Smoke-suppressing deodorant for road asphalt, application of smoke-suppressing deodorant in asphalt and preparation method of asphalt

A technology for road asphalt and smoke removal, which is used in building components, building insulation materials, buildings, etc., to achieve the effect of protecting the ecological environment, adding less amount, and suppressing smoke and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

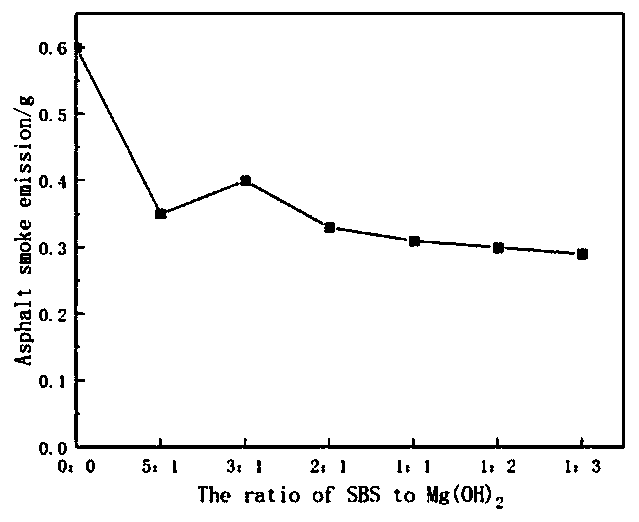

Method used

Image

Examples

Embodiment 1

[0030] A smoke-suppressing and deodorizing agent for asphalt comprises 60% of SBS, 15% of magnesium hydroxide, 10% of manganese dioxide and 15% of carbide in terms of mass percentage.

[0031] The structure of the SBS polymer is star-shaped, the purity is chemically pure, and the molecular weight is less than 300,000.

[0032] Described magnesium hydroxide, purity is analytical pure.

[0033] The manganese dioxide is chemically pure.

[0034] The additives used are self-made carbides, and the new purity of the reagents used are analytically pure; the preparation method is as follows, dissolve 3.0g of ammonium chloride in 10ml of deionized water, stir to dissolve, add 3.0g of melamine, and stir for 2h Finally, transfer to an oil bath at 80°C for the purpose of evaporating water, then heat in a muffle furnace at 550°C for 2 hours, and grind for later use.

[0035] The preparation method of road asphalt: by mass percentage, first add the above-mentioned 60% of SBS, 15% of magne...

Embodiment 2

[0039] A smoke-suppressing and deodorizing agent for road asphalt, which is prepared from the following materials in parts by weight:

[0040] Polymer SIS: Calcium Hydroxide: Iron Oxide: Zinc Oxide = 50:20:10:20.

[0041] The purity requirements of calcium hydroxide and iron oxide are chemically pure.

[0042] The application of a smoke-suppressing and deodorizing agent for road asphalt in asphalt comprises 5% of the smoke-suppressing and deodorizing agent and 95% of base asphalt in terms of mass percentage.

[0043] A preparation method for road asphalt, comprising the steps of:

[0044] At room temperature, put the polymer SIS, calcium hydroxide, iron oxide and zinc oxide into a dry mixer according to the above-mentioned ratio of parts by weight, and mix evenly to obtain the asphalt smoke suppressing and deodorizing agent; heat the base asphalt To 120°C, add smoke-suppressing and deodorizing agent for asphalt, and shear at a high speed at 4000r / min for 1 hour. %.

Embodiment 3

[0046] A smoke-suppressing and deodorizing agent for road asphalt, which is prepared from the following materials in parts by weight:

[0047] Polymer SEBS: zinc hydroxide: manganese dioxide: titanium dioxide = 65:10:5:20.

[0048] The purity requirements of zinc hydroxide and manganese dioxide are chemically pure.

[0049] The application of a smoke-suppressing and deodorizing agent for road asphalt in asphalt comprises 4% of the smoke-suppressing and deodorizing agent and 96% of base asphalt in terms of mass percentage.

[0050] A preparation method for road asphalt, comprising the steps of:

[0051] At room temperature, put the polymer, inorganic hydroxide, oxidizing agent and auxiliary agent into a dry mixer according to the above-mentioned ratio of parts by weight, and mix evenly to obtain the asphalt smoke suppressing and deodorizing agent; the base asphalt is heated to 130°C, add smoke suppressant and deodorant for asphalt, and shear at a high speed at 3500r / min for 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com