Magnetic levitation type slice medium thickness detecting device

A thin-sheet medium and thickness detection technology, which is used in the inspection of the authenticity of banknotes, processing coins or valuable banknotes, instruments, etc. The effect of streamlining parts and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further illustrate the thin sheet medium thickness detection device provided by the present invention, it will be further introduced in detail below with reference to the diagram of a preferred embodiment of the present invention.

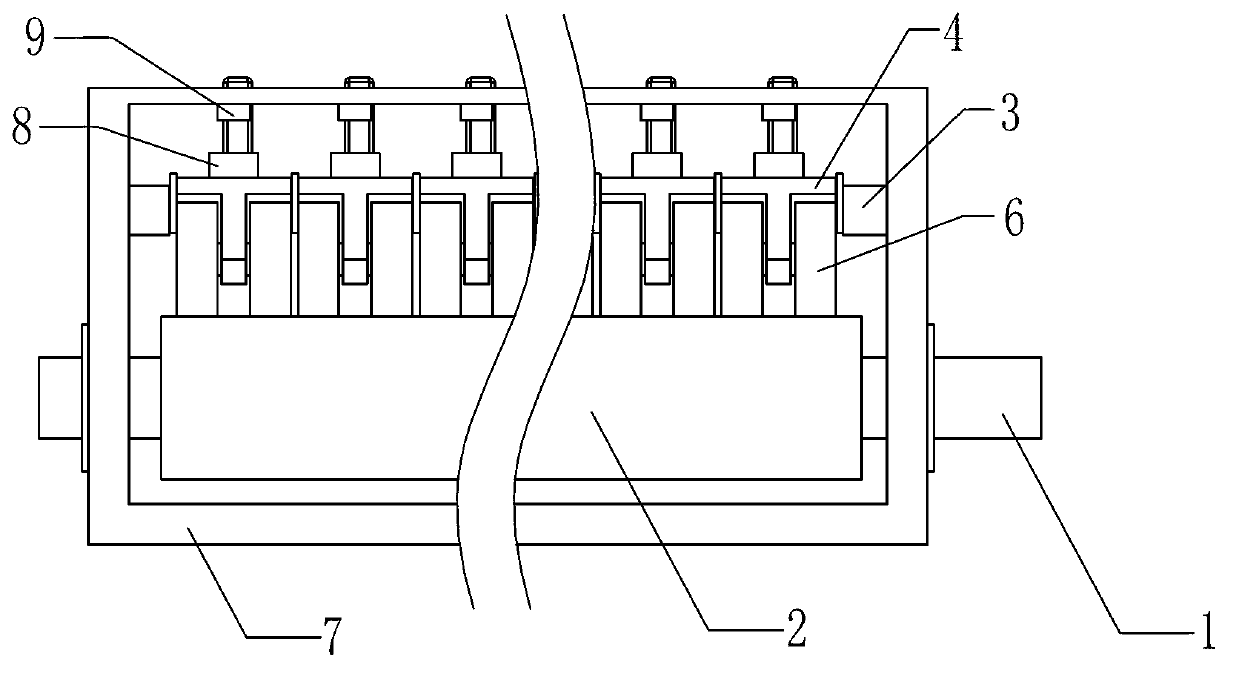

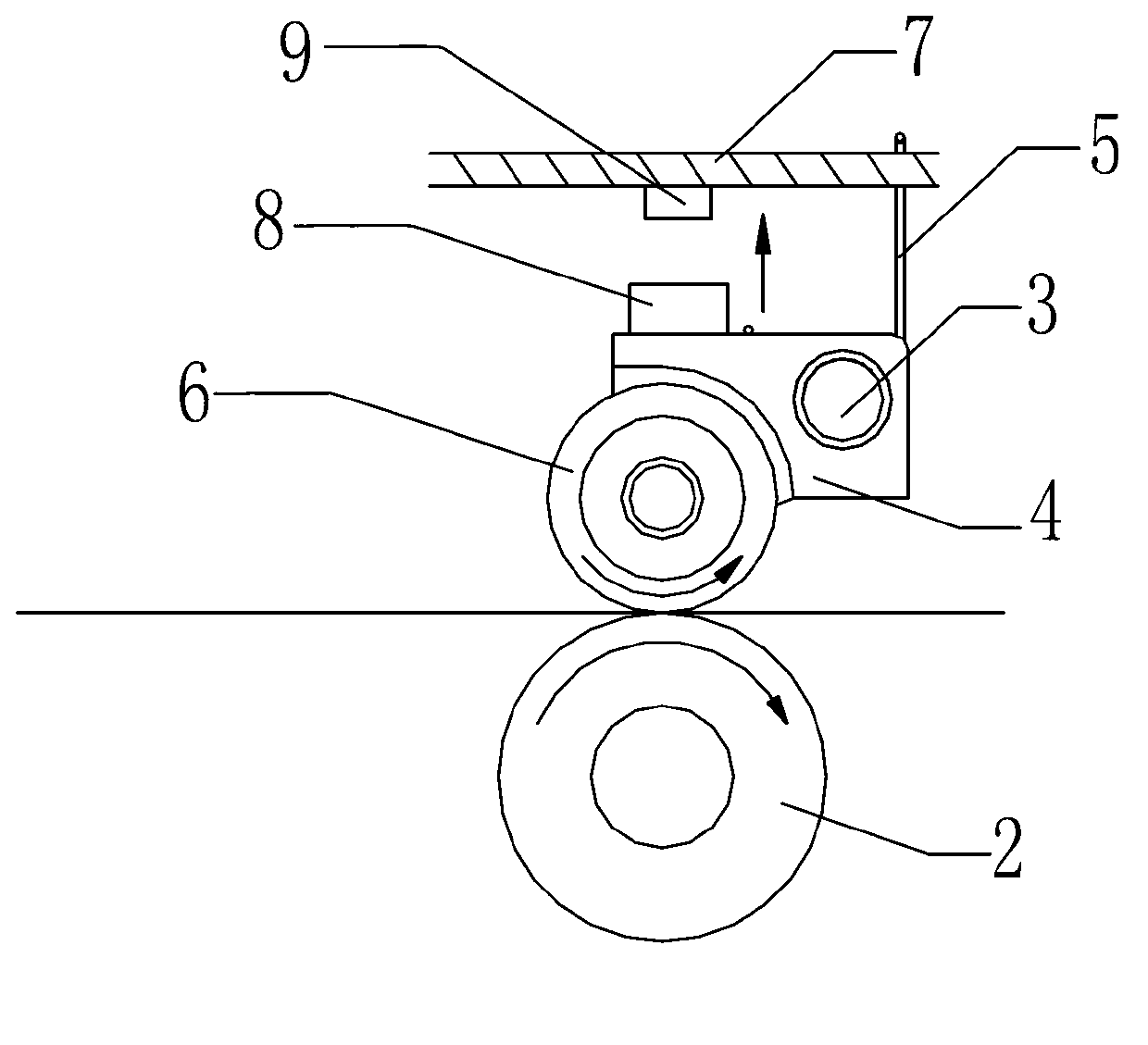

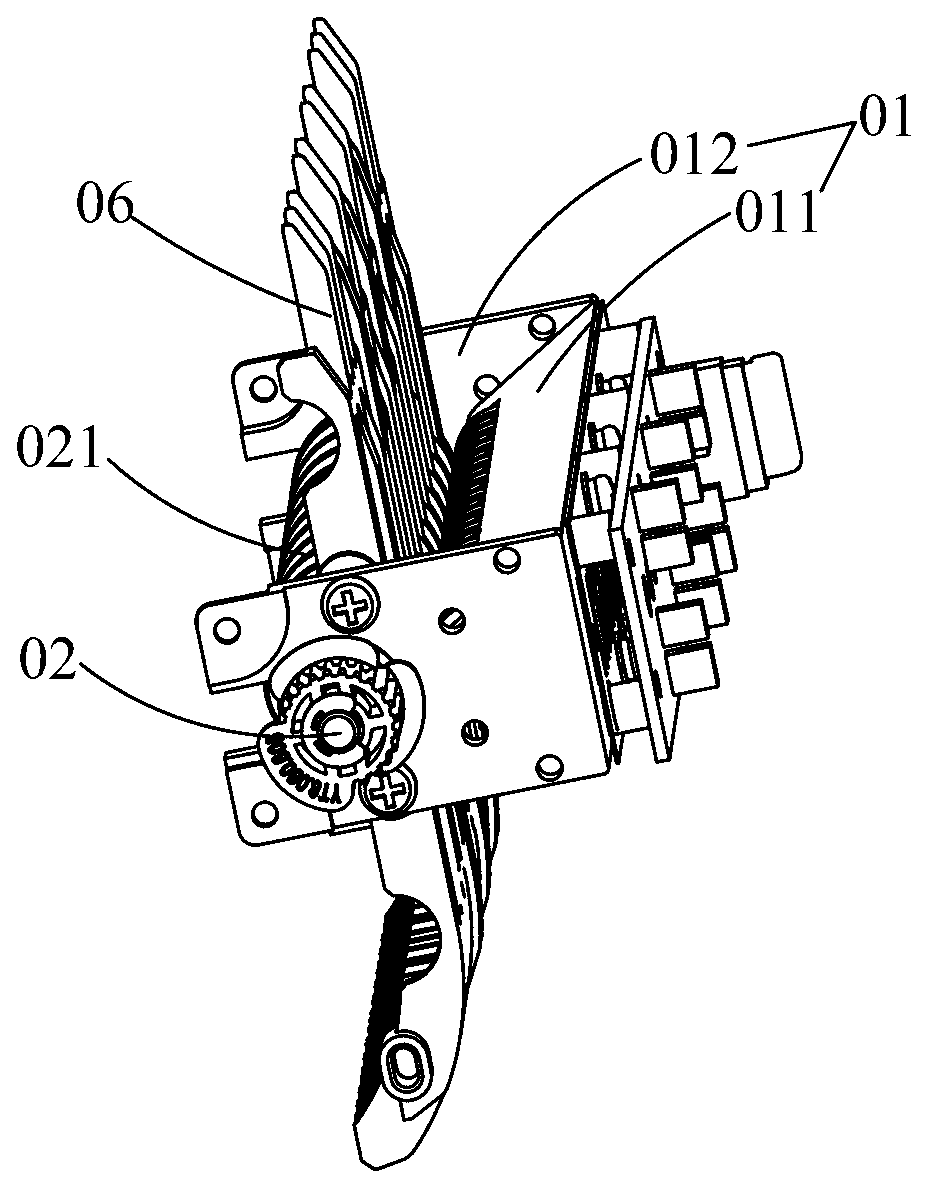

[0038] refer to image 3 and Figure 4As mentioned above, a preferred magnetic levitation thin sheet medium thickness detection device provided by the present invention includes: a fixed frame 01 for installing and carrying the following components, which has a pair of installation side walls 011 and a base plate 012, The base plate 012 is provided with a placement slot 0121; a reference shaft 02, both ends of which are mounted on a pair of installation side walls 011 of the fixing frame 01 through bearings, and a reference roller 021 is fixedly sleeved on the reference shaft 02; A detection idler mechanism 03, which includes a bracket 031, an idler 033 is provided on the bracket 031 through a bearing 032, and a magnetic element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com