Method for preparing compound fire-extinguishing particulate material

A kind of granular material and composite technology, which is applied in the direction of fire prevention equipment, etc., can solve the problems of long fire extinguishing time and low efficiency, and achieve the effect of large water carrying capacity, low consumption, and prevention of re-ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

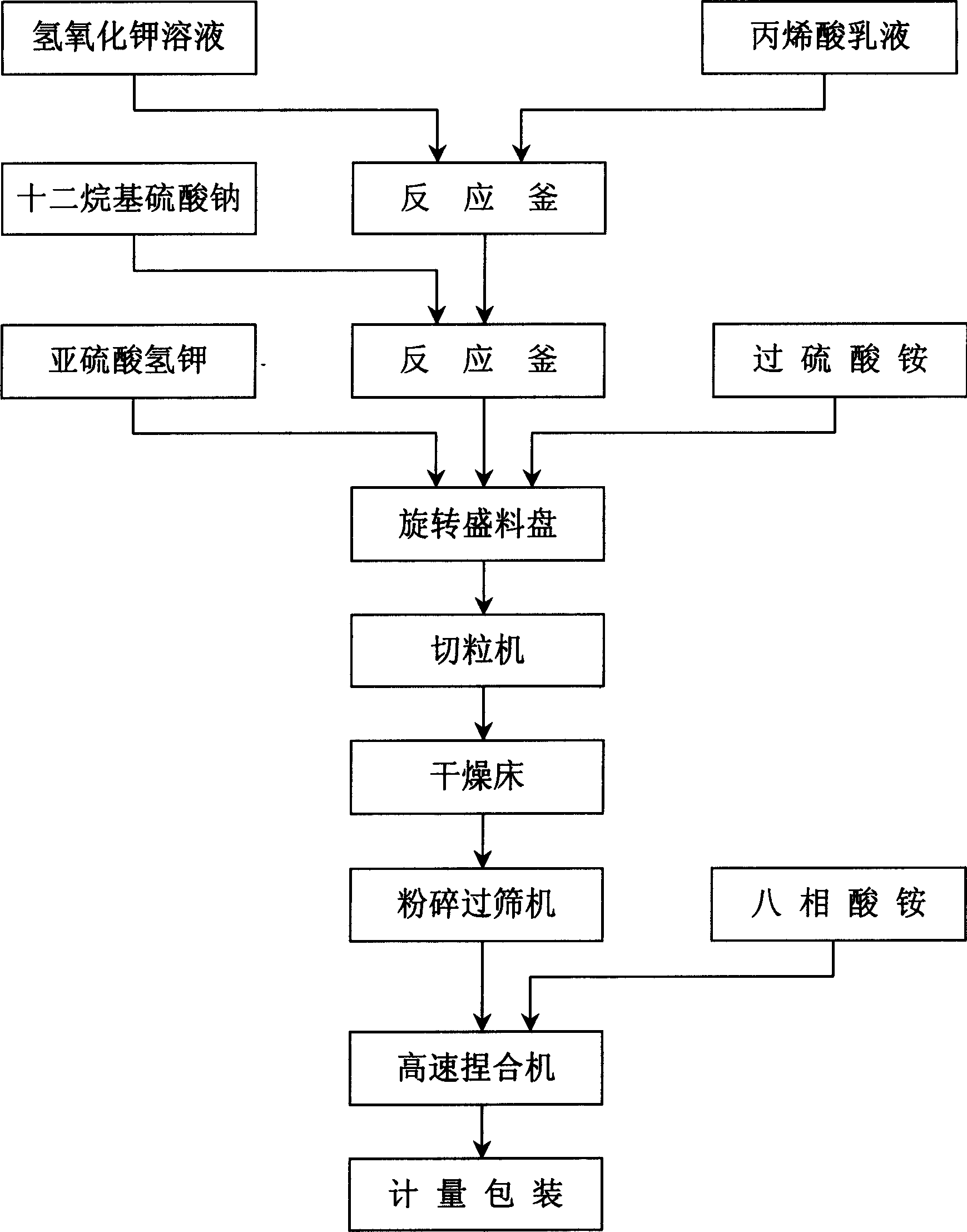

Image

Examples

Embodiment 1

[0014] Dilute 24 kg of potassium hydroxide with a purity of 99.0% with 3 times the amount of distilled water to a solution of 96 kg, place it in the reactor, start the mixer, control the stirring speed at 75r / min, and the temperature in the kettle at 78°C, slowly add 99.7% acrylic emulsion 70kg, after the neutralization reaction for 19min, add 35g sodium lauryl sulfate, stir for 6min, put it in the rotating pan, add 260g potassium bisulfite and 160g ammonium persulfate at the same time to initiate cross-linking polymerization, wait for the reactants After it is a gel, it is cut into particles of φ2.5×3mm in a granulator. After drying at 150℃ in a drying bed, it is placed in a crushing and sieving machine for crushing and sieving to obtain particles with a particle size of 60-100 mesh. Then put it in a high-speed kneader, add 9kg of ammonium octaphase acid with a purity of 98.5% for compound modification. The high-speed kneader has a stirring speed of 500r / min, a temperature of 75℃...

Embodiment 2

[0016] Dilute 22 kg of potassium hydroxide with a purity of 99.5% with 3 times the amount of distilled water to 88 kg of solution, place it in the reactor, start the mixer, control the stirring speed to 75r / min, and the temperature in the kettle to 76°C, slowly add acrylic emulsion with a purity of 99.9% 66kg, after 21min of neutralization, add 25g of sodium lauryl sulfate, stir for 7min, put it in the rotating pan, add 240g of potassium bisulfite and 140g of ammonium persulfate at the same time to initiate cross-linking polymerization. After it is a gel, it is cut into particles of φ2.5×3mm in a granulator. After drying at 150℃ in a drying bed, it is placed in a crushing and sieving machine for crushing and sieving to obtain particles with a particle size of 60-100 mesh. Then put it in a high-speed kneader, add 7kg of ammonium octaphasic acid with a purity of 99.5% for compound modification. The high-speed kneader has a stirring speed of 500r / min, a temperature of 75℃, and a time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com