Activated carbon pressing device

A technology of activated carbon and compressed powder, which is applied in the direction of presses, material forming presses, manufacturing tools, etc. It can solve the problems of complex structure, unfavorable installation and maintenance, and low production efficiency, so as to achieve uniform particle products, shorten pressing time, and improve production efficiency. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

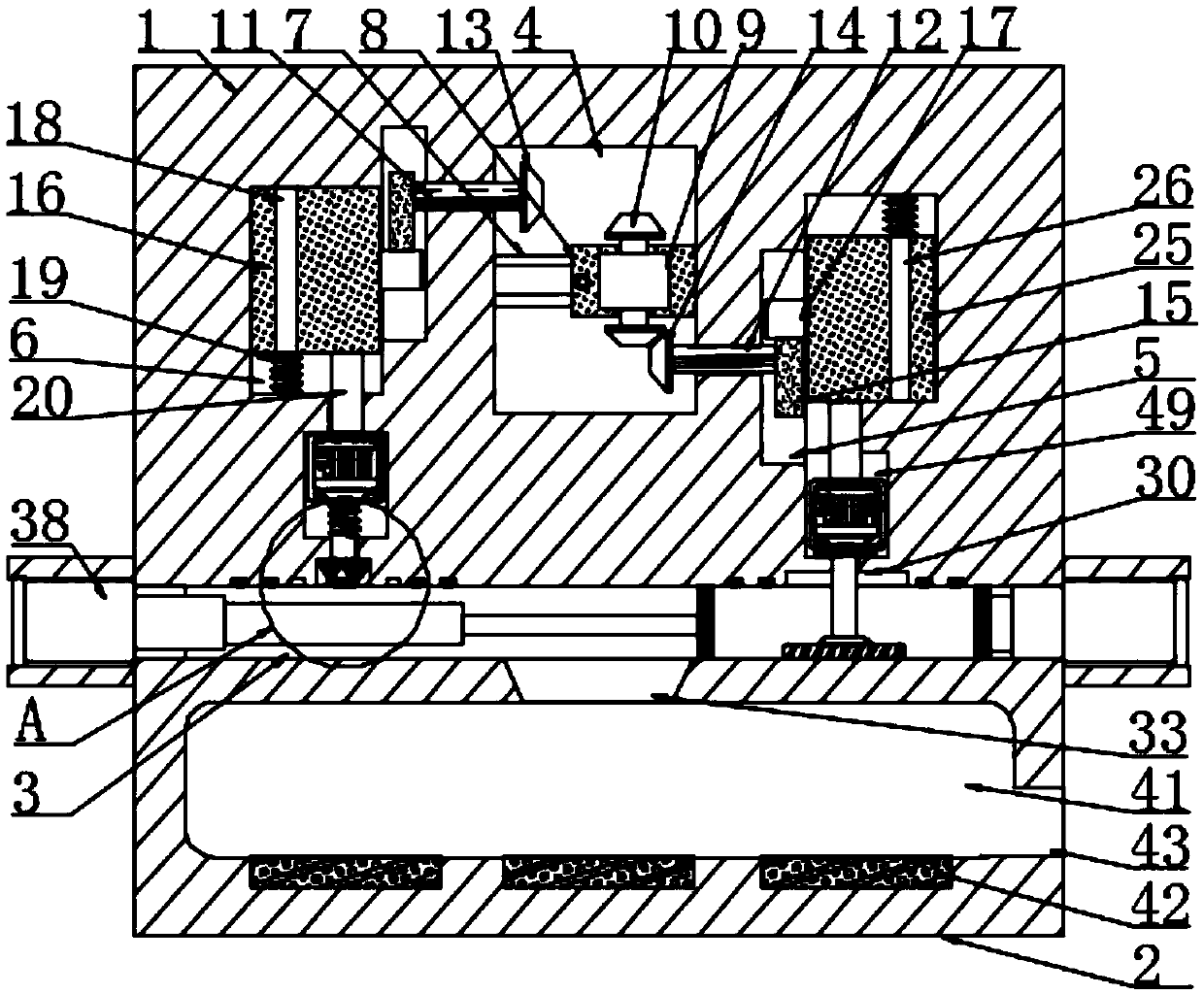

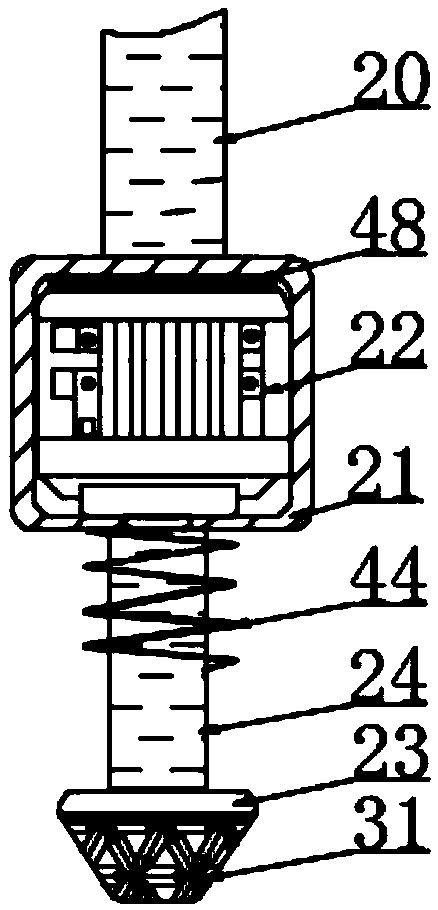

[0028] according to Figure 1-4 An activated carbon pressing device shown includes an upper case 1 and a lower case 2. The upper case 1 is fixedly connected to the top of the lower case 2, and a working channel 3 is provided between the upper case 1 and the lower case 2. The upper case 1 is provided with a first cavity 4, a connection conversion device is provided in the first cavity 4, a second cavity 5 is provided on both sides of the first cavity 4, and the second cavity 5 The side far from the first cavity 4 is provided with a third cavity 6, one of the third cavity 6 is provided with a particle suppression device, and the other of the third cavity 6 is provided with a powder suppression device, so The connection conversion device includes two sliding rods 7 distributed in parallel, a sliding sleeve box 8 is slidably connected to the outside of the two sliding rods 7, and a double-headed motor 9 is fixedly connected inside the sliding sleeve box 8. 9 Both output shafts are ...

Embodiment 2

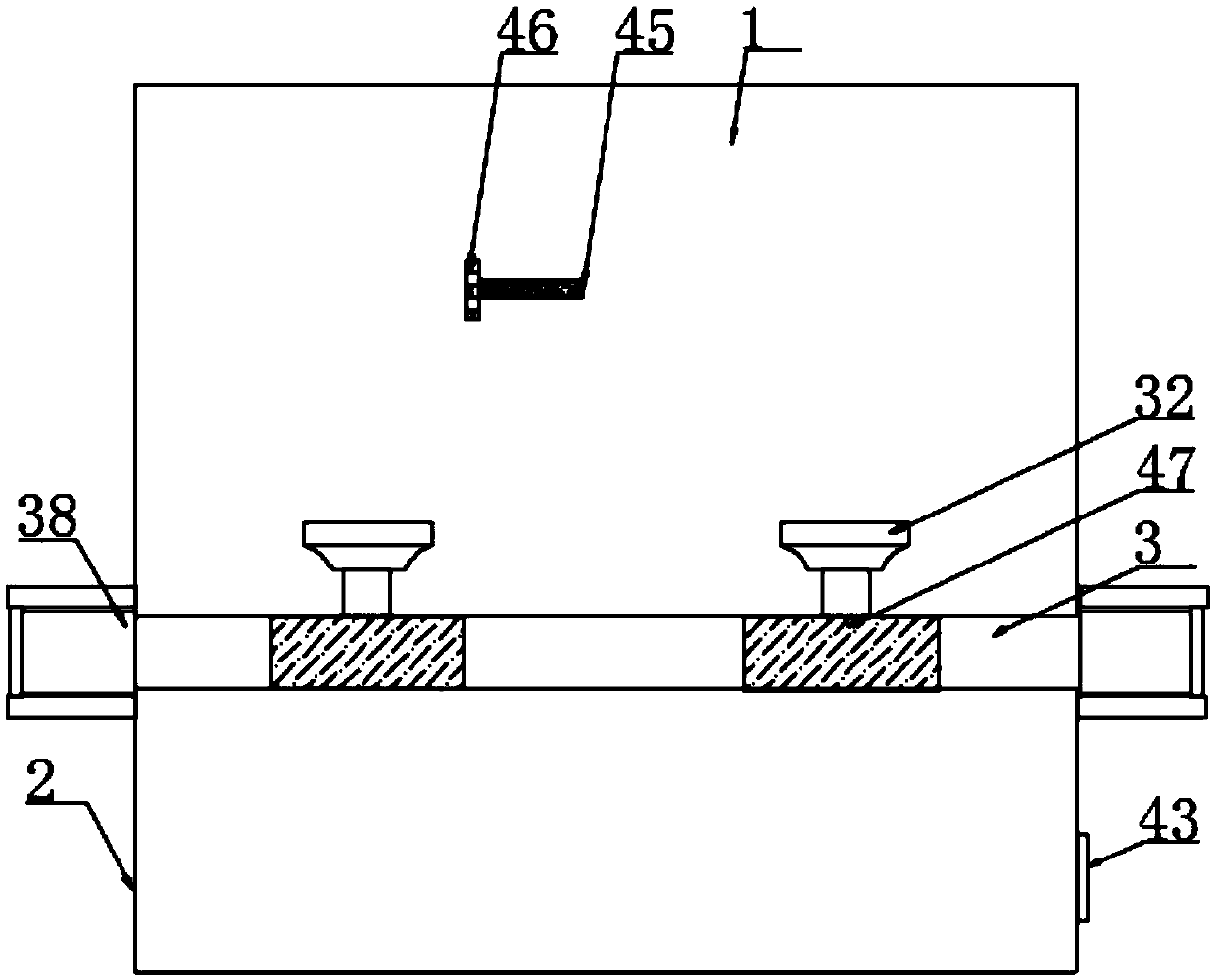

[0034] according to figure 2 Or an activated carbon pressing device shown in 5, the upper case 1 is provided with a feed opening 32 on one side, the feed opening 32 penetrates the working channel 3, and the top of the lower case 2 is provided with a discharge opening 33, so There are two sets of flaps 34 symmetrically distributed on both sides of the lower material opening 33, a slide rail 35 is provided at the bottom of the upper case 1, and the flap 34 is slidably connected to the slide rail 35, and the two flaps 34 Distributed symmetrically on both sides of the working channel 3, a second spring 36 is connected between the flap 34 and the inner wall of the working channel 3, the bottom of the working channel 3 is provided with a micro motor matching the flap 34, and the micro motor outputs The shaft is provided with an elliptical push block 37, both ends of the working channel 3 are fixedly connected with an electric push rod 38, and the output end of the electric push rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com