Patents

Literature

141results about How to "Shorten pressing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

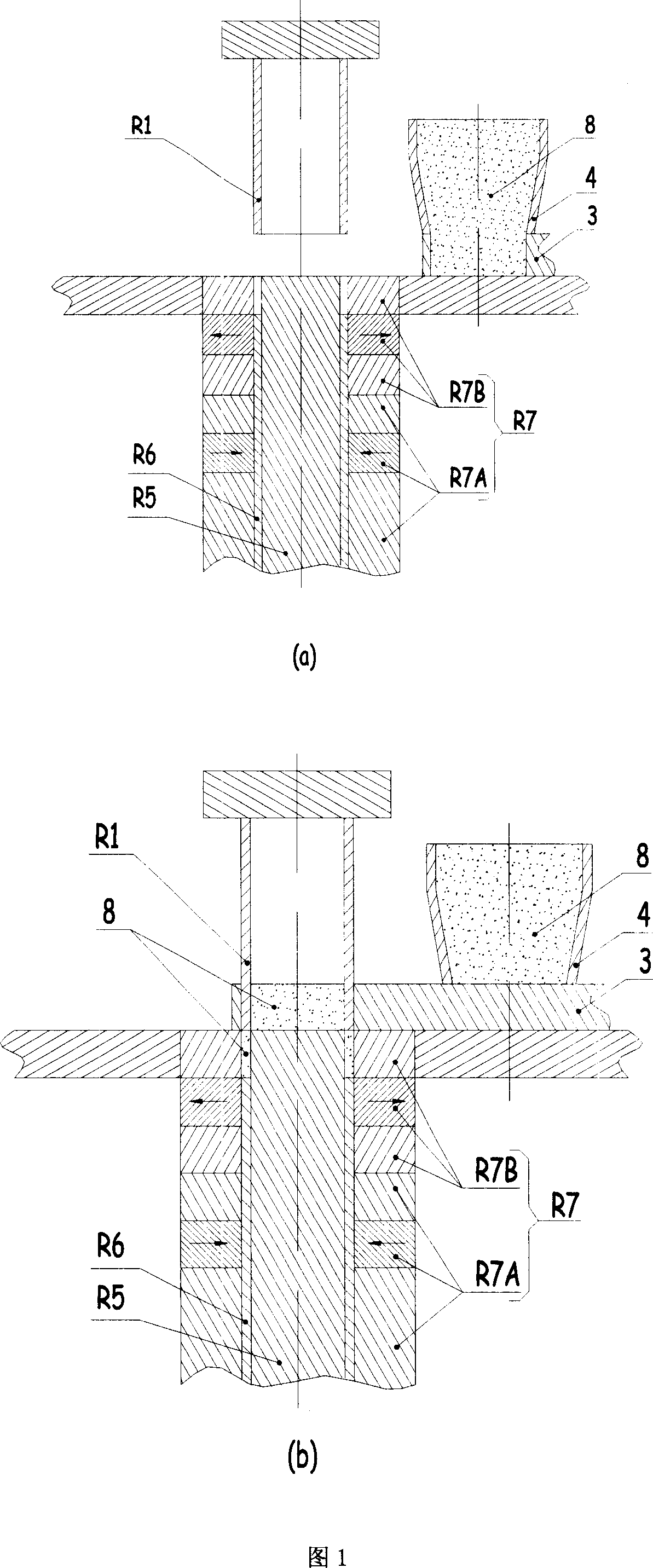

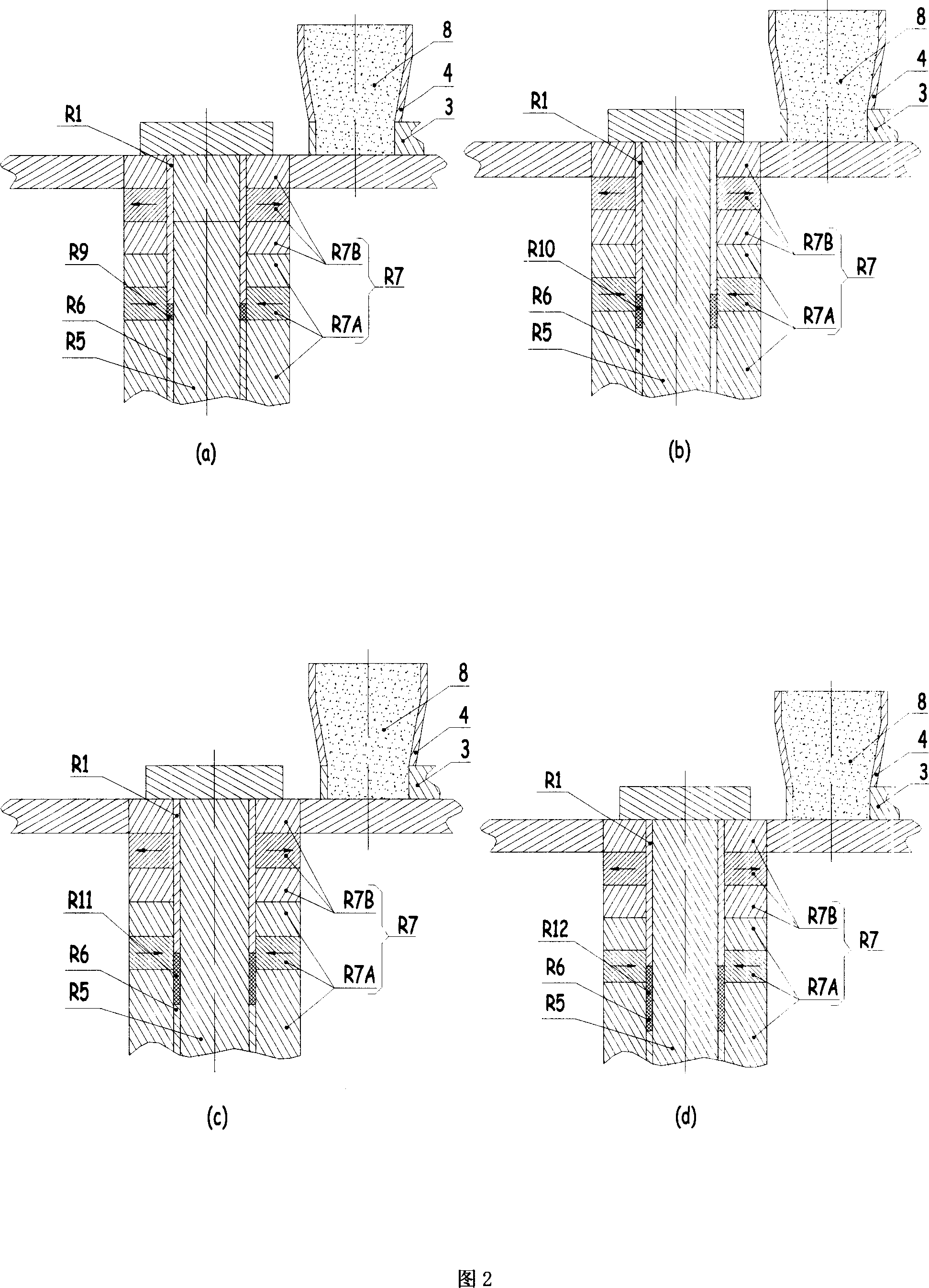

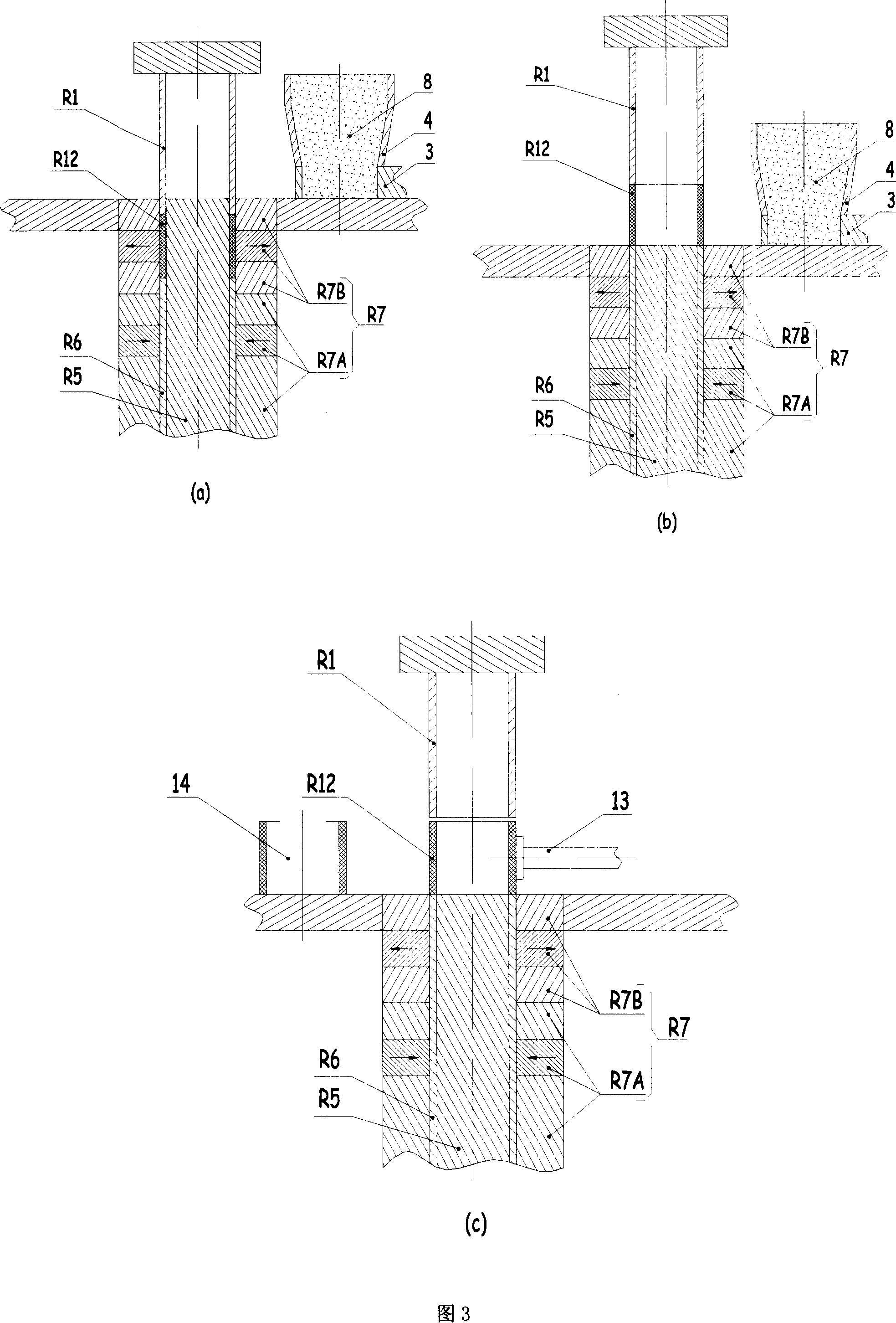

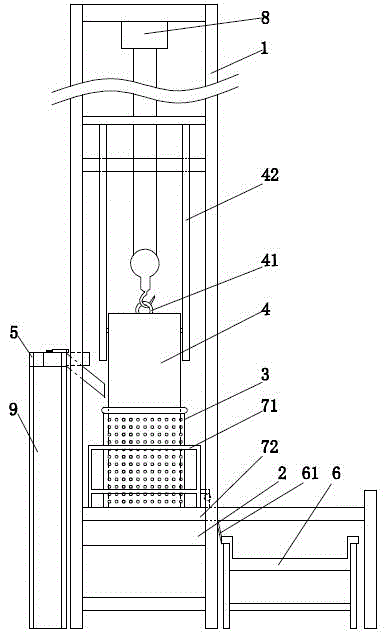

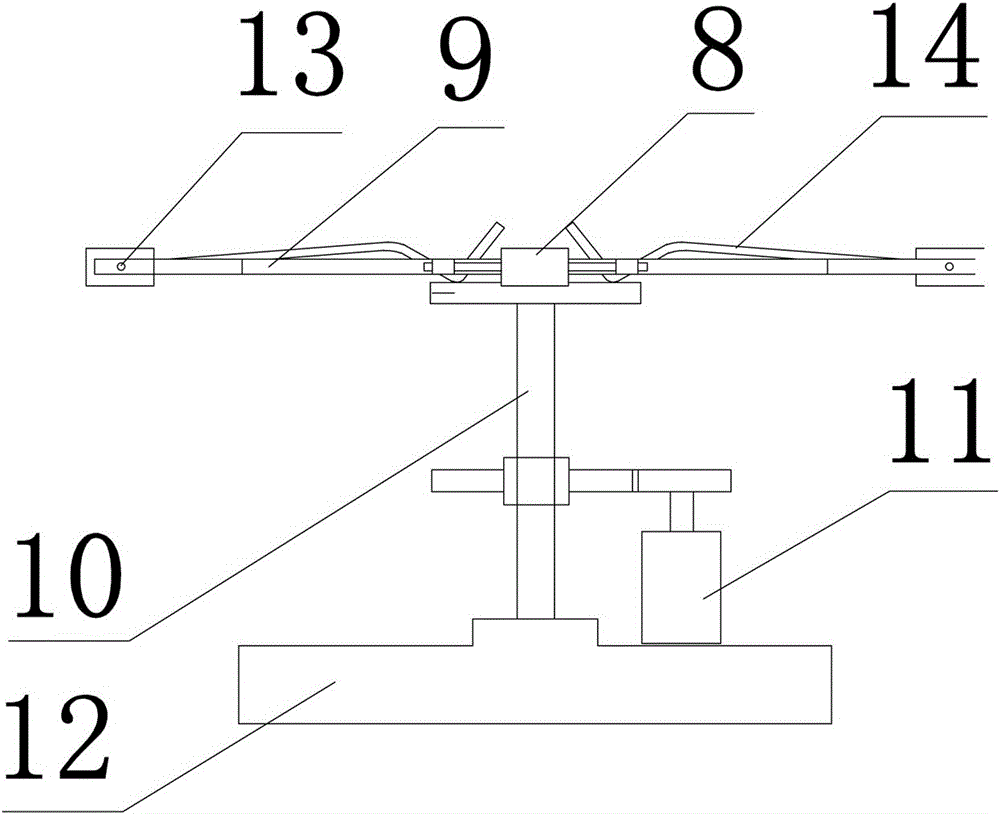

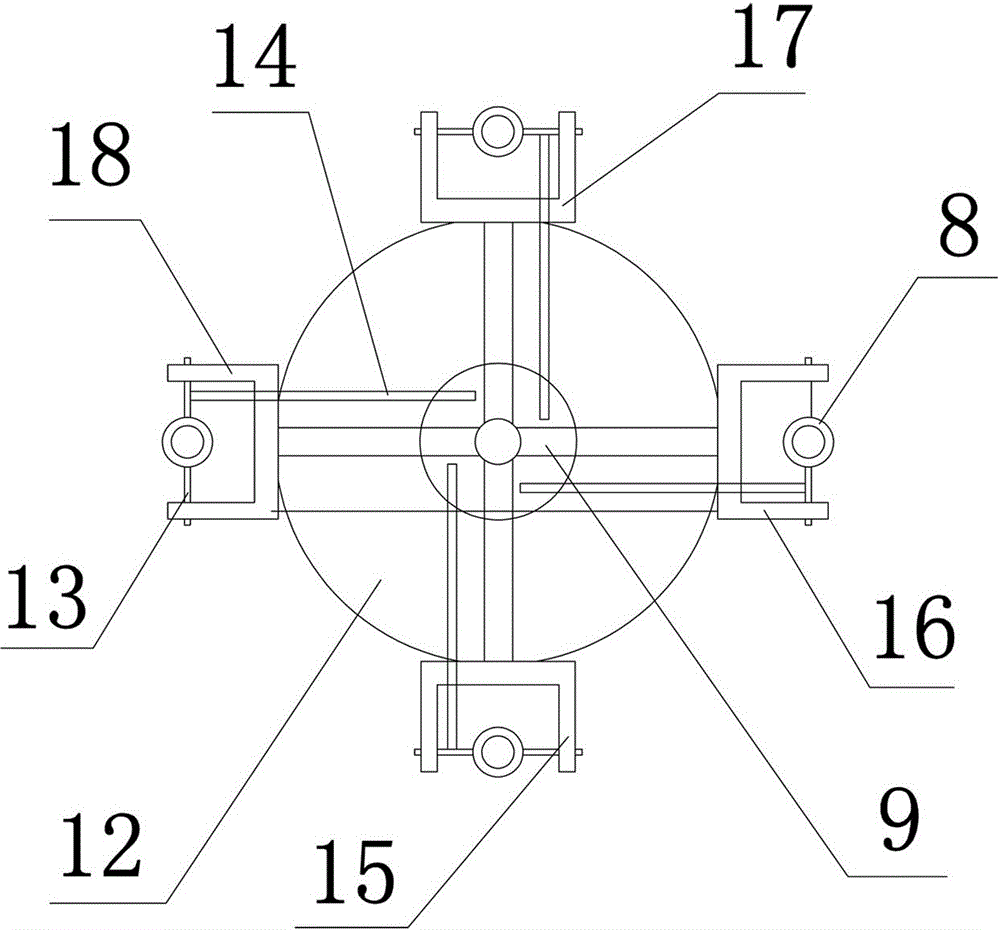

The method of the orientation profiling of the lanthanide permanent magnet and preparation device for the same

InactiveCN1996514AReduce volumeReduce consumptionPermanent magnetsInorganic material magnetismHead pressingRare earth

This invention relates to one rare each permanent part pressing and shaping method and its magnetic adding device and taking device, wherein, the shaping method comprises the following steps: top head presses the material case into magnetic powder into mode; top and down heads unmoved and negative mode elevates to fill powder into magnetic field; top head and negative mode unmoved, the top head presses into magnetic part; the negative mode drops till whole magnetic part outside negative mode; the top head elevates to push pull bar into finally product area; the materials add devices comprises materials case and barrel with changeable height.

Owner:姚燕 +1

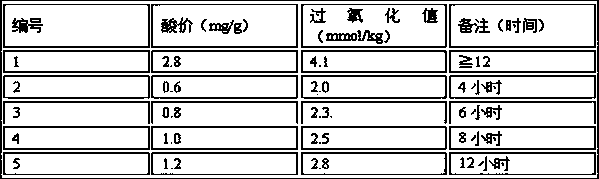

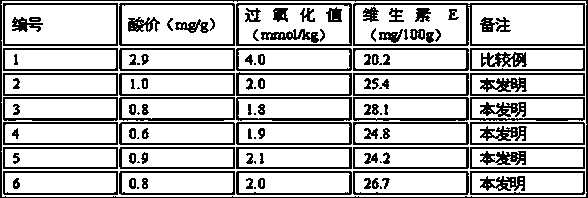

Camellia seed coldly-pressed tea-seed oil and processing process

ActiveCN104212628APrevent acidity riseQuality assuranceFatty-oils/fats refiningFatty-oils/fats productionChemistryFiltration

The invention provides camellia seed coldly-pressed tea-seed oil and a processing process. The processing process comprises the following steps: 1, pre-processing camellia seeds: selecting fresh camellia fruits; peeling and separating to obtain fresh camellia seeds; drying the camellia seeds at a low temperature; and storing; and 2, coldly pressing: cleaning the camellia seeds; shelling and removing shells; grinding; adding water and homogenizing; pressing to obtain primary oil; filtering; and finely filtering to obtain pure natural tea-seed oil. The fresh camellia seeds are dried at the low temperature within four hours and the drying temperature is controlled to be lower than 70 DEG C; the water is controlled to be 6%-10% and the camellia seeds are stored in a low-temperature warehouse to be processed; in the step of shelling and removing shells, the camellia seed shells with the weight percent of 15%-25% are remained in the camellia seeds; and the temperature of the water in the step of adding the water and homogenizing is 40-60 DEG C. By adopting the process to press the camellia seed oil, the quality of an obtained finished product is stable and the efficiency is improved; and the oil yield is guaranteed to the great extent.

Owner:HUBEI HUANGPAOSHAN GREEN PROD

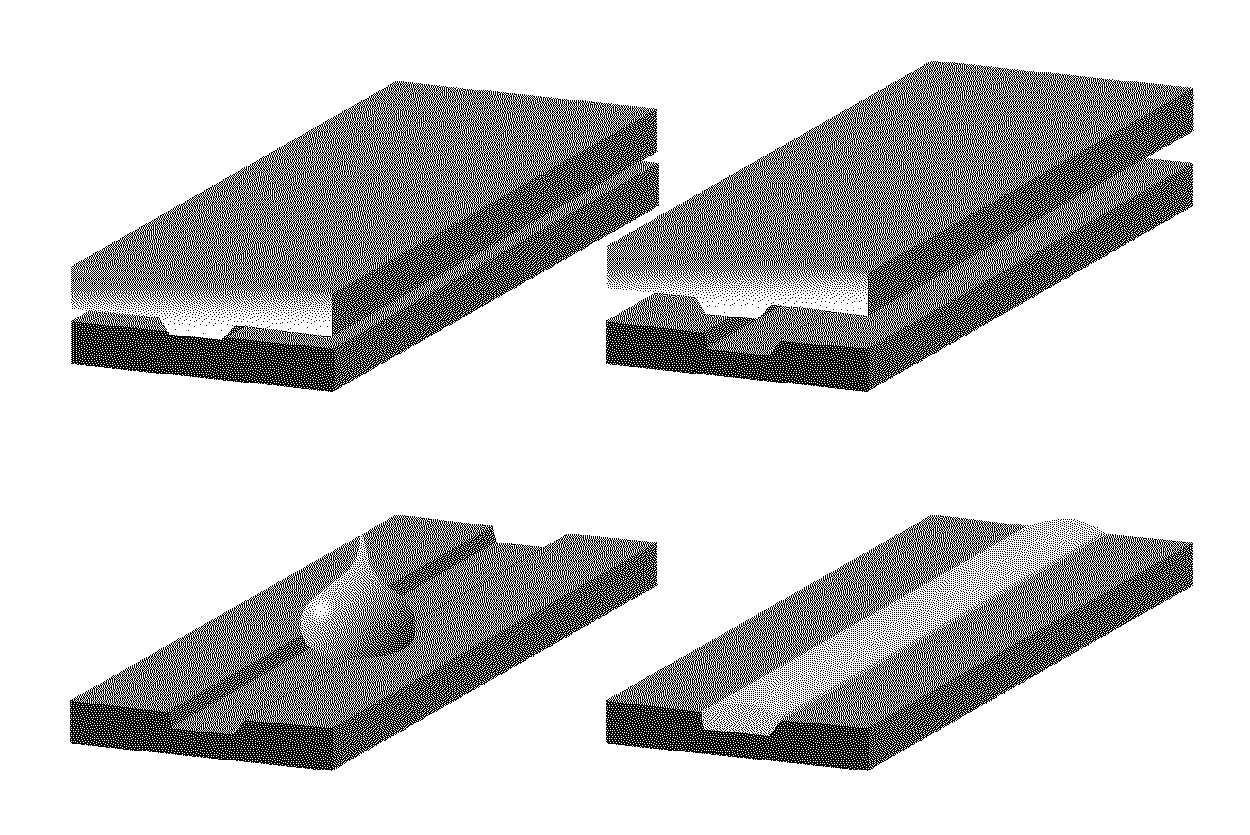

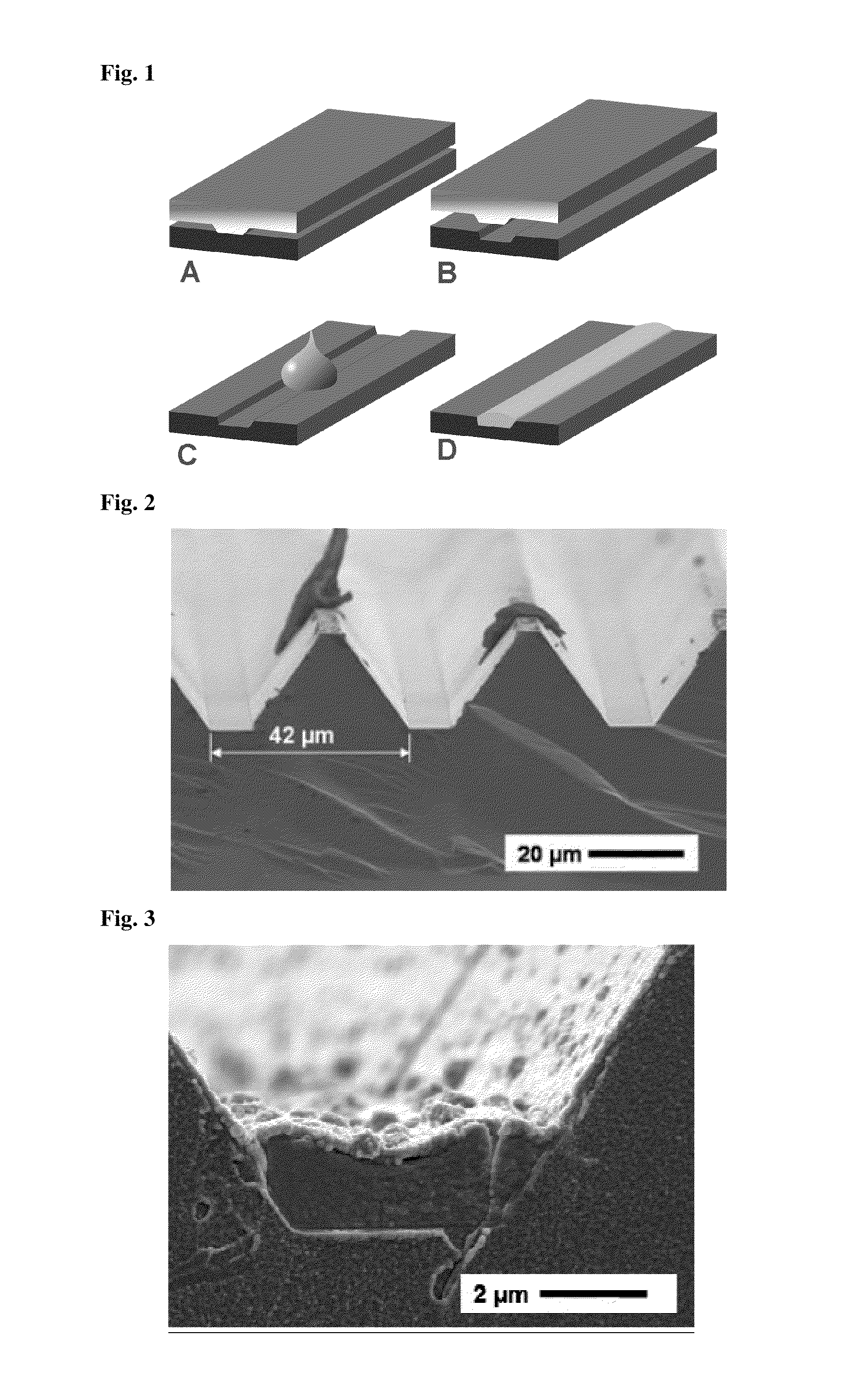

Method for fabricating minute conductive structures on surfaces

InactiveUS20090061213A1High flexibilityLow densityLayered productsSemiconductor/solid-state device manufacturingMicrostructureCapillary action

Method for producing small and micro conductive structures on surfaces by (hot) stamping and / or nanoscale imprinting microstructures on the surfaces, targeting conductive material into the channels thus created with the aid of capillary action, and appropriately after-treating the conductive material.

Owner:CLARIANT INT LTD +1

Material for information recording medium substrate, information recording medium substrate, information recording medium, and method for manufacturing them

InactiveUS8656734B2Reduce the warp of the disklike glassReduce warpageGlass drawing apparatusGlass forming apparatusShell moldingOptoelectronics

A method for manufacturing a disklike glass material comprising the successive molding of multiple pieces of disklike glass material from glass melt. Being suppressed variation over time in the concentration of infrared radiation-absorbing ions contained in the glass melt being molded into the pieces of disklike glass material so that the variation in the sheet thickness of the multiple pieces of disklike glass material falls within a range of ±15 percent of a reference value. The reference value being the median between the maximum value and the minimum value of the sheet thickness of 1,000 pieces of the glass material. In the course of molding multiple pieces of disklike glass material comprised of glass containing 0.1 to 100 ppm of infrared radiation-absorbing ions, vaiiation over time in the concentration of the infrared radiation-absorbing contained in the glass melt is suppressed to suppress variation in the sheet thickness of the multiple pieces of sheet like glass material.

Owner:HOYA CORP

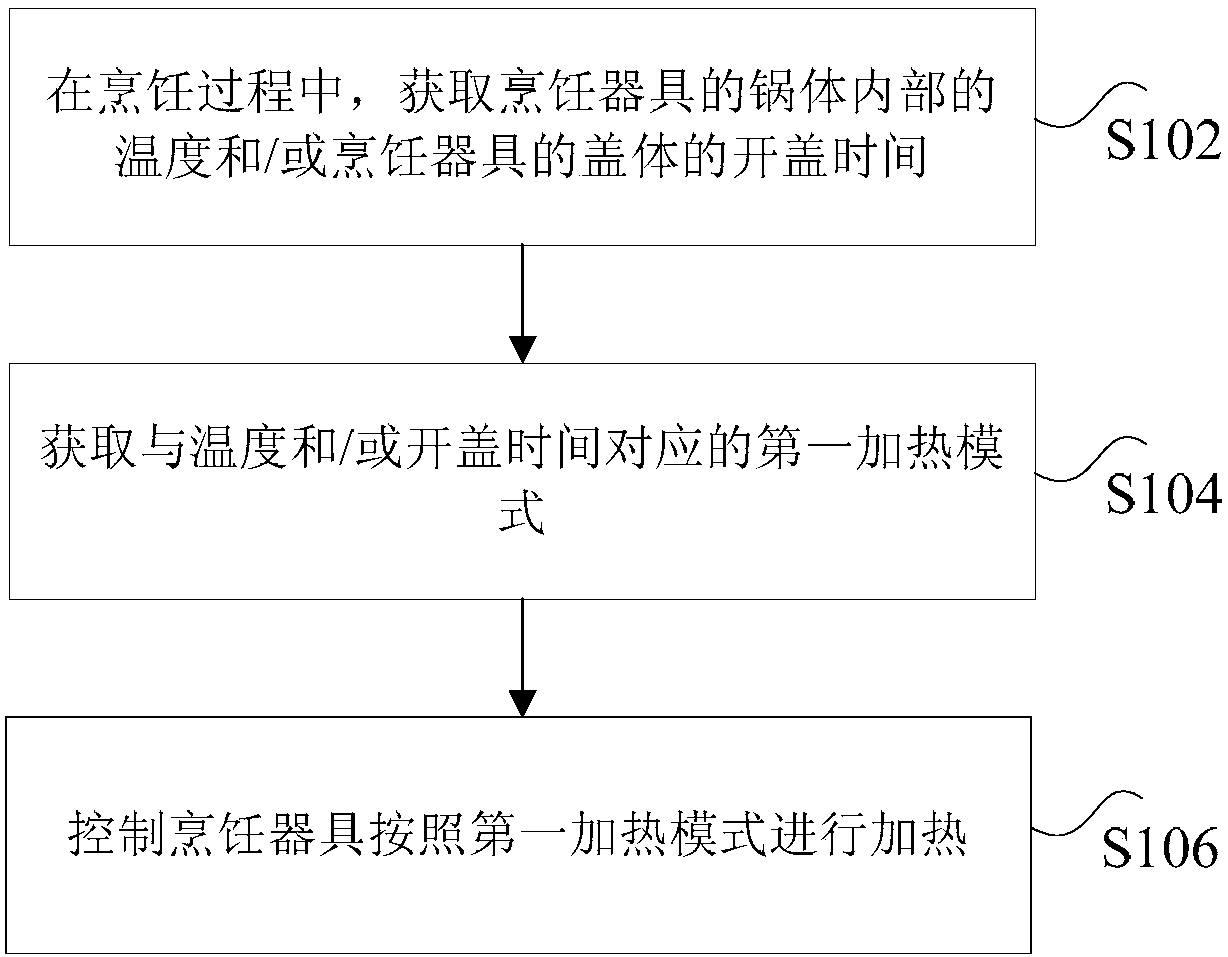

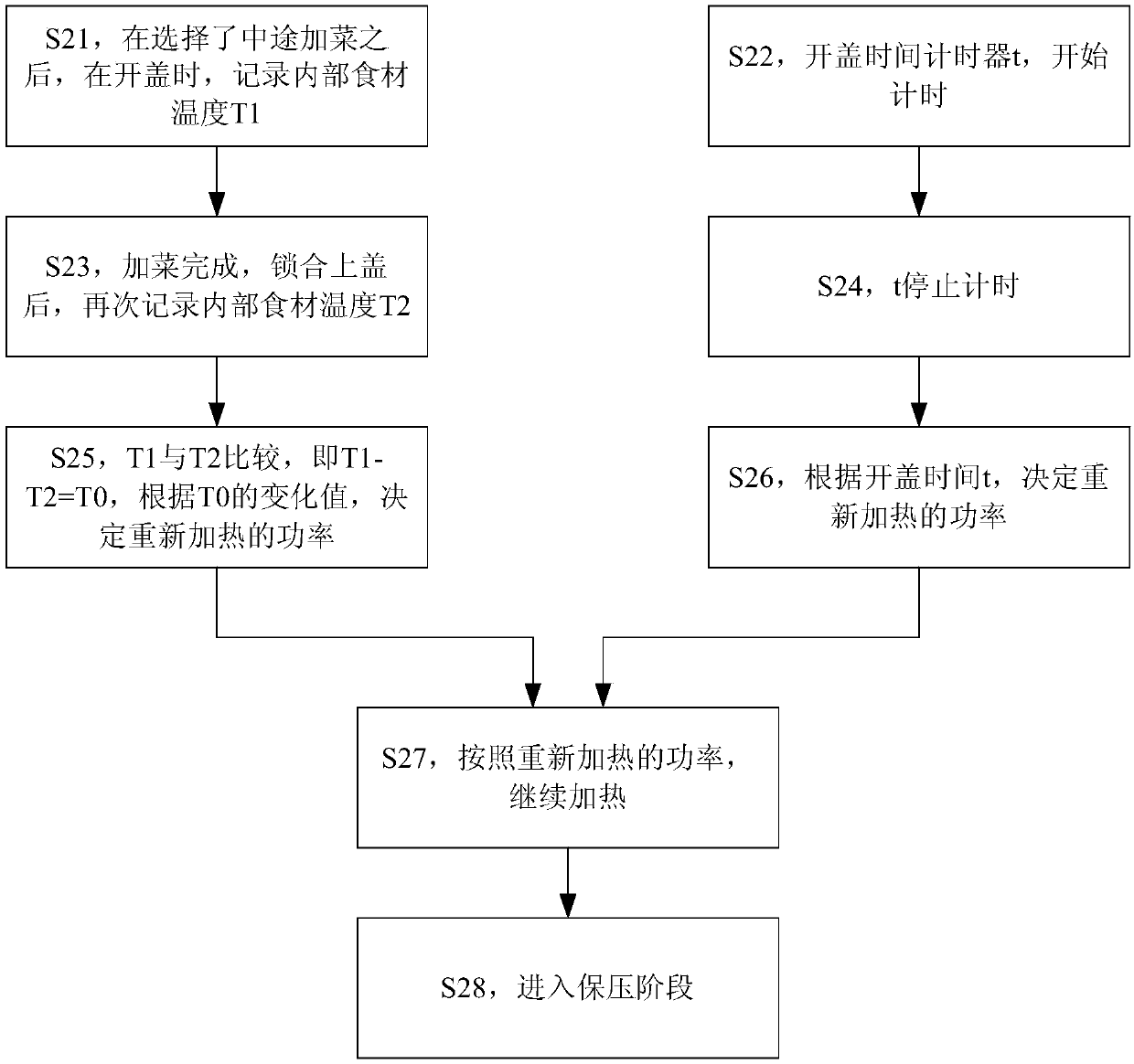

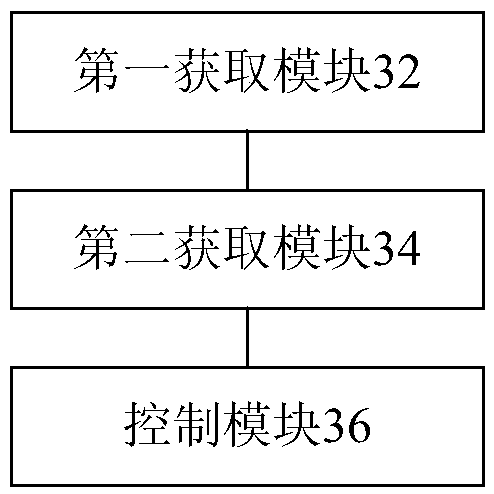

Cooking utensil, control method and device for same, storage medium and processor

ActiveCN109965683AShorten pressing timeImprove cooking resultsPressure-cookersProcess engineeringEngineering

The invention discloses a cooking utensil, a control method and a control device for the cooking utensil, a storage medium and a processor. The control method for the cooking utensil comprises the following steps: during the cooking process, acquiring the temperatures inside a pot of the cooking utensil and / or the uncovering time of a cover of the cooking utensil; acquiring a first heating mode corresponding to the temperatures and / or the uncovering time; and controlling the cooking utensil to carry out heating according to the first heating mode, wherein the temperatures inside the pot comprise a first temperature before the cover is opened and a second temperature after the cover is closed, and the uncovering time is the time from the opening of the cover to the closing of the cover. With the technical scheme, the technical problem that in the prior art, after halfway charging, the cooking utensil carries out heating according to the fixed power, so that the cooking effect is poor issolved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

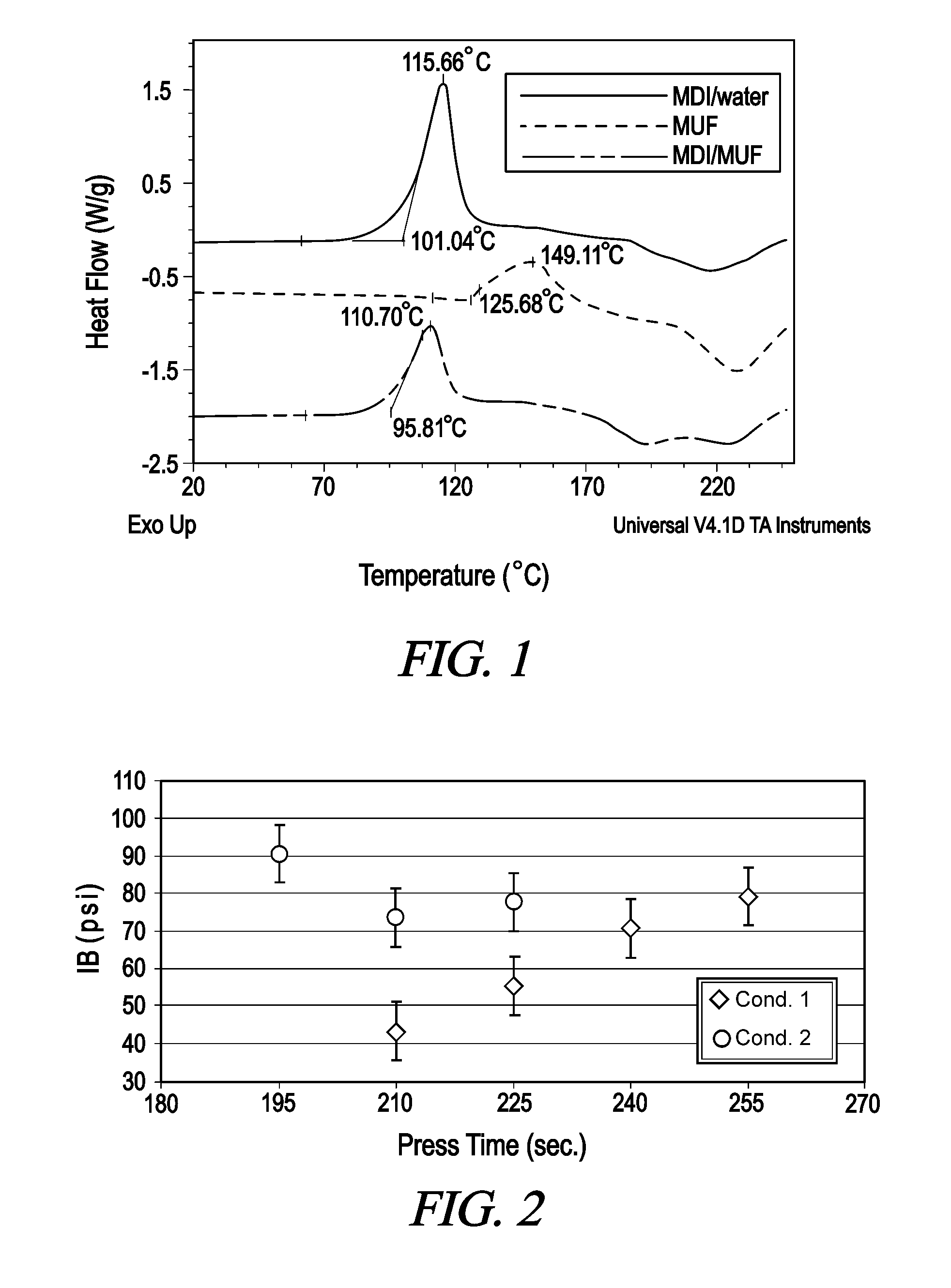

Accelerated Curing Adhesive For Wood Composites

InactiveUS20100071829A1Speed up the processEmission reductionWood working apparatusAbsorbent padsAdhesive cementAccelerated curing

An adhesive system for, inter alia, the manufacturing of wood composites, which includes a MDI adhesive and a formaldehyde-containing resin accelerator.

Owner:GANG NAIL SYST

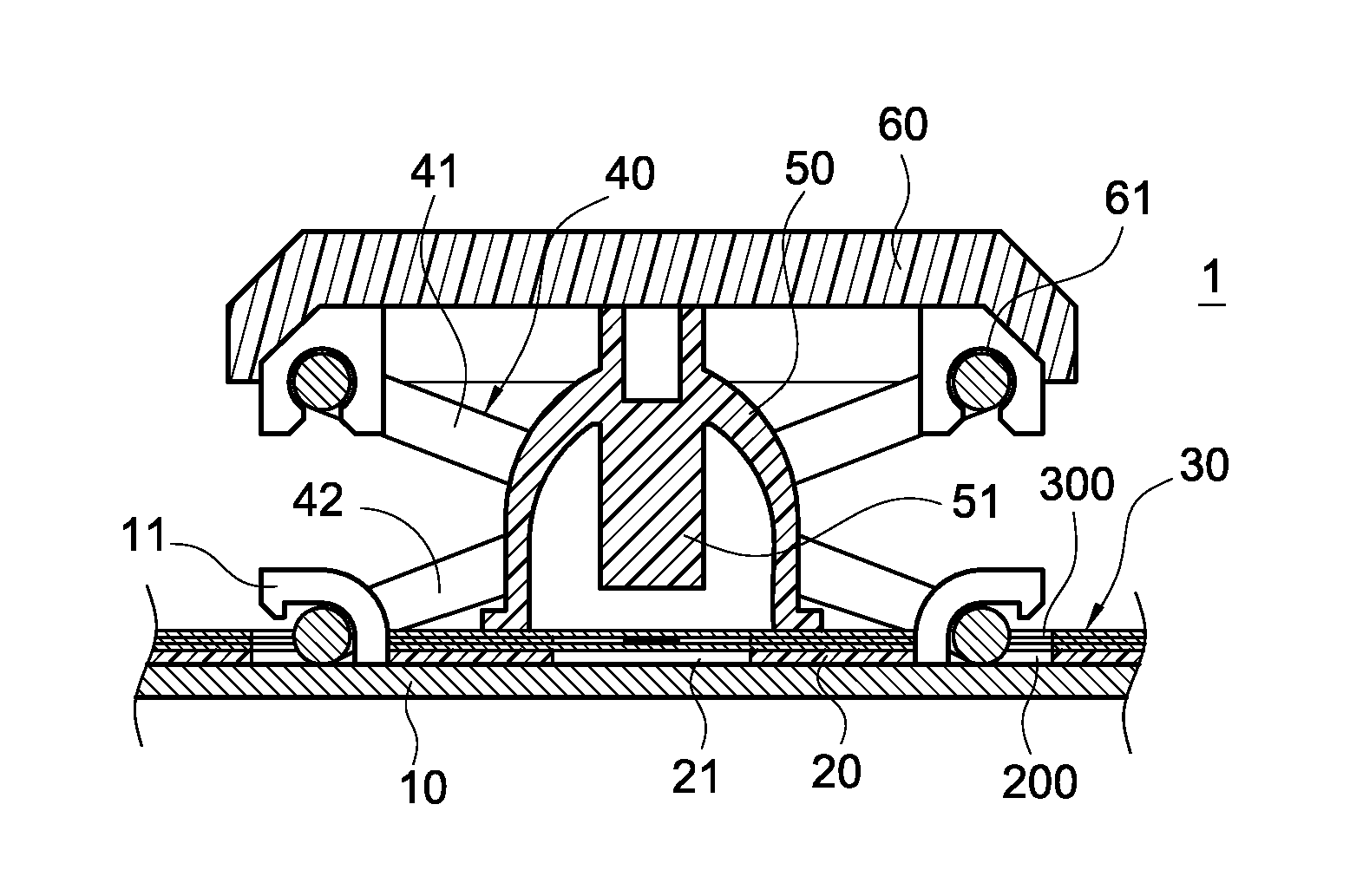

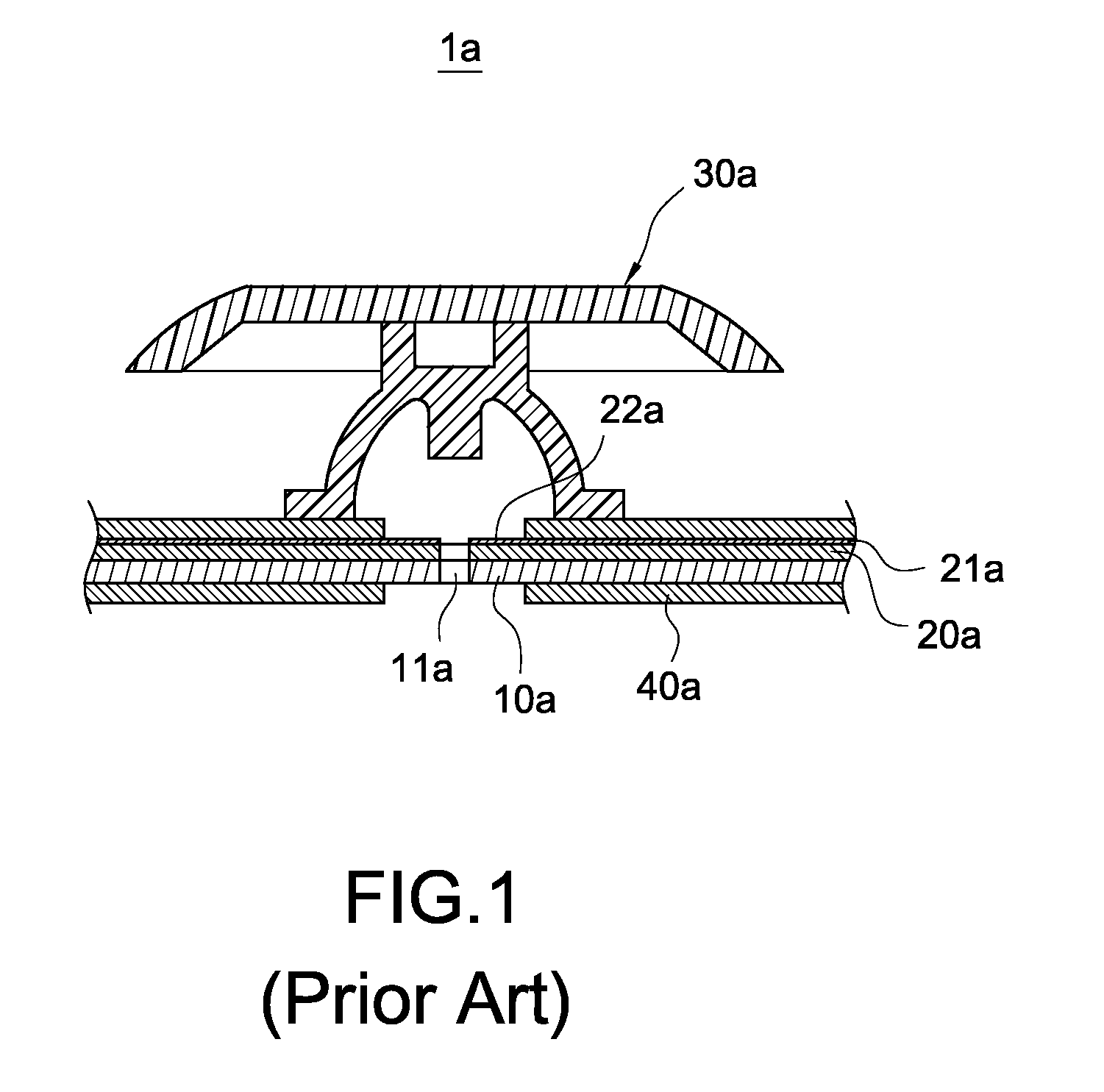

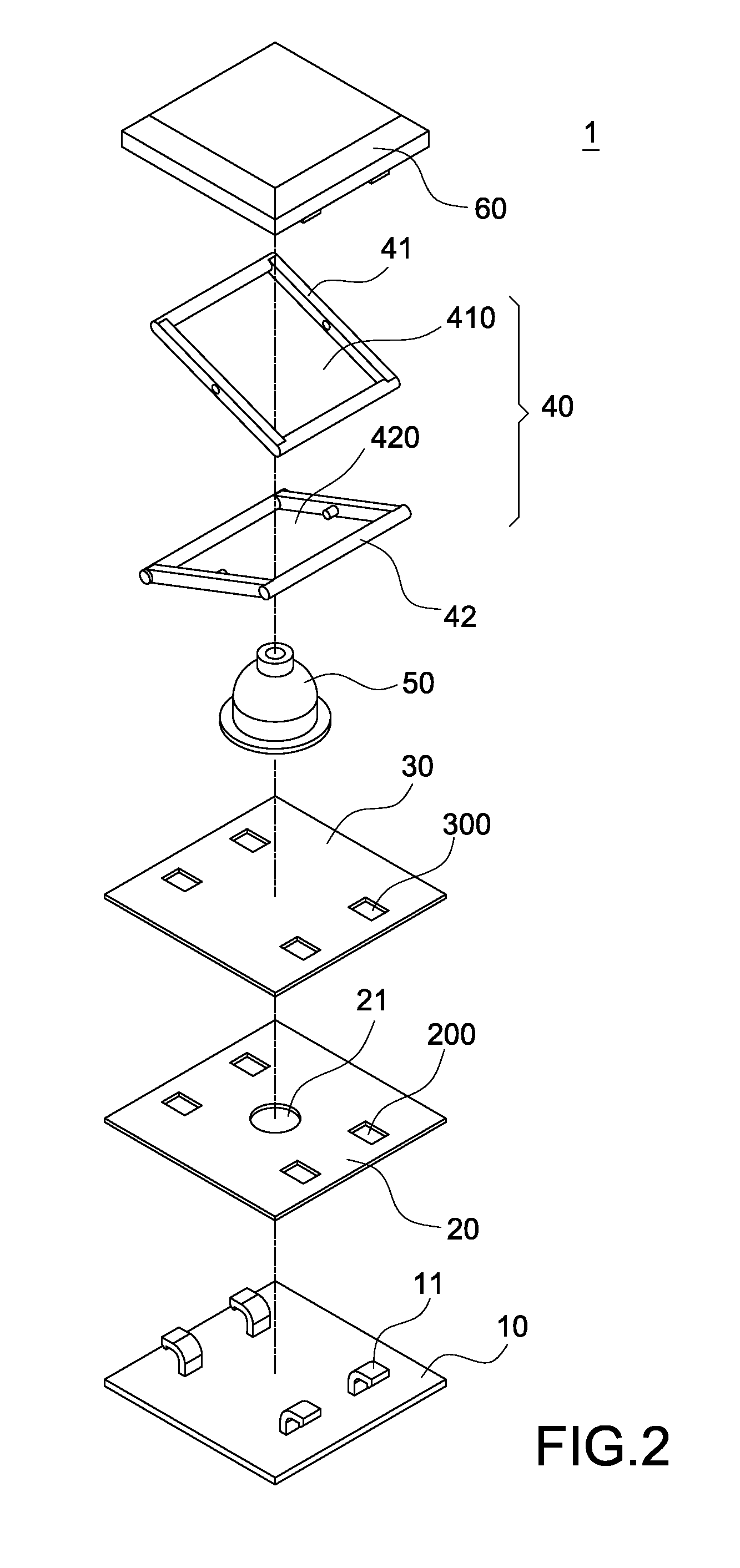

Dustproof press key structure

InactiveUS20110297525A1Thin thicknessMaintain structural strengthContact mechanismsContact surface shape/structureKey pressingMembrane switch

A press key structure includes a bottom board, an insulating plate, a thin film circuit board, an elastic trigger element, and a keycap covered onto the elastic trigger element, and the insulating plate is installed on the bottom board and includes a penetrating hole, and the thin film circuit board is covered onto the insulating plate, and the thin film circuit board and the bottom board are enclosed to define a containing space at a position corresponding to the penetrating hole, and the thin film circuit board includes a thin film switch disposed above the containing space, and the elastic trigger element is installed above the thin film circuit board, such that external dusts can be prevented from entering into the press key structure from the penetrating hole, and the adverse effect of the dusts on the electric connection and the press path of the press key can be avoided.

Owner:CHICONY ELECTRONICS

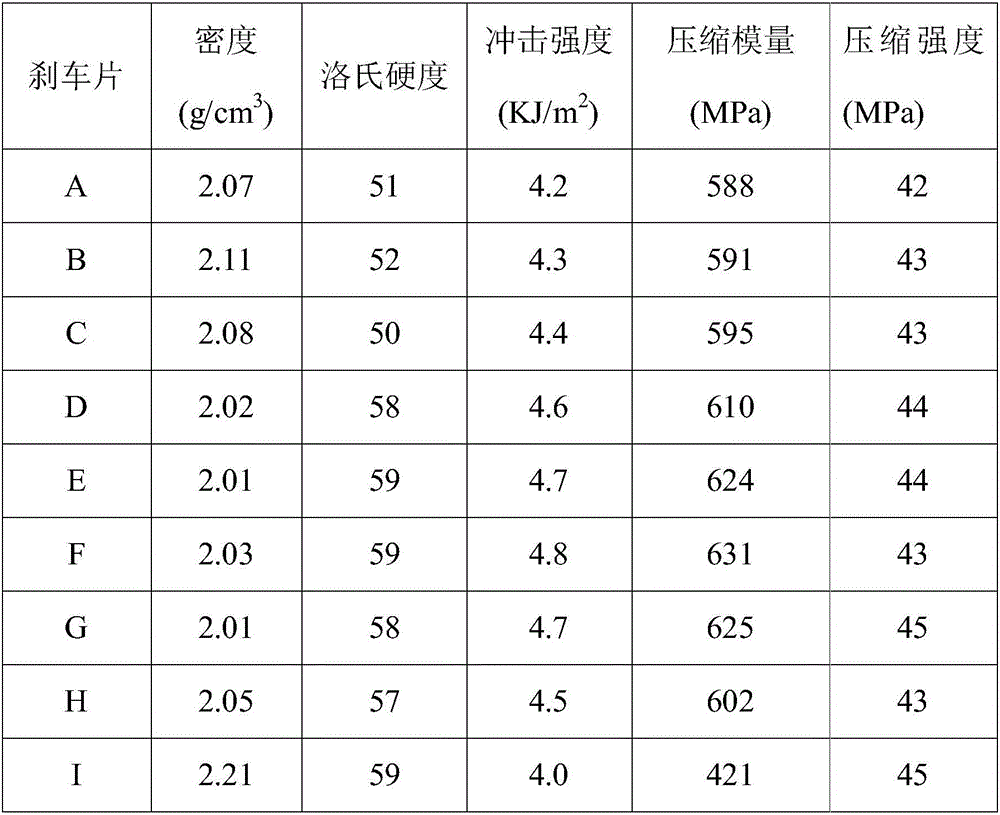

Friction material, brake pad with friction material and method for manufacturing brake pad

ActiveCN106763364AImprove thermal stabilityHigh impact strengthOther chemical processesFriction liningVolumetric Mass DensityEngineering

The invention provides a friction material, a brake pad with the friction material and a method for manufacturing the brake pad. According to the friction material, through reasonable selection and matching of all raw material components, especially by controlling the proportion of inorganic matter and organic matter and adjusting the variety of the inorganic matter, a synergetic cooperation function is generated among all the components, and finally the brake pad made of the friction material has the beneficial effects of being good in heat stability, high in impact strength, large in hardness and resistant to wear; and besides, the density of the friction material is small, and the dead weight of the friction material under the same size condition is small, that is, the friction material is small in consumption when used for manufacturing the brake pad, so that the production cost of the brake pad can be lowered effectively on the premise of not sacrificing the performance of the brad pad; and accordingly, the friction material is suitable for braking of rail vehicles with the higher speed, the larger thermal load and the larger passenger capacity.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

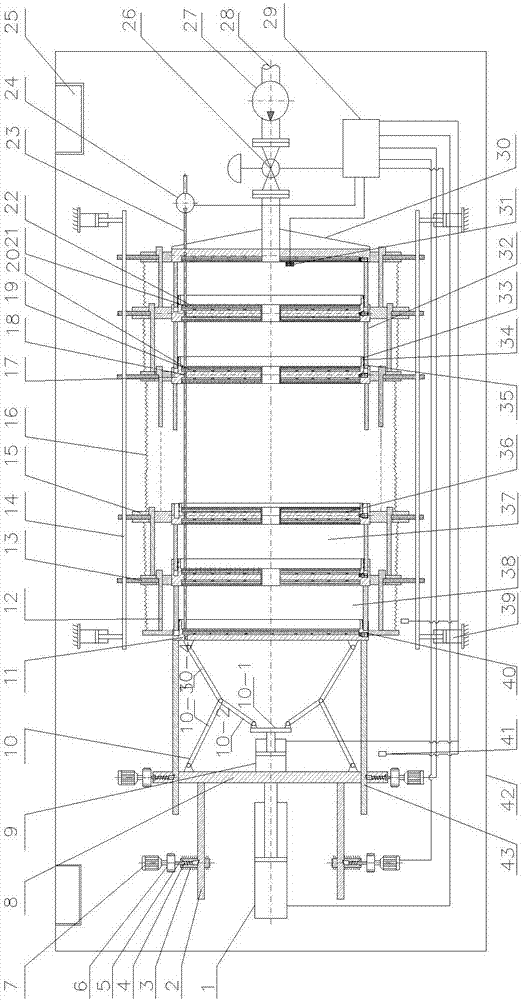

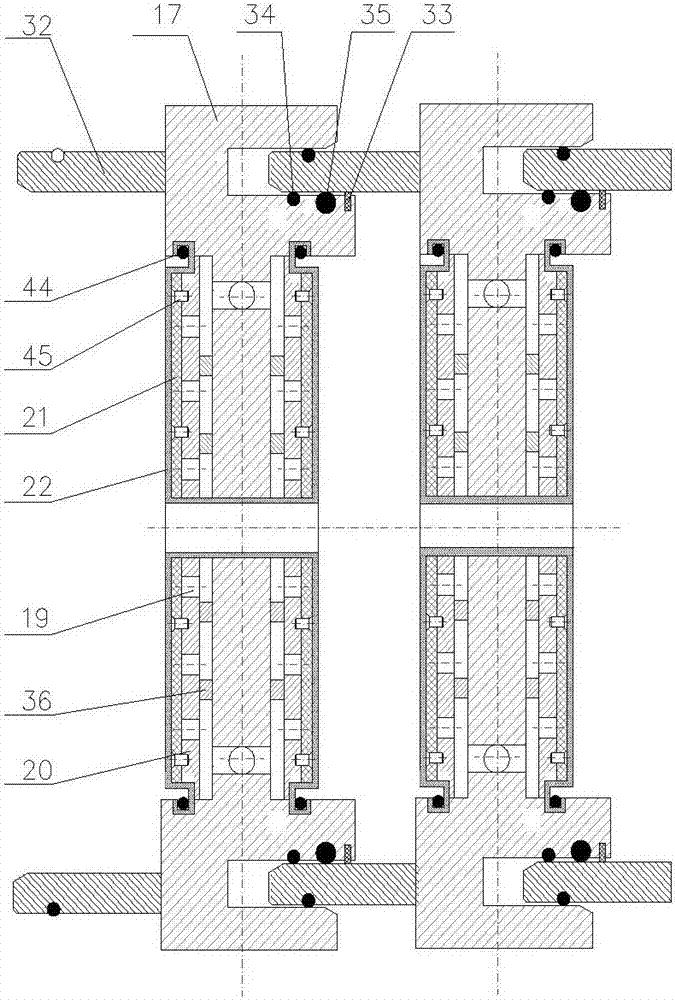

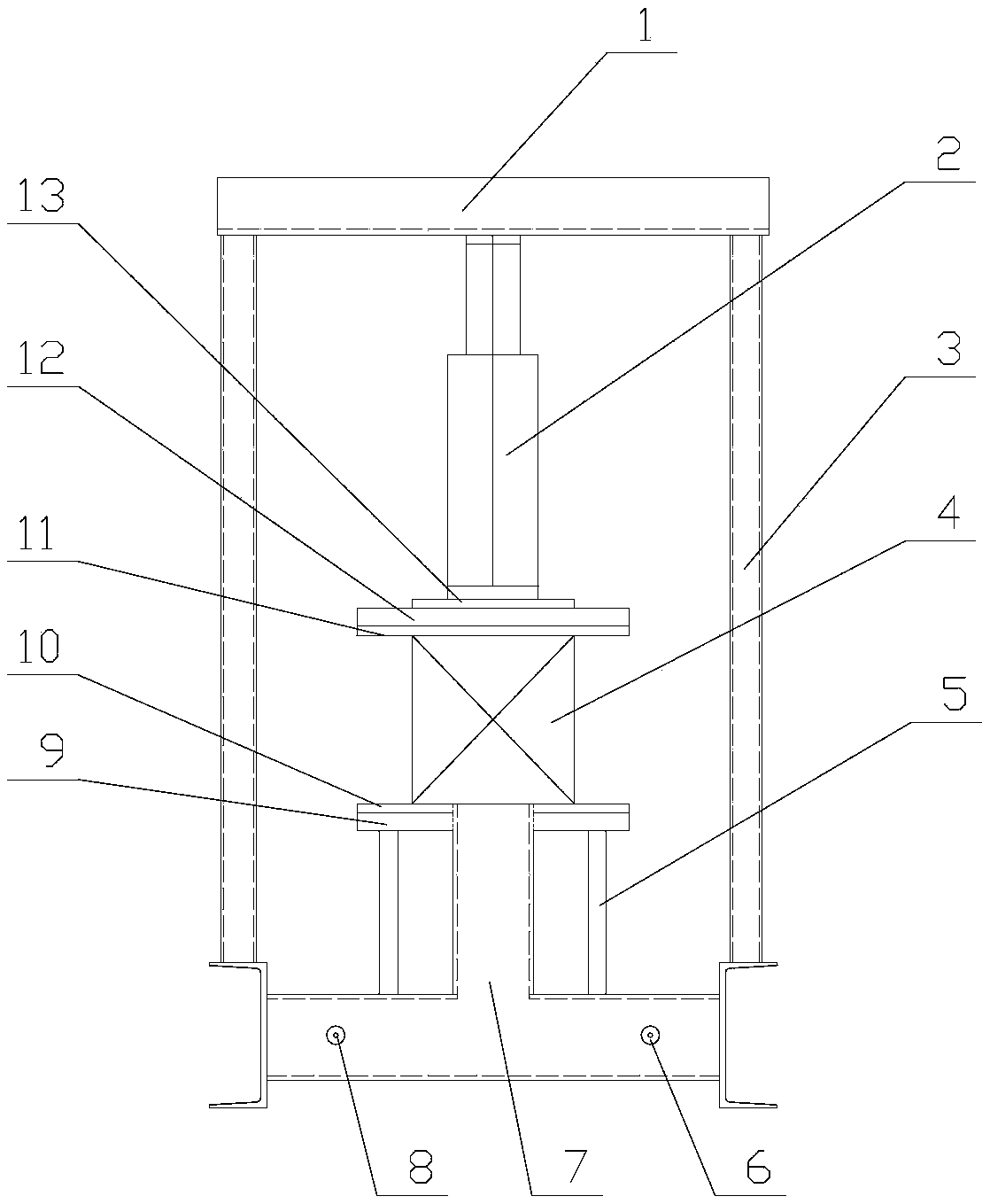

High-dryness dehydration device for thin layer sludge

ActiveCN106927658AImprove compression performanceHigh compressibility complies withSludge treatment by de-watering/drying/thickeningSludgeThin layer

The invention relates to a high-dryness dehydration device for thin layer sludge. The high-dryness dehydration device comprises a pressure filter plate frame, a long stroke oil cylinder (1), a short stroke oil cylinder (9), a force amplifying mechanism (10), a plate frame positioning and self-locking mechanism, a pressure filter cavity (37), a main push plate (8), an auxiliary push plate (11), a thrust plate (30), a high pressure sludge feed pump (28), a high pressure gas generator and components, and a rack (3), wherein the pressure filter plate frame comprises a filter frame (17) and a filter plate (20), and one side of the pressure filter plate frame is fixedly connected with an outer ring (32); a convex ring is also arranged at the other side of the pressure filter plate frame, and a sludge scraping ring, a first sealing piece and a second sealing piece are arranged on the convex ring; a circle of grooves is formed in the filter frame, and the adjacent filter plate frame, the outer ring (32), the convex ring and the sealing pieces form a volume-variable sealed chamber; the short stroke oil cylinder (9) and the force amplifying mechanism (10) are arranged between the main push plate (8) and the auxiliary push plate (11), and the main push plate (8) is fixedly connected with the long stroke oil cylinder.

Owner:CHINA JILIANG UNIV

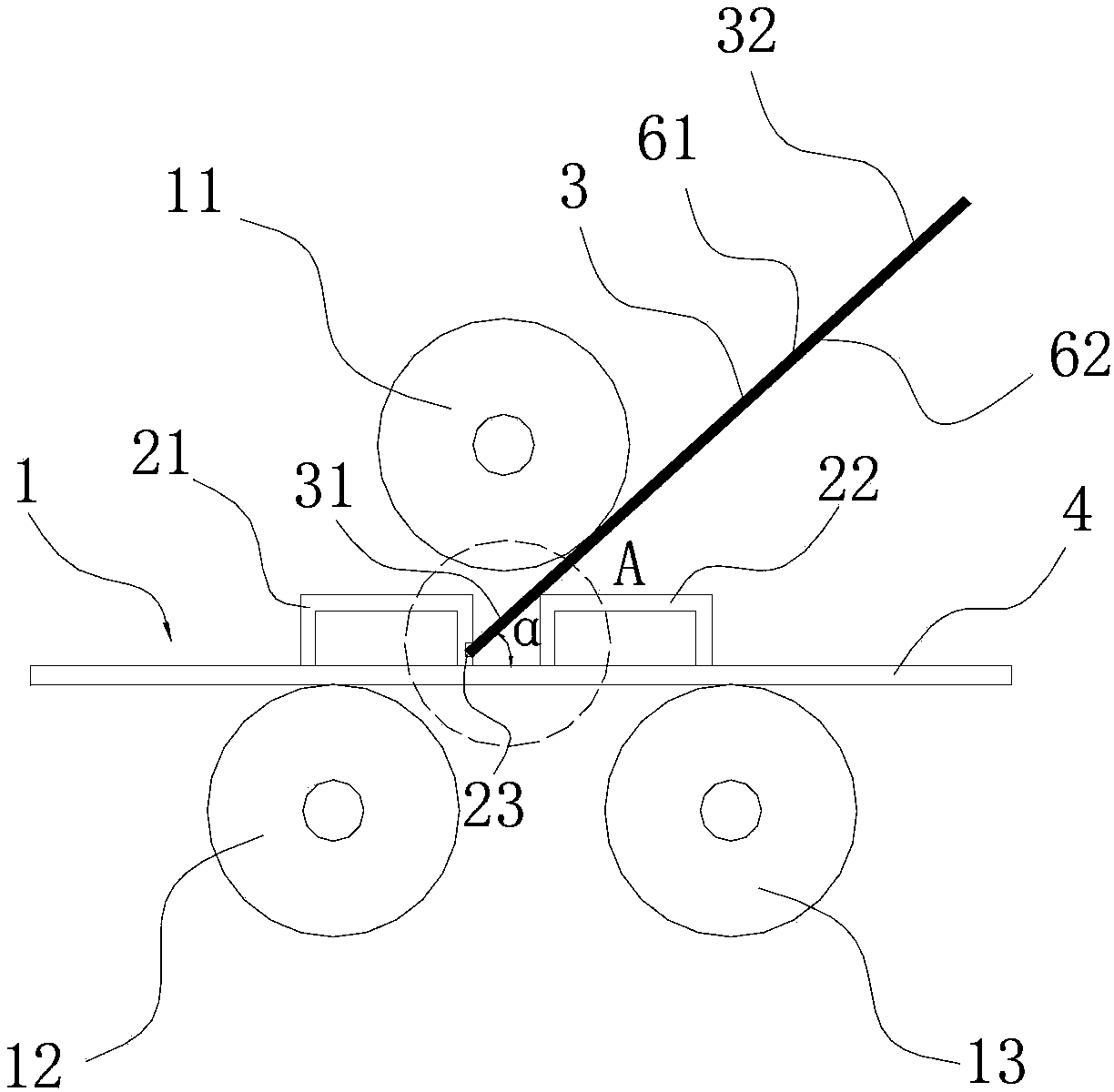

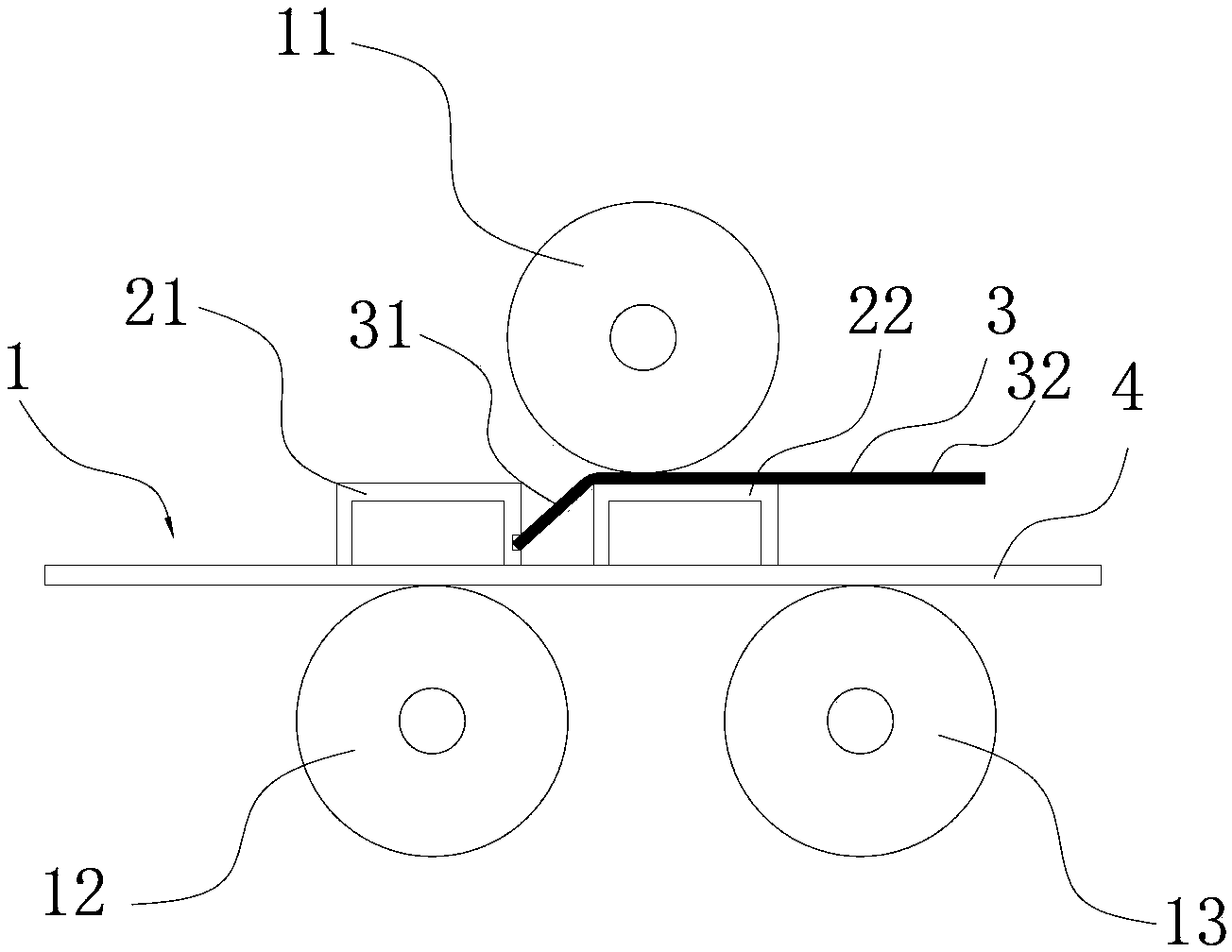

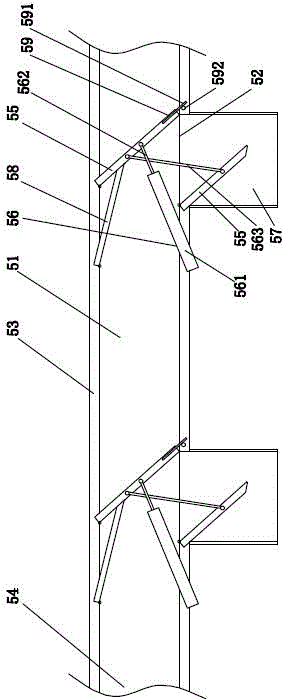

Method for veneer reeling machine pressed-steel ladder rung

InactiveCN103350131AImprove the quality of pressing processReduce stepping anglesEngineeringAngle alpha

The invention discloses a method for a veneer reeling machine pressed-steel ladder rung. The method can improve the quality of the pressed-steel ladder rung and reduce corner angles of the pressed-steel ladder rung. The method includes the following steps that a first fixing plate and a second fixing plate are manufactured and installed on a base plate, a material plate is installed between the first fixing plate and the second fixing plate on the base plate, the position of the material plate is adjusted, an angle alpha is formed between the material plate and the base plate, then the material plate is sent into a veneer reeling machine, a bent edge of the material plate is bent for the angle alpha, the material plate is taken out, the bent edge is vertically installed between the first fixing plate and the second fixing plate, a blocking plate is added between the first fixing plate and the second fixing plate so as to enable the bent edge to be clamped through the first fixing plate and the second fixing plate, the material plate is sent into the veneer reeling machine once again to be bent for the second time to enable the bent edge to be vertical to the material plate, the material plate is taken out and serves as one end to be installed on the base plate, the steps are repeated, and thus an N-shaped pressed-steel ladder rung or a Z-shaped pressed-steel ladder rung is obtained. By the adoption of the method, labor investment can be reduced, work efficiency is improved, and production cost is saved.

Owner:SICHUAN NO 3 ELECTRIC POWER CONSTR

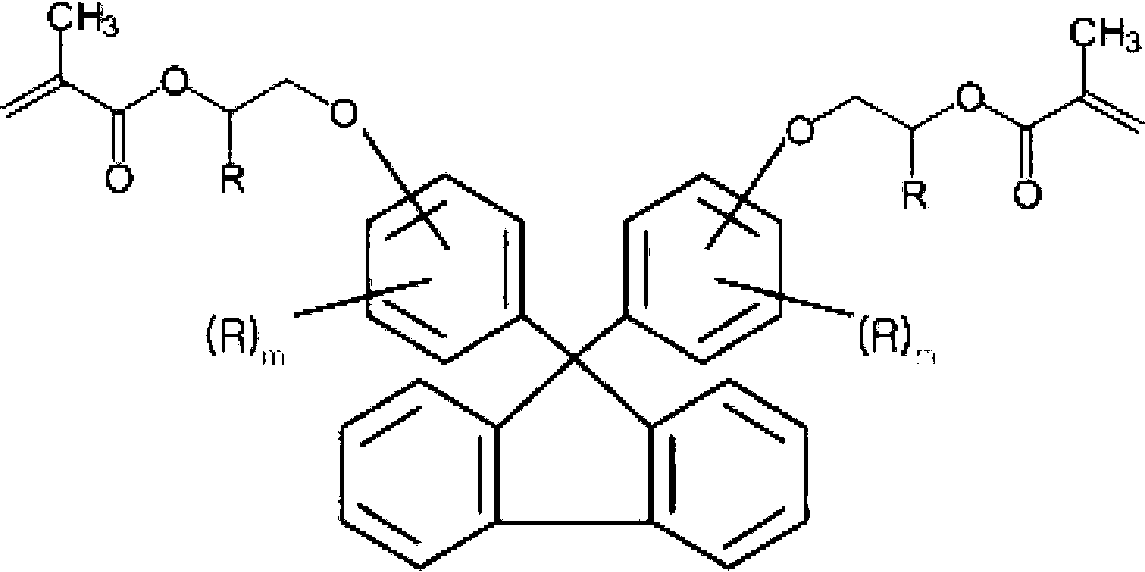

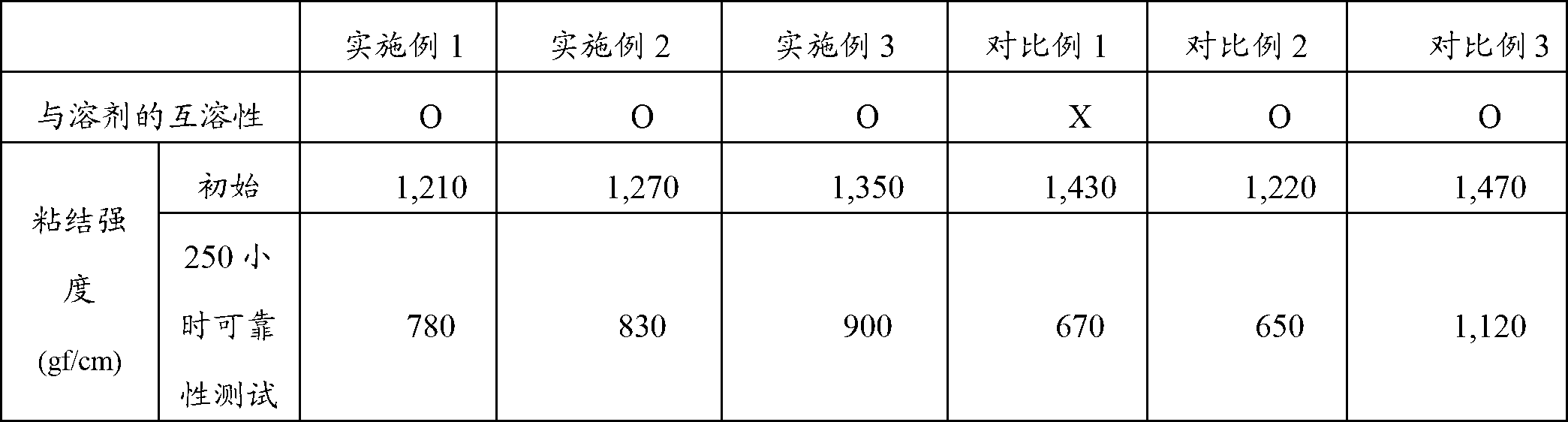

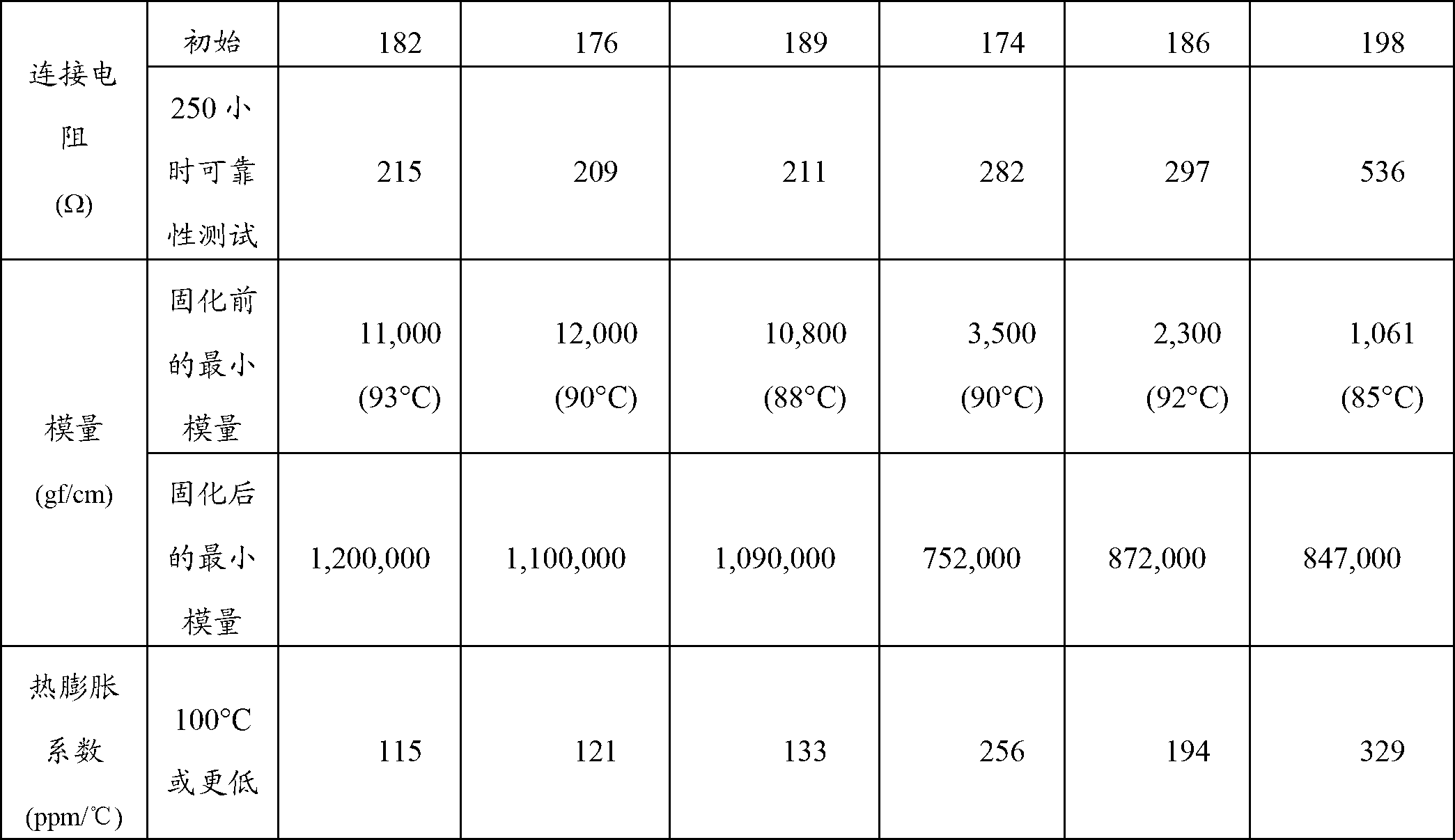

Composition for anisotropic conductive adhesive film, anisotropic conductive adhesive film and semiconductor device

ActiveCN103087650AProper dimensional stabilityImprove connection reliabilitySemiconductor/solid-state device detailsPolyureas/polyurethane adhesivesPolymer scienceAnisotropic conductive adhesive

Disclosed is an anisotropic conductive adhesive film that comprises an acrylic acid ester copolymer as a polymer binder system, an acrylic ester with high reactivity and forming a solid structure after being cured as a curing system, a solid content ratio between a polymer binder system and a curing system of about 40:60 to about 60:40, so that occurrence of bubbles in about 5 seconds or less at about 160 to about 200 DEG C can be prevented, which can not be realized in an epoxy film. Beside, the adhesive film has high adhesive strength, connection reliability and dimensional stability. The invention also discloses a composition for the anisotropic conductive adhesive film and a semiconductor device comprising the anisotropic conductive adhesive film.

Owner:KUKDO ADVANCED MATERIALS CO LTD

Novel release agent for composite panel

ActiveUS20100048444A1Easy to processSimple to useAnionic surface-active compoundsChemical paints/ink removersAdhesivePhosphate

The present invention is directed to a pMDI release agent that is simple to manufacture and use, provides release between the board and the metal surfaces, allows for production of OSB at high temperature, without causing excessive press buildup and improves the board physical properties and shortens press time. The release agent composition for use with a pMDI adhesive comprises a mixture of: (a) a sodium salt of a fatty acid having at least 8 carbon atoms, and (b) a sodium salt of a phosphate ester having 8-12 carbon atoms.

Owner:GUARDIAN CHEM

Composite curing agent and application of composite curing agent to production of melamine impregnated paper

InactiveCN102877359AShorten pressing timeGood application effectNon-fibrous pulp additionPaper/cardboardHexamethylenetetramineFirming agent

The invention discloses a composite curing agent. The composite curing agent comprises 10 parts of hexamethylenetetramine, 40 to 60 parts of ammonium chloride and 10 to 30 parts of triethanolamine. The regulation and control effect of the composite curing agent on the curing rate of thermosetting amino resin is superior to that of the conventional common curing agent. The invention also aims to provide a concrete method for applying the composite curing agent to the production process of melamine impregnated paper. The method comprises the step of adding the composite curing agent during the impregnation for the first time. The adhesive performance is improved by regulating and controlling the pre-curing rate and achieving the latent curing effect of the composite curing agent. In addition, the optimal combination of the cost and utility is realized by optimizing the adding amount of the curing agent.

Owner:CHANGZHOU WEIXING DECORATIVE MATERIALS

Material for information recording medium substrate, information recording medium substrate, information recording medium, and method for manufacturing them

InactiveUS20100011814A1Reduce the warp of the disklike glassReduce warpageRecord information storageGlass pressing apparatusShell moldingMetallurgy

The present invention has for its objects to provide a method for manufacturing a disklike glass material for the mass production of information recording media substrate-use materials of constant sheet thickness, to provide a method for manufacturing an information recording medium-use substrate from the material thus manufactured, and to provide a method for manufacturing an information recording medium. The provided is a method for manufacturing a disklike glass material comprising the successive molding of multiple pieces of disklike glass material from glass melt. Being suppressed variation over time in the concentration of infrared radiation-absorbing ions contained in the glass melt being molded into said pieces of disklike glass material so that the variation in the sheet thickness of said multiple pieces of disklike glass material falls within a range of ±15 percent of a reference value. The reference value being the median between the maximum value and the minimum value of the sheet thickness of 1,000 pieces of said glass material. In the course of molding multiple pieces of disklike glass material comprised of glass containing 0.1 to 100 ppm of infrared radiation-absorbing ions, variation over time in the concentration of the infrared radiation-absorbing ions contained in the glass melt being molded into said pieces of disklike glass material is suppressed to suppress variation in the sheet thickness of said multiple pieces of sheetlike glass material.

Owner:HOYA CORP

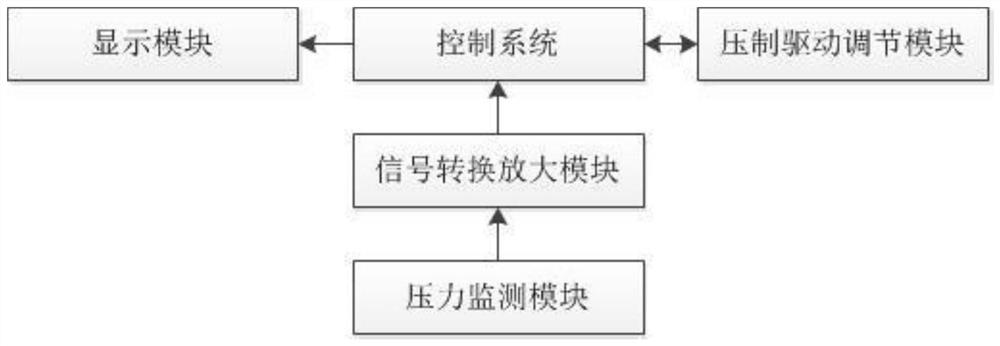

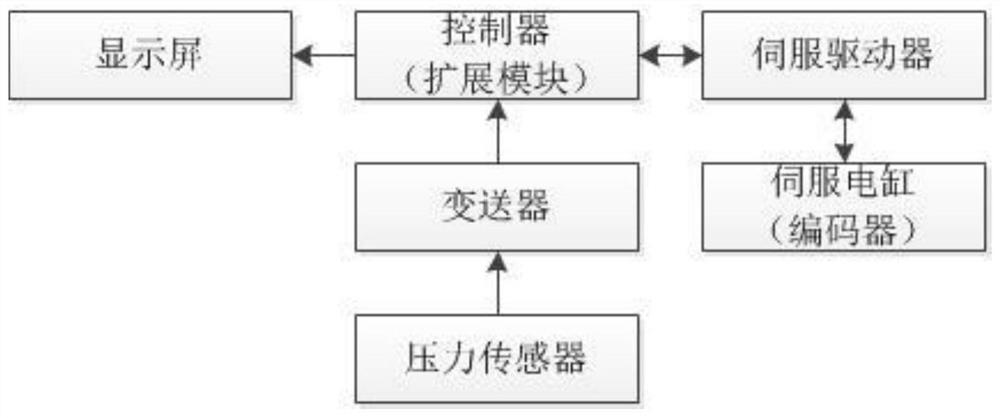

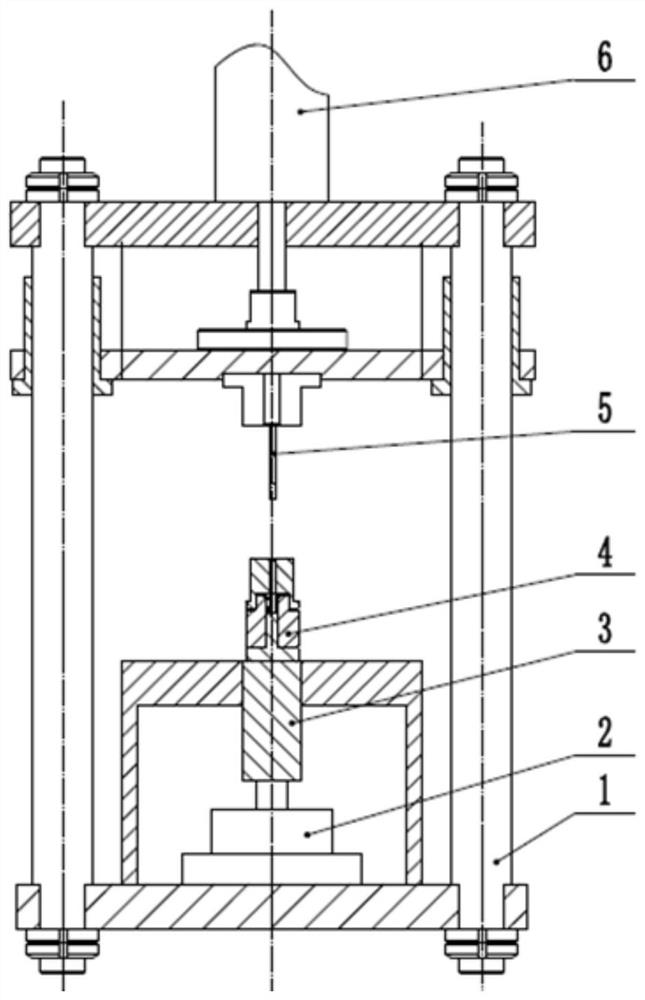

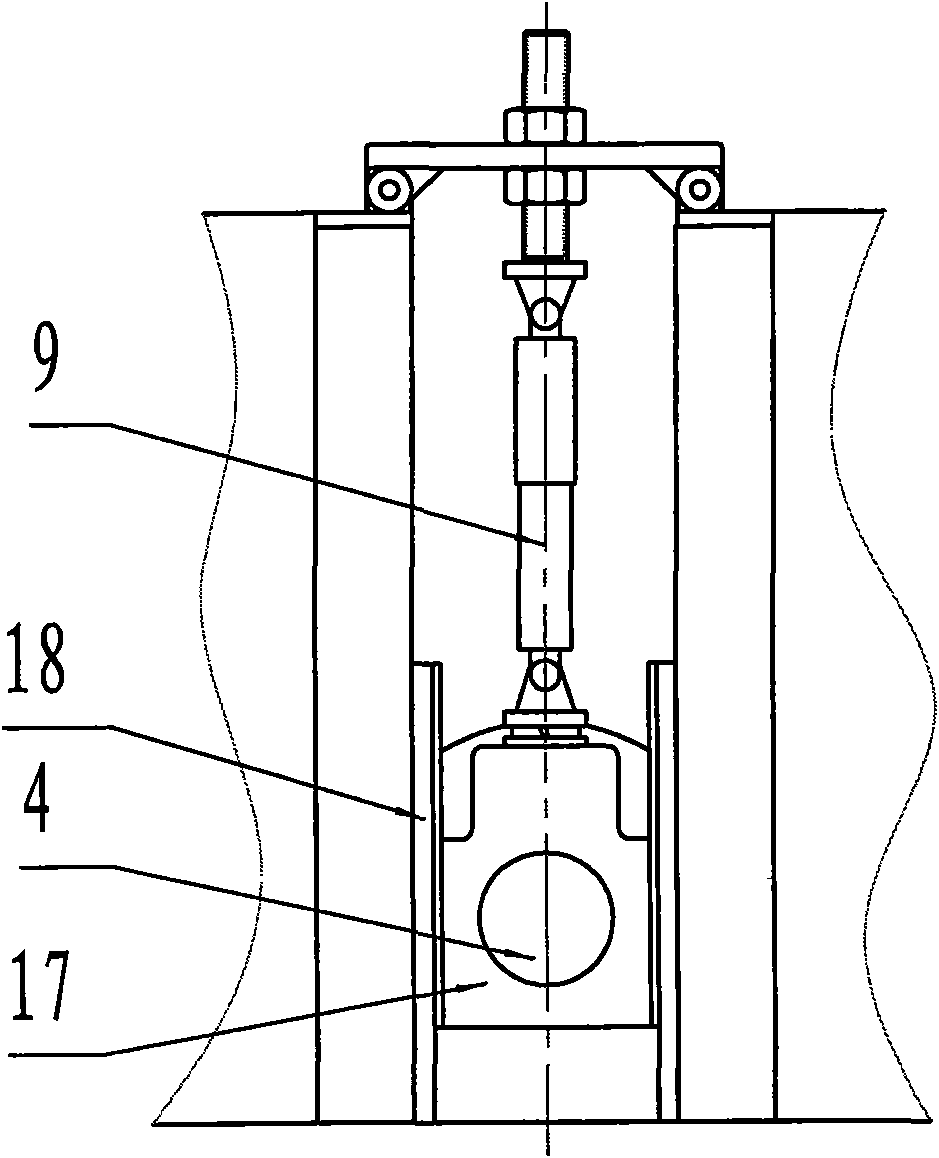

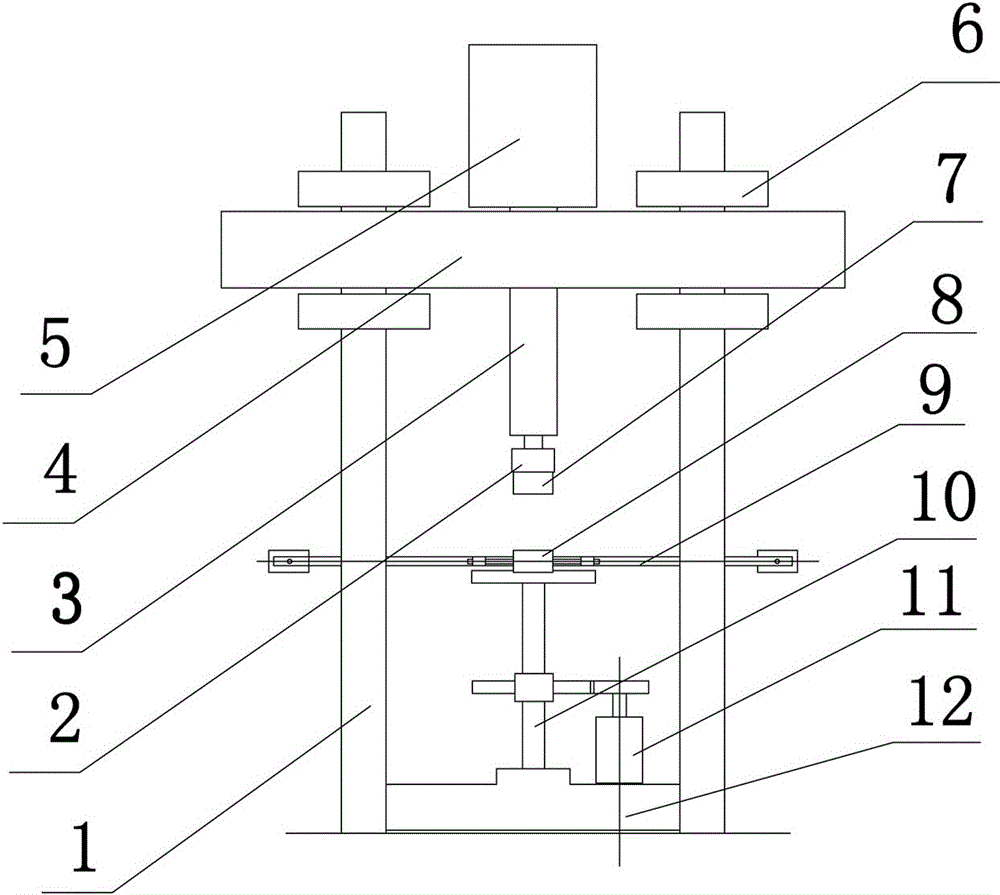

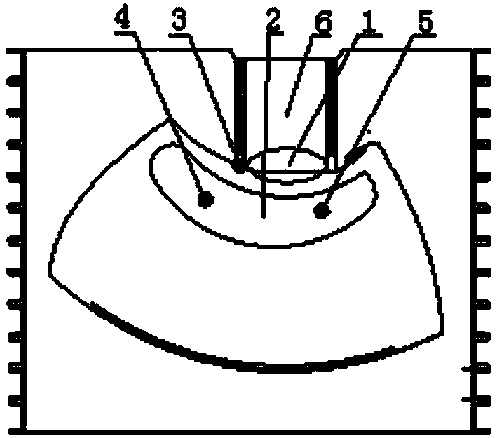

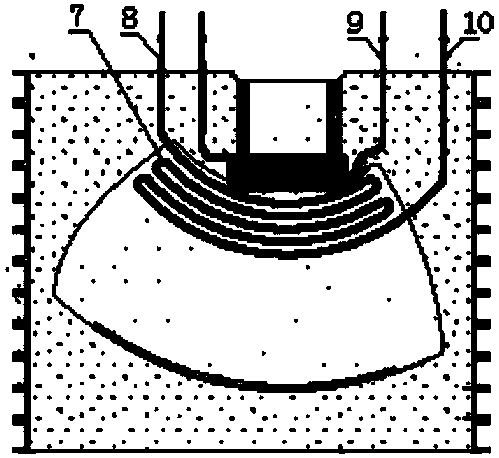

Initiating explosive device pressing system and method

The invention discloses an initiating explosive device pressing system and method, and the system comprises a punch which is used for pressing an initiating explosive device; a pressing driving adjusting mechanism which is connected with the punch; a pressure monitoring module which is used for measuring pressure information of pressing of the initiating explosive device; and a control system which receives the pressure information and controls the operation speed of the pressure driving adjusting mechanism according to the pressure information. The pressure monitoring module is arranged below the initiating explosive device, so that the magnitude of pressing force borne by the initiating explosive device can be obtained in real time and fed back to the control system; the control system controls the servo electric cylinder executing pressing according to pressure information, the operation speed of the servo electric cylinder is adjusted, and different pressing forces are applied to the initiating explosive device, so that the pressing force borne by the initiating explosive device reaches the target pressing force, and accurate pressure control in the pressing process is achieved; and the pressure adjusting process is simple, and automatic integration can be achieved.

Owner:中国兵器装备集团自动化研究所有限公司

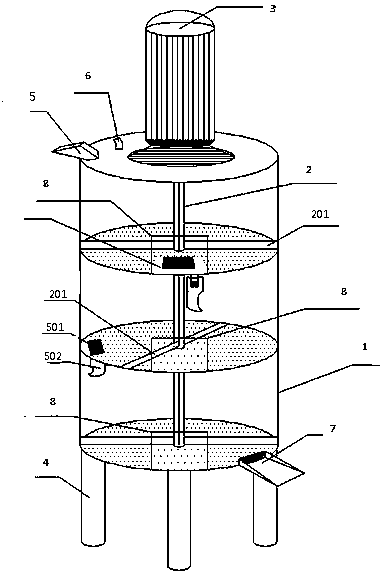

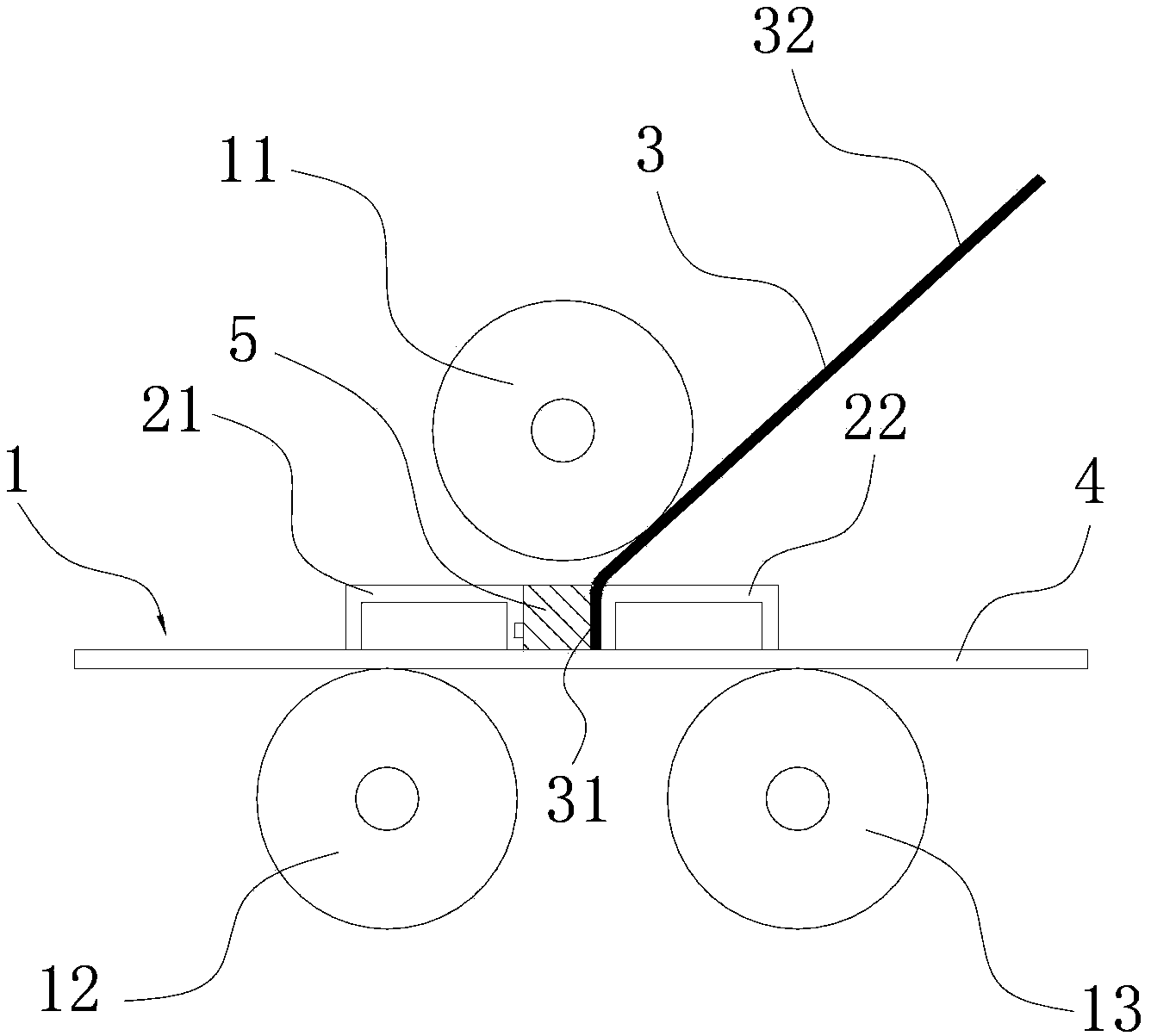

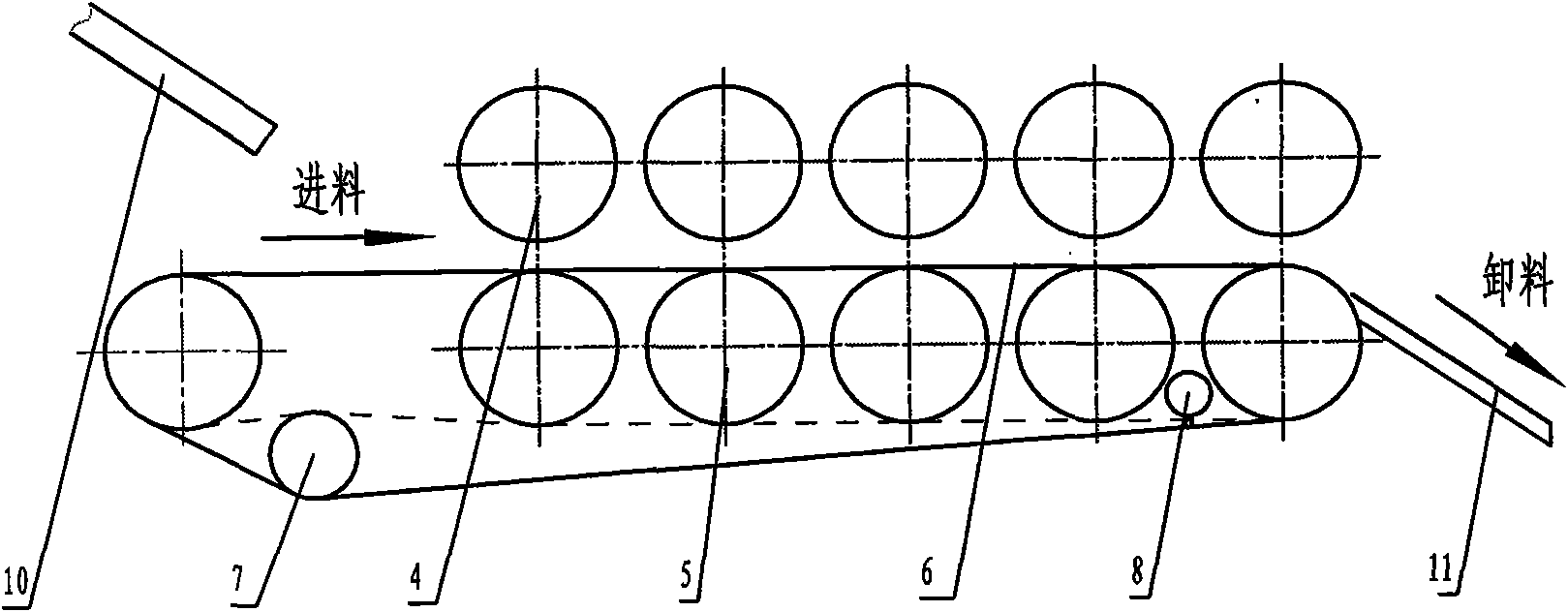

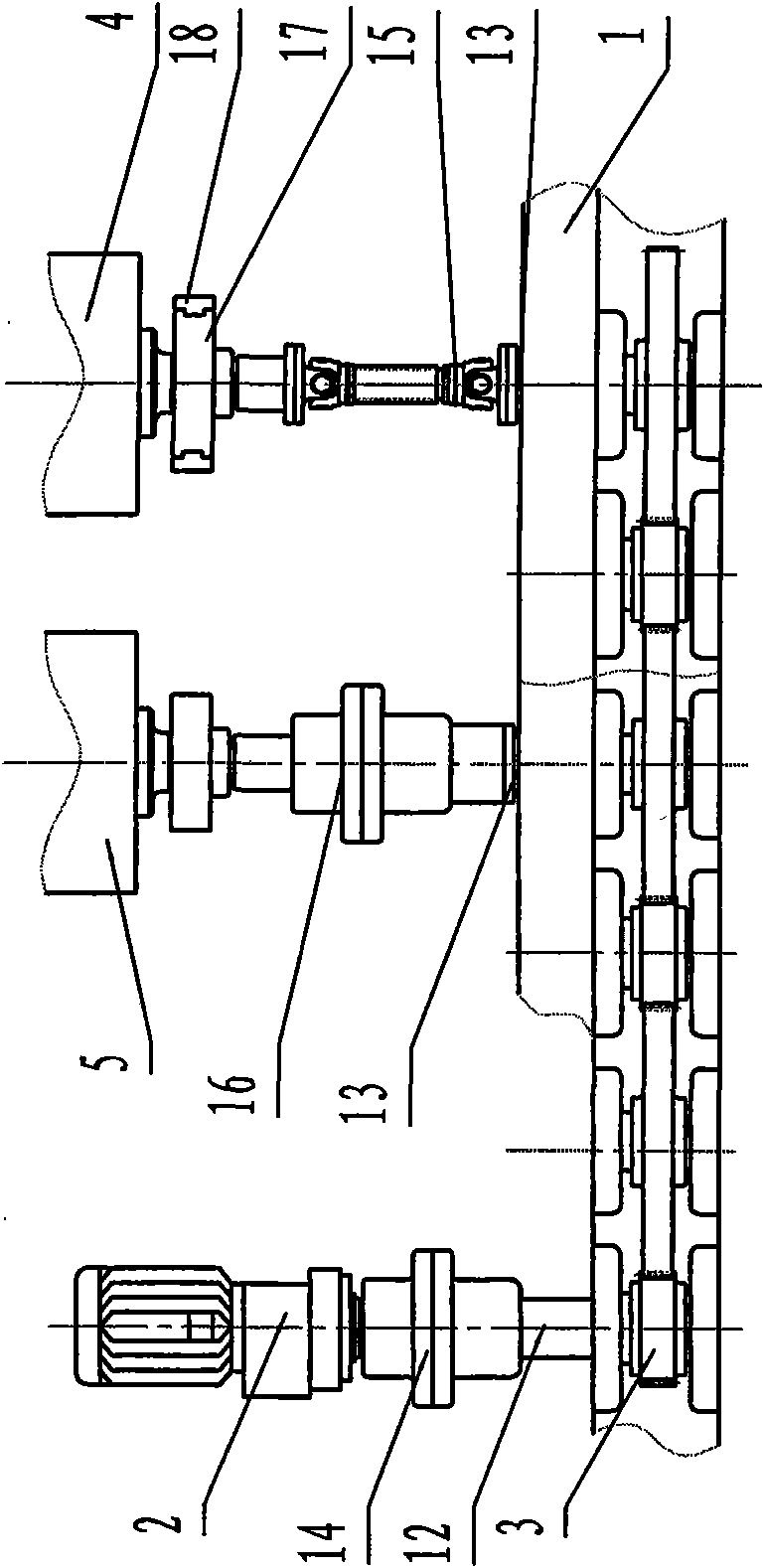

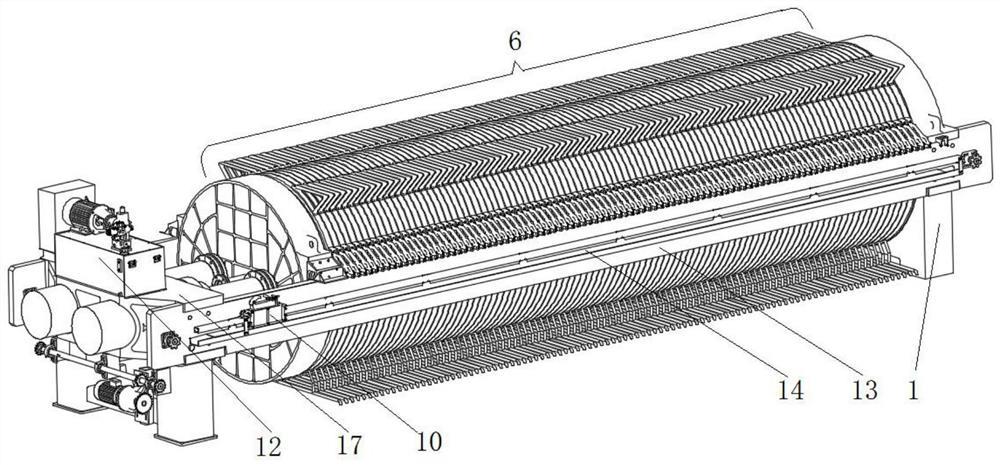

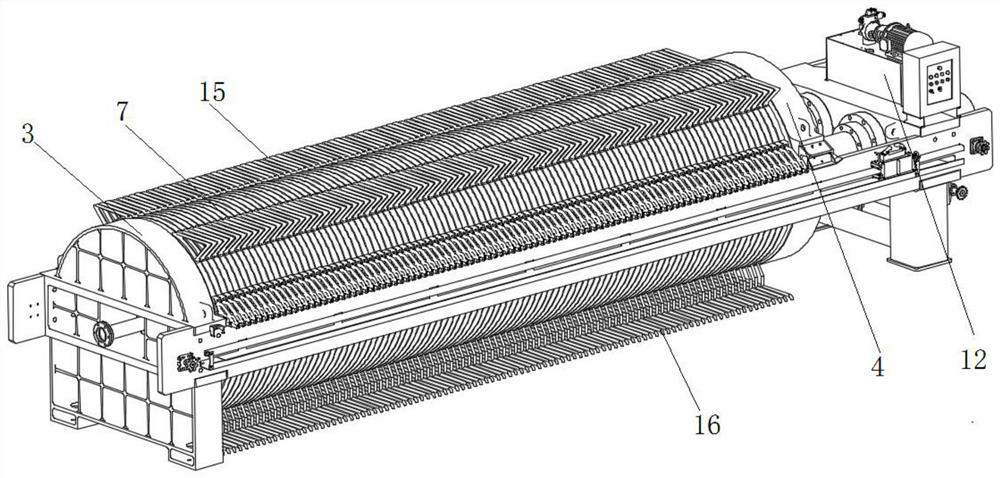

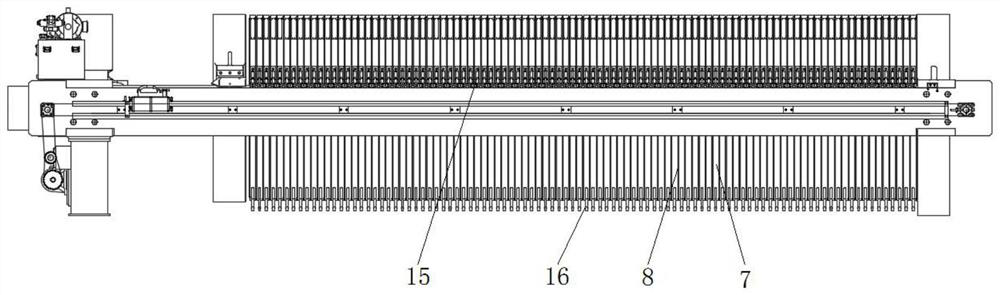

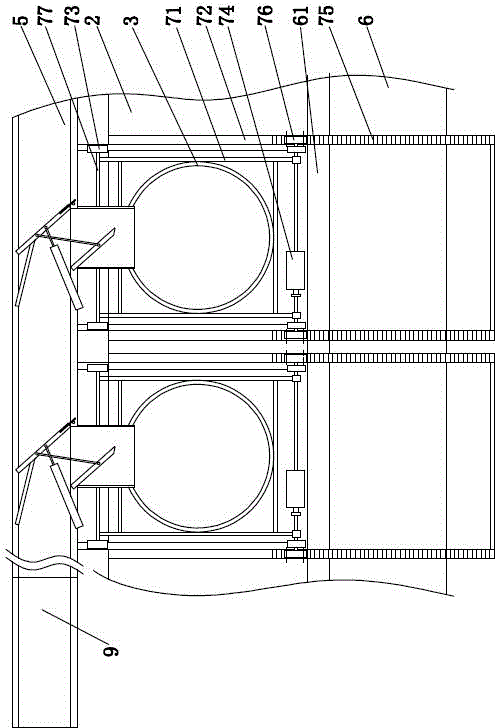

Continuous twin-roll counter-pressure dewaterer

ActiveCN101555090AIncrease productionIncrease solid contentSludge treatment by de-watering/drying/thickeningUniversal jointCoupling

The invention discloses a continuous twin-roll counter-pressure dewaterer which mainly comprises a frame (1), a power device (2), a transmission device (3), an upper roll component (4) and a lower roll component (5), wherein, the transmission device (3) is provided with an input shaft (12) and a plurality of output shafts (13); the input shaft (12) is connected with the power device (2) via a shaft joint I (14); an upper-row output shaft (13) is connected with the upper roll component (4) via a universal joint (15); a lower-row output shaft (13) is connected with the lower roll component (5) via a shaft joint II (16); and the upper roll component (4) and the lower roll component (5) are in roll-to-roll rotary relay type rolling fit. By dewatering under the action of pressure between rolls with small contact area, the invention has the advantages of large squeezing force and short squeezing time, ensures the solid content rate of mud cakes and solves the technical problems of twin-roll counter-pressure dewatering and draining.

Owner:张鑫珩

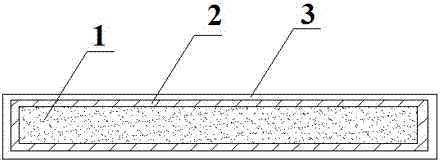

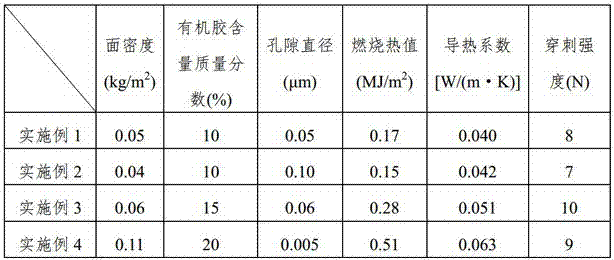

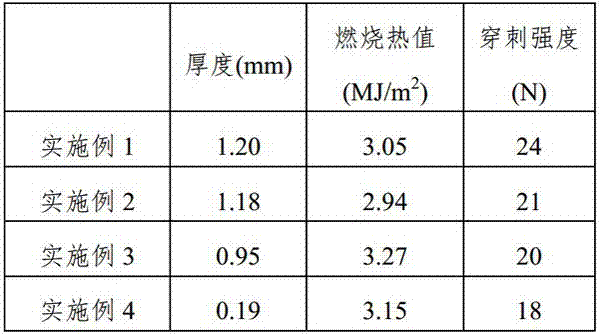

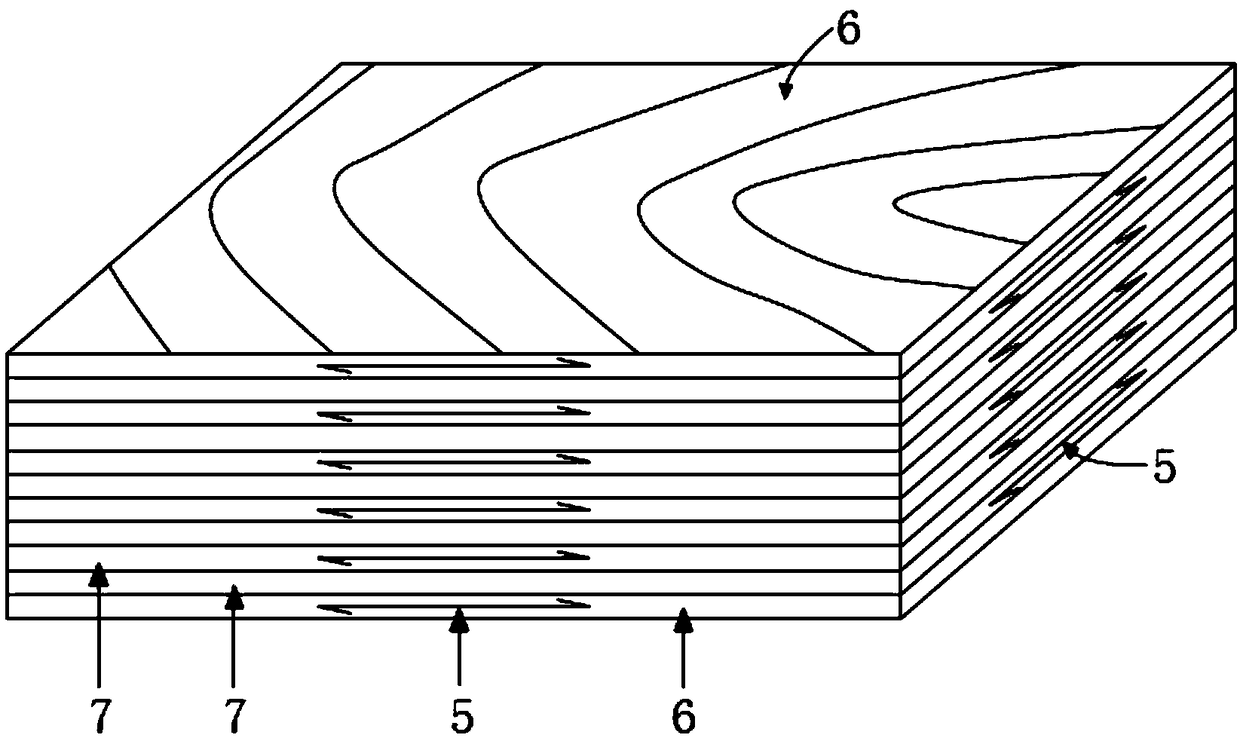

Vacuum insulated panel with excellent fireproof performance and production method thereof

ActiveCN107023087AImprove fire performanceImprove flame retardant performanceClimate change adaptationInsulation improvementHigh resistanceCombustion

The invention relates to a vacuum insulated panel with excellent fireproof performance. The vacuum insulated panel with the excellent fireproof performance comprises a core plate and a high-resistance air film bag. The high-resistance air film bag is mounted outside the core plate in a sealed mode, the core plate comprises a core material and a coating material, the coating material is mounted outside the core material in a sealed mode, the coating material is inorganic cotton felt, the surface density of the inorganic cotton felt is 25-150 g / m<2>, and the content mass fraction of organic glue is 6-25%; and the gross combustion heat valve of the high-resistance air film bag is 2.0-3.9 MJ / m<2>, and the total layer number of thin films forming the high-resistance air film bag is smaller than or equal to six. According to the vacuum insulated panel with the excellent fireproof performance, by controlling the surface density of the inorganic cotton felt, the content of the organic glue, the thickness of the thin films with the heat seal effect and in the high-resistance air film bag, the total layer number of the thin films and the gross combustion heat valve of high-resistance air films, the vacuum insulated panel has the advantages of being excellent in fireproof performance, good in flame-retarding effect, high in stabproof strength, good in heat preservation effect, low in pressing pressure, short in pressing time, not prone to being cracked and short in curing time after mortar coating.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

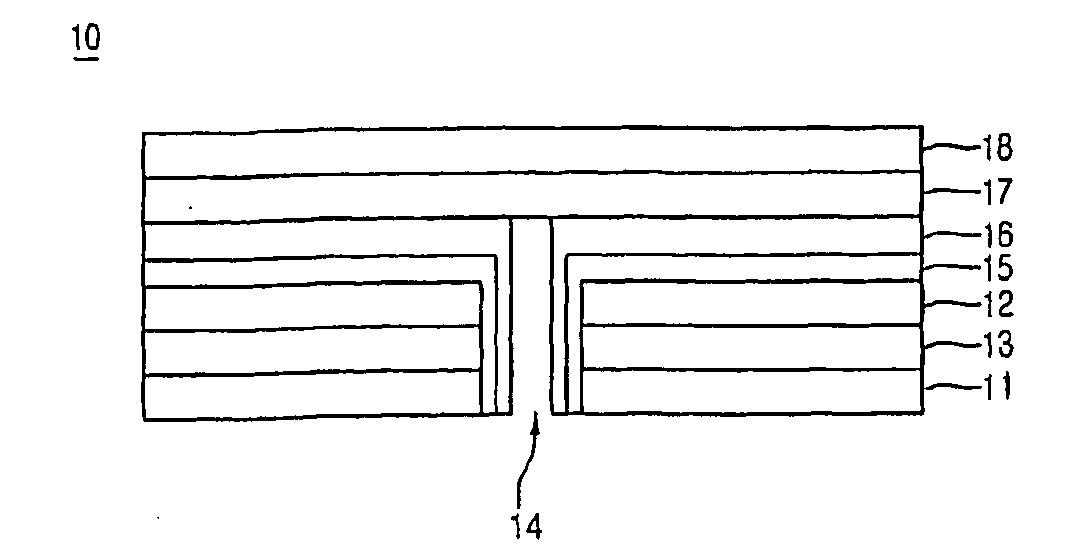

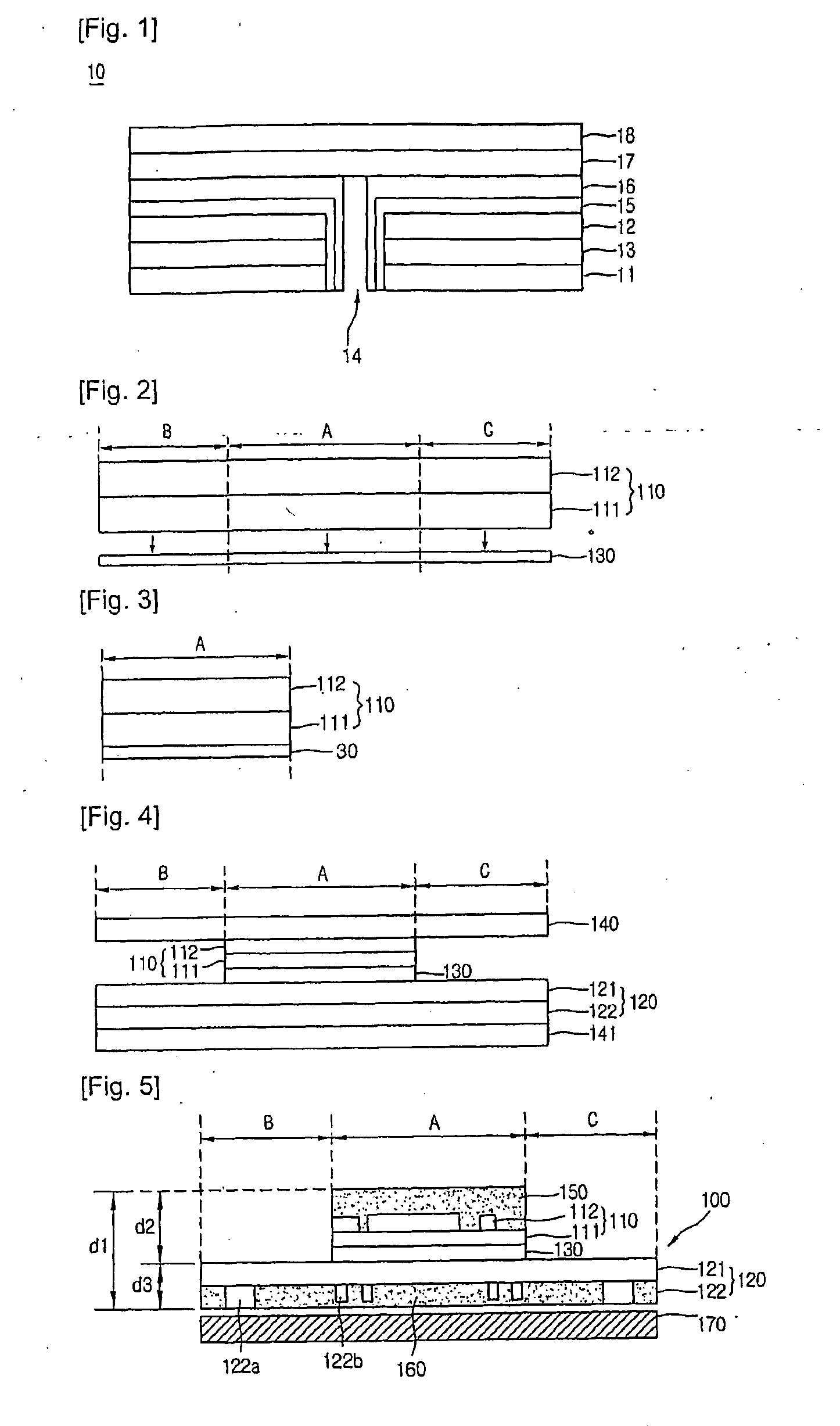

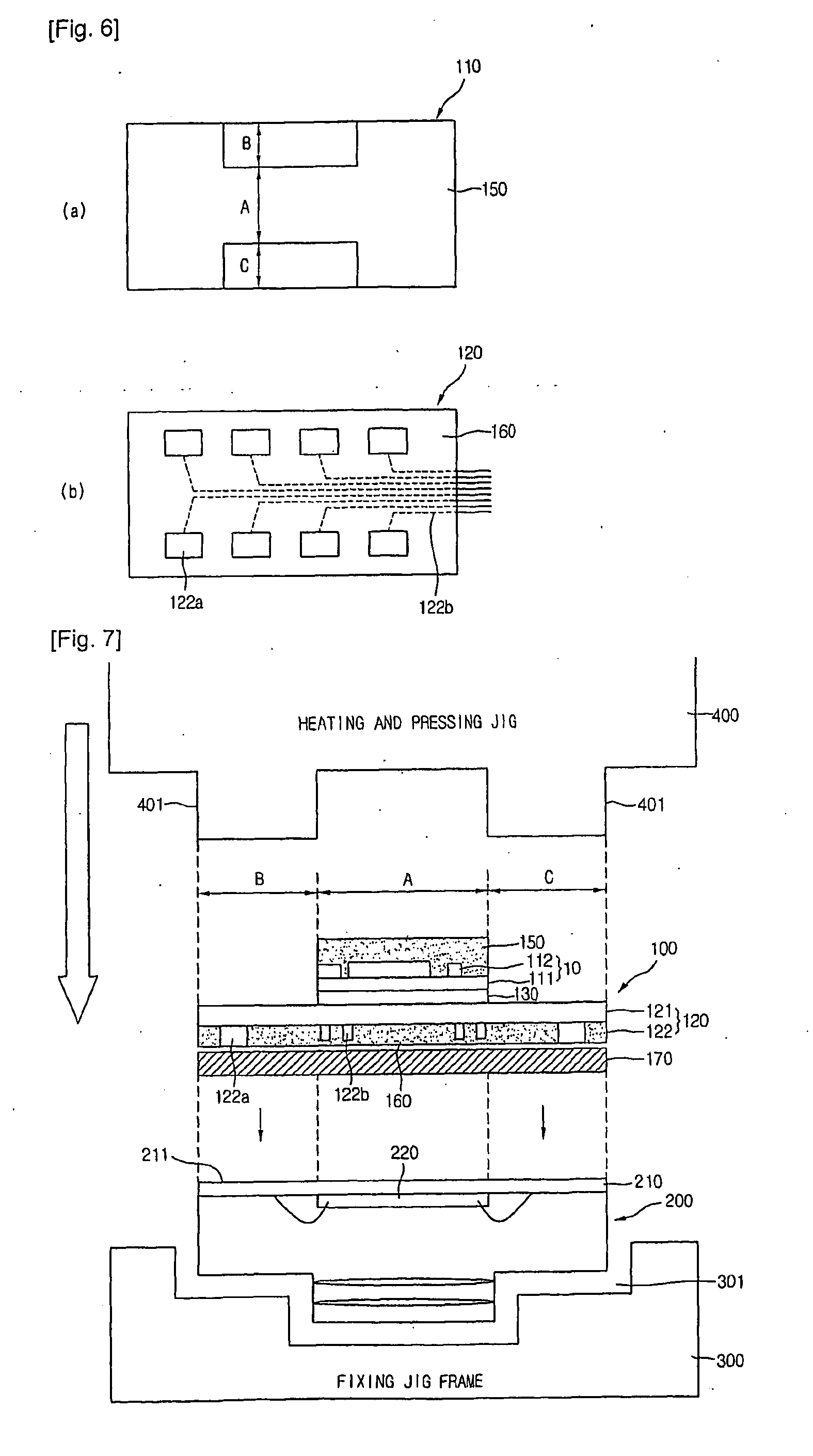

Multi-Layer Flexible Printed Circuit Board and Method For Manufacturing the Same

ActiveUS20080289861A1Improve thermal efficiencyThin formPrinted electric component incorporationSynthetic resin layered productsFlexible electronicsPrinted circuit board

Disclosed are a multi-layer flexible printed circuit board and a method for manufacturing the same. The multi-layer flexible printed circuit board includes an adhesion sheet from which a pressing and heating area is cut, an upper base layer, from which the pressing and heating area is cut, on the adhesion sheet, and a lower base layer under to the adhesion sheet.

Owner:LG INNOTEK CO LTD

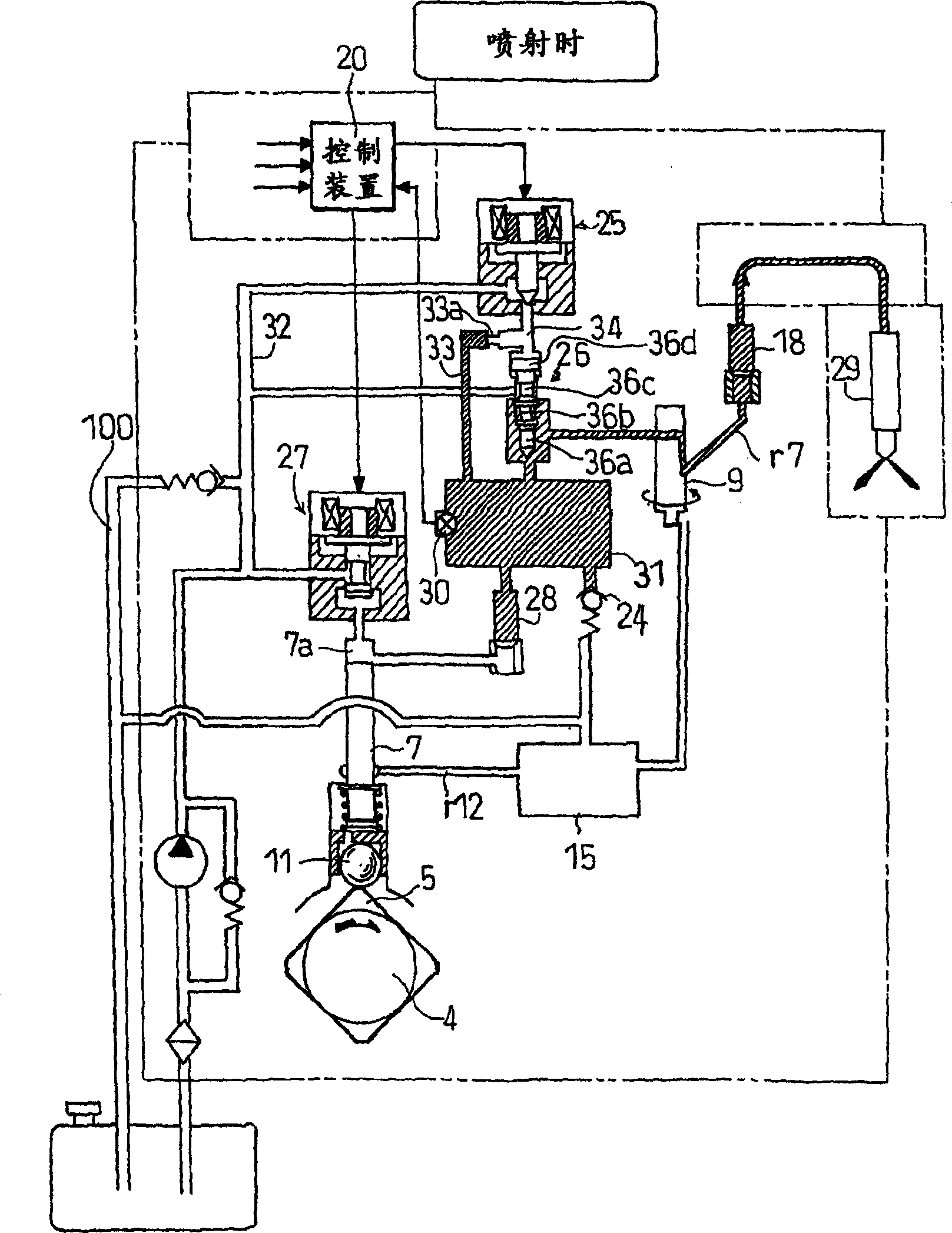

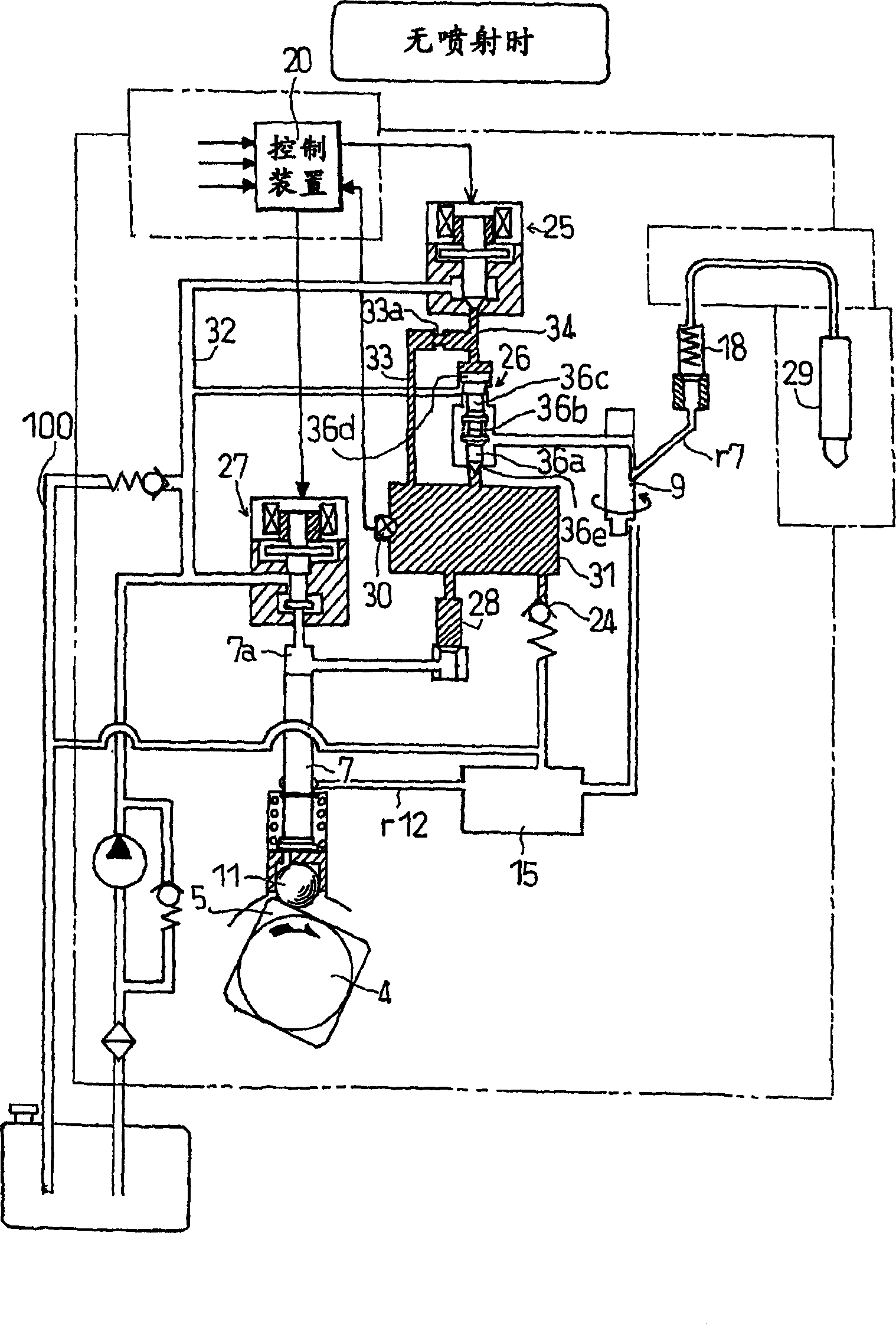

Accumulator distribution type fuel injection pump

InactiveCN1455845AImprove reliabilityPrevent partial wearPositive displacement pump componentsFuel injecting pumpsHigh pressureDiesel engine

An accumulator distribution type fuel injection pump usea as a fuel injection pump for low-pollution diesel engine low in fuel consumption and capable of meeting an exhaust emission control requirements, wherein a high-pressure fuel accumulated in an accumulating chamber is distributedly fed to each cylinder through a distribution shaft, functional members forming high-pressure routes such as a plunger, an injection control valve for fuel injection control, the accumulating chamber, and the distribution shaft are disposed inside a hydraulic base (Hb), and a plunger part for accumulating fuel into the accumulating chamber is installed in the hydraulic base.

Owner:YANMAR CO LTD

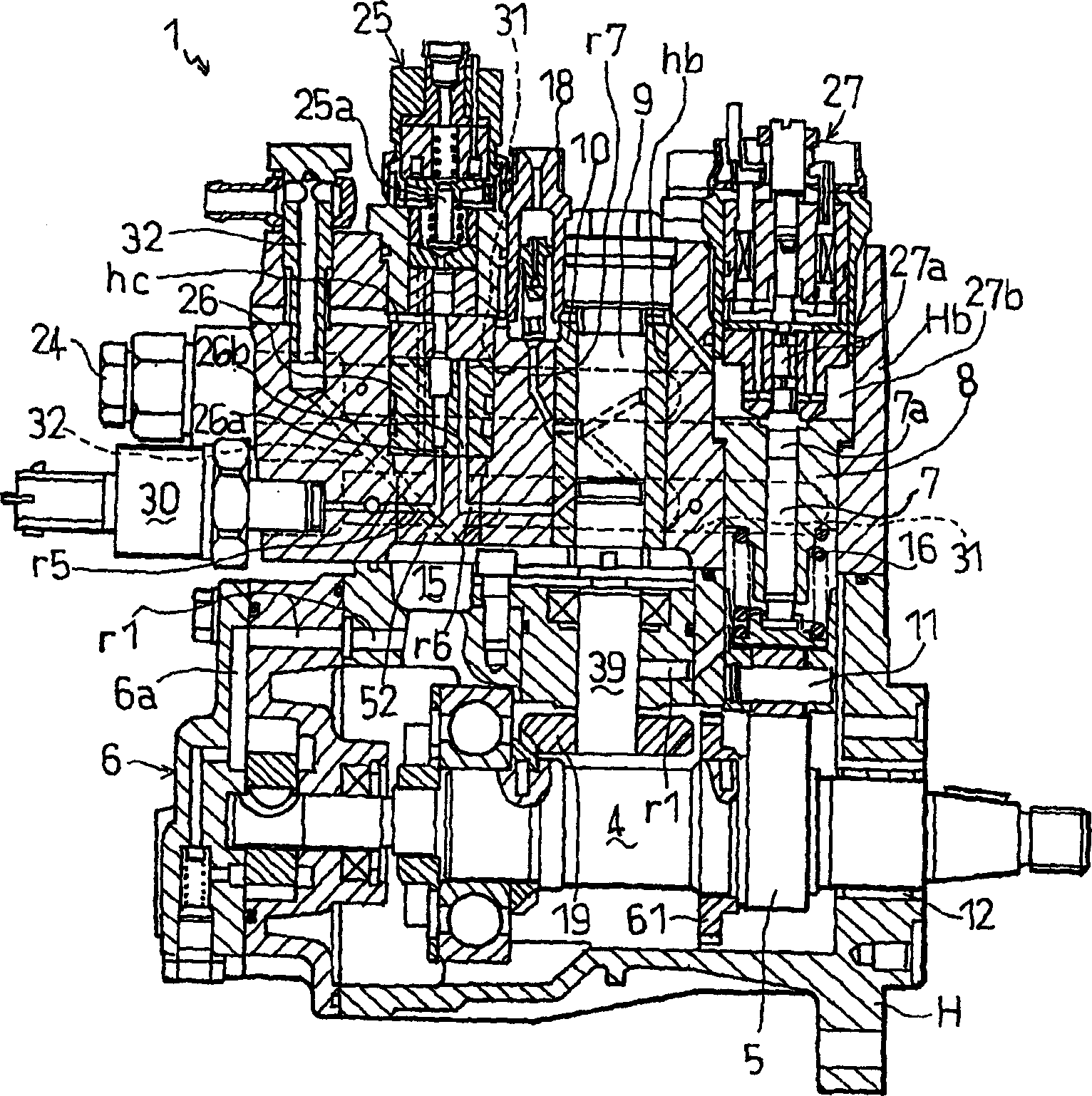

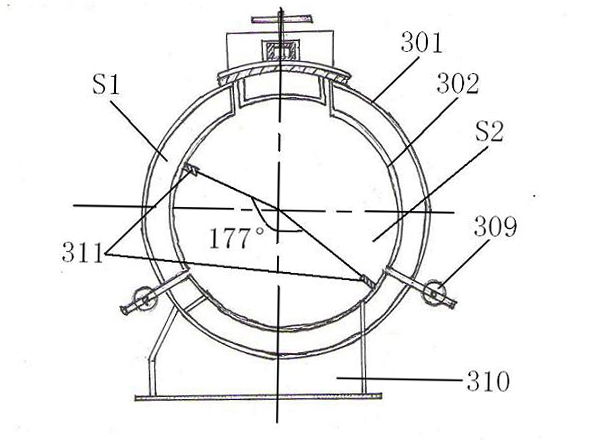

Multi-level flipping type proteopexy cooking machine and fishmeal machine

InactiveCN101926424AImprove processing outputNo raw meal phenomenonFood preparationElectricitySpiral blade

The invention discloses a multi-level flipping type proteopexy cooking machine and a fishmeal machine. The cooking machine comprises a cylindrical outer shell, a cylindrical inner shell, a heave dragon shaft, a feeding hole and a discharging hole, wherein the outer shell and the inner shell are coaxially sleeved; a confined space S1 is formed between the inner shell and the outer shell and is used for heating gases; both ends of the heave dragon shaft are respectively connected with a shaft head; the feeding hole is arranged on one end of the outer shell, and is communicated with an inner cavity S2; the discharging hole is arranged on the other end of the outer shell, and is communicated with the inner cavity S2; and a plurality of half-leaf spiral blades are arranged on the heave dragon shaft. The fishmeal machine comprises a multi-level flipping type proteopexy heating cooking machine, a heating type forced fat separation squeezing machine, a fishmeal drying chamber and a fishmeal sifting machine, which are sequentially connected. The invention has the advantages of stable mechanical property, simple and convenient operation, high security, electricity saving, no noise, large output, product purity, and simple and convenient maintenance, repair, installation and debugging.

Owner:孙仁和

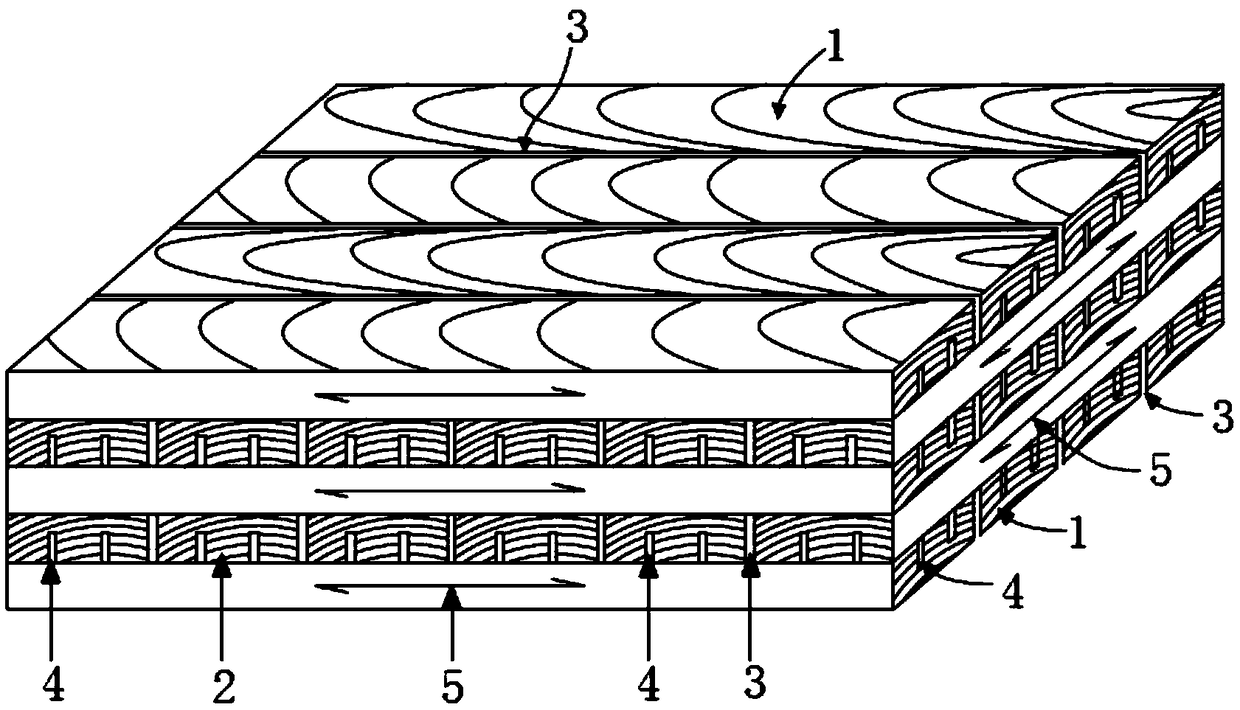

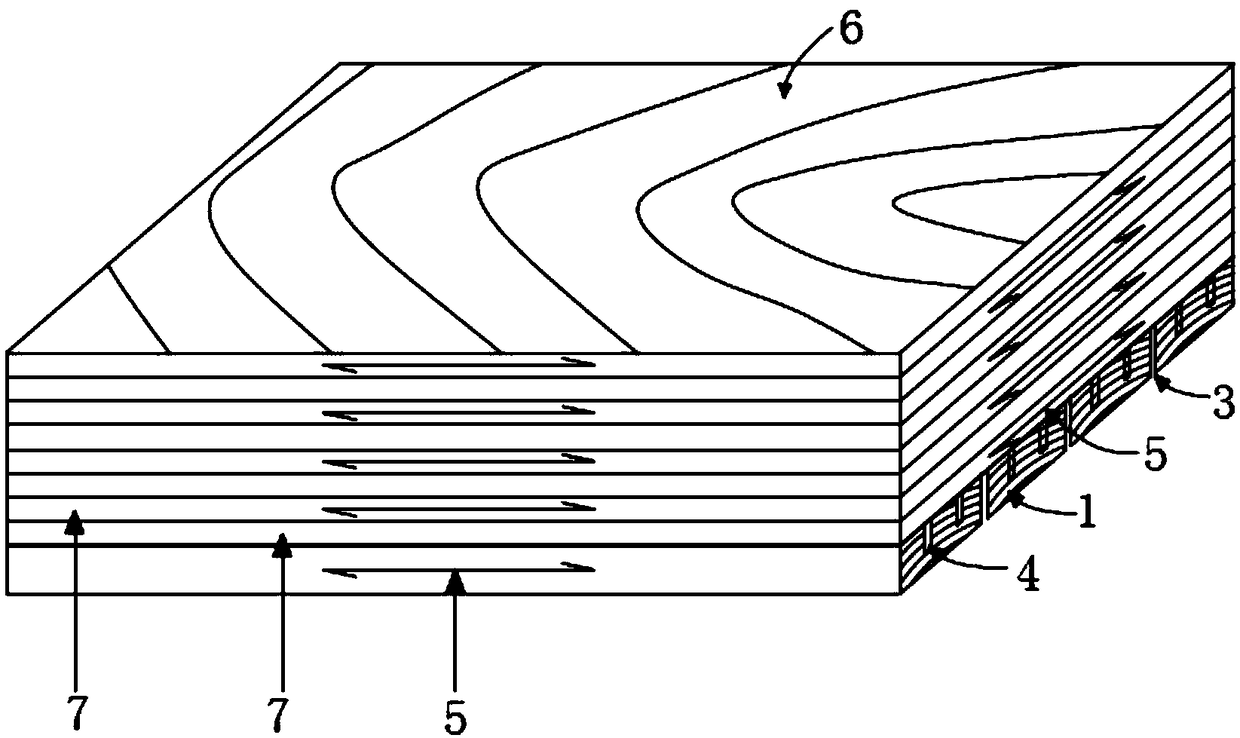

Cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and preparation method thereof

PendingCN109434975AImprove mechanical propertiesImprove fire resistanceLaminationLamination apparatusMechanical propertyAdverse effect

The invention discloses cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and a preparation method thereof, and belongs to the field of timber structures. A laminated board of the cross laminated timber comprises a fast growing timber laminated board with cracks, the fast growing timber laminated board is a whole cracked board, and lengths of all laminated boards of the cross laminated timber are consistent in the horizontal direction. In the preparation method, adjacent layers formed by the fast growing timber laminated board or fast growing timber laminated board combination are assembled and configured in a manner that wood textures are perpendicular to each other in the thickness direction of laminated wood. According to the cross laminated timber combining the fast growing timber material characteristics and meeting the building structure requirements and the preparation method thereof, the material characteristics that the fast growing timber is soft in material and prone to be made into the laminated board with the cracks in a rotary cutting mode are fully utilized, structural stock lumber is replaced for preparing the cross laminated timber, the utilization of the fast growing timber in the field of building structures is expanded, the material cost of a conventional component is greatly reduced, the component preparation process is simplified, the production period is shortened, and the problem that adverse effects on the mechanical property, durability and fireproof performance of the component are caused through gaps in laminated boards of a structural material cross laminated timber component is solved.

Owner:NANJING UNIV OF TECH

Large circular plate high-pressure automatic filter press

PendingCN112206555AIncrease productionGuaranteed tightnessFiltration separationAutomatic controlControl system

The invention discloses a large circular plate high-pressure automatic filter press, which relates to the field of environmental protection equipment and mainly comprises a rack part, a filtering part, a hydraulic system, an automatic plate pulling device and an electrical control system. The single-machine yield is increased by adopting large-area circular filter pressing plates, and meanwhile, the sealing surface is used for ensuring the sealing property of each filter chamber during filter pressing, so that the phenomenon of slurry leakage between the filter plates during high-pressure filter pressing is effectively avoided. Meanwhile, double oil cylinders are horizontally arranged side by side, so that the space is saved, and the filtering pressure can be effectively improved; a mode of simultaneously feeding slurry from two ends is also adopted, so that the filter pressing time is further shortened, and the filtering efficiency is improved. Besides, the automatic filter press provided by the invention is integrally designed and manufactured by machine, electricity and liquid, can realize automatic control of various processes such as filter plate pressing, filtering, squeezing, filter plate loosening, discharging and the like, and is high in practicability.

Owner:广东增盛机械科技有限公司

Semiautomatic settling type pickle squeezer

The invention discloses a semiautomatic settling type pickle squeezer, and belongs to the technical field of squeezing equipment. The semiautomatic settling type pickle squeezer comprises a machine frame, a squeezing platform, a bottomless filter tube, a solid squeezing tube, a feeding device, a material collecting device and a filter tube moving device, wherein the squeezing platform is arranged on the machine frame and is used for carrying the squeezing force, the bottomless filter tube is positioned on the squeezing platform, the solid squeezing tube is matched with the bottomless filter tube, the feeding device is used for feeding materials into the bottomless filter tube, the material collecting device is in seamless connection with the squeezing platform, the filter tube moving device is used for moving the bottomless filter tube to a position above the material collecting device, and the solid squeezing tube is connected with a lifting device driving the solid squeezing tube to ascend and descend. Great gravity of the solid squeezing tube per se is used for squeezing food materials and extruding water, the squeezing platform achieves a support effect on the solid squeezing tube, the pressure is greatly increased, the consumed squeezing time is short, the production efficiency is improved, the settling design is adopted, an additional pressure exertion element is not needed, and the structure is simpler and more effective.

Owner:四川红七公食品有限公司

Optical lens die casting device

InactiveCN105773892AShorten pressing timeGood optical performanceOptical articlesDie castingFree cooling

The invention discloses an optical lens die casting device. The optical lens die casting device comprises a press, a die casting mold and a multi-station switching device; the die casting mold consists of an upper mold and multiple lower molds; the upper mold is connected to the lower end of a pressing head of the press; and the lower molds are respectively mounted on all stations of the multi-station switching device. The multi-station switching device includes a base and a mold bracket; the mold bracket is rotationally connected with the base through a center shaft, and is provided with multiple die casting stations, cooling stations and mold rising stations capable of being switched; the die casting stations, the cooling stations and the mold rising stations are respectively connected to the lower molds through rotating shafts; and the center shaft is connected with a servo motor through a transmission part. The device performs the die casting for optical lenses; and the lenses, molded through hot pressing, timely rotate away from the die casting stations to reach the cooling stations for naturally cooling to form better internal lattice structures, so that the better optical performance of the optical lenses can be guaranteed, the quality is greatly improved, the molding pressing time is largely shortened, and the production efficiency can be improved by 5-10 times.

Owner:韩金桥

Method for pressing and shake-out for large steel casting

The invention relates to a method for pressing and shake-out for a steel casting, and particularly relates to a method for pressing and shake-out for a large steel casting. The method is characterizedby comprising the following steps: determining a casting part needing to be cooled, a temperature measurement point, and a casting temperature for starting to blow cold air, or a pressing time, designing an arbor, arranging a cooling pipe, connecting compressed air and blowing air to cool, measuring a temperature and monitoring, and carrying out shake-out. The invention provides a method which isunique and capable of realizing the purpose of rapidly cooling the casting, shortening a time from pouring to shake-out for the casting, increasing the production efficiency, and reducing the occupation rate of equipment and site resources.

Owner:王志斌

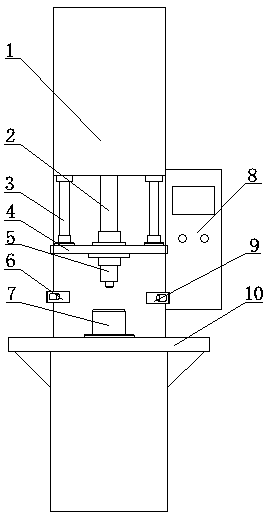

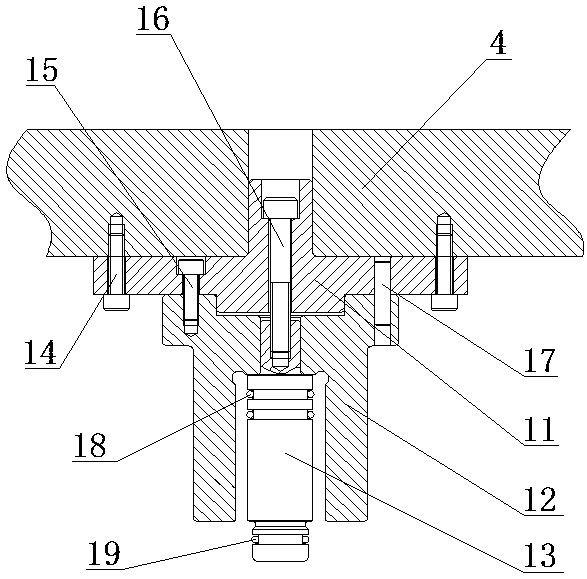

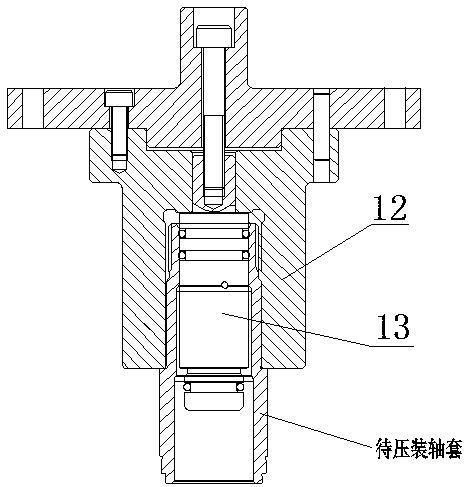

Intelligent press-fitting equipment and press-fitting process of automobile oil separator

PendingCN108942164AShorten pressing timeImprove pressing efficiencyMetal working apparatusEngineeringDistributor

The invention discloses intelligent press-fitting equipment of an automobile oil separator. The intelligent press-fitting equipment comprises an equipment body, wherein a lifting rod which is driven by a driving device to move in the vertical direction is arranged on the equipment body, the lower end of the lifting rod is connected with a lifting part, the lower end of the lifting part is connected with a pressure head, a shaft sleeve connecting part used for connecting the shaft sleeve and a bush connecting part used for connecting a bush are arranged on the pressure head, the shaft sleeve connecting part and the bush connecting part are coaxially arranged, and the equipment body is further provided with a positioning tool which is positioned below the pressure head and is used for containing the oil distributor body to be pressed. According to the intelligent press-fitting equipment, the oil separator shaft sleeve and the bush are pressed through the same pressure head, the positioning mode does not need to be changed after the shaft sleeve is pressed, and the bush is directly pressed on the original positioning base, so that not only is the press-fitting equipment simplified, but also the press-fitting time is shortened, and the press-fitting efficiency is improved.

Owner:杭州杰途传动部件有限公司

Release agent for composite panel

ActiveUS8309503B2Easy to processSimple to useOrganic detergent compounding agentsAnionic surface-active compoundsPhosphateAdhesive

The present invention is directed to a pMDI release agent that is simple to manufacture and use, provides release between the board and the metal surfaces, allows for production of OSB at high temperature, without causing excessive press buildup and improves the board physical properties and shortens press time. The release agent composition for use with a pMDI adhesive comprises a mixture of: (a) a sodium salt of a fatty acid having at least 8 carbon atoms, and (b) a sodium salt of a phosphate ester having 8-12 carbon atoms.

Owner:GUARDIAN CHEM

Sand-mold molding method for water turbine blade

ActiveCN106607559AReduce usageReduce manufacturing difficultyFoundry mouldsFoundry coresWater turbineAerospace engineering

A sand-mold molding method for a water turbine blade includes the following steps of model manufacturing, molding with the model, box closing and box erecting. By means of the sand-mold molding method for the water turbine blade, the sand consumption can be lowered, the production cost can be reduced, and the molding production cycle can be shortened.

Owner:KOCEL STEEL

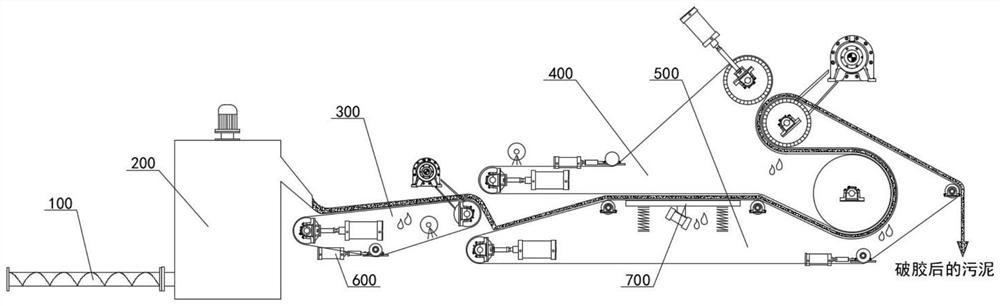

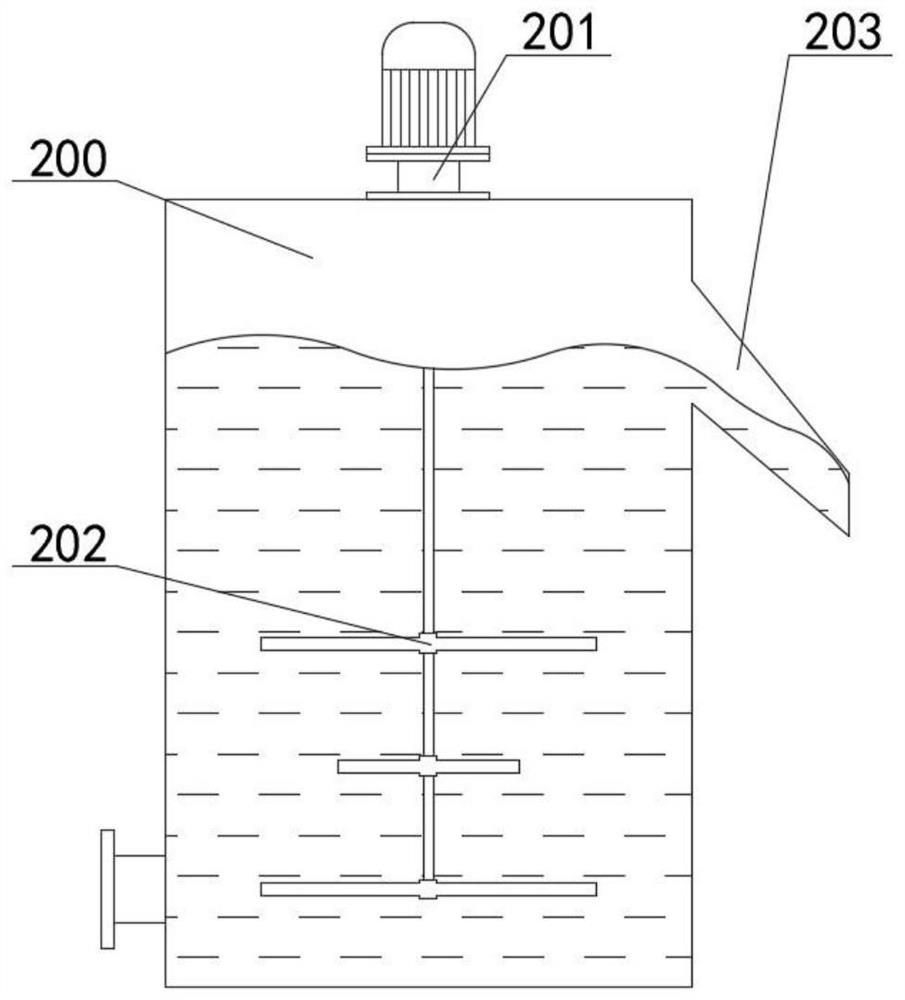

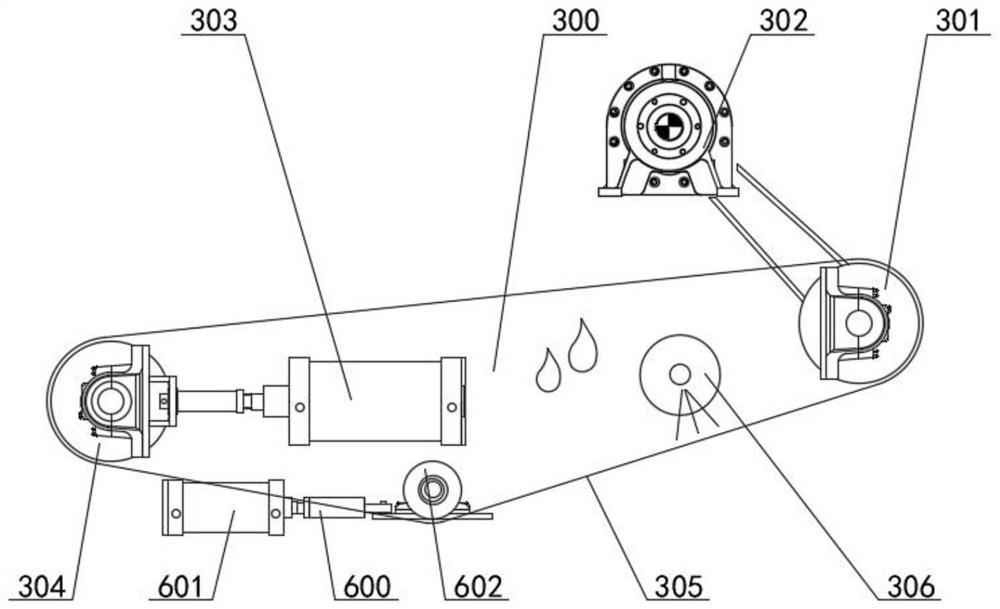

Sludge rubber crusher

PendingCN114275994AGood mud-water separation effectReduce drug consumptionSludge treatment by de-watering/drying/thickeningProcess engineeringEnvironmental geology

The sludge rubber crusher comprises a static mixer, a dynamic stirring tank, a belt type thickener, a first machine body and a second machine body, the static mixer is installed on a water inlet pipe opening in the bottom of the left end of the dynamic stirring tank, and the belt type thickener is located in the middle of the right side of the dynamic stirring tank; a first machine body and a second machine body are sequentially arranged on the right side of the belt thickener from top to bottom; the first machine body comprises a porous screen roller rotationally installed at the bottom of the right side of the first machine body. Compared with the prior art, the sludge gel breaker has good gel breaking and wall breaking effects on sludge which is complex in component and difficult to break and condition, when the sludge treated by the sludge gel breaker is flocculated again, the sludge pie reaction is thorough, the floccules are flourishing and firm, the sludge-water separation effect is good, the subsequent mechanical dehydration medicine consumption can be reduced, the sludge conditioning difficulty is reduced, lime does not need to be added, and the cost is reduced. The subsequent mechanical filter pressing time can be shortened, the production efficiency is improved, and the water content of a filter cake is reduced.

Owner:安徽中劭环保科技有限公司

Device for rapidly pressing coke oven valve and plug cock

InactiveCN103499423AImprove quality and efficiencyImprove work efficiencyMeasurement of fluid loss/gain rateCoke ovenEngineering

The invention discloses a device for rapidly pressing a coke oven valve and a plug cock. The device comprises a support, a pressing pipeline, a rubber washer, a rubber base plate, a cover sealing steel plate, a base plate and a jack. A horizontal beam is arranged on the top of the support. The pressing pipeline is fixedly connected with the support. An outlet which is vertically upward is formed in the pressing pipeline. The outlet in the pressing pipeline is formed in the central position of the lower portion of the support. A flange plate is arranged on the periphery of the outlet in the pressing pipeline. The outlet in the pressing pipeline is connected with an opening in a pressing part through the flange plate. The rubber washer is pressed between the outlet in the pressing pipeline and the pressing part in a clamped mode. The rubber base plate is laid on the other opening in the pressing part. The cover sealing steel plate additionally covers the rubber base plate. The base plate is arranged on the cover sealing steel plate. The jack is placed between the base plate and the horizontal beam. An air inlet and a pressure detection device are arranged on the pressing pipeline. According to the device for rapidly pressing the coke oven valve and the plug cock, the pressing quality and the working efficiency can be improved, and the pressing time can be shortened.

Owner:TIANJIN 20 CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com