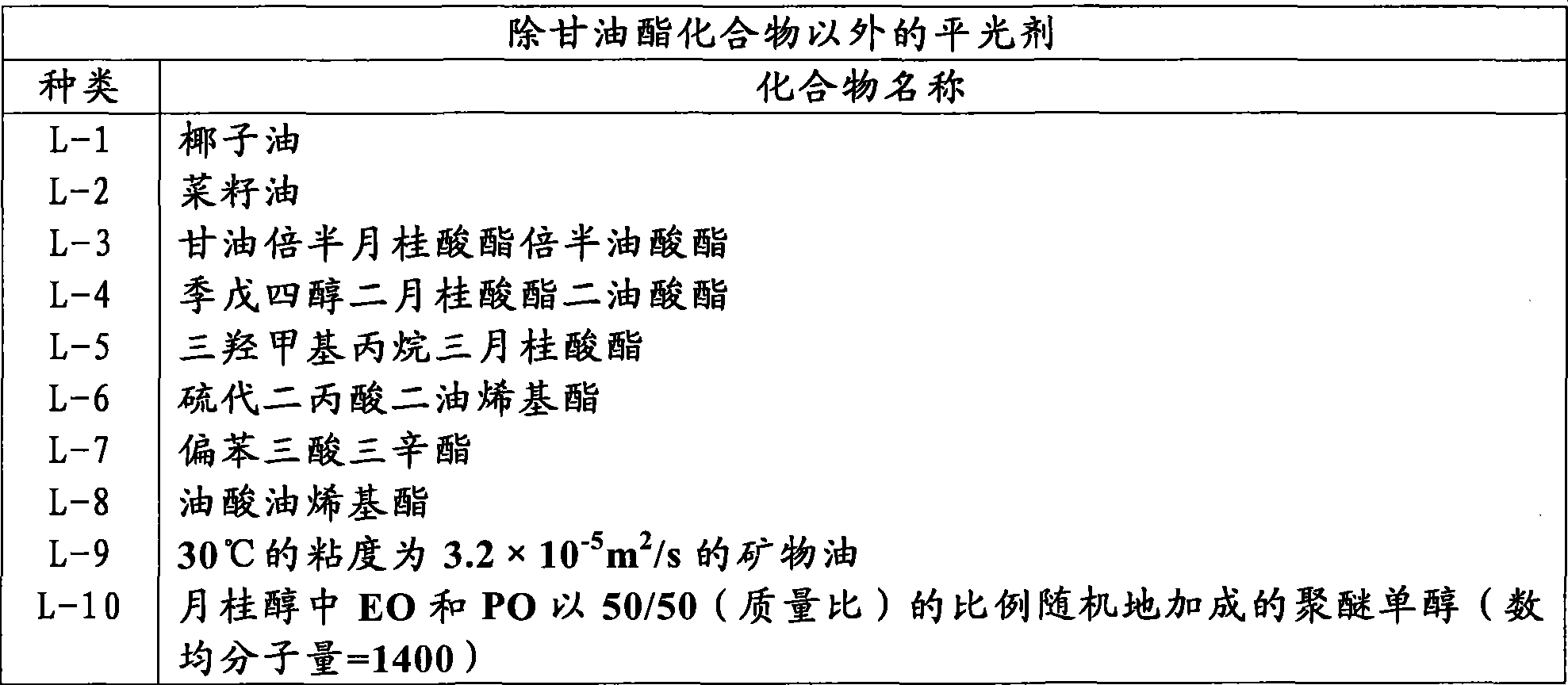

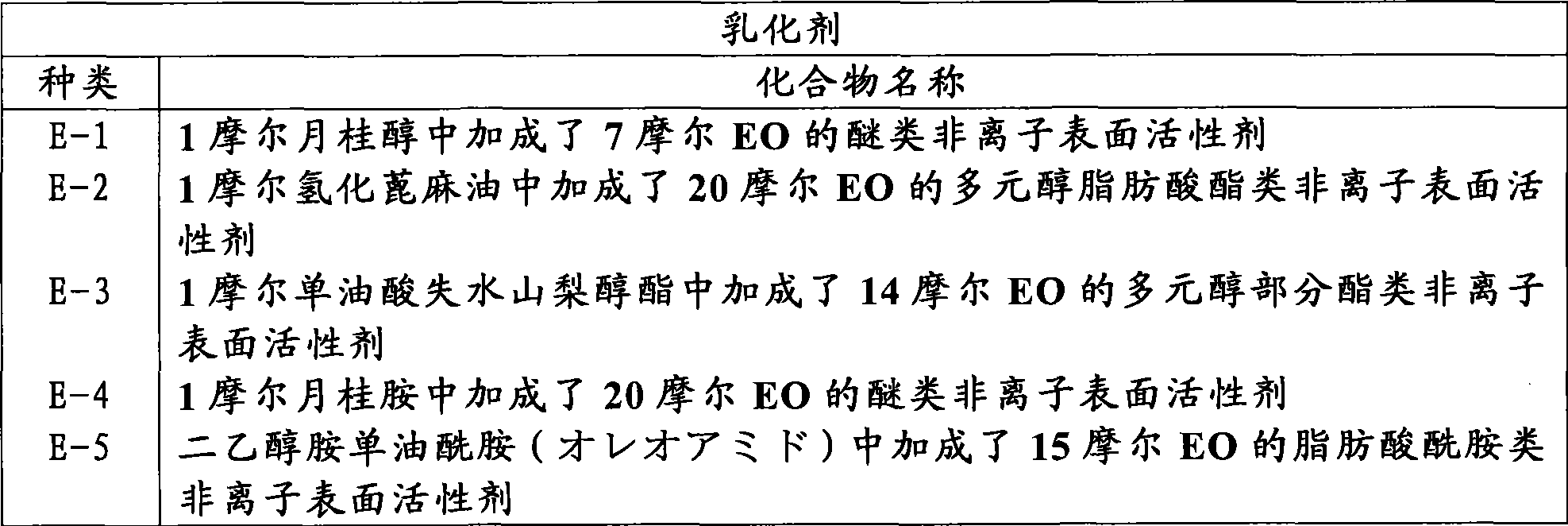

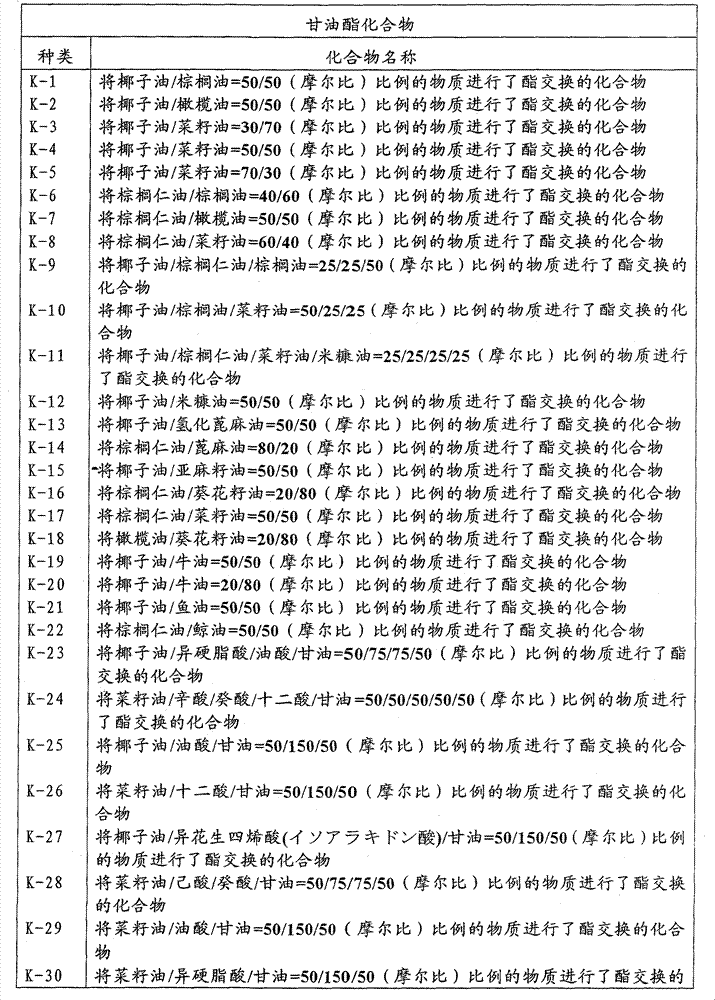

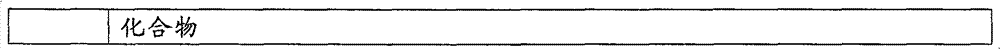

Treating agent for synthetic fibre, treating method for synthetic fibre and synthetic fibre

The present invention provides a processing agent which can restrain the generation of fine fur and tar oil and restrain the smoke generation when the synthetic fiber is executed with heat treatment in the rigorous high-temperature condition for further preventing the reduction of operability. The invention also provides a treating method using the treating agent and the synthetic fiber prepared by the treating method. The treating agent for synthetic fiber uses at least one object selected from 1) and 2): 1) a compound which is obtained by mixing at least two greases and heating in the presence of acid compound thereby executing random ester exchange, and 2) a compound which is obtained by heating the mixed grease, the aliphatic monocarboxylic acid and glycerol in the presence of acid compound thereby executing random ester exchange.

Owner:TAKEMOTO YUSHI KK

Method for manufacturing phase-change heat absorption swelling fire-retardant wood and swelling fire-retardant wood

ActiveCN106738149AAvoid spreadingIt has the function of filling and densifyingWood treatment detailsPressure impregnationSolid woodCarbon layer

The invention discloses a method for manufacturing phase-change heat absorption swelling fire-retardant wood and the swelling fire-retardant wood. The manufacturing method includes the following steps that the wood is processed and manufactured according to the dimensions required, so that a solid wood component is obtained; the solid wood component is subjected to degreasing and duct dredging pretreatment, and accordingly the pretreated solid wood component can be obtained; the pretreated solid wood component is put into phase-change heat absorption swelling fire-retardant steeping liquor for conducting vacuum pressure impregnation treatment, and then drying is performed, so that the solid wood component filled with a phase-change heat absorption swelling fire-retardant material is obtained; the solid wood component filled with the phase-change heat absorption swelling fire-retardant material is subjected to sanding shaping and surface closing protective treatment, and accordingly the phase-change heat absorption swelling fire-retardant wood is obtained. The swelling fire-retardant wood obtained through the manufacturing method achieves phase-change heat absorption in the heating process of the wood and forms a swelling foam carbon layer under the fire condition, the change of fires can be lowered and fire losses are reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

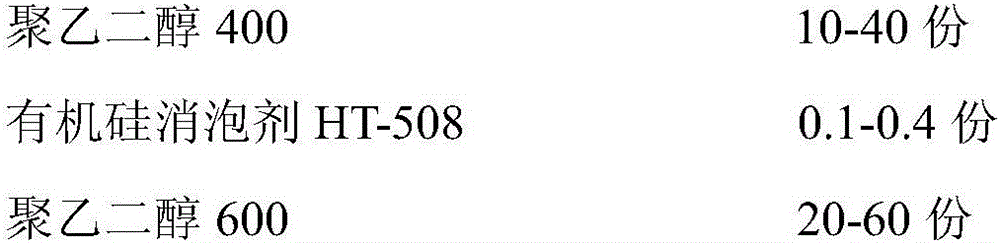

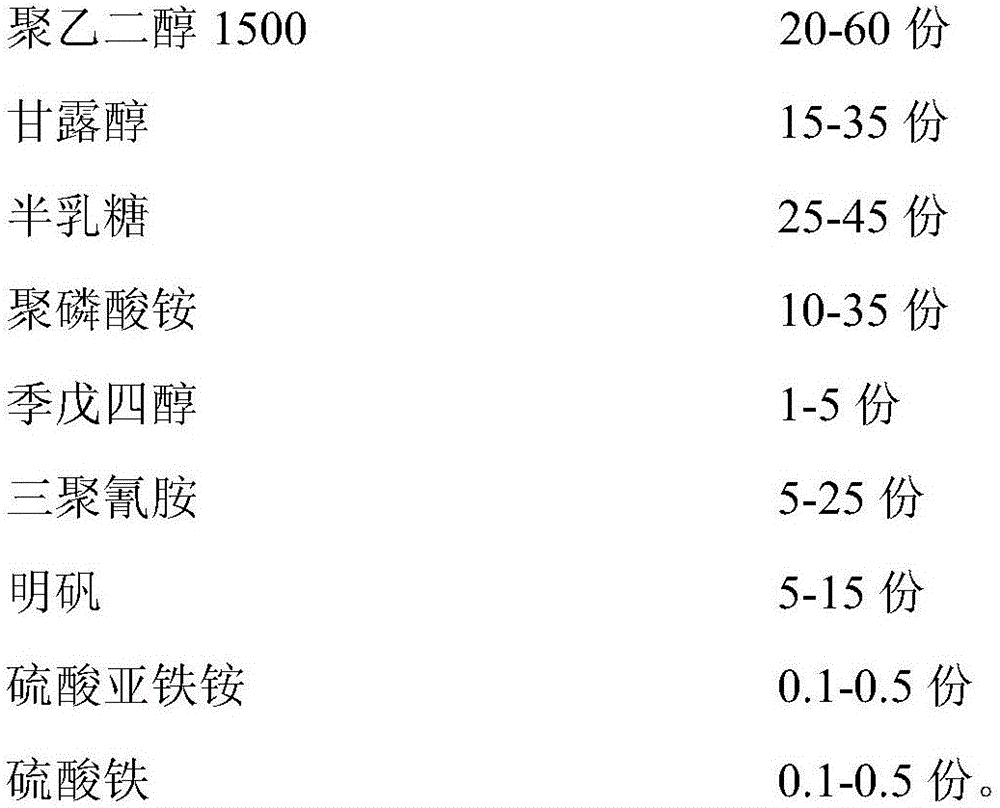

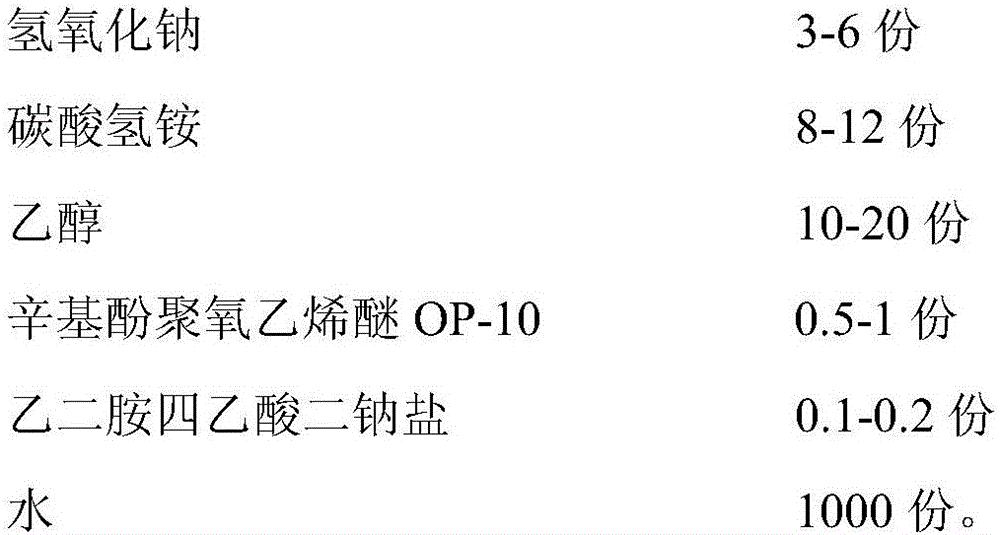

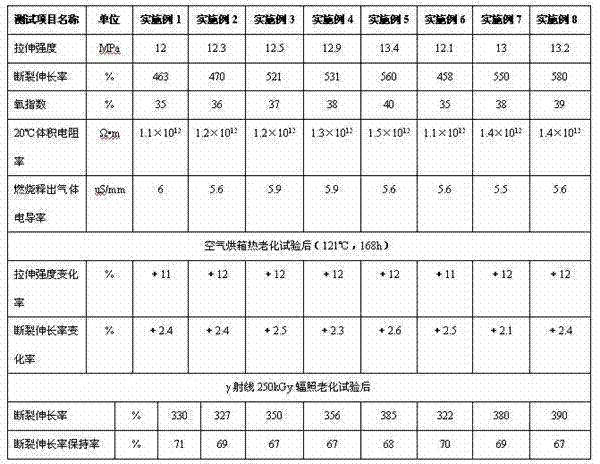

Grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for nuclear power plant and preparation method thereof

ActiveCN103087395AEnvironmental protection is goodReduce pollutionPlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention relates to a grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for a nuclear power plant and a preparation method thereof, belonging to the field of new chemical materials. The cable material comprises raw materials including base resin EVA (ethylene-vinyl acetate copolymer), flame retardants A and B, a flame retardant synergist, basic antioxidants 1010 and 168, a radiation-resistant auxiliary agent 4,4'-thiobis(6-tertiary-butyl-3-methylphenol) and a processing agent; and the preparation method comprises the process steps of material weighing, pretreatment, mixing, extrusion granulation, drying and the like. The cable material is a red-phosphorus-free halogen-free environment-friendly flame-retardant material, phenoxy polyphosphazene is used as a main flame retardant in a flame-retardant system of the cable material, an inorganic flame retardant is auxiliary, the flame-retardant system accounts for a small weight percentage of the material, and the cable material is high in flame-retardant efficiency and excellent in mechanical properties, processability and radiation resistance, so that the cable material is a novel environment-friendly flame-retardant material which has excellent comprehensive properties and is suitable for a nuclear power plant environment.

Owner:SICHUAN INST OF ATOMIC ENERGY +1

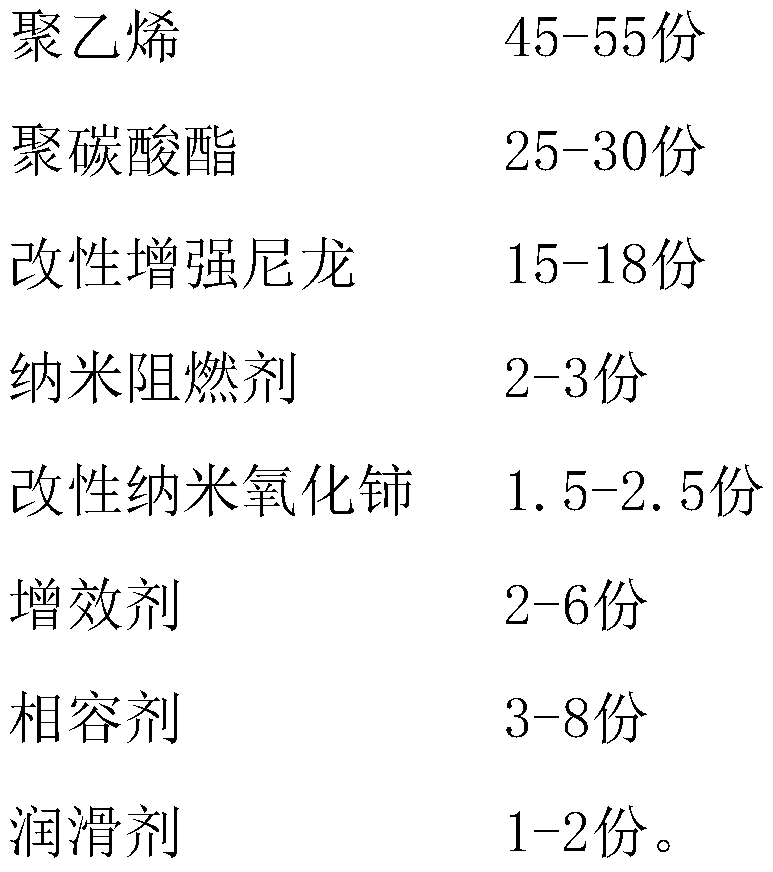

Fireproof aluminium-plastic panel containing nanometer flame retardant and core material special for fireproof aluminium-plastic panel containing nanometer flame retardant

InactiveCN110157072AGood compatibilityGood dispersionSynthetic resin layered productsMetal layered productsDispersityInjection moulding

The invention relates to the technical field of aluminium-plastic panels, in particular to a fireproof aluminium-plastic panel containing a nanometer flame retardant and a core material special for the fireproof aluminium-plastic panel containing the nanometer flame retardant. The core material comprises the following raw materials in parts by weight: 45-55 parts of polyethylene, 25-30 parts of polycarbonate, 15-18 parts of modified enhanced nylon, 2-3 parts of the nanometer flame retardant, 1.5-2.5 parts of modified nanometer cerium oxide, 2-6 parts of a synergist, 3-8 parts of a compatilizerand 1-2 parts of a lubricant. The core material has excellent flame-retardant and fireproof performance, the mobility is high, a core layer can be easily produced through extrusion molding and injection molding, and the core layer produced by using the core material is high in strength and excellent in hardness, resists bending, is not liable to deform, and is excellent in weather resistance; andby adopting the nanometer flame retardant, through combined action of the nanometer flame retardant and the synergist, the core material can have the excellent flame retardant and fireproof performance, and not only can the synergist have an flame-retardant effect, but also a powder state of the synergist can promote the dispersity of materials, so that the rheological property of the core material in the subsequent technologies is improved.

Owner:东莞华尔泰装饰材料有限公司

Method for preparing flame-retardant core-shell type waterborne acrylate resin coating

ActiveCN104086698AImprove the shortcomings of yellowingImprove wear resistanceCoatingsMANGANESE ACETATEPolymer science

The invention relates to a method for preparing a flame-retardant core-shell type waterborne acrylate resin coating. The method comprises the following steps of adding water, an emulsifier and acrylic acid, raising the temperature to 40 DEG C, stirring for 30 minutes, adding a monomer A, emulsifying for 15-45 minutes, raising the temperature to 70 DEG C, starting to introduce recirculation water, raising the temperature to 80 DEG C, reacting for 2 hours, dropwise adding an initiator for 2-4 hours, and reacting for 1-2 hours; adding manganese amino acid, stirring and reacting for 1-4 hours at 80 DEG C, adding a metal salt to adjust the pH value to be 4, adding manganese acetate, stirring and reacting for 1-2 hours at 60 DEG C to obtain a core layer emulsion; simultaneously dropwise adding a monomer B and an initiator into the core layer emulsion for 1-3 hours, stirring and reacting for 3 hours at 70-85 DEG C, adding a crosslinking agent, reacting for 1-3 hours at 70-90 DEG C, cooling to 40 DEG C, adding molybdenum di(2-ethylhexyl)phosphorodithioate and an emulsifier, reacting for 40 minutes, adding the material B, stirring and reacting for 1-3 hours at 65-85 DEG C and adding aqueous ammonia to adjust the pH value to be 7-8 to obtain the flame-retardant core-shell type waterborne acrylate resin coating. By virtue of the preparation method, the flame resistance of the acrylate resin can be greatly improved and the shortcoming of yellowing of a traditional acrylate resin film can also be improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

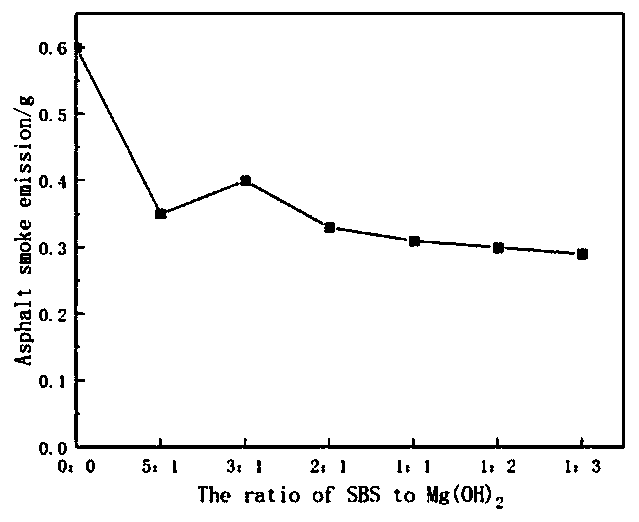

Smoke-suppressing deodorant for road asphalt, application of smoke-suppressing deodorant in asphalt and preparation method of asphalt

The invention relates to a smoke-suppressing deodorant for road asphalt, application of the smoke-suppressing deodorant in asphalt and a preparation method of asphalt. The smoke-suppressing deodorantis prepared from the following substance polymers, inorganic hydroxides, oxidizing agents and auxiliaries in parts by weight. The invention also discloses an application of the smoke-suppressing deodorant in modification of asphalt products, especially road asphalt, and the smoke-suppressing deodorant is especially used for suppressing smoke and removing odor in the paving construction process ofthe road asphalt, so that the health of construction personnel is protected; environmental protection.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Preparation method of high-content carbon black master batch

ActiveCN113999547AFirmly attachedNo sheddingGroup 5/15 element organic compoundsPigment treatment with macromolecular organic compoundsCarbon layerModified carbon

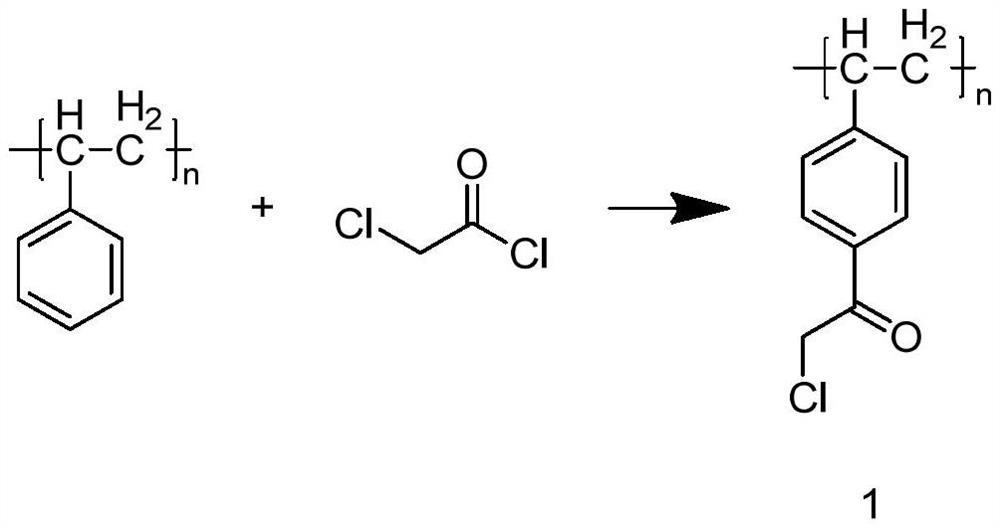

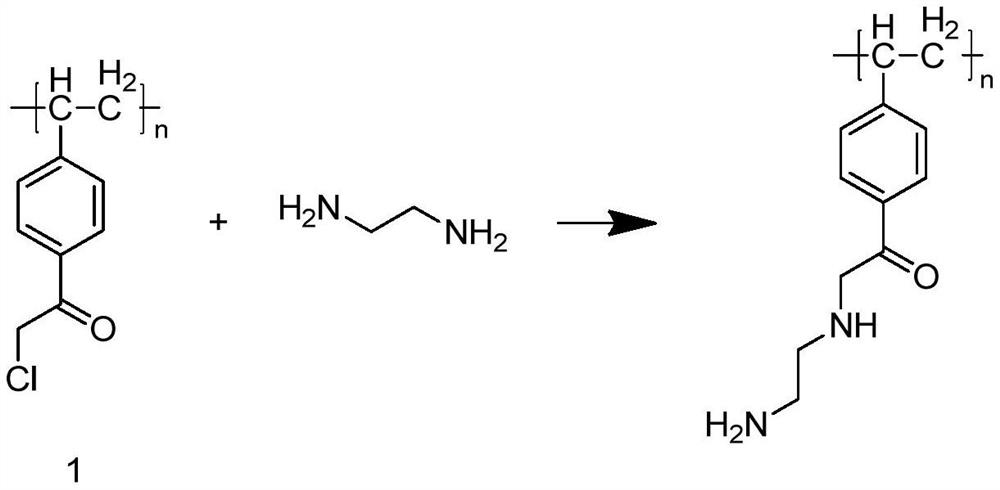

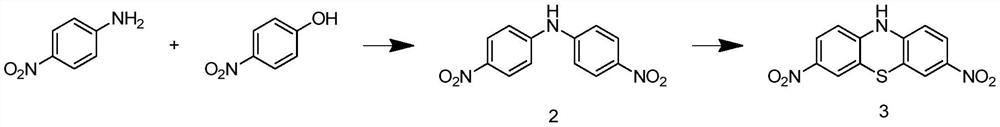

The invention discloses a preparation method of a high-content carbon black master batch. According to the method, modified polystyrene reacts with modified carbon black particles, and then melting and extruding are conducted with liquid paraffin, graphite, kaolin powder and sodium dodecyl benzene sulfonate; and modified polystyrene is dissolved in N,N-dimethylformamide to react with modified carbon black particles, so that chlorine atom sites on the modified carbon black particles are subjected to cross-linking reaction with the modified polystyrene, thereby ensuring that the modified carbon black particles are stably attached to the modified polystyrene and do not fall off when the content of the carbon black is increased. The surface of the modified carbon black particle is grafted with an oxyacid structure containing phosphorus in molecules, a continuous and compact carbon layer can be formed on the surface when the carbon black master batch is combusted, heat and oxygen can be isolated, smoke and molten drops can be inhibited, and phenothiazine structures in the molecules further improve the anti-aging performance of the carbon black master batch.

Owner:广东九彩新材料有限公司

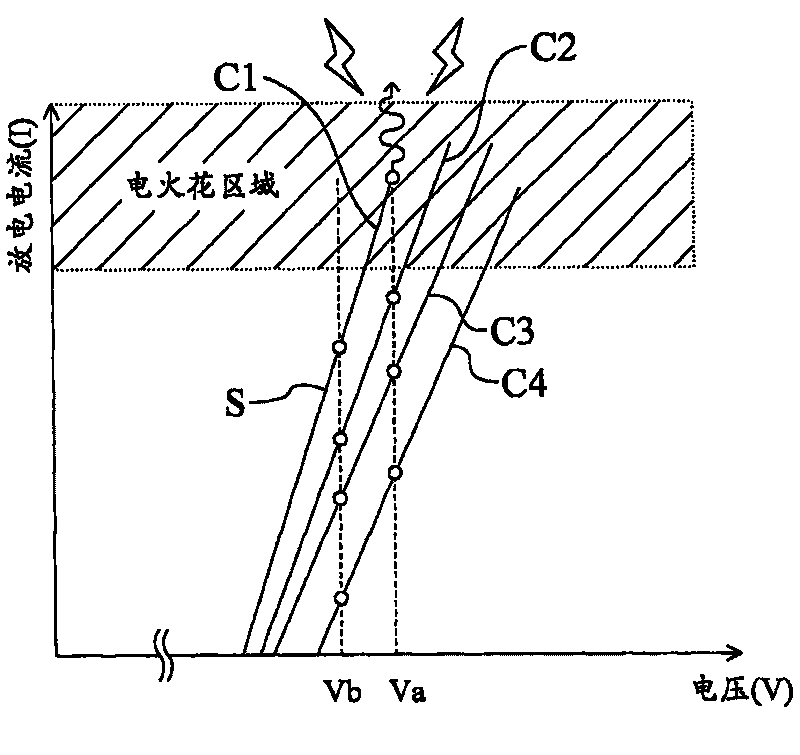

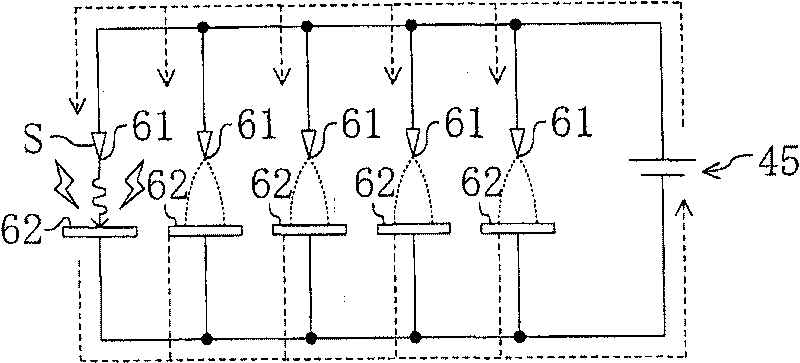

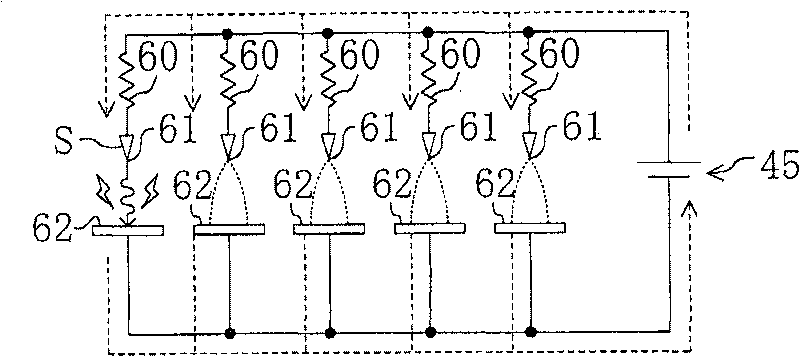

Discharge device and air cleaning device

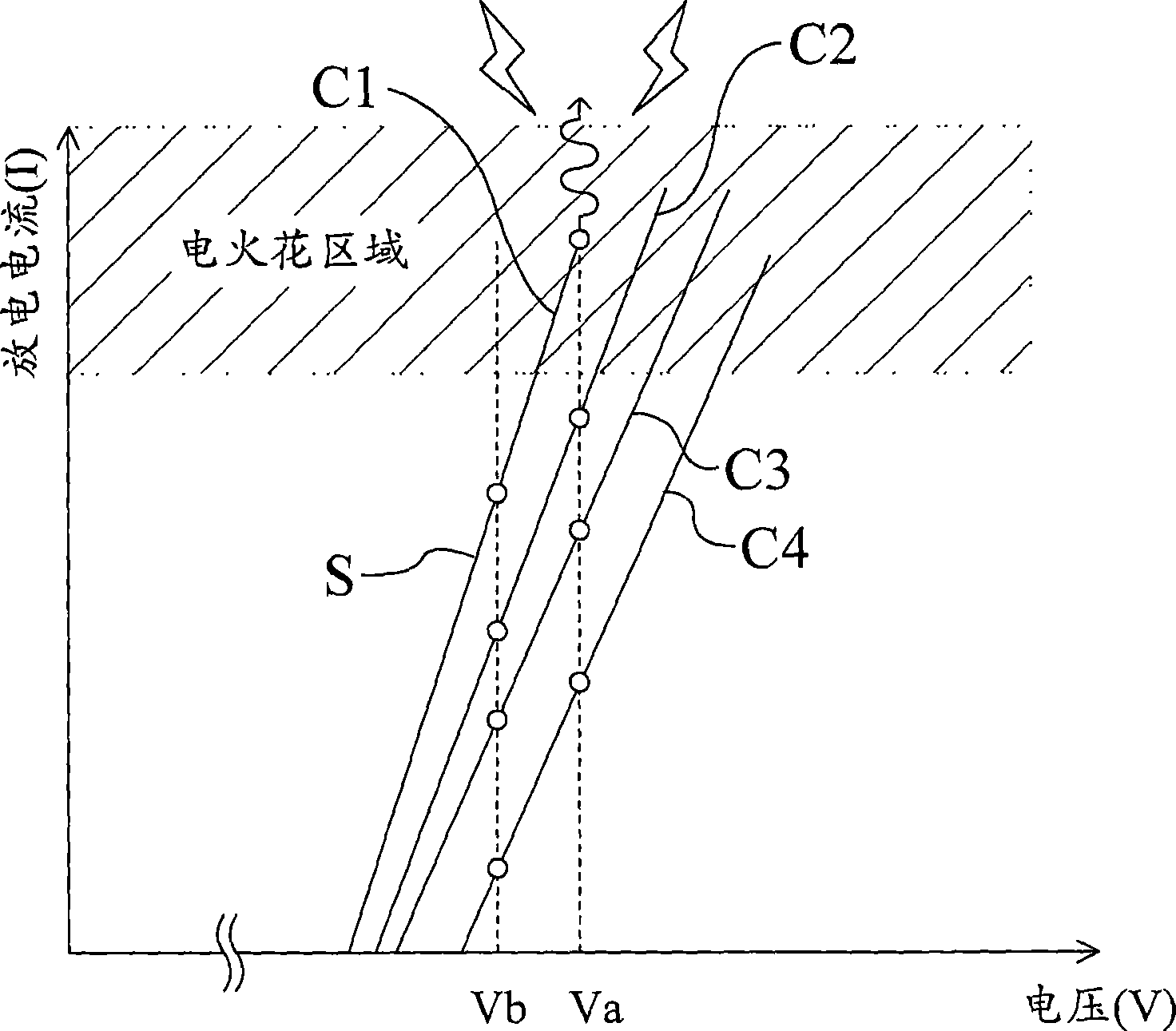

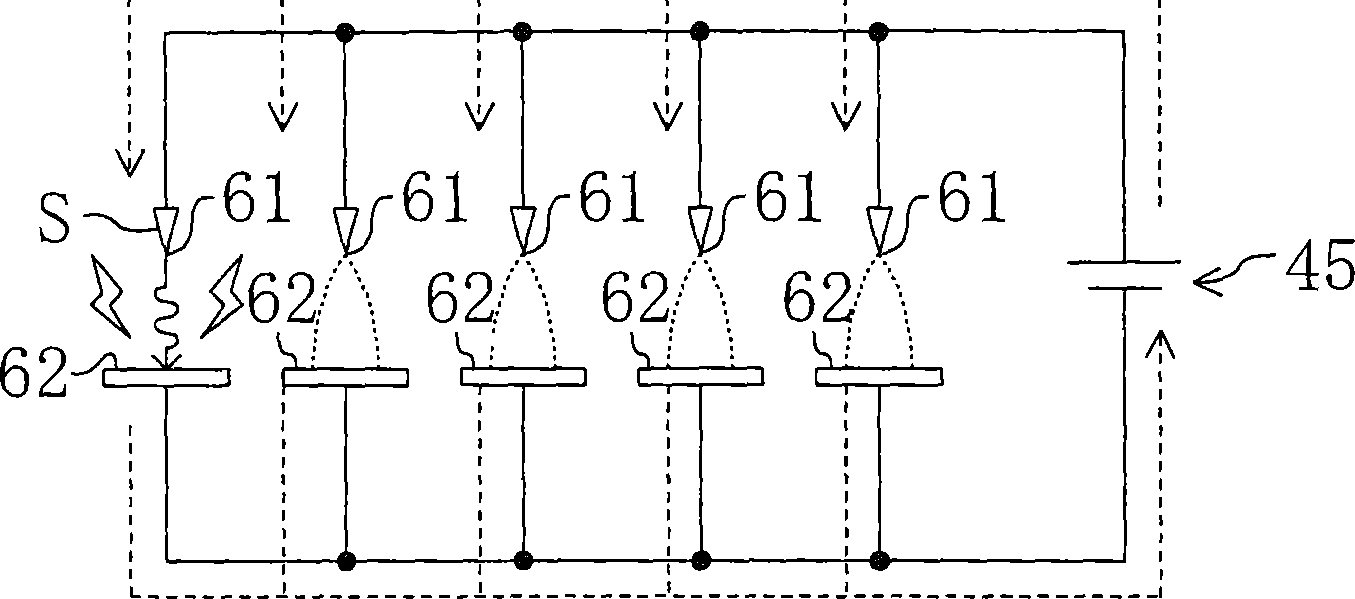

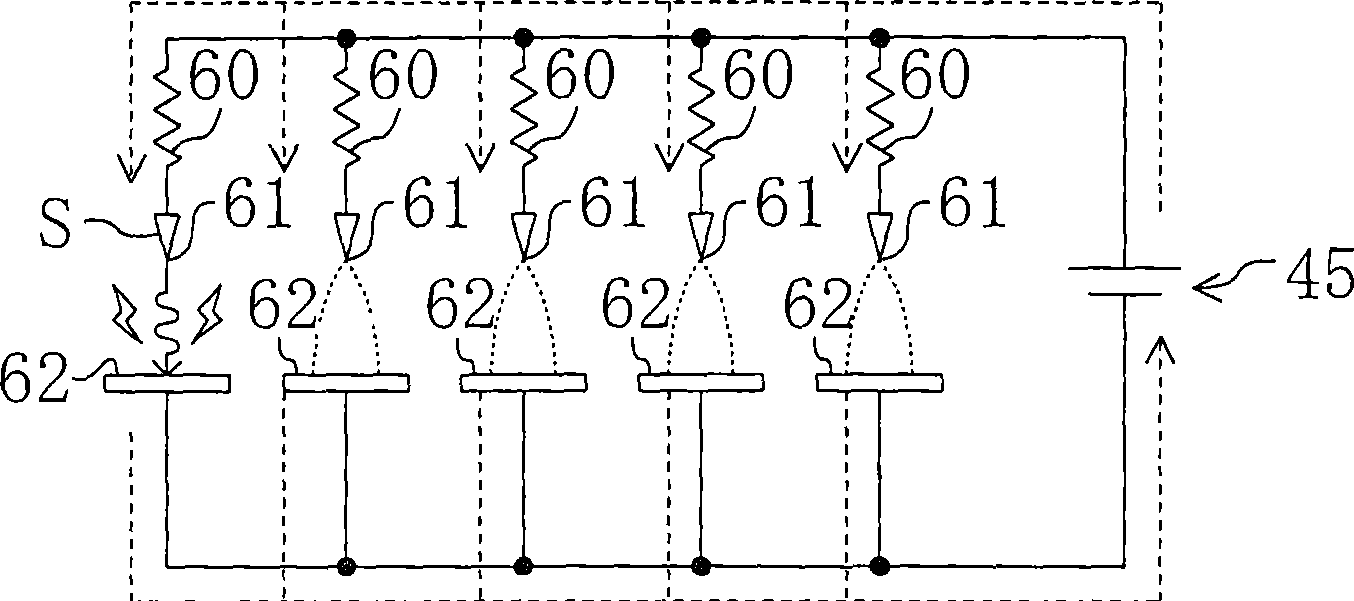

InactiveCN1910799AReduce productionReduce noiseSpark gap detailsGas treatmentAir cleaningEngineering

In a discharge device for performing streamer discharge between a discharge electrode (41) including a plurality of discharge parts (61) and a counter electrode (42) including a plurality of counter parts (62) confronting the discharge parts (61), a resistor (60) is provided in a current carrying path between power source means (45) and the discharge parts (61).

Owner:DAIKIN IND LTD

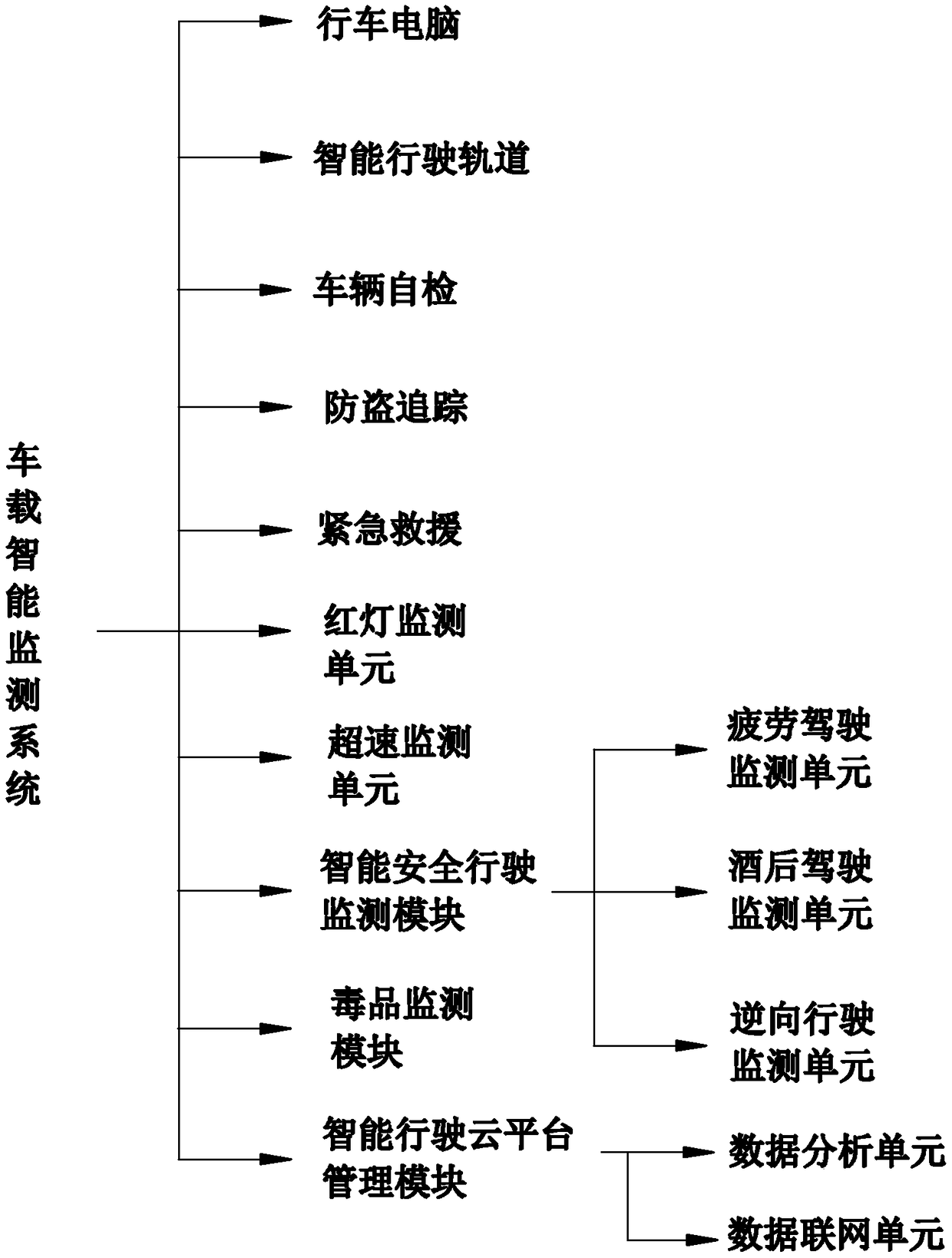

Car-mounted intelligent monitoring system

InactiveCN109191885ASmoke suppressionDetection of traffic movementAnti-theft devicesIntelligent lightingIn vehicle

A car-mounted intelligent monitoring system comprises an intelligent safe driving monitoring module, a drug monitoring module and an intelligent driving cloud platform management module used for conducting data interaction on monitoring data of the car-mounted intelligent monitoring system. The intelligent safe driving monitoring module comprises a fatigue driving monitoring unit, a drink-drivingmonitoring unit and a reverse driving monitoring unit. The fatigue driving monitoring unit is provided with a camera analyzer. The drink-driving monitoring unit comprises a car-mounted alcohol monitor. The reverse driving monitoring unit comprises a driving camera and an alarm. The drug monitoring module comprises a car-mounted terahertz wave detector. The car-mounted intelligent monitoring systemcan monitor safe driving in real time through the intelligent safe driving monitoring module, the drug monitoring module and the intelligent driving cloud platform management module, and thus the designed car-mounted intelligent monitoring system greatly improves the driving safety.

Owner:温州金益智能技术有限公司

Insulating fireproof coating for appliances and preparation method thereof

The invention discloses an insulating fireproof coating for appliances and a preparation method thereof, and relates to the technical field of coating. The coating is prepared from the following raw materials in parts by weight: 55-65 parts of modified acrylic resin, 40-45 parts of organic silicon modified epoxy resin, 30-40 parts of acrylic emulsion, 30-40 parts of insulating additive, 20-25 parts of modified hollow glass beads, 10-20 parts of adjuvant and 65-75 parts of water. After being used on an appliance surface, the coating has strong binding performance, cannot be cracked in long-term use, can form a hydrophobic molecular layer on the appliance surface, and has the effects of preventing water and fire, insulating and resisting abrasion.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

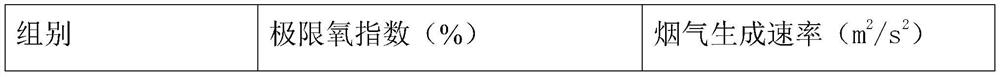

Iron phosphomolybdate smoke suppression PVC plate and preparation method thereof

InactiveCN108456374AHigh oxygen indexSmoke suppressionPhosphorus oxyacidsPhosphomolybdic acidFerric hydroxide

The invention belongs to the application field of high polymer materials, and relates to an iron phosphomolybdate smoke suppression PVC plate and a preparation method thereof. The iron phosphomolybdate smoke suppression PVC plate comprises the following components in parts by weight: 100 parts of PVC resin powder, 2-3 parts of a stabilizer, 2-3 parts of a processing aid, 0.5-1 part of a lubricant,3-5 parts of a flexibilizer, 8-15 parts of a filler, and 4-6 parts of a flame-retardant smoke suppressant. According to the iron phosphomolybdate smoke suppression PVC plate provided by the invention, phosphomolybdic acid and ferric hydroxide are used as raw materials, the iron phosphomolybdate prepared by a hydrothermal method is used as a flame-retardant smoke suppressant, and is added to PVC plate production in combination with other additives, the process is simple, the yield is high, and the flame-retardant and smoke-suppression effect is obvious.

Owner:HUBEI UNIV OF TECH

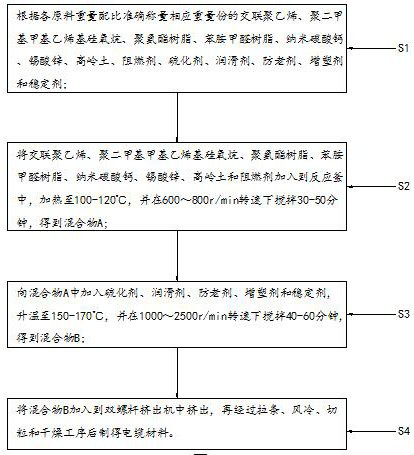

Environment-friendly flame-retardant high-temperature-resistant oil-resistant special flexible cable material and production method thereof

PendingCN114213773AImprove flame retardant performanceImprove high temperature resistancePlastic/resin/waxes insulatorsKaolin clayAniline

The invention belongs to the technical field of cable materials, and particularly relates to a green flame-retardant high-temperature-resistant oil-resistant special flexible cable material and a production method thereof. Comprising the following raw materials in parts by weight: 40-60 parts of crosslinked polyethylene, 20-30 parts of polydimethylmethylvinylsiloxane, 10-20 parts of polyurethane resin, 10-30 parts of aniline formaldehyde resin, 5-15 parts of nano calcium carbonate, 2-6 parts of zinc stannate, 5-10 parts of kaolin, 15-25 parts of a flame retardant, 3-5 parts of a vulcanizing agent, 1-3 parts of a lubricant, 2-3 parts of an anti-aging agent, 2-6 parts of a plasticizer and 3-5 parts of a stabilizer. Through the crosslinked polyethylene, the polydimethylmethylvinyl silicon, the flame retardant and the zinc stannate, the cable material can have high flame retardant performance, substances harmful to a human body cannot be generated during combustion, the zinc stannate can inhibit smoke, the visibility of people is improved when a fire breaks out, and the cable material is environment-friendly and energy-saving. And meanwhile, the cable material has relatively high high-temperature resistance and a relatively large temperature application range, and is suitable for various different environments.

Owner:JIANGSU DONGFANG CABLE MATERIAL

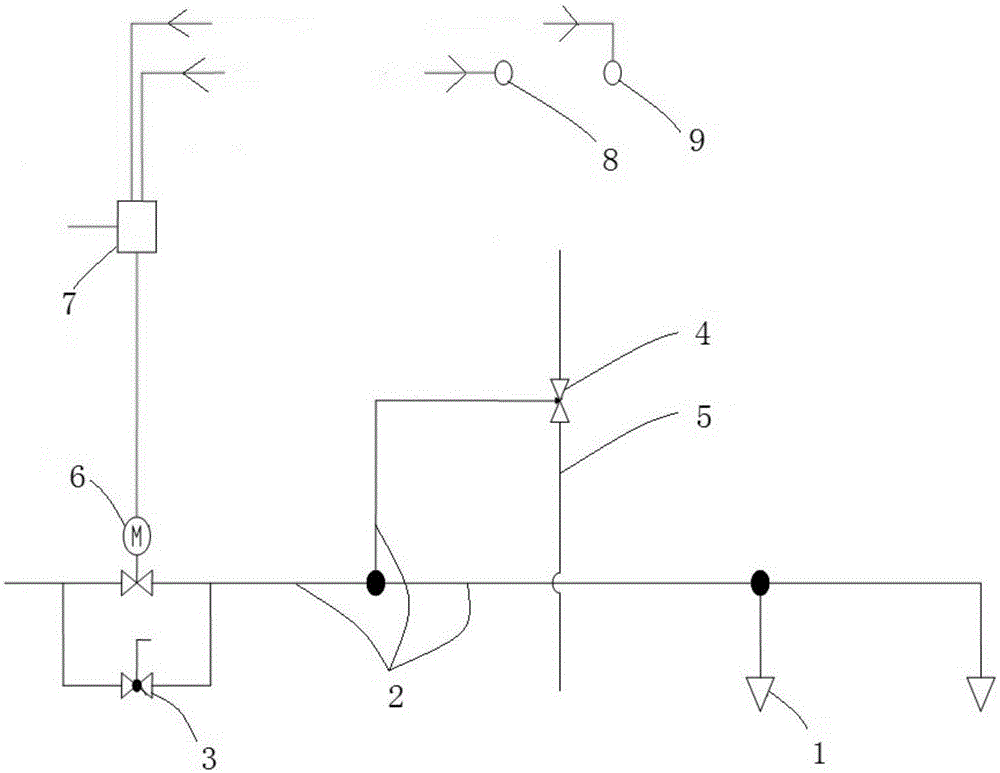

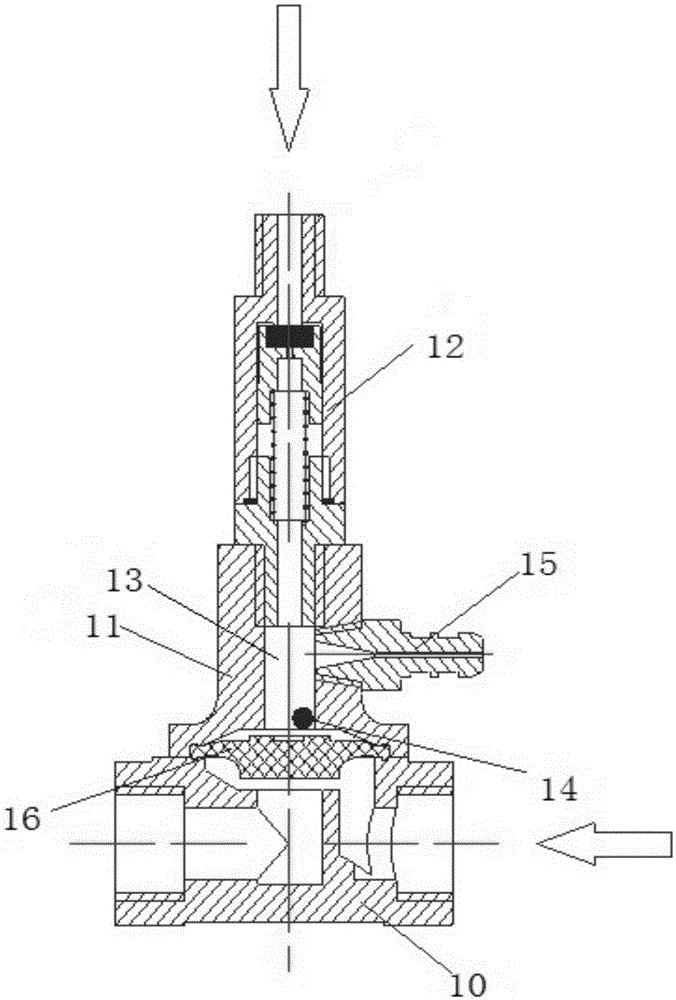

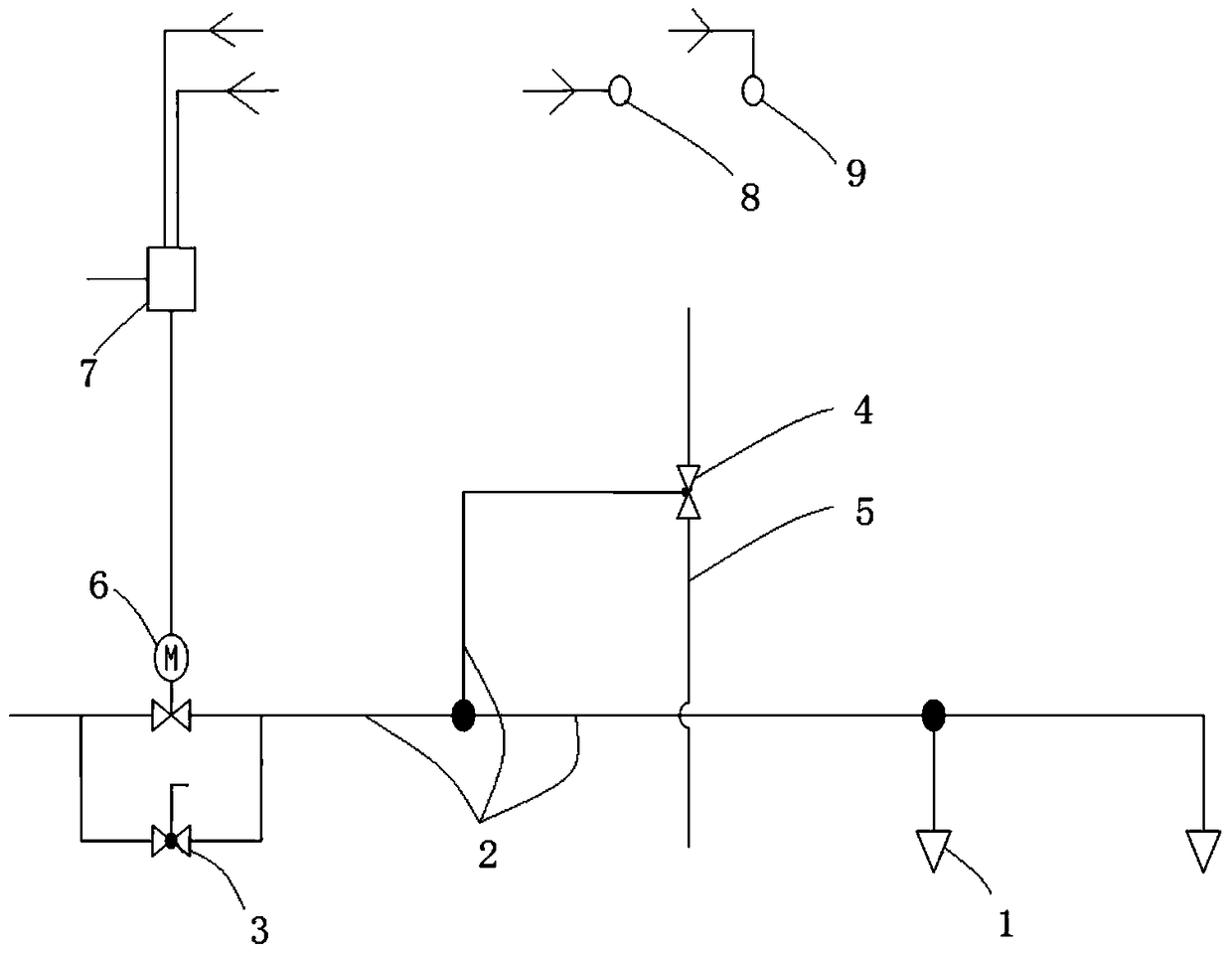

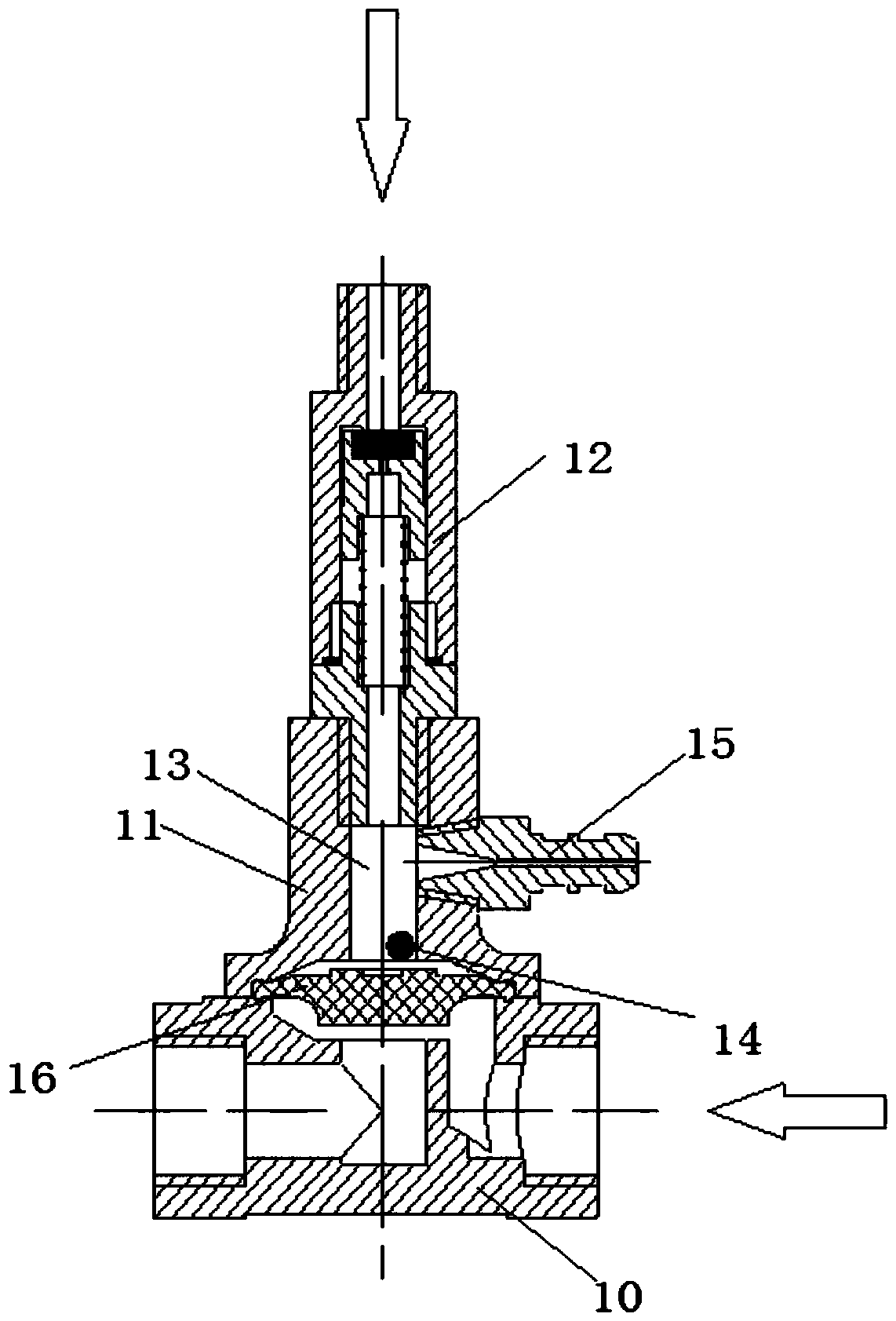

Low-pressure mist spraying system for fire protection of kitchen

The invention discloses a low-pressure mist spraying system for fire protection of a kitchen. The low-pressure spraying system comprises water mist nozzles, a water supply pipe and a water-controlled fuel gas stop valve. The low-pressure mist spraying system is characterized in that a valve is arranged on the water supply pipe, and after penetrating through the valve, the water supply pipe is connected with the water mist nozzles mounted at the top of the kitchen and the water-controlled fuel gas stop valve arranged on a fuel gas pipeline respectively. The low-pressure mist spraying system for the fire protection of the kitchen, disclosed by the invention, is convenient to mount without large-scale modification for the decorated kitchen; the system can be directly accessed into household pipeline networks of tap water without arranging a special fire fighting water source; the tap water is adopted to cut off the fuel gas, so that the supply of natural gas(coal gas) can be cut off without electric power in a mist spraying process; in the mist spraying process of the low-pressure mist spraying system, fire can be effectively restrained or eliminated, smoke and dust are effectively restrained, the temperature is lowered, and the decoration and the furniture of the kitchen are not damaged further.

Owner:VITALONG FIRE SAFETY GRP

Phosphomolybdic acid copper antiflaming smoke-suppression PVC (polyvinyl chloride) rigid foamed sheet and preparation method thereof

InactiveCN108250630AReduce thermal decompositionPlay a role in suppressing smokePhosphomolybdic acidWater baths

The invention belongs to the field of application of high polymer materials, and relates to a phosphomolybdic acid copper antiflaming smoke-suppression PVC (polyvinyl chloride) rigid foamed sheet anda preparation method thereof. The phosphomolybdic acid copper antiflaming smoke-suppression PVC rigid foamed sheet is prepared from the following ingredients in parts by weight: 100 parts by weight ofPVC resin powder, 3-6 parts by weight of stabilizer, 0.5-2 parts by weight of lubricating agent, 1-3 parts by weight of processing aid, 1-4 parts by weight of foaming agent, 8-25 parts by weight of filler and 3-6 parts by weight of antiflaming smoke-suppression agent. The phosphomolybdic acid copper antiflaming smoke-suppression PVC rigid foamed sheet takes phosphomolybdic acid and basic zinc carbonate as raw materials, the phosphomolybdic acid copper prepared under a water bath condition is adopted as the antiflaming smoke-suppression agent and is combined with other auxiliary agents, the mixture is added into the production of the PVC rigid foamed sheet, a technology is simple, yield is high, and an antiflaming smoke-suppression effect is obvious.

Owner:HUBEI UNIV OF TECH

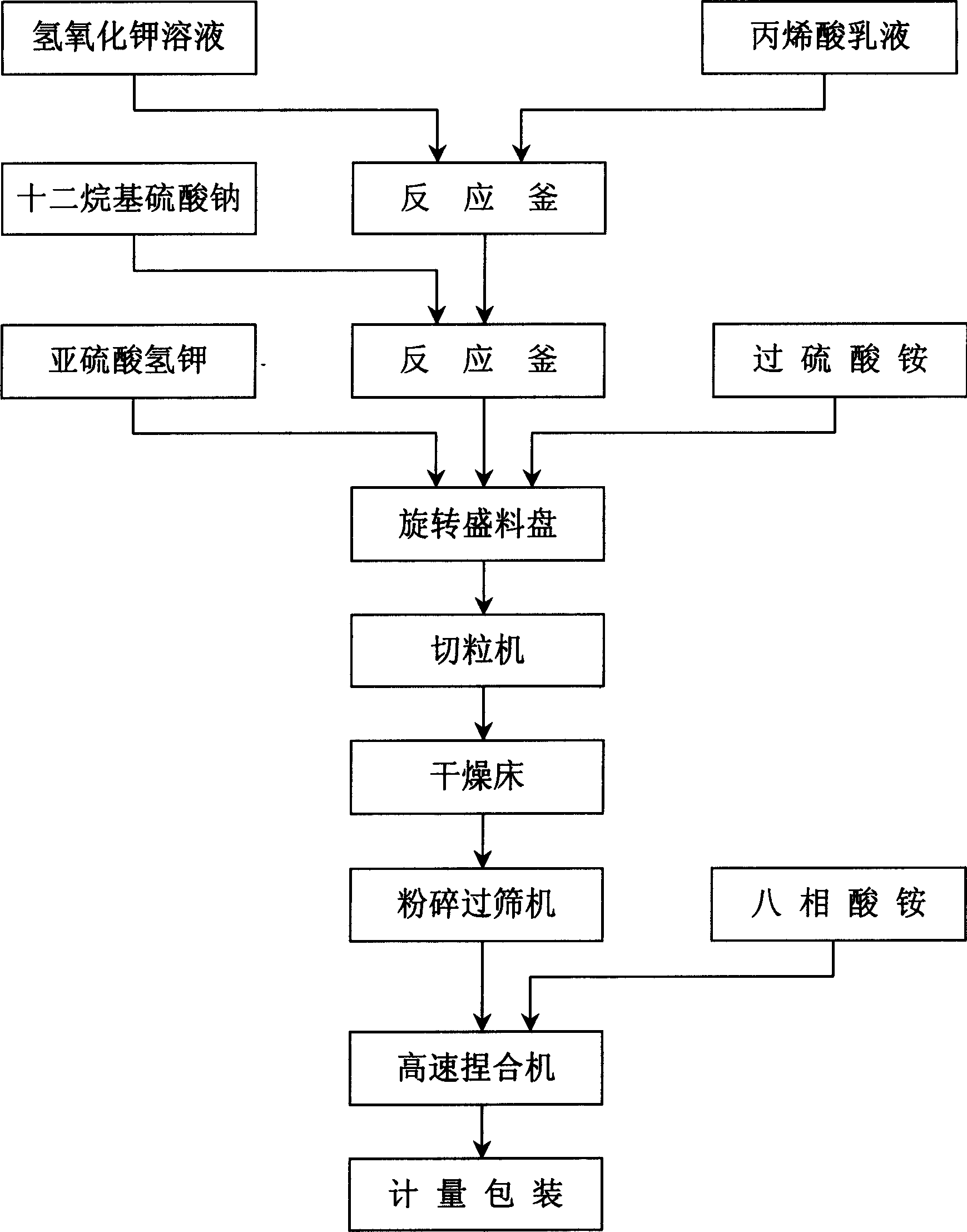

Method for preparing compound fire-extinguishing particulate material

InactiveCN1736516ASmoke suppressionReduce the temperatureFire extinguisherPotassium hydroxidePotassium bisulfite

The invention relates to a making method of composite fire-extinguishing particle material in new fire-extinguishing material domain, which is characterized by the following: adapting the potassium hydroxide and acrylic emulsion as the basic raw material; adding sodium lauryl sulfate, potassium bisulfite, ammonium peroxodisulfate and eight looks acid ammonium into the raw material; making the composite fire-extinguishing particle material by neutralization reaction, initiating crosslinking polymerization, dicing, drying, disintegrating, sifting, modifying property compound, measuring and packing. The composite particle material ejects the gelatin with 1:300 qualities mixing to the ignition area, which reduces the temperature of ignition area to inhibit the smog and reaches the goal of quick fire-extinguishing and flame-proof by forming a heat-proof layer and oxygen-proof gelatination layer.

Owner:FUJIAN NORMAL UNIV

Zinc borate corrosion preventing and flame retarding agent

The invention relates to a zinc borate corrosion preventing and flame retarding agent which is solvent prepared from effective ingredients and water. The effective ingredients comprise 10-20 wt% of zinc borate, 0-47 wt% of ammonia, 6-60 wt% of 2-aminoethanol and 10-20 wt% of quaternary ammonium surfactants. According to the zinc borate corrosion preventing and flame retarding agent, the problem that a borate flame retarding and corrosion preventing agent is poor in leachability is solved, and the zinc borate which cannot be easily dissolved in water is prepared into a soluble complex which can enable wood to be completely permeated and is finally combined with wood fiber in the mode of the zinc borate; the treated wood is colorless and odorless, the flame retarding and corrosion preventing effects are simultaneously achieved, harm of fungi, moulds, termites, longhorn beetles, lyctus and carpenter bees to the wood can be effectively resisted, the good smoke inhibiting effect and the good leachability resistance are achieved, the leachability of the normally-used borate flame retarding and corrosion preventing agent is larger than or equal to 80 percent, and the leachability of the zinc borate is about 3 percent.

Owner:FUJIAN ZHANGPING KIMURA FORESTRY PROD

Preparation method of core-shell type water-based acrylic resin paint for building and furniture

ActiveCN105111876AImprove the shortcomings of yellowingImprove wear resistanceFireproof paintsMANGANESE ACETATEPolymer science

The invention relates to a method for preparing a flame-retardant core-shell type waterborne acrylate resin coating. The method comprises the following steps of adding water, an emulsifier and acrylic acid, raising the temperature to 40 DEG C, stirring for 30 minutes, adding a monomer A, emulsifying for 15-45 minutes, raising the temperature to 70 DEG C, starting to introduce recirculation water, raising the temperature to 80 DEG C, reacting for 2 hours, dropwise adding an initiator for 2-4 hours, and reacting for 1-2 hours; adding manganese amino acid, stirring and reacting for 1-4 hours at 80 DEG C, adding a metal salt to adjust the pH value to be 4, adding manganese acetate, stirring and reacting for 1-2 hours at 60 DEG C to obtain a core layer emulsion; simultaneously dropwise adding a monomer B and an initiator into the core layer emulsion for 1-3 hours, stirring and reacting for 3 hours at 70-85 DEG C, adding a crosslinking agent, reacting for 1-3 hours at 70-90 DEG C, cooling to 40 DEG C, adding molybdenum di(2-ethylhexyl)phosphorodithioate and an emulsifier, reacting for 40 minutes, adding the material B, stirring and reacting for 1-3 hours at 65-85 DEG C and adding aqueous ammonia to adjust the pH value to be 7-8 to obtain the flame-retardant core-shell type waterborne acrylate resin coating. By virtue of the preparation method, the flame resistance of the acrylate resin can be greatly improved and the shortcoming of yellowing of a traditional acrylate resin film can also be improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

Environment-friendly high intensity high flame resistance cable prepared by utilizing tannery chromium-containing sludge

ActiveCN105845247AGood weather resistanceImprove thermal stabilityInsulated cablesCable/conductor manufactureInsulation layerSodium Bentonite

The invention relates to an environment-friendly high intensity high flame resistance cable prepared by utilizing tannery chromium-containing sludge. The cable sequentially comprises a core, an insulation layer, an internal protection layer and a sheath tube from inside to outside, wherein raw materials of the sheath tube comprise polyacrylonitrile / ethane / styrol copolymer, the tannery chromium-containing sludge, bentonite, methyl triethoxysilane, zinc oxide, sodium alginate, bisphenol fluorenes and hexaphenoxy cyclotriphosphazene. The cable has advantages of high flame resistance and high intensity and further has the low smog release effect.

Owner:JIANGSU SANQI CABLE & WIRE

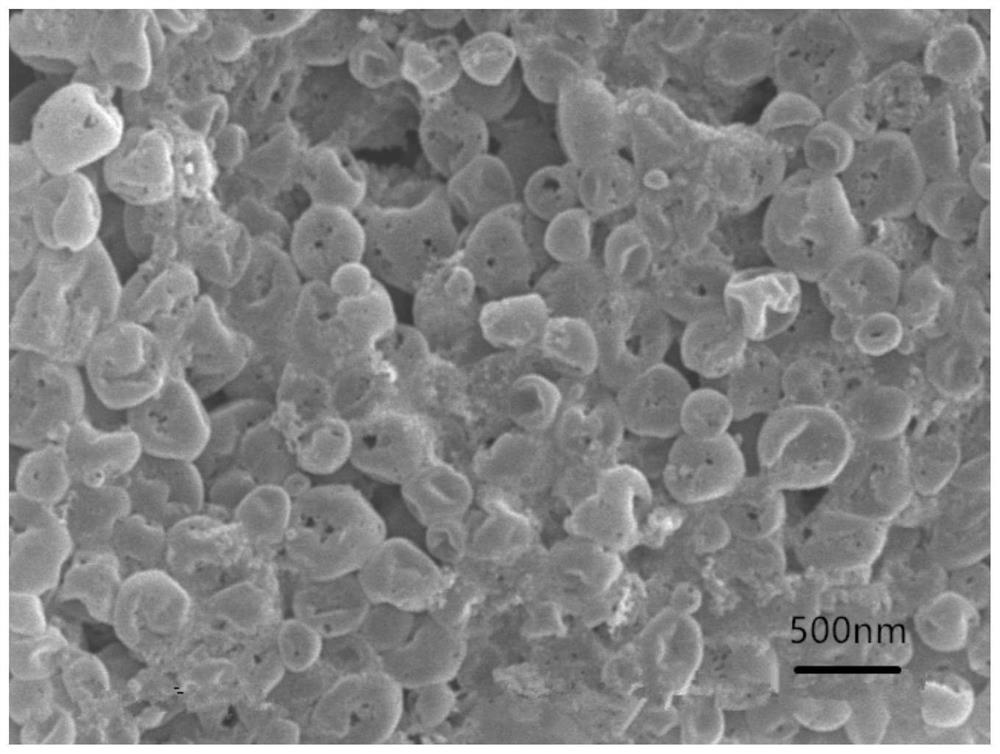

Flame-retardant PVC material and preparation method thereof

The invention provides a flame-retardant PVC material and a preparation method thereof, belonging to the technical field of PVC materials. The flame-retardant PVC material is prepared from the following raw materials in parts by weight: 100-120 parts of PVC resin, 10-15 parts of surface-modified porous aluminum hydroxide microspheres, 5-10 parts of SbOCl, 2-3 parts of a smoke suppressant, 2-5 parts of a plasticizer and 1-3 parts of an antioxidant, wherein the surface modified porous aluminum hydroxide microspheres are porous aluminum hydroxide microspheres with surfaces coated with polydopamine, and the particle sizes of the microspheres range from 100 nm to 500 nm. The flame-retardant PVC material prepared by the invention not only has good flame retardance, but also has better smoke suppression and abatement effects; cost is low due to the addition of an inorganic flame retardant; and the prepared PVC material has little influence on mechanical properties and has good market prospects.

Owner:杨春生

Environment-friendly type carbon fiber modified acrylonitrile-ethylene-styrene cable with high strength and high flame retardance

ActiveCN105802103AGood weather resistanceImprove thermal stabilityPlastic/resin/waxes insulatorsInsulated cablesCarbon fibersSodium Bentonite

An environment-friendly type carbon fiber modified acrylonitrile-ethylene-styrene cable with high strength and high flame retardance comprises a cable core, an insulation layer, an inner jacket and a protective sleeve sequentially from inside to outside, wherein the protective sleeve comprises raw materials of a polyacrylonitrile / ethylene / styrene copolymer, tannery sludge, bentonite, triethoxyoctylsilane, stearic acid, zinc oxide, sodium alginate, fluorene-9-bisphenol and hexaphenoxycyclotriphosphazene, and the prepared cable is high in flame retardance and strength and has a low smoke release effect.

Owner:天津中玻北方新材料有限责任公司

Environment-friendly cable with high strength and high flame retardancy

InactiveCN105647089AGood weather resistanceImprove thermal stabilityInsulated cablesInsulated conductorsPolymer scienceSludge

An environment-friendly cable with high strength and high flame retardancy sequentially comprises a cable core, an insulating layer, an inner protecting layer and a sheath tube from inside to outside, wherein raw materials of the sheath tube comprise polyacrylonitrile / ethylene / styrene copolymers, chromium-containing sludge for tanning, bentonite, methyl triethoxysilane, stearic acid, zinc oxide, sodium alginate, bisphenol fluorine and hexaphenoxy cyclotriphosphazene. The prepared cable has high flame retardancy and strength and has the effect of low smoke release.

Owner:段宝荣

Environment-friendly anti-oxidation cable protective sleeve material

InactiveCN108822413AImprove mechanical propertiesGood stretchRubber insulatorsEnvironmental resistanceEpoxy

The invention discloses an environment-friendly anti-oxidation cable protective sleeve material. The material comprises the following raw materials in parts by weight: 30-40 parts of ethylene-propylene rubber, 10-16 parts of butyl rubber, 10-15 parts of epoxy resin, 4-10 parts of organic silicon resin, 4-8 parts of an aluminum hydroxide colloid, 5-12 parts of glass fibers, 0.7-1.3 parts of paraffin oil and 1-5 parts of talcum powder, 4-9 parts of diatomite, 0.5-3 parts of zinc stearate, 0.6-1.5 parts of a vulcanizing agent DPC, 2-5 parts of a coupling agent, 1-4 parts of an assistant crosslinker TAIC, 1-4 parts of an anti-aging agent and 1.5-4 parts of an antioxidant. The preparation process of the protective sleeve material is as follows: adding the ethylene propylene-rubber, the butyl rubber, the epoxy resin and the organic silicon resin into a screw extruder, carrying out fusion for 10-20 minutes, controlling the melting temperature to be 125-135 DEG C, and then adding the remainingraw materials, carrying out extrusion after the fusion is carried out for 20 minutes, placing the extruded material in a flat vulcanizing machine, and carrying out pressing and crushing to obtain theenvironment-friendly anti-oxidation cable protective sleeve material. The protective sleeve material has excellent oxidation resistance, and the service life is prolonged.

Owner:安徽电信器材贸易工业有限责任公司

Discharge device and air cleaning device

InactiveCN1910799BReduce productionReduce noiseSpark gap detailsGas treatmentAir cleaningEngineering

In a discharge device for performing streamer discharge between a discharge electrode (41) including a plurality of discharge parts (61) and a counter electrode (42) including a plurality of counter parts (62) confronting the discharge parts (61), a resistor (60) is provided in a current carrying path between power source means (45) and the discharge parts (61).

Owner:DAIKIN IND LTD

A low-pressure spray system for kitchen fire fighting

The invention discloses a low-pressure mist spraying system for fire protection of a kitchen. The low-pressure spraying system comprises water mist nozzles, a water supply pipe and a water-controlled fuel gas stop valve. The low-pressure mist spraying system is characterized in that a valve is arranged on the water supply pipe, and after penetrating through the valve, the water supply pipe is connected with the water mist nozzles mounted at the top of the kitchen and the water-controlled fuel gas stop valve arranged on a fuel gas pipeline respectively. The low-pressure mist spraying system for the fire protection of the kitchen, disclosed by the invention, is convenient to mount without large-scale modification for the decorated kitchen; the system can be directly accessed into household pipeline networks of tap water without arranging a special fire fighting water source; the tap water is adopted to cut off the fuel gas, so that the supply of natural gas(coal gas) can be cut off without electric power in a mist spraying process; in the mist spraying process of the low-pressure mist spraying system, fire can be effectively restrained or eliminated, smoke and dust are effectively restrained, the temperature is lowered, and the decoration and the furniture of the kitchen are not damaged further.

Owner:VITALONG FIRE SAFETY GRP

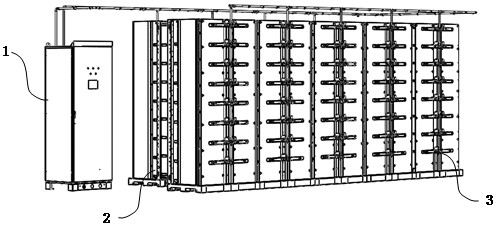

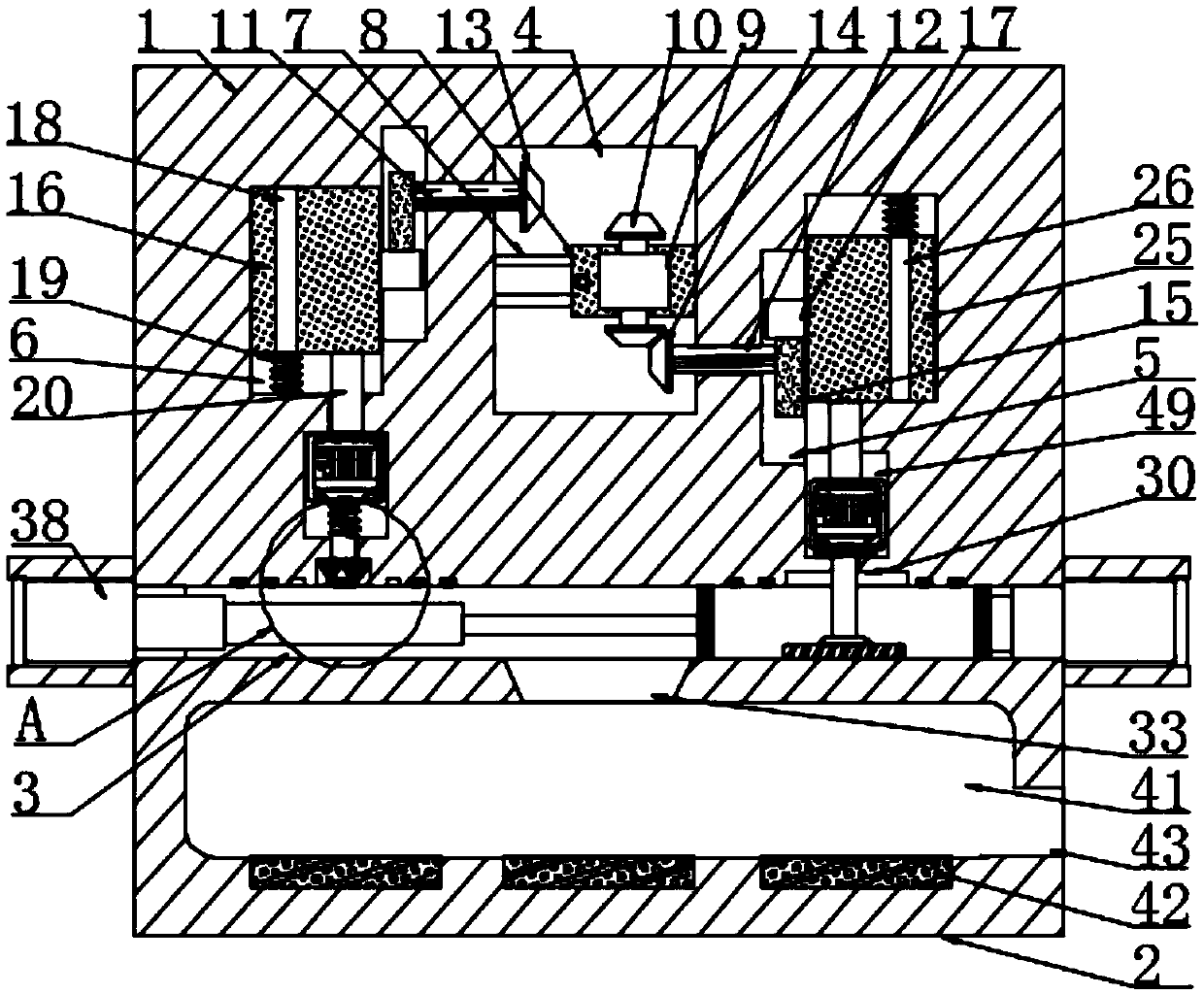

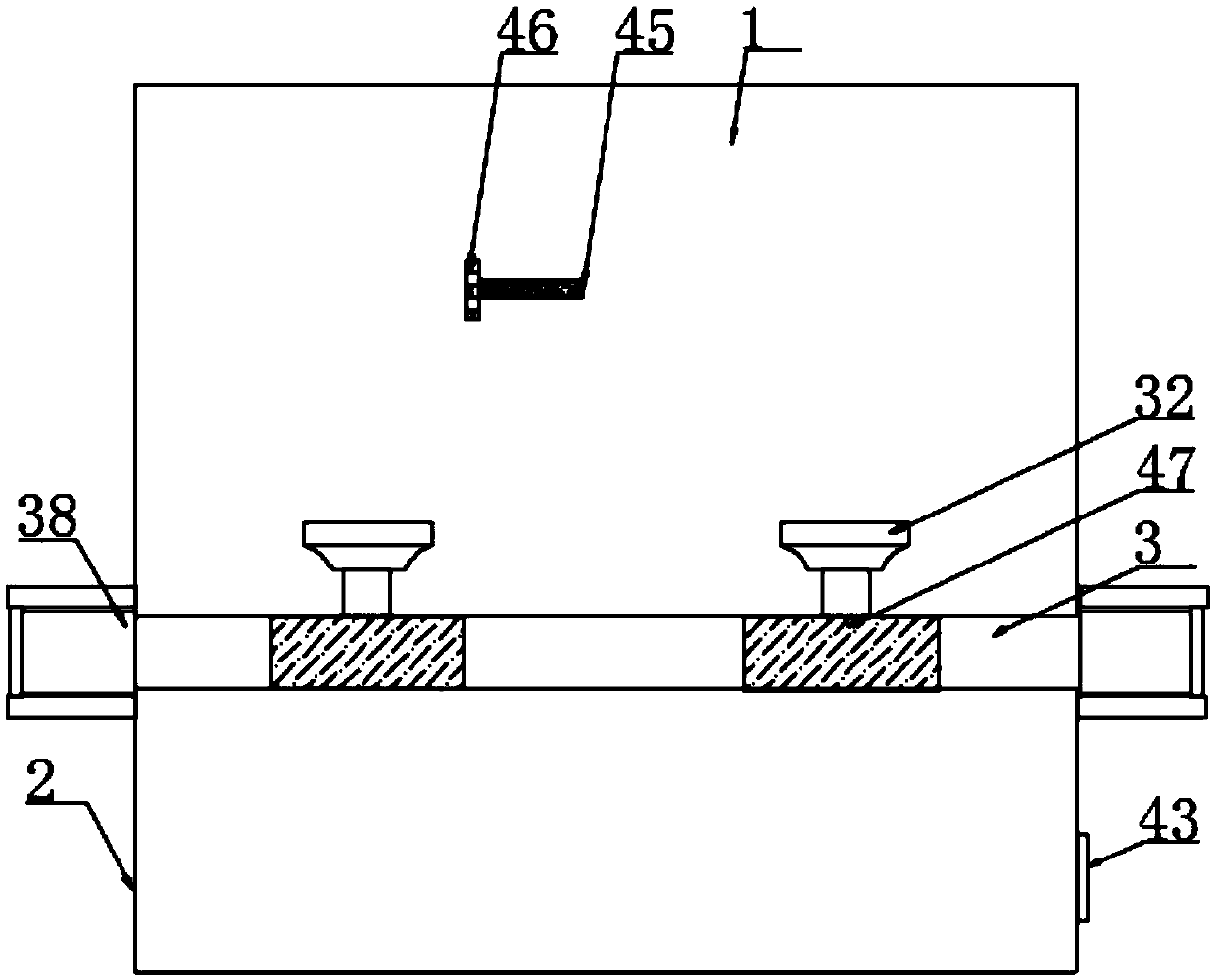

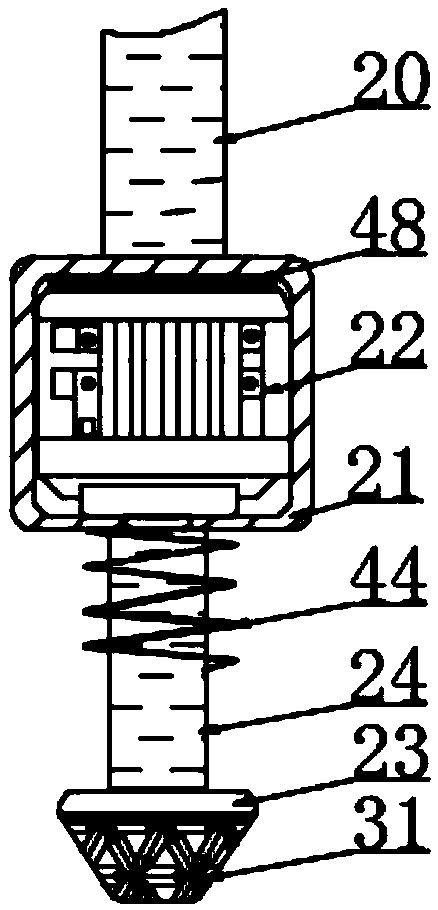

Activated carbon pressing device

The invention discloses an activated carbon pressing device. The activated carbon pressing device comprises an upper machine box and a lower machine box, wherein the upper machine box is fixedly connected to the top of the lower machine box, a working channel is arranged between the upper machine box and the lower machine box, a first cavity is formed in the upper machine box, and a connection conversion device is arranged in the first cavity; the two sides of the first cavity are provided with second cavities correspondingly, the sides, far away from the first cavity, of the second cavities are provided with third cavities, and a particle pressing device is arranged in one of the third cavities. According to the device, the connection conversion device, the particle pressing device and apowder pressing device are arranged, so that the conversion of manufacturing powder shape / granular shape of the activated carbon is realized, a pressing unified structure is arranged, accessories areconvenient to maintain and replace, a pressing rod drives a first motor or a second motor to press down, when a granulating head and a powder pressing block are in contact with the activated carbon,the first motor or the second motor works to drive the granulating head or the powder pressing block to rotate, meanwhile, a reamer blade is used to grind the activated carbon, so that the working efficiency is improved.

Owner:安徽金叶碳素科技有限公司

Treating agent for synthetic fibre, treating method for synthetic fibre and synthetic fibre

The present invention provides a processing agent which can restrain the generation of fine fur and tar oil and restrain the smoke generation when the synthetic fiber is executed with heat treatment in the rigorous high-temperature condition for further preventing the reduction of operability. The invention also provides a treating method using the treating agent and the synthetic fiber prepared by the treating method. The treating agent for synthetic fiber uses at least one object selected from 1) and 2): 1) a compound which is obtained by mixing at least two greases and heating in the presence of acid compound thereby executing random ester exchange, and 2) a compound which is obtained by heating the mixed grease, the aliphatic monocarboxylic acid and glycerol in the presence of acid compound thereby executing random ester exchange.

Owner:TAKEMOTO YUSHI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com